J Adv Prosthodont.

2009 Jul;1(2):68-74. 10.4047/jap.2009.1.2.68.

Shear bond strength of composite resin to titanium according to various surface treatments

- Affiliations

-

- 1Department of Prosthodontics, Graduate School, Chonnam National University, Gwangju, Korea. msvang@chonnam.ac.kr

- KMID: 2045466

- DOI: http://doi.org/10.4047/jap.2009.1.2.68

Abstract

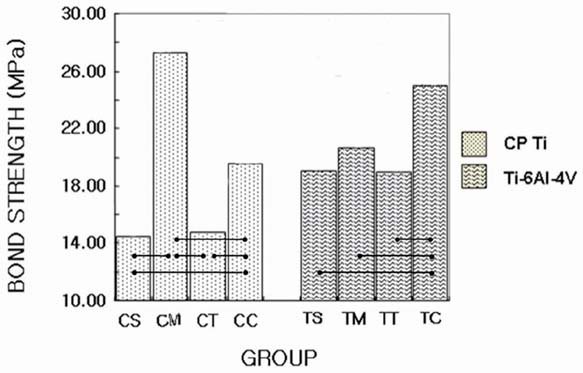

- STATEMENT OF PROBLEM: When veneering composite resin-metal restoration is prepared, the fact that bond strength between Ti and composite resin is relatively weak should be considered. PURPOSE: The purpose of this study is to evaluate the shear bond strength between the veneering composite resin and commercial pure (CP) Ti / Ti-6Al-4V alloy according to the method of surface treatment. MATERIAL AND METHODS: The disks were cast by two types of metal. Their surfaces were treated by sandblasting, metal conditioner, TiN coating and silicoating respectively. After surface treatment, the disks were veneered by composite resin (Tescera(TM), Bisco, USA) which is 5 mm in diameter and 3 mm in thickness. The specimens were stored in water at 25degrees C for 24 hours, and then evaluated for their shear bond strength by universal testing machine (STM-5(R), United Calibration, USA). These values were statistically analyzed. RESULTS: 1. All methods of surface treatment were used in this study satisfied the requirements of ISO 10477 which is the standard of polymer-based crown and bridge materials. 2. The metal conditioner treated group showed the highest value in shear bond strength of CP Ti, silicoated group, TiN coated group, sandblasted group, in following order. 3. The silicoated group showed the highest value in shear bond strength of Ti-6Al-4V alloy, metal conditioner treated group, sandblasted group, TiN coated group, in following order. CONCLUSION: Within the limitations of this study, all methods of surface treatment used in this study are clinically available.

