J Adv Prosthodont.

2018 Jun;10(3):245-251. 10.4047/jap.2018.10.3.245.

Accuracy evaluation of dental models manufactured by CAD/CAM milling method and 3D printing method

- Affiliations

-

- 1Department of Dental Science, Graduate School, Kyungpook National University, Daegu, Republic of Korea.

- 2Advanced Dental Device Development Institute (A3DI), Kyungpook National University, Daegu, Republic of Korea. kblee@knu.ac.kr

- 3Department of Prosthodontics, School of Dentistry, Kyungpook National University, Daegu, Republic of Korea.

- KMID: 2413494

- DOI: http://doi.org/10.4047/jap.2018.10.3.245

Abstract

- PURPOSE

To evaluate the accuracy of a model made using the computer-aided design/computer-aided manufacture (CAD/CAM) milling method and 3D printing method and to confirm its applicability as a work model for dental prosthesis production.

MATERIALS AND METHODS

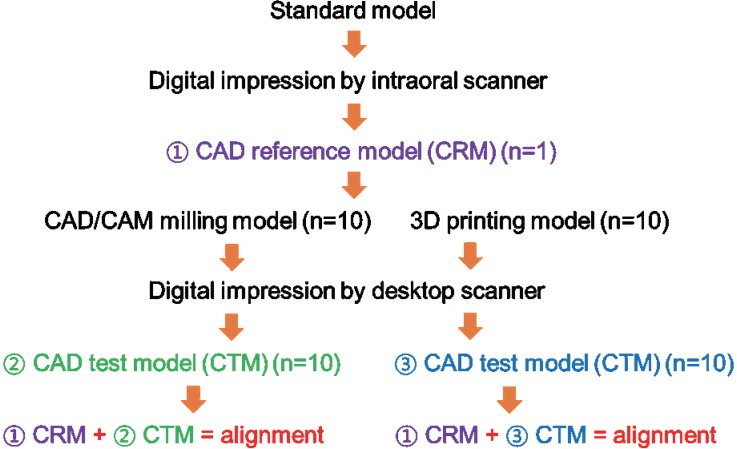

