J Periodontal Implant Sci.

2017 Aug;47(4):251-262. 10.5051/jpis.2017.47.4.251.

Effects of implant tilting and the loading direction on the displacement and micromotion of immediately loaded implants: an in vitro experiment and finite element analysis

- Affiliations

-

- 1Department of Oral and Maxillofacial Surgery, Nara Medical University, Nara, Japan. sugiurat@naramed-u.ac.jp

- 2Applied Electronics Laboratory, Kanazawa Institute of Technology, Tokyo, Japan.

- KMID: 2388112

- DOI: http://doi.org/10.5051/jpis.2017.47.4.251

Abstract

- PURPOSE

The purpose of this study was to investigate the effects of implant tilting and the loading direction on the displacement and micromotion (relative displacement between the implant and bone) of immediately loaded implants by in vitro experiments and finite element analysis (FEA).

METHODS

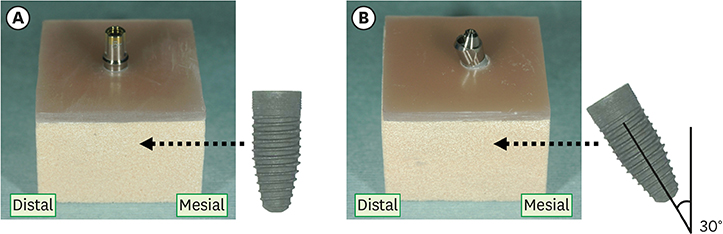

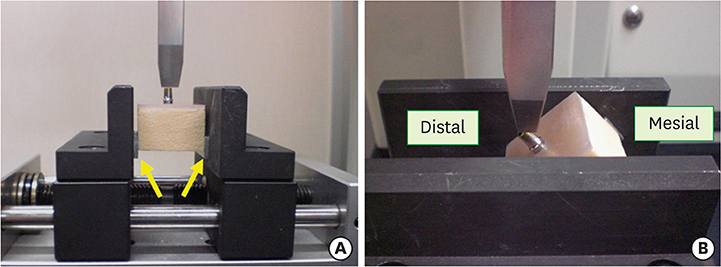

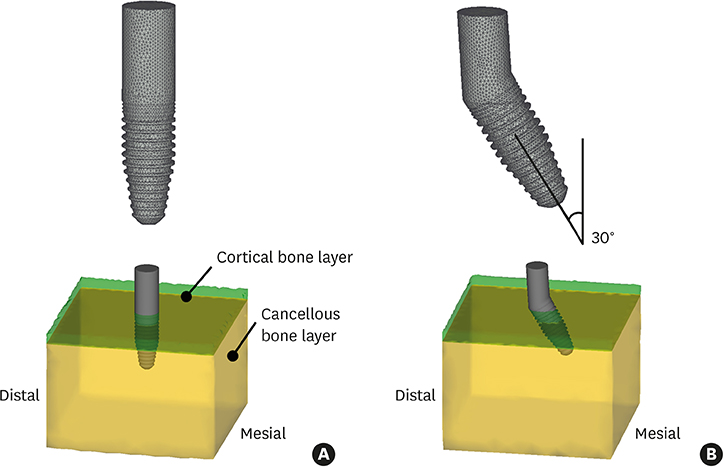

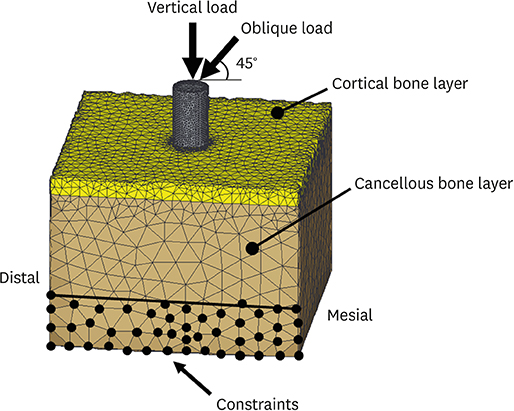

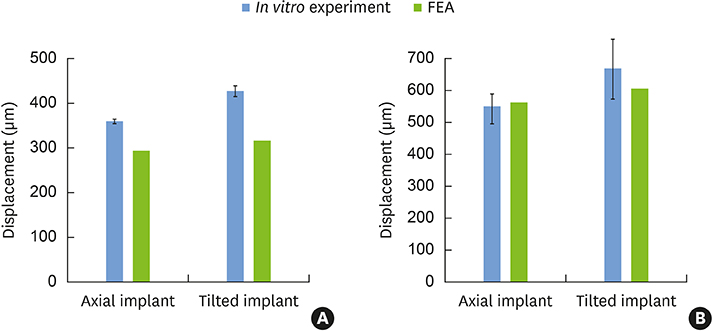

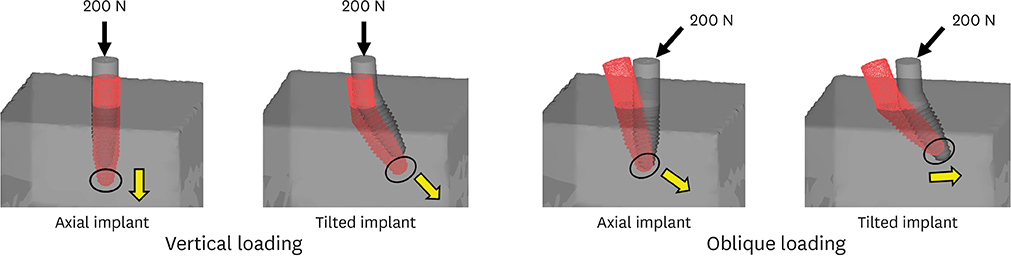

Six artificial bone blocks were prepared. Six screw-type implants with a length of 10 mm and diameter of 4.3 mm were placed, with 3 positioned axially and 3 tilted. The tilted implants were 30° distally inclined to the axial implants. Vertical and mesiodistal oblique (45° angle) loads of 200 N were applied to the top of the abutment, and the abutment displacement was recorded. Nonlinear finite element models simulating the in vitro experiment were constructed, and the abutment displacement and micromotion were calculated. The data on the abutment displacement from in vitro experiments and FEA were compared, and the validity of the finite element model was evaluated.

RESULTS

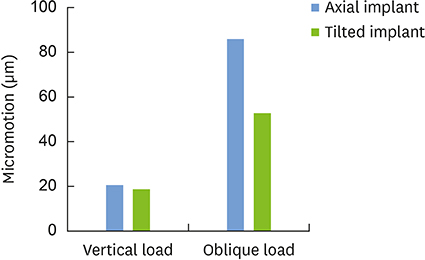

