J Korean Acad Prosthodont.

2019 Jul;57(3):203-210. 10.4047/jkap.2019.57.3.203.

Effect of abutment superimposition process of dental model scanner on final virtual model

- Affiliations

-

- 1Department of Dental Science, Graduate School, School of Dentistry, Kyungpook National University, Daegu, Republic of Korea.

- 2Advanced Dental Device Development Institute (A3DI), Kyungpook National University, Daegu, Republic of Korea. kblee@knu.ac.kr

- 3Department of Prosthodontics, School of Dentistry, Kyungpook National University, Daegu, Republic of Korea.

- KMID: 2453773

- DOI: http://doi.org/10.4047/jkap.2019.57.3.203

Abstract

- PURPOSE

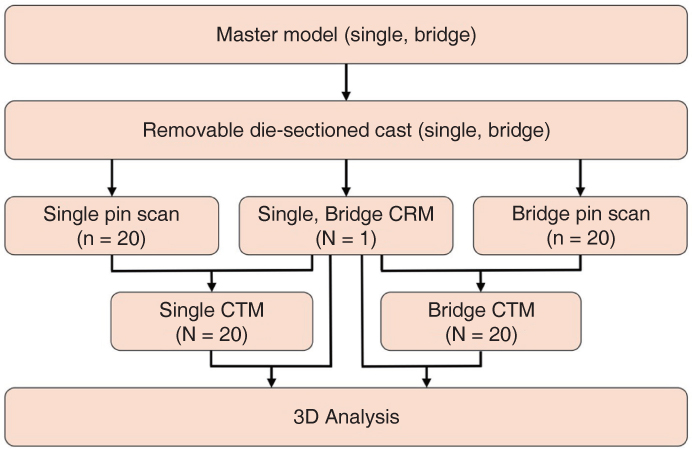

The purpose of this study was to verify the effect of the abutment superimposition process on the final virtual model in the scanning process of single and 3-units bridge model using a dental model scanner.

MATERIALS AND METHODS

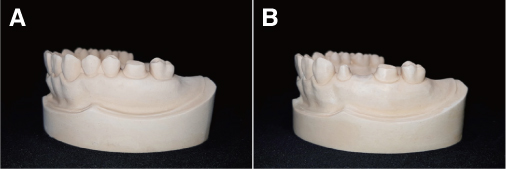

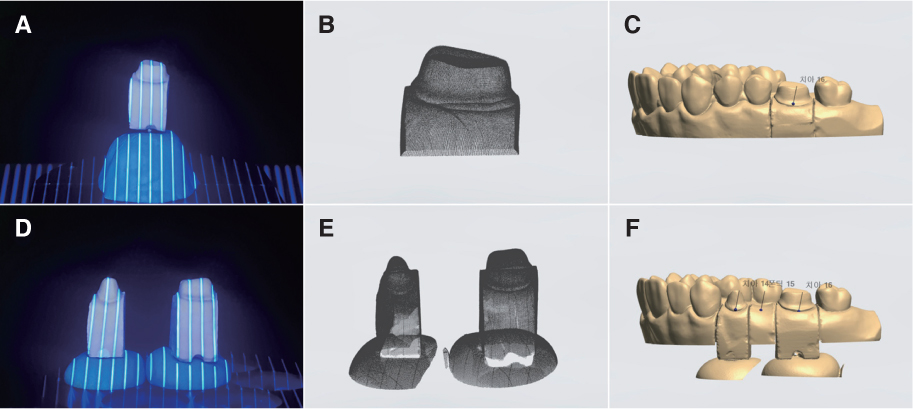

A gypsum model for single and 3-unit bridges was manufactured for evaluating. And working casts with removable dies were made using Pindex system. A dental model scanner (3Shape E1 scanner) was used to obtain CAD reference model (CRM) and CAD test model (CTM). The CRM was scanned without removing after dividing the abutments in the working cast. Then, CTM was scanned with separated from the divided abutments and superimposed on the CRM (n=20). Finally, three-dimensional analysis software (Geomagic control X) was used to analyze the root mean square (RMS) and Mann-Whitney U test was used for statistical analysis (α=.05).

