J Adv Prosthodont.

2011 Sep;3(3):140-144. 10.4047/jap.2011.3.3.140.

Finite element study on the effect of abutment length and material on implant bone interface against dynamic loading

- Affiliations

-

- 1Department of Removal Prosthodontics, School of Dentistry, Aichi Gakuin University, Nagoya, Japan. manish@dpc.aichi-gakuin.ac.jp

- KMID: 2118123

- DOI: http://doi.org/10.4047/jap.2011.3.3.140

Abstract

- PURPOSE

Finite element study on the effect of abutment length and material on implant bone interface against dynamic loading.

MATERIALS AND METHODS

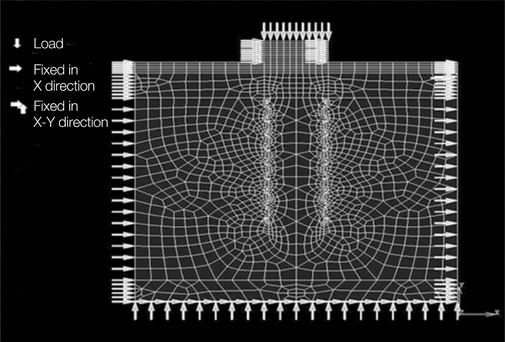

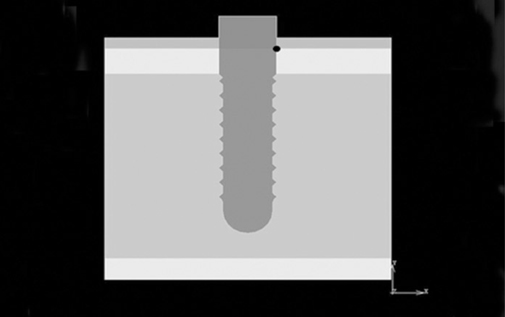

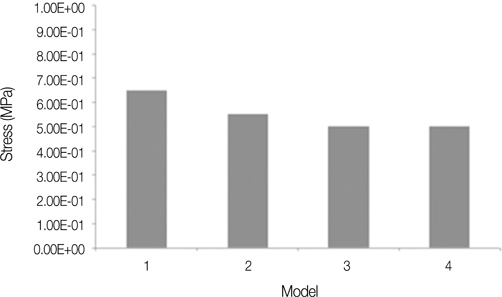

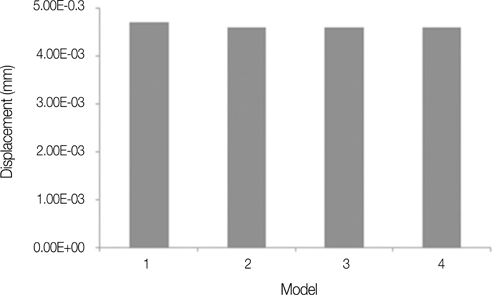

Two dimensional finite element models of cylinderical implant, abutments and bone made by titanium or polyoxymethylene were simulated with the aid of Marc/Mentat software. Each model represented bone, implant and titanium or polyoxymethylene abutment. Model 1: Implant with 3 mm titanium abutment, Model 2: Implant with 2 mm polyoxymethylene resilient material abutment, Model 3: Implant with 3 mm polyoxymethylene resilient material abutment and Model 4: Implant with 4 mm polyoxymethylene resilient material abutment. A vertical load of 11 N was applied with a frequency of 2 cycles/sec. The stress distribution pattern and displacement at the junction of cortical bone and implant was recorded.

