Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system

- Affiliations

-

- 1Advanced Dental Device Development Institute (A3DI), Kyungpook National University, Daegu, Republic of Korea. kblee@knu.ac.kr

- 2Department of Prosthodontics, School of Dentistry, Kyungpook National University, Daegu, Republic of Korea.

- KMID: 2398073

- DOI: http://doi.org/10.4047/jap.2017.9.4.265

Abstract

- PURPOSE

This study is to evaluate the internal fit of the crown manufactured by CAD/CAM milling method and 3D printing method.

MATERIALS AND METHODS

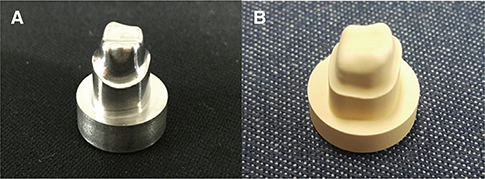

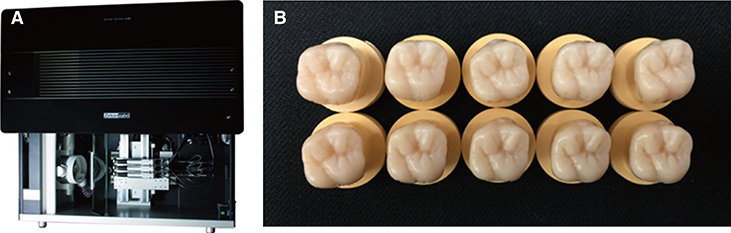

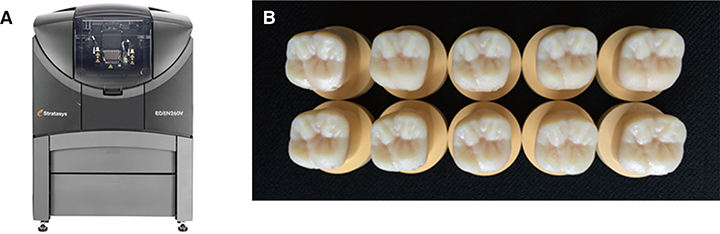

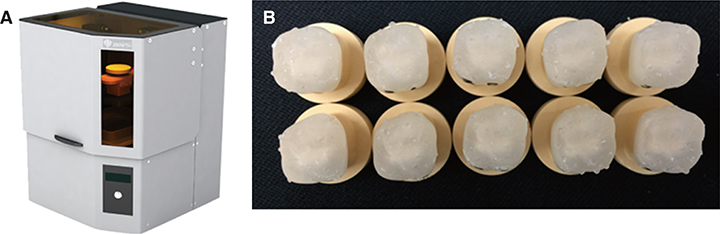

The master model was fabricated with stainless steel by using CNC machine and the work model was created from the vinyl-polysiloxane impression. After scanning the working model, the design software is used to design the crown. The saved STL file is used on the CAD/CAM milling method and two types of 3D printing method to produce 10 interim crowns per group. Internal discrepancy measurement uses the silicon replica method and the measured data are analyzed with One-way ANOVA to verify the statistic significance.

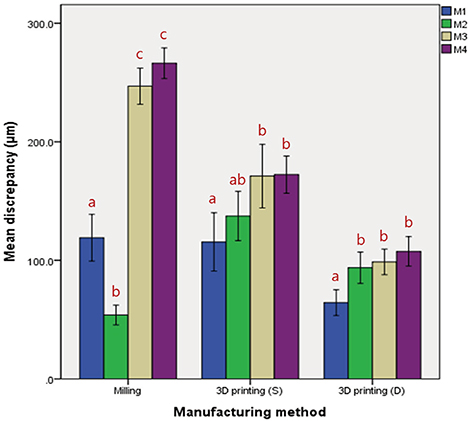

RESULTS

The discrepancy means (standard deviation) of the 3 groups are 171.6 (97.4) µm for the crown manufactured by the milling system and 149.1 (65.9) and 91.1 (36.4) µm, respectively, for the crowns manufactured with the two types of 3D printing system. There was a statistically significant difference and the 3D printing system group showed more outstanding value than the milling system group.

CONCLUSION

The marginal and internal fit of the interim restoration has more outstanding 3D printing method than the CAD/CAM milling method. Therefore, the 3D printing method is considered as applicable for not only the interim restoration production, but also in the dental prosthesis production with a higher level of completion.

MeSH Terms

Figure

Cited by 4 articles

-

Marginal and internal discrepancy of 3-unit fixed dental prostheses fabricated by subtractive and additive manufacturing

Jae-Won Choi

J Korean Acad Prosthodont. 2020;58(1):7-13. doi: 10.4047/jkap.2020.58.1.7.Trueness and precision of scanning abutment impressions and stone models according to dental CAD/CAM evaluation standards

Jin-Hun Jeon, Seong-Sig Hwang, Ji-Hwan Kim, Woong-Chul Kim

J Adv Prosthodont. 2018;10(5):335-339. doi: 10.4047/jap.2018.10.5.335.Influence of surface treatments and repair materials on the shear bond strength of CAD/CAM provisional restorations

Ki-Won Jeong, Sung-Hun Kim

J Adv Prosthodont. 2019;11(2):95-104. doi: 10.4047/jap.2019.11.2.95.Accuracy of provisional crowns made using stereolithography apparatus and subtractive technique

Seen-Young Kang, Jung-Hyun Park, Ji-Hwan Kim, Woong-Chul Kim

J Adv Prosthodont. 2018;10(5):354-360. doi: 10.4047/jap.2018.10.5.354.