RESULTS

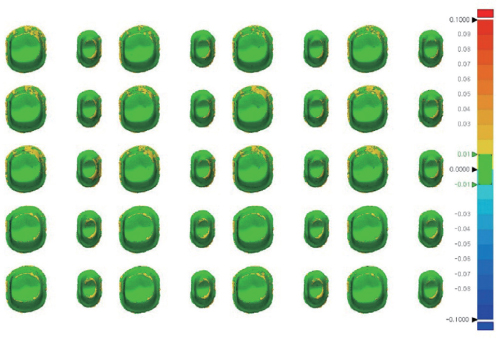

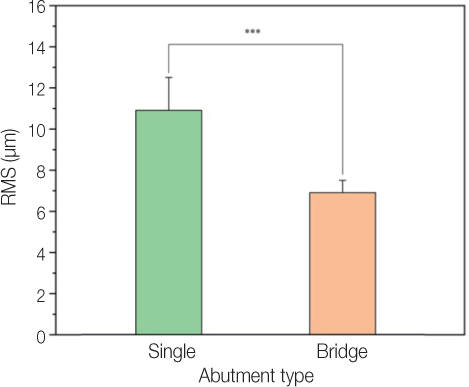

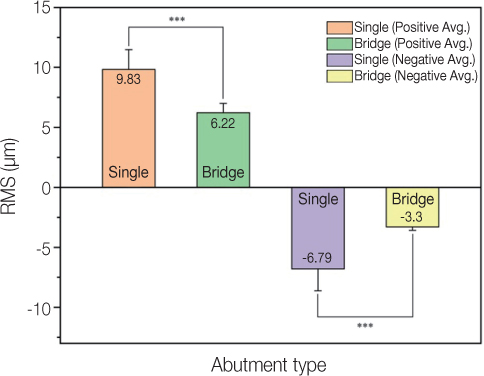

The RMS mean abutment for single full crown preparation was 10.93 µm and the RMS average abutment for 3 unit bridge preparation was 6.9 µm. The RMS mean of the two groups showed statistically significant differences (P<.001). In addition, errors of positive and negative of two groups averaged 9.83 µm, −6.79 µm and 3-units bridge abutment 6.22 µm, −3.3 µm, respectively. The mean values of the errors of positive and negative of two groups were all statistically significantly lower in 3-unit bridge abutments (P<.001).

CONCLUSION

Although the number of abutments increased during the scan process of the working cast with removable dies, the error due to the superimposition of abutments did not increase. There was also a significantly higher error in single abutments, but within the range of clinically acceptable scan accuracy.

Figure

Cited by 1 articles

-

가철성 다이 시스템으로 제작된 작업 모형과 솔리드 작업 모형 상에서 제작된 지르코니아 3본 고정성 치과 보철물의 변연 및 내면 적합도 비교

Wan-Sun Lee

J Dent Rehabil Appl Sci. 2024;40(2):72-81. doi: 10.14368/jdras.2024.40.2.72.

Reference

-

1. Lee JJ, Park JY, Bae SY, Jeon JH, Kim JH, Kim WC. Evaluation of the model accuracy according to three types of dental scanner. J Dent Hyg Sci. 2015; 15:226–231.

Article2. Duret F, Preston JD. CAD/CAM imaging in dentistry. Curr Opin Dent. 1991; 1:150–154.3. Son K, Lee WS, Lee KB. Effect of repeated learning for two dental CAD software programs. J Dent Rehabil Appl Sci. 2017; 33:88–96.

Article4. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12.

Article5. Luthardt RG, Kühmstedt P, Walter MH. A new method for the computer-aided evaluation of three-dimensional changes in gypsum materials. Dent Mater. 2003; 19:19–24.

Article6. Besl PJ, McKay ND. A method for registration of 3D shapes. IEEE Trans Pattern Anal Mach Intell. 1992; 14:239–256.

Article7. Sin YD, Park JH, Park GW, Baek SH, Baek MH. 3D range image registration using ICP algorithm. In : Korea Autom Control Conf; 2009. 9:p. 177–181.8. He Y, Liang B, Yang J, Li S, He J. An iterative closest points algorithm for registration of 3D laser scanner point clouds with geometric features. Sensors (Basel). 2017; 17(8):pii: E1862.

