J Korean Acad Prosthodont.

2017 Oct;55(4):436-443. 10.4047/jkap.2017.55.4.436.

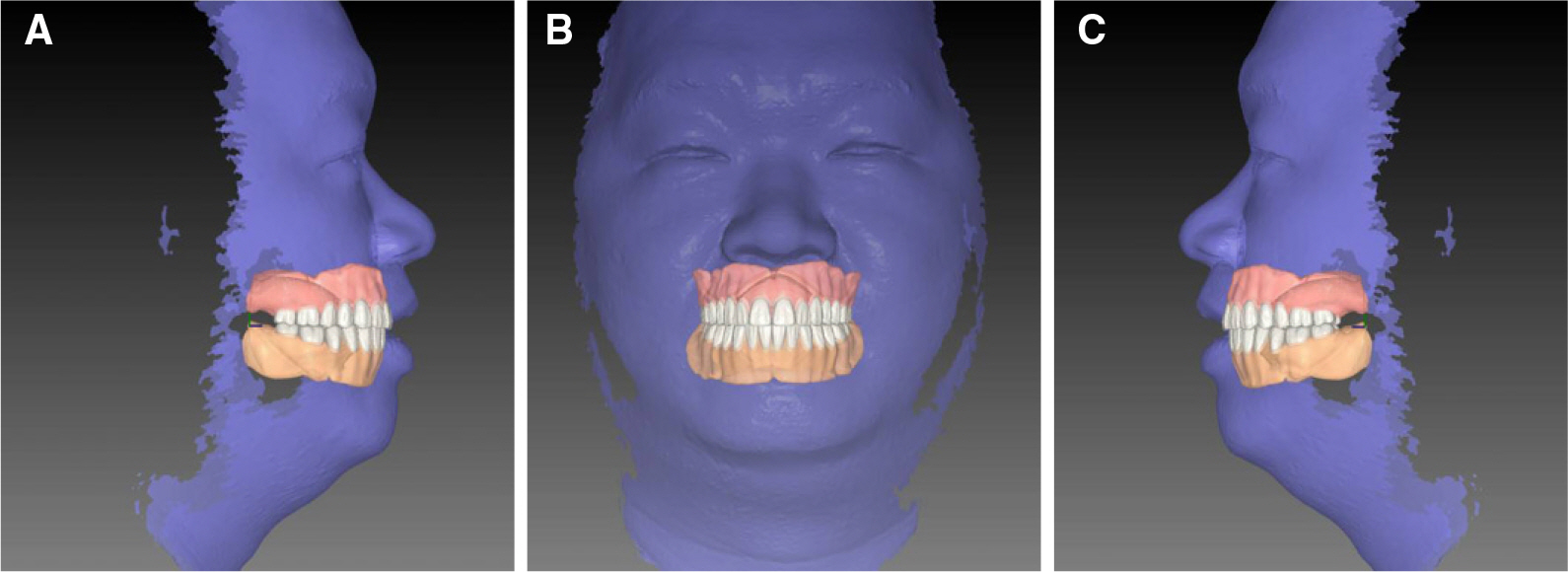

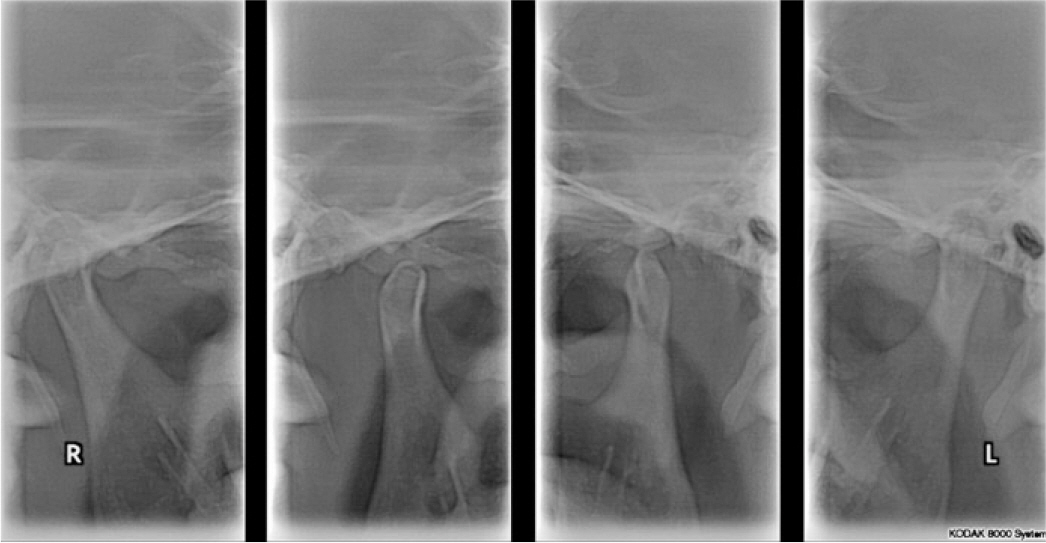

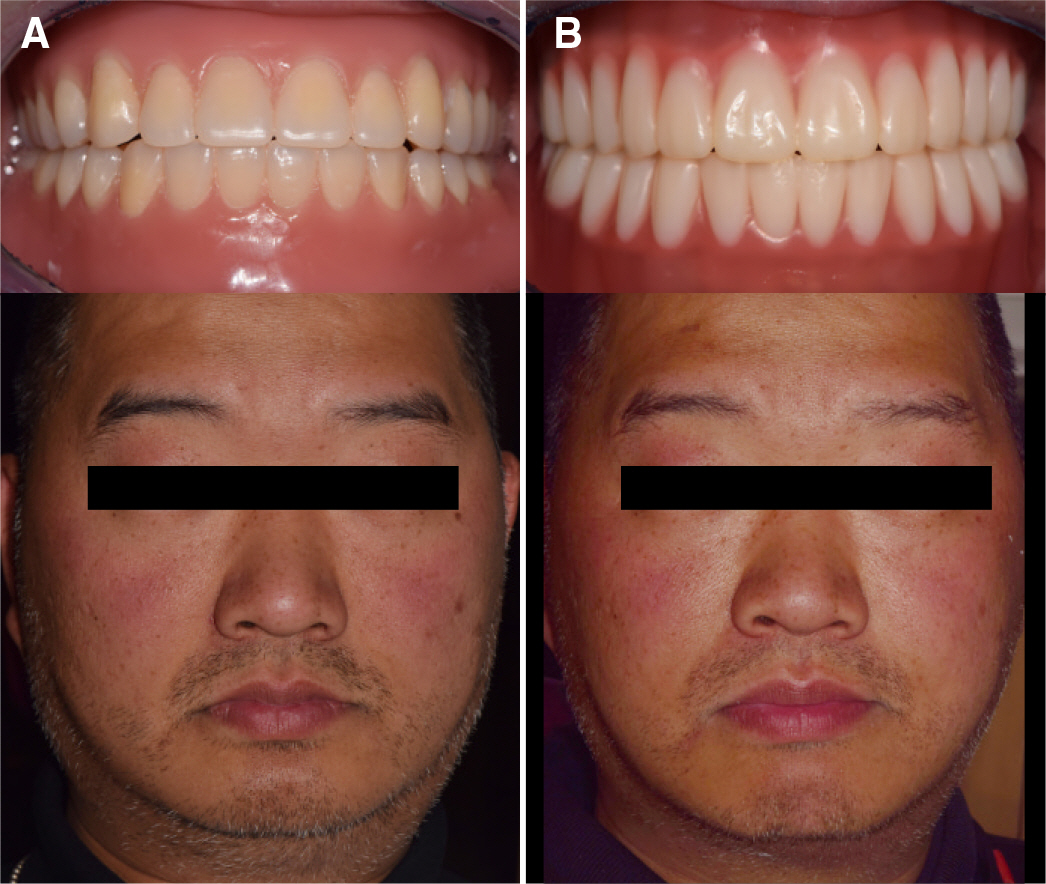

CAD/CAM fabricated complete denture using 3D face scan: A case report

- Affiliations

-

- 1Department of Biomaterials & Prosthodontics, Kyung Hee University Dental Hospital at Gangdong, Seoul, Republic of Korea. hswhsh@khu.ac.kr