The abutment displacement was greater under oblique loading than under axial loading and greater for the tilted implants than for the axial implants. The in vitro and FEA results showed satisfactory consistency. The maximum micromotion was 2.8- to 4.1-fold higher under oblique loading than under vertical loading. The maximum micromotion values in the axial and tilted implants were very close under vertical loading. However, in the tilted implant model, the maximum micromotion was 38.7% less than in the axial implant model under oblique loading. The relationship between abutment displacement and micromotion varied according to the loading direction (vertical or oblique) as well as the implant insertion angle (axial or tilted).

CONCLUSIONS

Tilted implants may have a lower maximum extent of micromotion than axial implants under mesiodistal oblique loading. The maximum micromotion values were strongly influenced by the loading direction. The maximum micromotion values did not reflect the abutment displacement values.

MeSH Terms

Figure

Reference

-

1. Brunski JB, Puleo DA, Nanci A. Biomaterials and biomechanics of oral and maxillofacial implants: current status and future developments. Int J Oral Maxillofac Implants. 2000; 15:15–46.2. Bardyn T, Gédet P, Hallermann W, Büchler P. Quantifying the influence of bone density and thickness on resonance frequency analysis: an in vitro study of biomechanical test materials. Int J Oral Maxillofac Implants. 2009; 24:1006–1014.3. Tabassum A, Meijer GJ, Wolke JG, Jansen JA. Influence of surgical technique and surface roughness on the primary stability of an implant in artificial bone with different cortical thickness: a laboratory study. Clin Oral Implants Res. 2010; 21:213–220.

Article4. Chang PK, Chen YC, Huang CC, Lu WH, Chen YC, Tsai HH. Distribution of micromotion in implants and alveolar bone with different thread profiles in immediate loading: a finite element study. Int J Oral Maxillofac Implants. 2012; 27:e96–e101.5. Bayarchimeg D, Namgoong H, Kim BK, Kim MD, Kim S, Kim TI, et al. Evaluation of the correlation between insertion torque and primary stability of dental implants using a block bone test. J Periodontal Implant Sci. 2013; 43:30–36.

Article6. Marquezan M, Lima I, Lopes RT, Sant'Anna EF, de Souza MM. Is trabecular bone related to primary stability of miniscrews? Angle Orthod. 2014; 84:500–507.