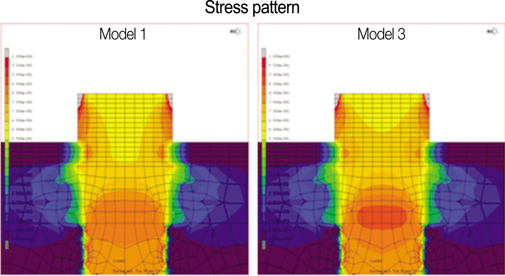

RESULTS

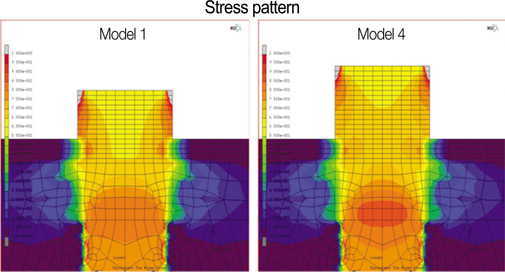

When Model 2, 3 and 4 are compared with Model 1, they showed narrowing of stress distribution pattern in the cortical bone as the height of the polyoxymethylene resilient material abutment increases. Model 2, 3 and 4 showed slightly less but similar displacement when compared to Model 1.

CONCLUSION

Within the limitation of this study, we conclude that introduction of different height resilient material abutment with different heights i.e. 2 mm, 3 mm and 4 mm polyoxymethylene, does not bring about significant change in stress distribution pattern and displacement as compared to 3 mm Ti abutment. Clinically, with the application of resilient material abutment there is no significant change in stress distribution around implant-bone interface.

Keyword

MeSH Terms

Figure

Reference

-

1. Kirsch A, Mentag PJ. The IMZ endosseous two phase implant system: a complete oral rehabilitation treatment concept. J Oral Implantol. 1986. 12:576–589.2. Babbush CA, Kirsch A, Mentag PJ, Hill B. Intramobile cylinder (IMZ) two-stage osteointegrated implant system with the intramobile element (IME): part I. Its ratinale and procedure for use. Int J Oral Maxillofac Implants. 1987. 2:203–216.3. Achour T, Merdji A, Bachir BB, Serier B, Djebbar N. Stress distribution in dental implant with elastomeric stress barrier. Mater Des. 2011. 32:282–290.4. Holmes DC, Grigsby WR, Goel VK, Keller JC. Comparison of stress transmission in the IMZ implant system with polyoxymethylene or titanium intramobile element: a finite element stress analysis. Int J Oral Maxillofac Implants. 1992. 7:450–458.5. McGlumphy EA, Campagni WV, Peterson LJ. A comparison of the stress transfer characteristics of a dental implant with a rigid or a resilient internal element. J Prosthet Dent. 1989. 62:586–593.6. van Rossen IP, Braak LH, de Putter C, de Groot K. Stress-absorbing elements in dental implants. J Prosthet Dent. 1990. 64:198–205.7. Sato M, Kuboki T, Itasaka M, Kondo Y, Yamashita A. Stres-stransfer characteristics of stress-absorbing elements in the IMZ implant system: Part 1. Stress around a freestanding single implant under static loading conditions. J Jpn Prosthodont Soc. 1992. 36:1102–1110.8. Haganman CR, Holmes DC, Aquilino SA, Diaz-Arnold AM, Stanford CM. Deflection and stress distribution in three different IMZ abutment designs. J Prosthodont. 1997. 6:110–121.9. Morton D, Stanford CM, Aquilino SA. Evaluation of resilient abutment components on measured strain using dynamic loading conditions. J Prosthet Dent. 1998. 80:46–51.10. Skalak R. Biomechanical considerations in osseointegrated prostheses. J Prosthet Dent. 1983. 49:843–848.11. Geng JP, Tan KB, Liu GR. Application of finite element analysis in implant dentistry: a review of the literature. J Prosthet Dent. 2001. 85:585–598.12. Oh TJ, Yoon J, Misch CE, Wang HL. The causes of early implant bone loss: myth or science? J Periodontol. 2002. 73:322–333.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Finite element analysis of the effect of novel Lock Screw system preventing abutment screw loosening

- Finite element analysis of the effect of cantilever and implant orientation on stress distribution in a mandibular implant-supported bar overdenture

- Finite element stress analysis of implant prosthesis with internal connection between the implant and the abutment

- Finite element stress analysis of implant prosthesis according to connection types of implant-abutment

- Effects of implant tilting and the loading direction on the displacement and micromotion of immediately loaded implants: an in vitro experiment and finite element analysis