J Adv Prosthodont.

2018 Aug;10(4):328-334. 10.4047/jap.2018.10.4.328.

Evaluation of the reproducibility of various abutments using a blue light model scanner

- Affiliations

-

- 1Institute for Health Science, Korea University, Seoul, Republic of Korea.

- 2Department of Dental Laboratory Science and Engineering, College of Health Science, Korea University, Seoul, Republic of Korea. kuc2842@korea.ac.kr

- 3Department of Dental Technology, Medical Campus, Kyung-Dong University, Wonju, Republic of Korea.

- KMID: 2418640

- DOI: http://doi.org/10.4047/jap.2018.10.4.328

Abstract

- PURPOSE

To evaluate the reproducibility of scan-based abutments using a blue light model scanner.

MATERIALS AND METHODS

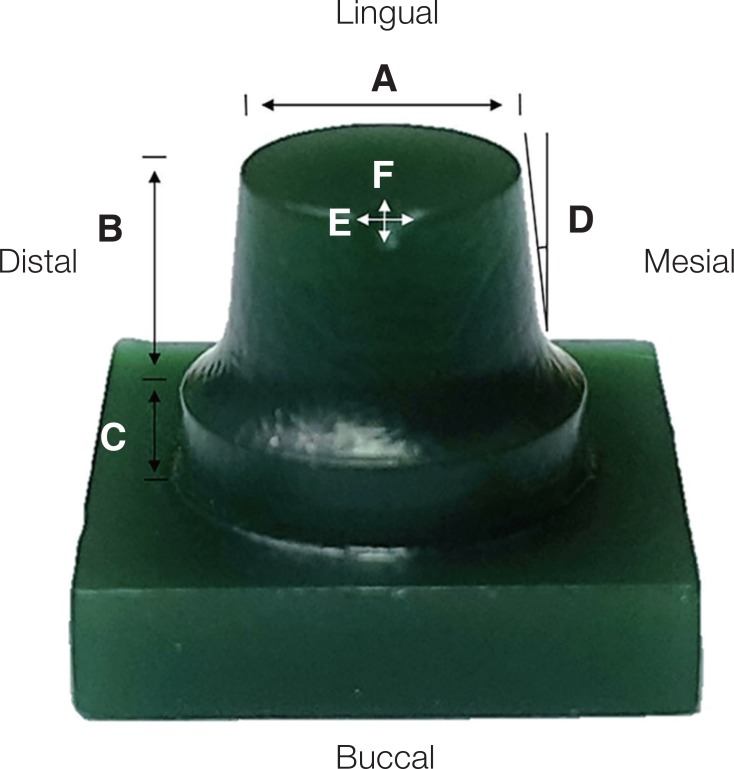

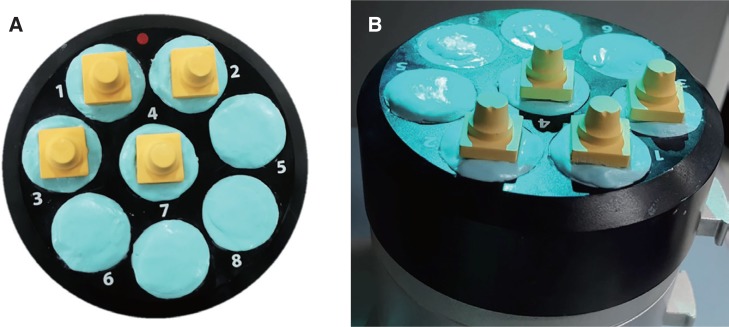

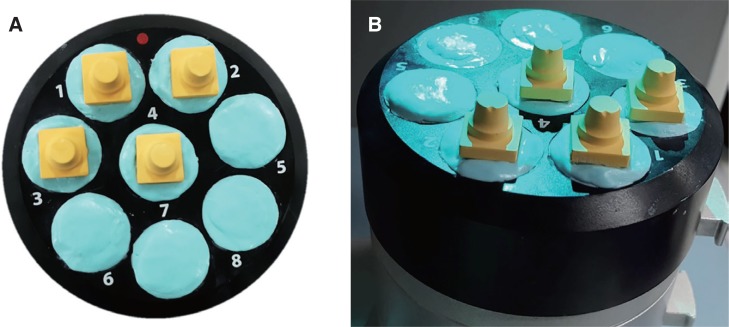

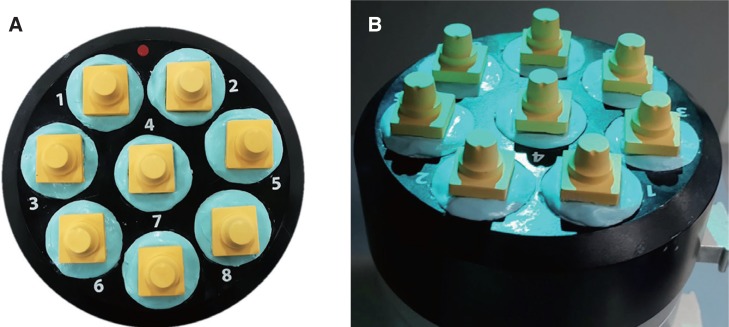

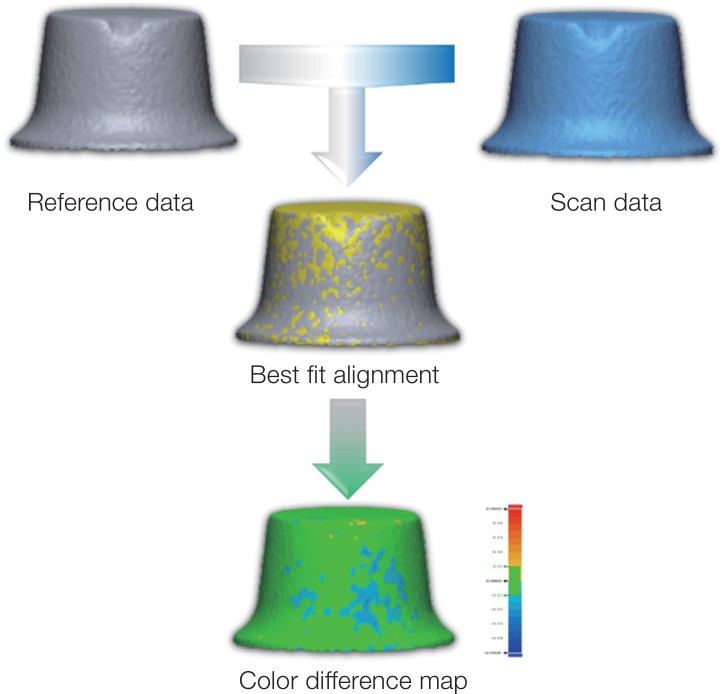

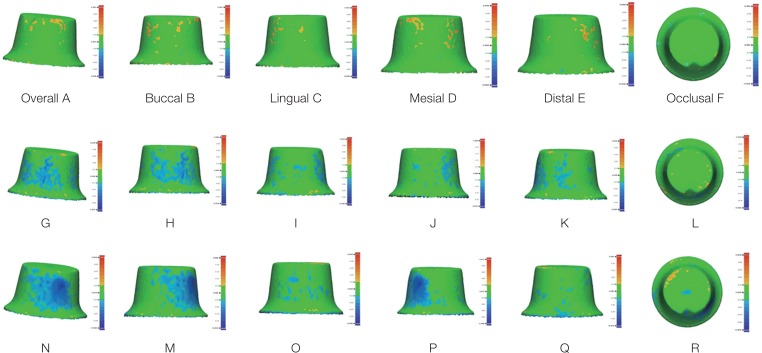

A wax cast abutment die was fabricated, and a silicone impression was prepared using a silicone material. Nine study dies were constructed using the prepared duplicable silicone, and the first was used as a reference. These dies were classified into three groups and scanned using a blue light model scanner. The first three-dimensional (3D) data set was obtained by scanning eight dies separately in the first group. The second 3D data set was acquired when four dies were placed together in the scanner and scanned twice in the second group. Finally, the third 3D data set was obtained when eight dies were placed together in the scanner and scanned once. These data were then used to define the data value using third-dimension software. All the data were then analyzed using the non-parametric Kruskal-Wallis H test (α=.05) and the post-hoc Mann-Whitney U-test with Bonferroni's correction (α=.017).

RESULTS

The means and standard deviations of the eight dies together were larger than those of the four dies together and of the individual die. Moreover, significant differences were observed among the three groups (P < .05).