Keyword

Figure

Reference

-

1. Staffanou RS, Hembree JH Jr, Rivers JA, Myers ML, Kilgore JL. Leakage study of three esthetic veneering materials. J Prosthet Dent. 1985. 54:204–206.2. Jones RM, Moore BK, Goodacre CJ, Munoz-Viveros CA. Microleakage and shear bond strength of resin and porcelain veneers bonds to cast alloys. J Prosthet Dent. 1991. 65:221–228.3. Petridis H, Hirayama H, Kugel G, Habib C, Garefis P. Shear bond strength of techniques for bonding esthetic veneers to metal. J Prosthet Dent. 1999. 82:608–614.4. Mukai M, Fukui H, Hasegawa J. Relationship between sandblasting and composite resin-alloy bond strength by a silica coating. J Prosthet Dent. 1995. 74:151–155.5. Kelly JR, Rose TC. Nonprecious alloys for use in fixed prosthodontics: literature review. J Prosthet Dent. 1983. 49:363–370.6. Barzilay I, Myers ML, Cooper LB, Graser GN. Mechanical and chemical retention of laboratory cured composite to metal surfaces. J Prosthet Dent. 1988. 59:131.7. El-Sherif MH, El-Messery A, Halhoul MN. The effecs of alloy surface treatments and resins on the retention of resin bonded retainers. J Prosthet Dent. 1991. 65:782.8. Dunny JA, King GE. Minor connector designs for anterior acrylic resin bases: a preliminary study. J Prosthet Dent. 1975. 34:496–502.9. Brown DT, Desjardins RP, Chao EYS. Fatigue failure in acrylic resin retaining minor connectors. J Prosthet Dent. 1987. 58:329–335.10. Livaditis GJ. A chemical etching system for creating micromechanical retention in resin bonded retainers. J Prosthet Dent. 1986. 56:181–188.11. Doukoudakis A, Cohen B, Tsoutsos A. A new chemical method for etching metal frameworks of the acid etched prothesis. J Prosthet Dent. 1987. 58:421–423.12. Zurasky JE, Duke ES. Improved adhesion of acrylic resins to base metal alloy. J Prosthet Dent. 1987. 57:520–524.13. Tanaka T, Fujiyama E, Shimizu H, Tanaki A, Atsuta M. Surface treatment of nonprecious alloys for adhension-fixed partial dentures. J Prosthet Dent. 1986. 55:456.14. Barzilay I, Mayers ML, Cooper LB, Graser GN. Mechanical and chemical retention of laboratory cured composite to metal surfaces. J Prosthet Dent. 1988. 59:131–137.15. Bahannan SA, Connelly ME, Mueninghoff LA. Application of silica coating technique for removable prosthodontics. A clinical report. J Prosthet Dent. 1991. 65:1.16. Hansson O. Strength of bond with Comspan Opaque to three silicoated alloys and titanium. Scand J Dent Res. 1990. 98:248.17. ISO 10477. Dentistry - polymer-based crown and bridge materials. 2004(E).18. Touati B, Aidan N. Second generation laboratory composite resins for indirect restorations. J Esthet Dent. 1997. 9:108–118.19. Staffanou RS, Hembree JH Jr, Rivers JA, Myers ML. Abrasion resistance of three types of esthetic veneering materials. J Prosthet Dent. 1985. 53:309–310.20. Ameye C, Lambrechts P, Vanherle G. Conventional and microfilled composite resins. Part I: color and marginal adaptation. J prosthet Dent. 1981. 46:623–630.21. Kakaboura A, Rahiotis C, Zinelis S, Al-Dhamadi YA, Silikas N, Watts DC. In vitro characterization of two laboratory-processed resin composites. Dent Mater. 2003. 19:393–398.22. Vojvodic D, Jerolimov V, Celebic A, Catovic A. Bond strength of silicoated and acrylic resin bonding system to metal. J Prosthet Dent. 1999. 81:1–6.23. Yoshida K, Kamada K, Taira Y, Atsuta M. Effect of three adhesive primers on the bond strengths of four light-activated opaque resins to noble alloy. J Oral Rehabil. 2001. 28:168–173.24. Moffa JP. Biological effects of nickel-containing dental alloys. Council on dental materials, instruments and equiment. J Am Dent Assoc. 1982. 104:501–505.25. Ekstrand K, Ruyter IE, Oysad H. Adhesion to titanium of methacrylate-based polymer materials. Dent Mater. 1988. 4:111–115.26. Matsumura H, Yoshida K, Tanaka T, Atsuta M. Adhesive bonding of titanium with a titanate coupler and 4-META/MMA-TBB opaque resin. J Dent Res. 1990. 69:1614–1621.27. May KB, Van Putten MC, Bow DA, Lang BR. 4-META polymethyl methacrylate shear bond strength to titanium. Oper Dent. 1997. 22:37–40.28. Tanaka T, Kimoto K, Sawada T, Toyoda M. Shear bond strength of veneering composite resin to titanium nitride coating alloy deposited by radiofrequency sputtering. J Dent. 2006. 34:277–282.29. Mezger PR, Creugers NH. Titanium nitride coatings in clinical dentistry. J Dent. 1992. 20:342–344.30. Steele JG, McCabe JF, Barnes IE. Properties of a titanium nitride coating for dental instruments. J Dent. 1991. 19:226–229.31. May KB, Russell MM, Razzoog ME, Lang BR. The shear strength of polymethyl methacrylate bonded to titanium partial denture framework material. J Prosthet Dent. 1993. 70:410–413.32. May KB, Fox J, Razzoog ME, Lang BR. Silane to enhance the bond between polymethyl methacrylate and titanium. J Prosthet Dent. 1995. 73:428–431.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Shear Bond Strengths between Abrasion-Resistant Denture Teeth and Composite Resins

- Effect of delayed time, surface treatment, and repair material on shear bond strength of repaired bis-acryl composite resin

- The shear bond strength of two adhesives bonded to composite resin and glass ionomer cement restorations

- Effect of thermocycling on shear bond strength and mode of failure of bonded retainer using flowable composite resin

- Bonding of conventional provisional resin to 3D printed resin: the role of surface treatments and type of repair resins