- KMID: 2393916

- DOI: http://doi.org/10.4047/jkap.2017.55.4.436

Abstract

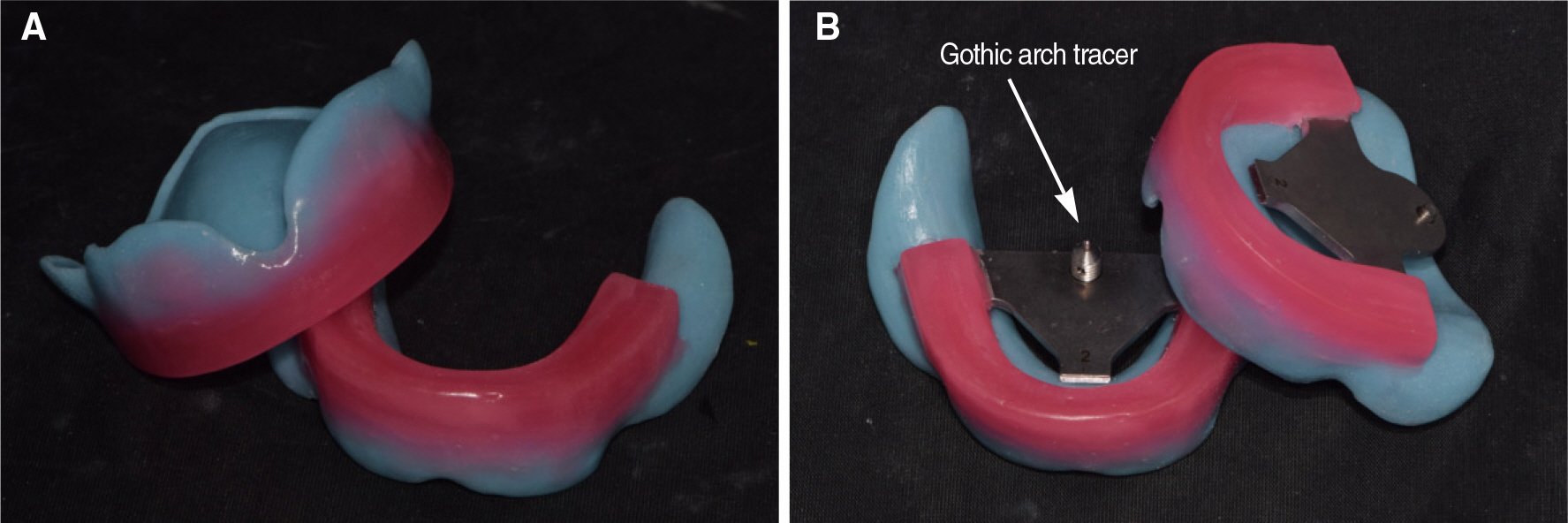

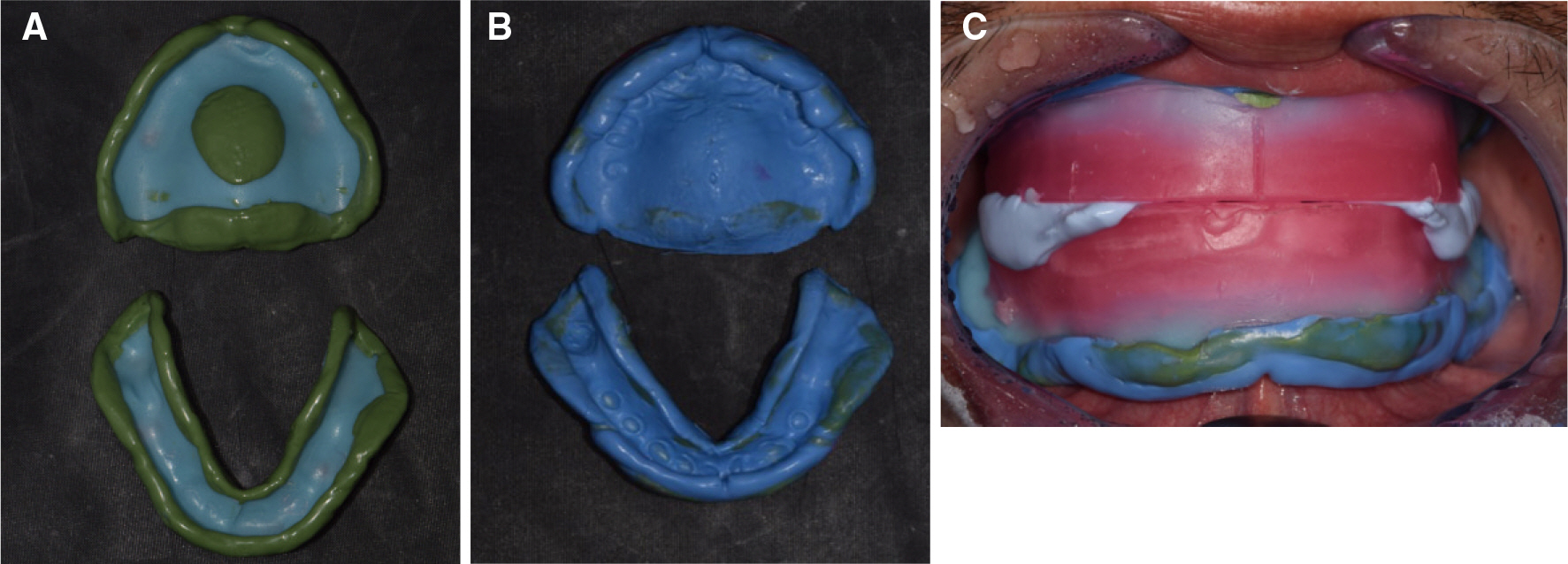

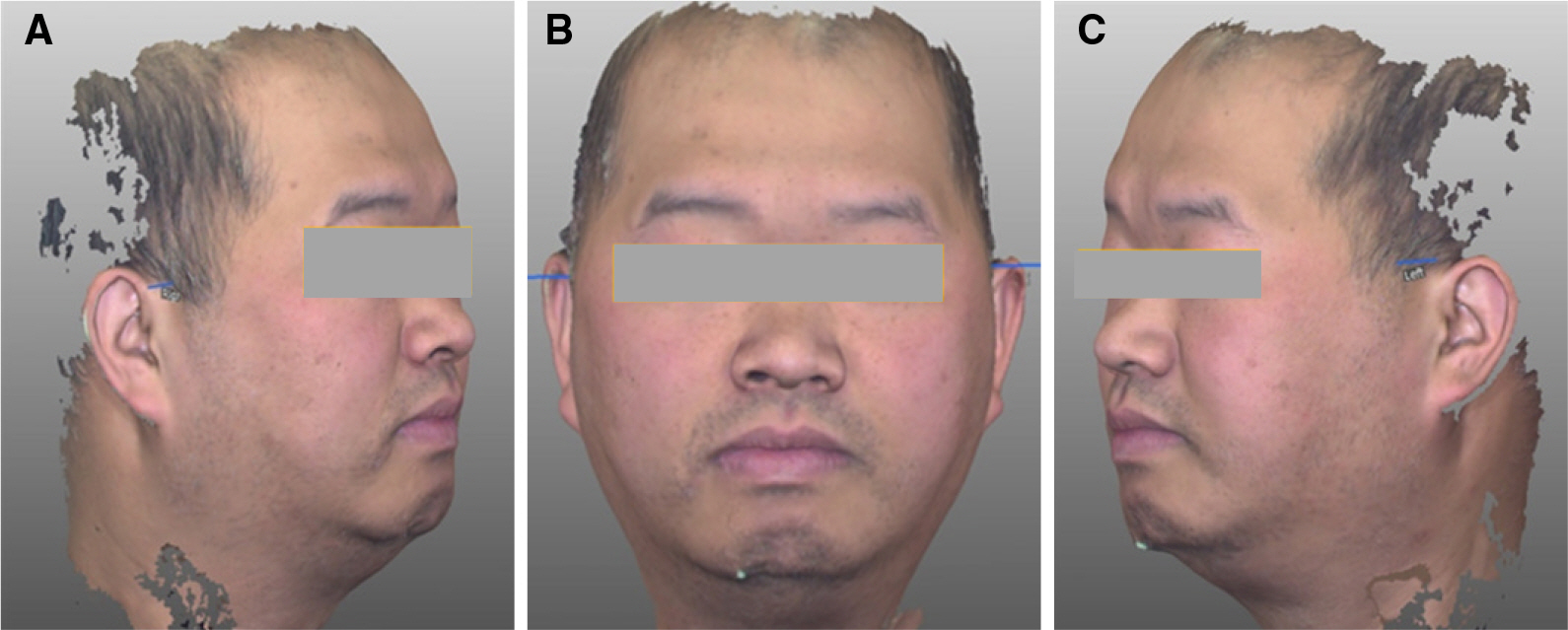

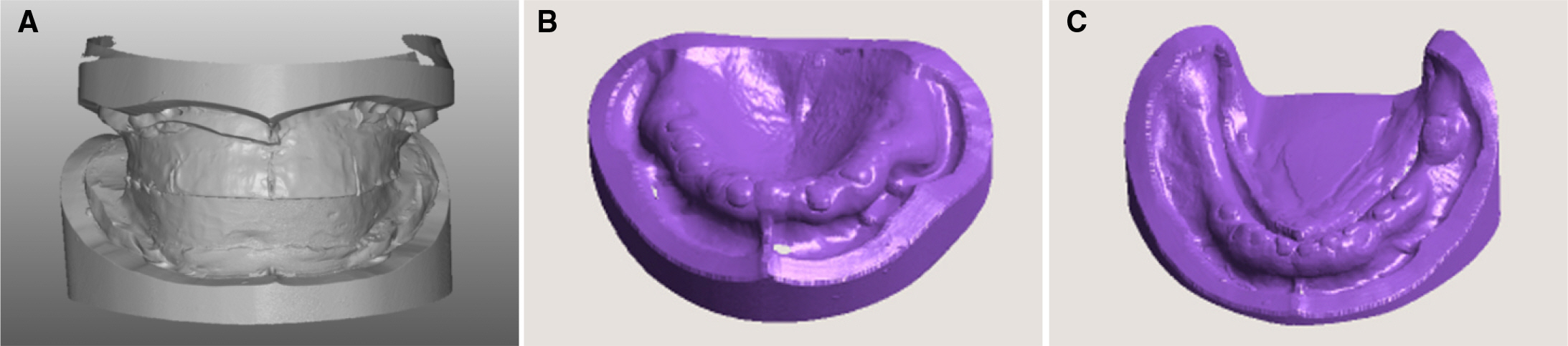

- In the past, computer-aided design/computer-aided manufacturing (CAD/CAM) technology was the closed system that users had to use the components of only one manufacturer. At present, it has changed to the open system with the flexibility to select and use the components of various manufacturers' components according to their needs. Despite the development of dental materials and prostheses manufacturing methods, denture manufacturing has followed conventional manufacturing methods for nearly 100 years. However, studies on CAD/CAM fabricated denture have been recently carried out to overcome the disadvantages of conventional denture manufacturing. Some commercialized products using milling or 3D printing have already been applied clinically. This case report confirms the possibility of CAD/CAM dentures using 3D face scan and compared them to conventionally fabricated dentures.