Article7. Howashi M, Tsukiyama Y, Ayukawa Y, Isoda-Akizuki K, Kihara M, Imai Y, et al. Relationship between the CT value and cortical bone thickness at implant recipient sites and primary implant stability with comparison of different implant types. Clin Implant Dent Relat Res. 2016; 18:107–116.

Article8. Freitas AC Jr, Bonfante EA, Giro G, Janal MN, Coelho PG. The effect of implant design on insertion torque and immediate micromotion. Clin Oral Implants Res. 2012; 23:113–118.

Article9. Winter W, Klein D, Karl M. Effect of model parameters on finite element analysis of micromotions in implant dentistry. J Oral Implantol. 2013; 39:23–29.

Article10. Sennerby L, Pagliani L, Petersson A, Verrocchi D, Volpe S, Andersson P. Two different implant designs and impact of related drilling protocols on primary stability in different bone densities: an in vitro comparison study. Int J Oral Maxillofac Implants. 2015; 30:564–568.

Article11. Huang HL, Fuh LJ, Hsu JT, Tu MG, Shen YW, Wu CL. Effects of implant surface roughness and stiffness of grafted bone on an immediately loaded maxillary implant: a 3D numerical analysis. J Oral Rehabil. 2008; 35:283–290.

Article12. Kao HC, Gung YW, Chung TF, Hsu ML. The influence of abutment angulation on micromotion level for immediately loaded dental implants: a 3-D finite element analysis. Int J Oral Maxillofac Implants. 2008; 23:623–630.13. Trisi P, Perfetti G, Baldoni E, Berardi D, Colagiovanni M, Scogna G. Implant micromotion is related to peak insertion torque and bone density. Clin Oral Implants Res. 2009; 20:467–471.

Article14. Tu MG, Hsu JT, Fuh LJ, Lin DJ, Huang HL. Effects of cortical bone thickness and implant length on bone strain and interfacial micromotion in an immediately loaded implant. Int J Oral Maxillofac Implants. 2010; 25:706–714.15. Goellner M, Schmitt J, Karl M, Wichmann M, Holst S. The effect of axial and oblique loading on the micromovement of dental implants. Int J Oral Maxillofac Implants. 2011; 26:257–264.16. Sugiura T, Yamamoto K, Horita S, Murakami K, Tsutsumi S, Kirita T. The effects of bone density and crestal cortical bone thickness on micromotion and peri-implant bone strain distribution in an immediately loaded implant: a nonlinear finite element analysis. J Periodontal Implant Sci. 2016; 46:152–165.

Article17. Qian L, Todo M, Matsushita Y, Koyano K. Effects of implant diameter, insertion depth, and loading angle on stress/strain fields in implant/jawbone systems: finite element analysis. Int J Oral Maxillofac Implants. 2009; 24:877–886.18. Pessoa RS, Coelho PG, Muraru L, Marcantonio E Jr, Vaz LG, Vander Sloten J, et al. Influence of implant design on the biomechanical environment of immediately placed implants: computed tomography-based nonlinear three-dimensional finite element analysis. Int J Oral Maxillofac Implants. 2011; 26:1279–1287.19. Hsu JT, Fuh LJ, Lin DJ, Shen YW, Huang HL. Bone strain and interfacial sliding analyses of platform switching and implant diameter on an immediately loaded implant: experimental and three-dimensional finite element analyses. J Periodontol. 2009; 80:1125–1132.

Article20. Horita S, Sugiura T, Yamamoto K, Murakami K, Imai Y, Kirita T. Biomechanical analysis of immediately loaded implants according to the “All-on-Four” concept. J Prosthodont Res. 2017; 61:123–132.

Article21. Wang TM, Lee MS, Wang JS, Lin LD. The effect of implant design and bone quality on insertion torque, resonance frequency analysis, and insertion energy during implant placement in low or low- to medium-density bone. Int J Prosthodont. 2015; 28:40–47.

Article22. Miyamoto I, Tsuboi Y, Wada E, Suwa H, Iizuka T. Influence of cortical bone thickness and implant length on implant stability at the time of surgery--clinical, prospective, biomechanical, and imaging study. Bone. 2005; 37:776–780.

Article23. Sugiura T, Yamamoto K, Kawakami M, Horita S, Murakami K, Kirita T. Influence of bone parameters on peri-implant bone strain distribution in the posterior mandible. Med Oral Patol Oral Cir Bucal. 2015; 20:e66–e73.