Article9. Persson AS, Odén A, Andersson M, Sandborgh-Englund G. Digitization of simulated clinical dental impressions: virtual three-dimensional analysis of exactness. Dent Mater. 2009; 25:929–936.

Article10. Jeon JH, Jung ID, Kim JH, Kim HY, Kim WC. Three-dimensional evaluation of the repeatability of scans of stone models and impressions using a blue LED scanner. Dent Mater J. 2015; 34:686–691.

Article11. Kim KB, Jung JK, Kim JH. Accuracy of digital impression made from different elastomeric impression materials: Three-dimensional superimpositional analysis. J Dent Hyg Sci. 2014; 14:94–100.12. Eom SH, Oh SC. Accuracy of stone cast produced by adjustable dental impression tray. J Korean Acad Prosthodont. 2005; 43:453–465.13. Kim KB, Kim SJ, Kim JH, Kim JH. An evaluation of validity of three dimensional digital model fabricated by dental scannable stone. J Korean Acad Dent Technol. 2013; 35:29–35.

Article14. Jeon JH, Choi BY, Kim CM, Kim JH, Kim HY, Kim WC. Three-dimensional evaluation of the repeatability of scanned conventional impressions of prepared teeth generated with white- and blue-light scanners. J Prosthet Dent. 2015; 114:549–553.

Article15. Rudolph H, Salmen H, Moldan M, Kuhn K, Sichwardt V, Wöstmann B, Luthardt RG. Accuracy of intraoral and extraoral digital data acquisition for dental restorations. J Appl Oral Sci. 2016; 24:85–94.

Article16. Emir F, Piskin B, Sipahi C. Effect of dental technician disparities on the 3-dimensional accuracy of definitive casts. J Prosthet Dent. 2017; 117:410–418.

Article17. Choi SS, Kim JH, Kim JH. Comparative analysis on digital models obtained by white light and blue LED optical scanners. J Korean Acad Dent Technol. 2014; 36:17–23.

Article18. Persson A, Andersson M, Oden A, Sandborgh-Englund G. A three-dimensional evaluation of a laser scanner and a touchprobe scanner. J Prosthet Dent. 2006; 95:194–200.

Article19. Lim JH. The accuracy according to the various dowel pins of working cast with removable dies. J Korean Acad Prosthodont. 1997; 35:373–384.20. Miranda FJ, Dilts WE, Duncanson MG, Collard EW. Comparative stability of two removable die systems. J Prosthet Dent. 1976; 36:326–333.

Article21. Jeon JH, Sung HK, Min BK, Hwang JS, Kim JH, Kim WC. Comparison of reproducibility of prepared tooth impression scanning utilized with white and blue light scanners. J Korean Acad Dent Technol. 2015; 37:213–218.

Article22. Lee H, Lee DH, Lee KB. In vitro evaluation methods on adaptation of fixed dental prosthesis. J Dent Rehabil Appl Sci. 2017; 33:63–70.

Article23. Ender A, Attin T, Mehl A. In vivo precision of conventional and digital methods of obtaining complete-arch dental impressions. J Prosthet Dent. 2016; 115:313–320.

Article24. Bernal C, de Agustina B, Marin M, Camacho A. Performance evaluation of optical scanner based on blue LED structured light. Proc Eng. 2013; 63:591–598.

Article25. Ganzer N, Feldmann I, Liv P, Bondemark L. A novel method for superimposition and measurements on maxillary digital 3D models-studies on validity and reliability. Eur J Orthod. 2018; 40:45–51.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of the accuracy of intraoral scanner by three-dimensional analysis in single and 3-unit bridge abutment model: In vitro study

- Restoration of implant-supported fixed dental prosthesis using the automatic abutment superimposition function of the intraoral scanner in partially edentulous patients

- Evaluation of the effect of abutment preparation angles on the repeatability and reproducibility using a blue light model scanner

- Clinical case of implant restoration using customized healing abutment

- Finite element study on the effect of abutment length and material on implant bone interface against dynamic loading