CONCLUSION

With larger numbers of abutments scanned together, the scan becomes more inaccurate and loses reproducibility. Therefore, scans of smaller numbers of abutments are recommended to ensure better results.

Keyword

Figure

Reference

-

1. Hung SH, Hung K-S, Eick JD, Chappell RP. Marginal fit of porcelain-fused-to-metal and two types of ceramic crown. J Prosthet Dent. 1990; 63:26–31. PMID: 2404103.

Article2. Tjan AH, Dunn JR, Grant BE. Marginal leakage of cast gold crowns luted with an adhesive resin cement. J Prosthet Dent. 1992; 67:11–15. PMID: 1548593.

Article3. Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent. 2009; 102:253–259. PMID: 19782828.

Article4. Hamza TA, Sherif RM. In vitro evaluation of marginal discrepancy of monolithic zirconia restorations fabricated with different CAD-CAM systems. J Prosthet Dent. 2017; 117:762–766. PMID: 27836145.5. Liebermann A, Wimmer T, Schmidlin PR, Scherer H, Löffler P, Roos M, Stawarczyk B. Physicomechanical characterization of polyetheretherketone and current esthetic dental CAD/CAM polymers after aging in different storage media. J Prosthet Dent. 2016; 115:321–328. PMID: 26548869.

Article6. Ruse ND, Sadoun MJ. Resin-composite blocks for dental CAD/CAM applications. J Dent Res. 2014; 93:1232–1234. PMID: 25344335.

Article7. Ciocca L, Ragazzini S, Fantini M, Corinaldesi G, Scotti R. Work flow for the prosthetic rehabilitation of atrophic patients with a minimal-intervention CAD/CAM approach. J Prosthet Dent. 2015; 114:22–26. PMID: 25862269.

Article8. González de, Martínez-Rus F, García-Orejas A, Salido MP, Pradíes G. In vitro comparison of the accuracy (trueness and precision) of six extraoral dental scanners with different scanning technologies. J Prosthet Dent. 2016; 116:543–550. PMID: 27112413.9. Goracci C, Franchi L, Vichi A, Ferrari M. Accuracy, reliability, and efficiency of intraoral scanners for full-arch impressions: a systematic review of the clinical evidence. Eur J Orthod. 2016; 38:422–428. PMID: 26487391.

Article10. Atia MA, El-Gheriani AA, Ferguson DJ. Validity of 3 shape scanner techniques: A comparison with the actual plaster study casts. Biom Biostat Int J. 2015; 2:00026.

Article11. Jeon JH, Choi BY, Kim CM, Kim JH, Kim HY, Kim WC. Three-dimensional evaluation of the repeatability of scanned conventional impressions of prepared teeth generated with white- and blue-light scanners. J Prosthet Dent. 2015; 114:549–553. PMID: 26182854.

Article12. Keeling A, Wu J, Ferrari M. Confounding factors affecting the marginal quality of an intra-oral scan. J Dent. 2017; 59:33–40. PMID: 28189718.

Article13. Lee JJ, Jeong ID, Park JY, Jeon JH, Kim JH, Kim WC. Accuracy of single-abutment digital cast obtained using intraoral and cast scanners. J Prosthet Dent. 2017; 117:253–259. PMID: 27666500.

Article14. Lee WS, Park JK, Kim JH, Kim HY, Kim WC, Yu CH. New approach to accuracy verification of 3D surface models: An analysis of point cloud coordinates. J Prosthodont Res. 2016; 60:98–105. PMID: 26603682.

Article15. Mandelli F, Gherlone E, Gastaldi G, Ferrari M. Evaluation of the accuracy of extraoral laboratory scanners with a single-tooth abutment model: A 3D analysis. J Prosthodont Res. 2017; 61:363–370. PMID: 27771189.

Article16. Ender A, Mehl A. In-vitro evaluation of the accuracy of conventional and digital methods of obtaining full-arch dental impressions. Quintessence Int. 2015; 46:9–17. PMID: 25019118.17. Jeon JH, Jung ID, Kim JH, Kim HY, Kim WC. Three-dimensional evaluation of the repeatability of scans of stone models and impressions using a blue LED scanner. Dent Mater. 2015; 34:686–691.

Article18. Jeon JH, Kim DY, Lee JJ, Kim JH, Kim WC. Repeatability and reproducibility of individual abutment impression, assessed with a blue light scanner. J Adv Prosthodont. 2016; 8:214–218. PMID: 27350856.

