J Dent Rehabil Appl Sci.

2019 Sep;35(3):132-142. 10.14368/jdras.2019.35.3.132.

Finite element analysis of the effect of novel Lock Screw system preventing abutment screw loosening

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Yonsei University, Seoul, Republic of Korea. drybpark@yuhs.ac.kr

- KMID: 2463622

- DOI: http://doi.org/10.14368/jdras.2019.35.3.132

Abstract

- PURPOSE

The purpose of this finite element analysis study is to introduce the novel Lock screw system and analyze its mechanical property to see if it can prevent abutment screw loosening.

MATERIALS AND METHODS

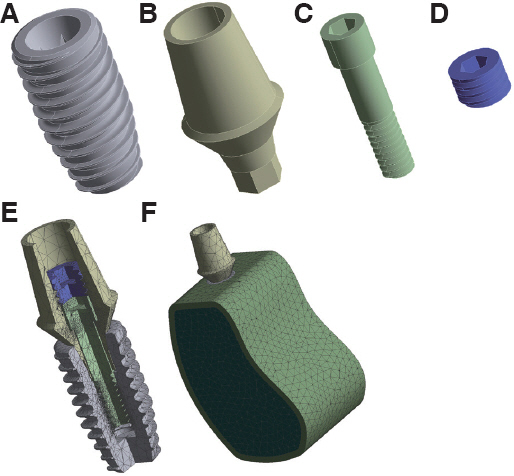

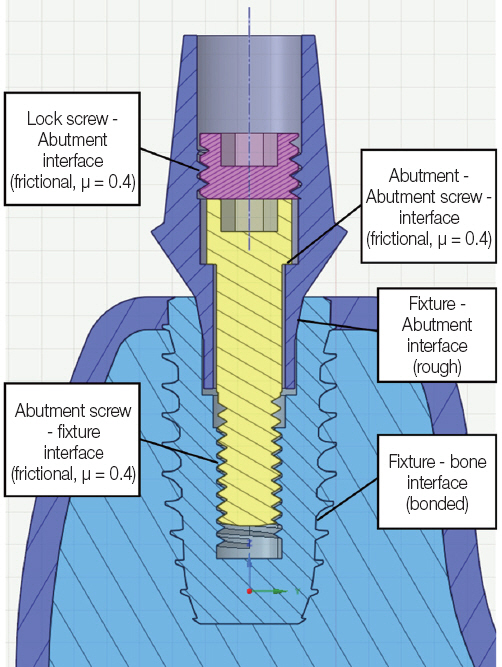

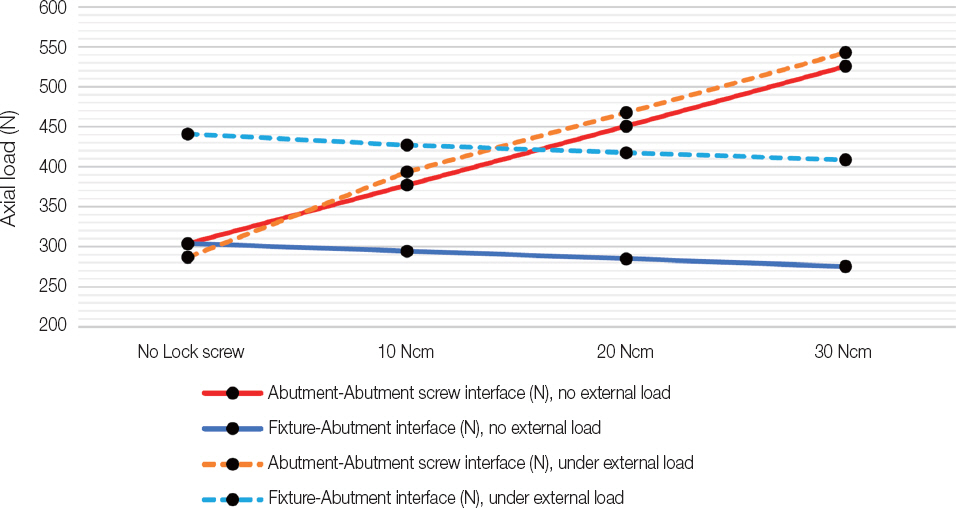

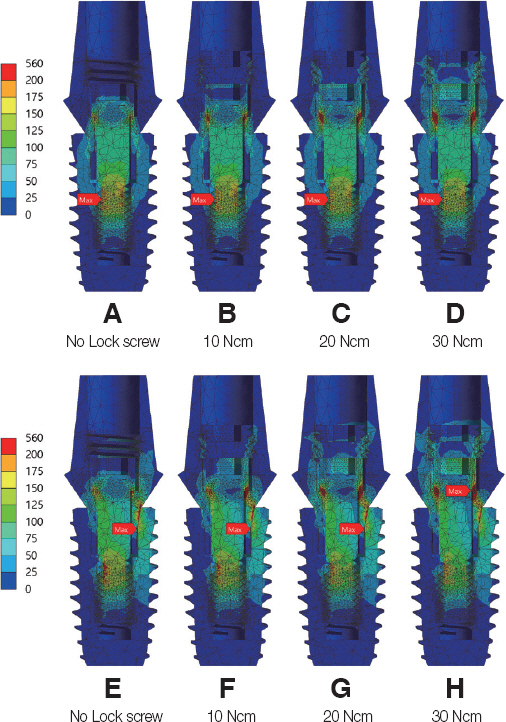

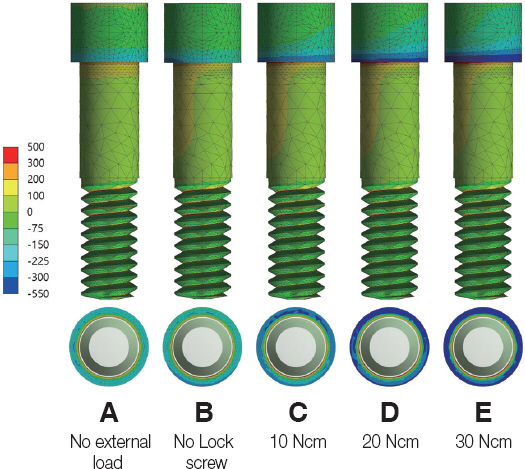

The Lock screw is a component tightened on the inside of the implant abutment which applies compressive force to the abutment screw head. To investigate the effect, modeling was done using CAD program and it was analyzed by finite element analysis under various load conditions. First, the preload was measured according to the tightening torque of the abutment screw then it was compared with the theoretical value to verify the analytical model. The validated analytical model was then divided into those with no external load and those with 178 N, and the tightening torque of the lock screw was changed to 10, 20, 30 Ncm respectively to examine the property of stress distribution on the implant components.

RESULTS

Using Lock screw under various loading conditions did not produce equivalent stresses beyond the yield strength of the implant components. In addition, the axial load was increased at the abutment-abutment screw interface.

CONCLUSION

The use of Lock screw does not exert excessive stress on the implant components and may increase the frictional force between the abutment-abutment screw interface, thus it is considered to prevent loosening of the abutment screw.