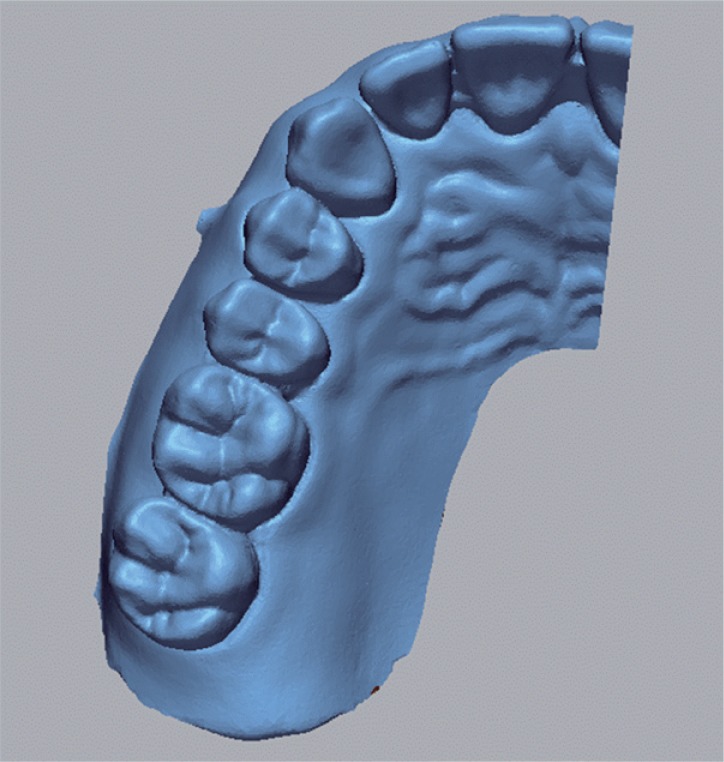

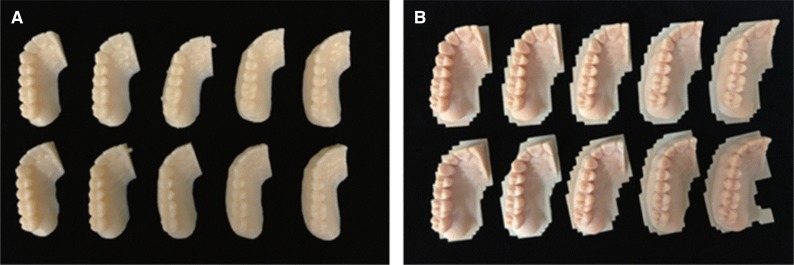

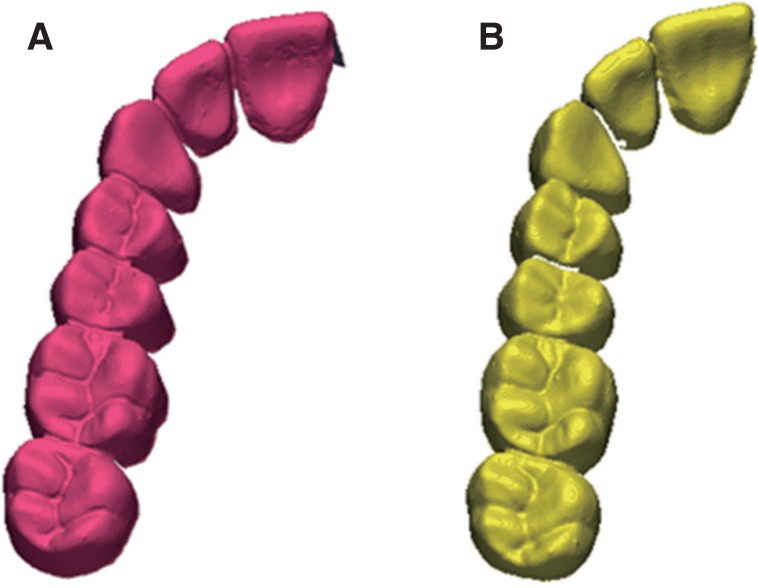

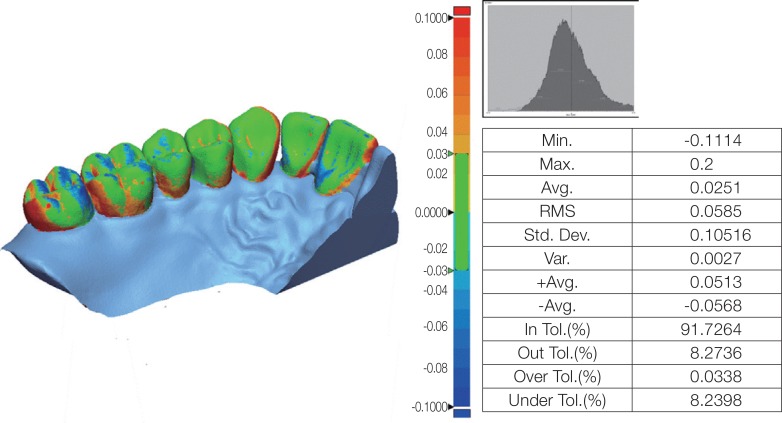

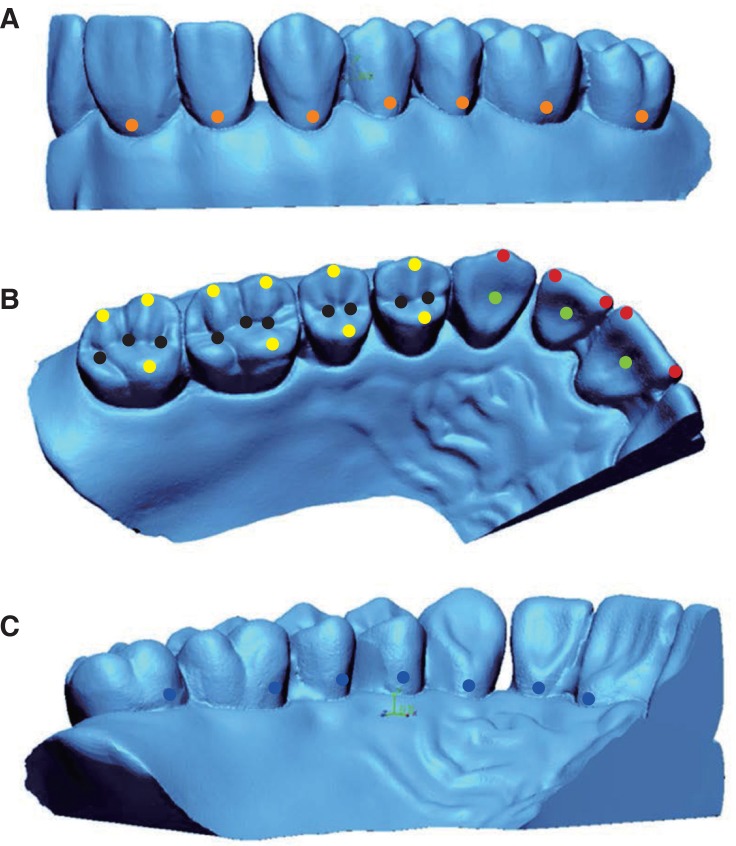

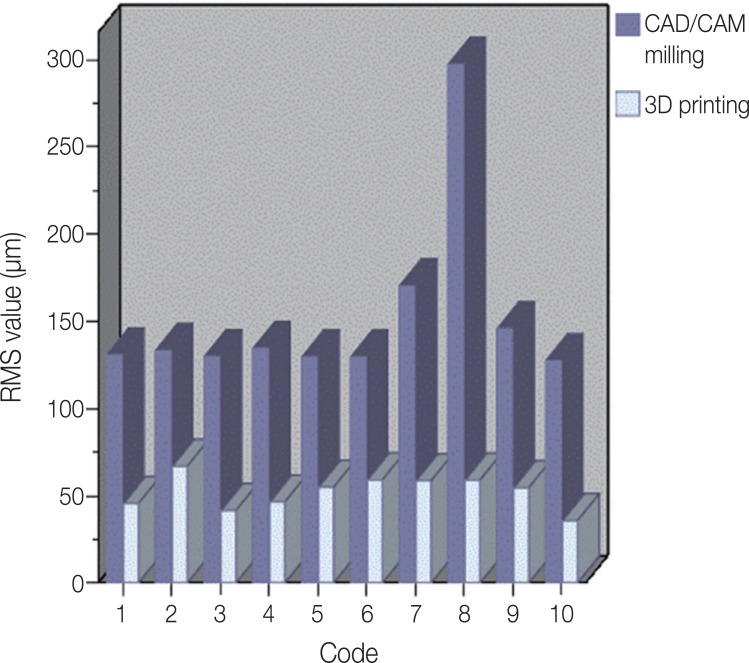

First, a natural tooth model (ANA-4, Frasaco, Germany) was scanned using an oral scanner. The obtained scan data were then used as a CAD reference model (CRM), to produce a total of 10 models each, either using the milling method or the 3D printing method. The 20 models were then scanned using a desktop scanner and the CAD test model was formed. The accuracy of the two groups was compared using dedicated software to calculate the root mean square (RMS) value after superimposing CRM and CAD test model (CTM).

RESULTS

The RMS value (152±52 µm) of the model manufactured by the milling method was significantly higher than the RMS value (52±9 µm) of the model produced by the 3D printing method.

CONCLUSION

The accuracy of the 3D printing method is superior to that of the milling method, but at present, both methods are limited in their application as a work model for prosthesis manufacture.

Keyword

MeSH Terms

Figure

Cited by 1 articles

-

Marginal fit of three different nanocomposite inlays fabricated with computer-aided design/computer-aided manufacturing (CAD/CAM) technology: a comparative study

Hyunsuk Choi, Jae-Young Jo, Min-Ho Hong

J Yeungnam Med Sci. 2024;41(2):80-85. doi: 10.12701/jyms.2023.00934.

Reference

-

1. Perakis N, Belser UC, Magne P. Final impressions: a review of material properties and description of a current technique. Int J Periodontics Restorative Dent. 2004; 24:109–117. PMID: 15119881.2. Wettstein F, Sailer I, Roos M, Hämmerle CH. Clinical study of the internal gaps of zirconia and metal frameworks for fixed partial dentures. Eur J Oral Sci. 2008; 116:272–279. PMID: 18471247.