Keyword

MeSH Terms

Figure

Reference

-

1.Miyazaki T1., Hotta Y., Kunii J., Kuriyama S., Tamaki Y. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009. 28:44–56.

Article2.Bidra AS., Taylor TD., Agar JR. Computer-aided technology for fabricating complete dentures: systematic review of historical background, current status, and future perspectives. J Prosthet Dent. 2013. 109:361–6.

Article3.Maeda Y., Minoura M., Tsutsumi S., Okada M., Nokubi T. A CAD/CAM system for removable denture. Part I: Fabrication of complete dentures. Int J Prosthodont. 1994. 7:17–21.4.Baba NZ., AlRumaih HS., Goodacre BJ., Goodacre CJ. Current techniques in CAD/CAM denture fabrication. Gen Dent. 2016. 64:23–8.5.Stansbury JW., Idacavage MJ. 3D printing with polymers: Challenges among expanding options and opportunities. Dent Mater. 2016. 32:54–64.

Article6.van Noort R. The future of dental devices is digital. Dent Mater. 2012. 28:3–12.

Article7.Kattadiyil MT., Goodacre CJ., Baba NZ. CAD/CAM complete dentures: a review of two commercial fabrication systems. J Calif Dent Assoc. 2013. 41:407–16.8.Abduo J., Lyons K., Bennamoun M. Trends in computer-aided manufacturing in prosthodontics: a review of the available streams. Int J Dent. 2014. 2014:783948.

Article9.Sabol JV., Grant GT., Liacouras P., Rouse S. Digital image capture and rapid prototyping of the maxillofacial defect. J Prosthodont. 2011. 20:310–4.

Article10.Park CJ. Current status and future perspectives of CAD/CAM fabricated complete denture. J Korean Dent Assoc. 2014. 52:347–53.11.Goodacre BJ., Goodacre CJ., Baba NZ., Kattadiyil MT. Comparison of denture base adaptation between CAD-CAM and conventional fabrication techniques. J Prosthet Dent. 2016. 116:249–56.

Article12.Hajeer MY., Millett DT., Ayoub AF., Siebert JP. Applications of 3D imaging in orthodontics: part I. J Orthod. 2004. 31:62–70.13.Moss JP., Ismail SF., Hennessy RJ. Three-dimensional assessment of treatment outcomes on the face. Orthod Craniofac Res. 2003. 6:126–31.

Article14.Hajeer MY., Ayoub AF., Millett DT. Three-dimensional assessment of facial soft-tissue asymmetry before and after orthognathic surgery. Br J Oral Maxillofac Surg. 2004. 42:396–404.

Article15.Schweiger J., Guth JF., Edelhoff D., Stumbaum J. Virtual evaluation for CAD-CAM-fabricated complete dentures. J Prosthet Dent. 2017. 117:28–33.

Article16.DENTCA web site. [Accessed 31 August, 2017]. Available from. https://www.dentca.com/products/dentca-3d.17.Lee KY., Lee DJ. A comparative study of teeth and dental arch of Korean and Caucasian. Oral Biol Res. 1993. 71:1–15.18.Kook YA., Nojima K., Moon HB., McLaughlin RP., Sinclair PM. Comparison of arch forms between Korean and North American white populations. Am J Orthod Dentofacial Orthop. 2004. 126:680–6.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Fabrication of computer-aided design/computer-aided manufacturing complete denture and conventional complete denture: case report

- Fabrication of complete denture using conventional method and monolithic digital denture system: a case report

- Fabrication of complete denture using CAD-based vertical dimension increase and monolithic disc: a case report

- Rehabilitation of fully edentulous patient using Ceramill full denture system (FDS)

- Adherence of Candida to complete denture surfaces in vitro: A comparison of conventional and CAD/CAM complete dentures