MeSH Terms

Figure

Reference

-

References

1. Goodacre CJ, Bernal G, Rungcharassaeng K, Kan JY. Clinical complications with implants and implant prostheses. J Prosthet Dent. 2003; 90:121–32. DOI: 10.1016/S0022-3913(03)00212-9. PMID: 12886205.2. Goodacre CJ, Kan JY, Rungcharassaeng K. Clinical complications of osseointegrated implants. J Prosthet Dent. 1999; 81:537–52. DOI: 10.1016/S0022-3913(99)70208-8. PMID: 10220658.3. Schwarz MS. Mechanical complications of dental implants. Clin Oral Implants Res. 2000; 11(Suppl 1):156–8. DOI: 10.1034/j.1600-0501.2000.011S1156.x. PMID: 11168264.4. Jemt T, Linden B, Lekholm U. Failures and complications in 127 consecutively placed fixed partial prostheses supported by Branemark implants:from prosthetic treatment to first annual checkup. Int J Oral Maxillofac Implants. 1992; 7:40–4. DOI: 10.1097/00008505-199200140-00014. PMID: 1398822.5. Hemmings KW, Schmitt A, Zarb GA. Complications and maintenance requirements for fixed prostheses and overdentures in the edentulous mandible:a 5-year report. Int J Oral Maxillofac Implants. 1994; 9:191–6. PMID: 8206555.6. Winkler S, Ring K, Ring JD, Boberick KG. Implant screw mechanics and the settling effect:overview. J Oral Implantol. 2003; 29:242–5. DOI: 10.1563/1548-1336(2003)029<0242:ISMATS=2.3.CO;2. PMID: 14620687.7. Jorneus L, Jemt T, Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992; 7:353–9. PMID: 1289261.8. Bickford JH. An introduction to the design and behavior of bolted joints. 2nd ed. New York: Marcel Dekker;1990. p. 127–35.9. Lang LA, Kang B, Wang RF, Lang BR. Finite element analysis to determine implant preload. J Prosthet Dent. 2003; 90:539–46. DOI: 10.1016/j.prosdent.2003.09.012. PMID: 14668754.10. Jorn D, Kohorst P, Besdo S, Rucker M, Stiesch M, Borchers L. Influence of lubricant on screw preload and stresses in a finite element model for a dental implant. J Prosthet Dent. 2014; 112:340–8. DOI: 10.1016/j.prosdent.2013.10.016. PMID: 24529658.11. Bulaqi HA, Mousavi Mashhadi M, Geramipanah F, Safari H, Paknejad M. Effect of the coefficient of friction and tightening speed on the preload induced at the dental implant complex with the finite element method. J Prosthet Dent. 2015; 113:405–11. DOI: 10.1016/j.prosdent.2014.09.021. PMID: 25749081.12. Geng JP, Tan KB, Liu GR. Application of finite element analysis in implant dentistry:a review of the literature. J Prosthet Dent. 2001; 85:585–98. DOI: 10.1067/mpr.2001.115251. PMID: 11404759.13. Lee YS, Kang KT, Han DH. The non-linear FEM analysis of different connection lengths of internal connection abutment. J Korean Acad Prosthodont. 2016; 54:110–9. DOI: 10.4047/jkap.2016.54.2.110.14. McCracken M. Dental implant materials:commercially pure titanium and titanium alloys. J Prosthodont. 1999; 8:40–3. DOI: 10.1111/j.1532-849X.1999.tb00006.x. PMID: 10356553.15. Eom TG, Suh SW, Jeon G-R, Shin JW, Jeong CM. Effect of Tightening Torque on Abutment-Fixture Joint Stability using 3-Dimensional Finite Element Analysis. J Korean Acad Prosthodont. 2009; 47:125–35. DOI: 10.4047/jkap.2009.47.2.125.16. Budinski KG. Tribological properties of titanium alloys. Wear. 1991; 151:203–17. DOI: 10.1016/0043-1648(91)90249-T.17. Hsu ML, Chen FC, Kao HC, Cheng CK. Influence of off-axis loading of an anterior maxillary implant:a 3-dimensional finite element analysis. Int J Oral Maxillofac Implants. 2007; 22:301–9. DOI: 10.1016/S0021-9290(06)85337-6. PMID: 17465356.18. Park CW, Kim SH, Yeo IS, Yoon HI, Han JS. Three-dimensional finite element analysis according to the insertion depth of an immediately loaded implant in the anterior maxilla. J Korean Acad Prosthodont. 2018; 56:105–13. DOI: 10.4047/jkap.2018.56.2.105.19. Korioth TW, Cardoso AC, Versluis A. Effect of washers on reverse torque displacement of dental implant gold retaining screws. J Prosthet Dent. 1999; 82:312–6. DOI: 10.1016/S0022-3913(99)70086-7. PMID: 10479258.20. Versluis A, Korioth TW, Cardoso AC. Numerical analysis of a dental implant system preloaded with a washer. Int J Oral Maxillofac Implants. 1999; 14:337–41. PMID: 10379106.21. Martin WC, Woody RD, Miller BH, Miller AW. Implant abutment screw rotations and preloads for four different screw materials and surfaces. J Prosthet Dent. 2001; 86:24–32. DOI: 10.1067/mpr.2001.116230. PMID: 11458261.22. Aboyoussef H, Weiner S, Ehrenberg D. Effect of an antirotation resistance form on screw loosening for single implant-supported crowns. J Prosthet Dent. 2000; 83:450–5. DOI: 10.1016/S0022-3913(00)70040-0. PMID: 10756295.23. Kim JH, Lim JH, Cho IH, Lee JS. A study of the anti-rotating inner post screw system as a means of preventing abutment screw loosening. J Korean Acad Prosthodont. 2005; 43:671–83.24. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995; 10:529–36. PMID: 7590997.25. Halliday D. Fundamentals of Physics. 10th ed. New Jersey: Wiley;2013. p. 124–7.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Study of screw loosening in cementation type implant abutment

- Three-dimensional finite element stress analysis of single implant restoration using different fixture and abutment screw diameters

- Finite element stress analysis of implant prosthesis according to connection types of implant-abutment

- 3-D Finite element stress analysis in screw-type, cement-type, and combined-type implant fixed partial denture designs

- Effect of Tightening Torque on Abutment-Fixture Joint Stability using 3-Dimensional Finite Element Analysis