Article3. Persson AS, Odén A, Andersson M, Sandborgh-Englund G. Digitization of simulated clinical dental impressions: virtual three-dimensional analysis of exactness. Dent Mater. 2009; 25:929–936. PMID: 19264353.

Article4. Christensen GJ. The state of fixed prosthodontic impressions: room for improvement. J Am Dent Assoc. 2005; 136:343–346. PMID: 15819348.5. Christensen GJ. Impressions are changing: deciding on conventional, digital or digital plus in-office milling. J Am Dent Assoc. 2009; 140:1301–1304. PMID: 19797561.6. Beuer F, Schweiger J, Edelhoff D. Digital dentistry: an overview of recent developments for CAD/CAM generated restorations. Br Dent J. 2008; 204:505–511. PMID: 18469768.

Article7. Mehl A, Ender A, Mörmann W, Attin T. Accuracy testing of a new intraoral 3D camera. Int J Comput Dent. 2009; 12:11–28. PMID: 19213357.8. Fasbinder DJ. Digital dentistry: innovation for restorative treatment. Compend Contin Educ Dent. 2010; 31:2–11. PMID: 21049823.9. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12. PMID: 22119539.

Article10. Yau HT, Yang TJ, Lin YK. Comparison of 3-D printing and 5-axis milling for the production of dental emodels from intra-oral scanning. CAD App. 2016; 13:32–38.

Article11. Kasparova M, Grafova L, Dvorak P, Dostalova T, Prochazka A, Eliasova H, Prusa J, Kakawand S. Possibility of reconstruction of dental plaster cast from 3D digital study models. Biomed Eng Online. 2013; 12:49. PMID: 23721330.

Article12. Jeong ID, Lee JJ, Jeon JH, Kim JH, Kim HY, Kim WC. Accuracy of complete-arch model using an intraoral video scanner: An in vitro study. J Prosthet Dent. 2016; 115:755–759. PMID: 26794703.13. Quaas S, Rudolph H, Luthardt RG. Direct mechanical data acquisition of dental impressions for the manufacturing of CAD/CAM restorations. J Dent. 2007; 35:903–908. PMID: 17980951.

Article14. Koch GK, Gallucci GO, Lee SJ. Accuracy in the digital workflow: From data acquisition to the digitally milled cast. J Prosthet Dent. 2016; 115:749–754. PMID: 26803173.

Article15. Rhee YK, Huh YH, Cho LR, Park CJ. Comparison of intraoral scanning and conventional impression techniques using 3-dimensional superimposition. J Adv Prosthodont. 2015; 7:460–467. PMID: 26816576.

Article16. Martins LM, Lorenzoni FC, Melo AO, Silva LM, Oliveira JL, Oliveira PC, Bonfante G. Internal fit of two all-ceramic systems and metal-ceramic crowns. J Appl Oral Sci. 2012; 20:235–240. PMID: 22666843.

Article17. Moldovan O, Luthardt RG, Corcodel N, Rudolph H. Three-dimensional fit of CAD/CAM-made zirconia copings. Dent Mater. 2011; 27:1273–1278. PMID: 21983002.

Article18. Seelbach P, Brueckel C, Wöstmann B. Accuracy of digital and conventional impression techniques and workflow. Clin Oral Investig. 2013; 17:1759–1764.

Article19. Moldovan O, Luthardt RG, Corcodel N, Rudolph H. Threedimensional fit of CAD/CAM-made zirconia copings. Dent Mater. 2011; 27:1273–1278. PMID: 21983002.

Article20. Joo YH, Lee JH. Three dimensional accuracy analysis of dental stone casts fabricated using irreversible hydrocolloid impressions. J Dent Rehabil Appl Sci. 2015; 31:316–328.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system

- Full mouth rehabilitation of patient with severe dental caries with implant fixed prosthesis fabricated with milling and 3D printing method: A case report

- Accuracy of CAD-CAM RPD framework according to manufacturing method: A literature review

- CAD/CAM fabricated complete denture using 3D face scan: A case report

- Comparing accuracy of denture bases fabricated by injection molding, CAD/CAM milling, and rapid prototyping method