Article24. Kim KS, Kim YL, Bae JM, Cho HW. Biomechanical comparison of axial and tilted implants for mandibular full-arch fixed prostheses. Int J Oral Maxillofac Implants. 2011; 26:976–984.25. Mobilio N, Stefanoni F, Contiero P, Mollica F, Catapano S. Experimental and numeric stress analysis of titanium and zirconia one-piece dental implants. Int J Oral Maxillofac Implants. 2013; 28:e135–e142.

Article26. Wu AY, Hsu JT, Chee W, Lin YT, Fuh LJ, Huang HL. Biomechanical evaluation of one-piece and two-piece small-diameter dental implants: in-vitro experimental and three-dimensional finite element analyses. J Formos Med Assoc. 2016; 115:794–800.

Article27. Mericske-Stern R, Assal P, Mericske E, Bürgin W. Occlusal force and oral tactile sensibility measured in partially edentulous patients with ITI implants. Int J Oral Maxillofac Implants. 1995; 10:345–353.

Article28. Yoda N, Liao Z, Chen J, Sasaki K, Swain M, Li Q. Role of implant configurations supporting three-unit fixed partial denture on mandibular bone response: biological-data-based finite element study. J Oral Rehabil. 2016; 43:692–701.

Article29. Grant JA, Bishop NE, Götzen N, Sprecher C, Honl M, Morlock MM. Artificial composite bone as a model of human trabecular bone: the implant-bone interface. J Biomech. 2007; 40:1158–1164.

Article30. Patel PS, Shepherd DE, Hukins DW. Compressive properties of commercially available polyurethane foams as mechanical models for osteoporotic human cancellous bone. BMC Musculoskelet Disord. 2008; 9:137.

Article31. Bell CG, Weinrauch P, Crawford R, Pearcy M. Thermomechanical investigation of the cortical bone analogue in third-generation Sawbones femurs. Proc Inst Mech Eng H. 2007; 221:213–217.

Article32. Matsuzaki M, Ayukawa Y, Sakai N, Matsuzaki T, Matsushita Y, Koyano K. A comparison of the peri-implant bone stress generated by the preload with screw tightening between ‘bonded’ and ‘contact’ model. Comput Methods Biomech Biomed Engin. 2017; 20:393–402.

Article33. Szmukler-Moncler S, Salama H, Reingewirtz Y, Dubruille JH. Timing of loading and effect of micromotion on bone-dental implant interface: review of experimental literature. J Biomed Mater Res. 1998; 43:192–203.

Article34. Wang G, Zhang S, Bian C, Kong H. Verification of finite element analysis of fixed partial denture with in vitro electronic strain measurement. J Prosthodont Res. 2016; 60:29–35.

Article35. Chatzigianni A, Keilig L, Duschner H, Götz H, Eliades T, Bourauel C. Comparative analysis of numerical and experimental data of orthodontic mini-implants. Eur J Orthod. 2011; 33:468–475.

Article36. Shimura Y, Sato Y, Kitagawa N, Omori M. Biomechanical effects of offset placement of dental implants in the edentulous posterior mandible. Int J Implant Dent. 2016; 2:17.

Article37. Watanabe F, Hata Y, Komatsu S, Ramos TC, Fukuda H. Finite element analysis of the influence of implant inclination, loading position, and load direction on stress distribution. Odontology. 2003; 91:31–36.

Article38. Fazi G, Tellini S, Vangi D, Branchi R. Three-dimensional finite element analysis of different implant configurations for a mandibular fixed prosthesis. Int J Oral Maxillofac Implants. 2011; 26:752–759.39. Murakami N, Wakabayashi N. Finite element contact analysis as a critical technique in dental biomechanics: a review. J Prosthodont Res. 2014; 58:92–101.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The effects of bone density and crestal cortical bone thickness on micromotion and peri-implant bone strain distribution in an immediately loaded implant: a nonlinear finite element analysis

- Three-dimensional finite element analysis according to the insertion depth of an immediately loaded implant in the anterior maxilla

- Does matching relation exist between the length and the tilting angle of terminal implants in the all-on-four protocol? stress distributions by 3D finite element analysis

- ANALYSIS OF THE FIT IN THE IMPLANT PROSTHESIS USING LASER DISPLACEMENT METER AND THREE-DIMENSIONAL FINITE ELEMENT METHOD

- Finite element study on the effect of abutment length and material on implant bone interface against dynamic loading