Reference

-

1. Balkenhol M, Knapp M, Ferger P, Heun U, Wöstmann B. Correlation between polymerization shrinkage and marginal fit of temporary crowns. Dent Mater. 2008; 24:1575–1584.2. Ehrenberg D, Weiner GI, Weiner S. Long-term effects of storage and thermal cycling on the marginal adaptation of provisional resin crowns: a pilot study. J Prosthet Dent. 2006; 95:230–236.3. Ehrenberg DS, Weiner S. Changes in marginal gap size of provisional resin crowns after occlusal loading and thermal cycling. J Prosthet Dent. 2000; 84:139–148.4. JD Oxman SE Anderson . Dental crown liner composition and methods of preparing provisional applications. United States patent. U.S. Patent No 5,709,548. 1998.5. Abouelatta OB, El-Bediwi A, Sakrana A, Jiang XQ, Blunt L. Surface integrity of provisional resin materials. Meas Sci Technol. 2006; 17:584–591.6. Nejatidanesh F, Lotfi HR, Savabi O. Marginal accuracy of interim restorations fabricated from four interim autopolymerizing resins. J Prosthet Dent. 2006; 95:364–367.7. Michalakis K, Pissiotis A, Hirayama H, Kang K, Kafantaris N. Comparison of temperature increase in the pulp chamber during the polymerization of materials used for the direct fabrication of provisional restorations. J Prosthet Dent. 2006; 96:418–423.8. Heying JJ, Gratton DG. Flexural strength of interim fixed prosthesis materials after simulated function. MS Thesis. University of Iowa;2009.9. Regish KM, Sharma D, Prithviraj DR. Techniques of fabrication of provisional restoration: An overview. Int J Dent. 2011; 2011:134659.10. Alharbi N, Osman R, Wismeijer D. Effects of build direction on the mechanical properties of 3D-printed complete coverage interim dental restorations. J Prosthet Dent. 2016; 115:760–767.11. Syed M, Chopra R, Sachdev V. Allergic reactions to dental materials-a systematic review. J Clin Diagn Res. 2015; 9:ZE04–ZE09.12. Torabi K, Farjood E, Hamedani S. Rapid prototyping technologies and their applications in prosthodontics, a review of literature. J Dent (Shiraz). 2015; 16:1–9.13. Frazier WE. Metal additive manufacturing: A review. J Mater Eng Perform. 2014; 23:1917–1928.14. Stopp S, Wolff T, Irlinger F, Lueth T. A new method for printer calibration and contour accuracy manufacturing with 3D-print technology. Rapid Prototyp J. 2008; 14:167–172.15. Sun J, Zhang FQ. The application of rapid prototyping in prosthodontics. J Prosthodont. 2012; 21:641–644.16. Kelvin Khng KY, Ettinger RL, Armstrong SR, Lindquist T, Gratton DG, Qian F. In vitro evaluation of the marginal integrity of CAD/CAM interim crowns. J Prosthet Dent. 2016; 115:617–623.17. Pimenta MA, Frasca LC, Lopes R, Rivaldo E. Evaluation of marginal and internal fit of ceramic and metallic crown copings using x-ray microtomography (micro-CT) technology. J Prosthet Dent. 2015; 114:223–228.18. Sorensen JA. A standardized method for determination of crown margin fidelity. J Prosthet Dent. 1990; 64:18–24.19. Grenade C, Mainjot A, Vanheusden A. Fit of single tooth zirconia copings: comparison between various manufacturing processes. J Prosthet Dent. 2011; 105:249–255.20. Molin M, Karlsson S. The fit of gold inlays and three ceramic inlay systems. A clinical and in vitro study. Acta Odontol Scand. 1993; 51:201–206.21. Ostlund LE. Cavity design and mathematics: their effect on gaps at the margins of cast restorations. Oper Dent. 1985; 10:122–137.22. McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971; 131:107–111.23. Boening KW, Wolf BH, Schmidt AE, Kästner K, Walter MH. Clinical fit of Procera AllCeram crowns. J Prosthet Dent. 2000; 84:419–424.24. Liu Q, Leu M, Schmitt S. Rapid prototyping in dentistry: technology and application. Int J Adv Manuf Technol. 2006; 29:317–335.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Full mouth rehabilitation of patient with severe dental caries with implant fixed prosthesis fabricated with milling and 3D printing method: A case report

- Marginal and internal fit of interim crowns fabricated with 3D printing and milling method

- A Surface Treatment Technique for Interim Crown Fabricated by Three-Dimensional Printing with Digital Light-Processing Technology

- CAD/CAM fabricated complete denture using 3D face scan: A case report

- Accuracy evaluation of dental models manufactured by CAD/CAM milling method and 3D printing method