Article19. Jeon JH, Lee KT, Kim HY, Kim JH, Kim WC. White light scanner-based repeatability of 3-dimensional digitizing of silicon rubber abutment teeth impressions. J Adv Prosthodont. 2013; 5:452–456. PMID: 24353885.

Article20. Jeong ID, Lee JJ, Jeon JH, Kim JH, Kim HY, Kim WC. Accuracy of complete-arch model using an intraoral video scanner: An in vitro study. J Prosthet Dent. 2016; 115:755–759. PMID: 26794703.21. Jeon JH, Kim HY, Kim JH, Kim WC. Accuracy of 3D white light scanning of abutment teeth impressions: evaluation of trueness and precision. J Adv Prosthodont. 2014; 6:468–473. PMID: 25551007.

Article22. Rudolph H, Salmen H, Moldan M, Kuhn K, Sichwardt V, Wöstmann B, Luthardt RG. Accuracy of intraoral and extraoral digital data acquisition for dental restorations. J Appl Oral Sci. 2016; 24:85–94. PMID: 27008261.

Article23. Ulusoy AO, Calakli F, Taubin G. Robust one-shot 3D scanning using loopy belief propagation: Proceedings of the computer vision and pattern recognition workshops. 13-18 June 2010; San Francisco, CA, USA. p. 15–22.24. Bae SY, Park JY, Jeong ID, Kim HY, Kim JH, Kim WC. Three-dimensional analysis of marginal and internal fit of copings fabricated with polyetherketoneketone (PEKK) and zirconia. J Prosthodont Res. 2017; 61:106–112. PMID: 27484816.

Article25. Kim CM, Jeon JH, Kim JH, Kim HY, Kim WC. Three-dimensional evaluation of the reproducibility of presintered zirconia single copings fabricated with the subtractive method. J Prosthet Dent. 2016; 116:237–241. PMID: 27038527.

Article26. Kim CM, Kim SR, Kim JH, Kim HY, Kim WC. Trueness of milled prostheses according to number of ball-end mill burs. J Prosthet Dent. 2016; 115:624–629. PMID: 26774318.

Article27. Kim DY, Jeon JH, Kim JH, Kim HY, Kim WC. Reproducibility of different arrangement of resin copings by dental microstereolithography: Evaluating the marginal discrepancy of resin copings. J Prosthet Dent. 2017; 117:260–265. PMID: 27646792.

Article28. Kim DY, Jeong ID, Kim JH, Kim HY, Kim WC. Reproducibility of different coping arrangements fabricated by dental microstereolithography: Evaluation of marginal and internal gaps in metal copings. J Dent Sci. 2017; DOI: 10.1016/j.jds.2017.06.006.

Article29. Kim DY, Kim EB, Kim HY, Kim JH, Kim WC. Evaluation of marginal and internal gap of three-unit metal framework according to subtractive manufacturing and additive manufacturing of CAD/CAM systems. J Adv Prosthodont. 2017; 9:463–469. PMID: 29279766.

Article30. Kim DY, Kim JH, Kim HY, Kim WC. Comparison and evaluation of marginal and internal gaps in cobalt-chromium alloy copings fabricated using subtractive and additive manufacturing. J Prosthodont Res. 2018; 62:56–64. PMID: 28663024.

Article31. Park JY, Bae SY, Lee JJ, Kim JH, Kim HY, Kim WC. Evaluation of the marginal and internal gaps of three different dental prostheses: comparison of the silicone replica technique and three-dimensional superimposition analysis. J Adv Prosthodont. 2017; 9:159–169. PMID: 28680546.

Article32. Trifkovic B, Budak I, Todorovic A, Vukelic D, Lazic V, Puskar T. Comparative analysis on measuring performances of dental intraoral and extraoral optical 3D digitization systems. Measurement. 2014; 47:45–53.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of the effect of abutment preparation angles on the repeatability and reproducibility using a blue light model scanner

- Repeatability and reproducibility of individual abutment impression, assessed with a blue light scanner

- Effect of abutment superimposition process of dental model scanner on final virtual model

- Validity, Reliability and Reproducibility of Space Analysis using Digital Model taken via Model Scanner and Intraoral Scanner: An In vivo Study

- Comparative study of two CAD software programs on consistency between custom abutment design and the output