J Adv Prosthodont.

2019 Feb;11(1):55-64. 10.4047/jap.2019.11.1.55.

Comparing accuracy of denture bases fabricated by injection molding, CAD/CAM milling, and rapid prototyping method

- Affiliations

-

- 1Private Practice, Seoul, Republic of Korea.

- 2Department of Prosthodontics, Kyung Hee University Dental Hospital, Seoul, Republic of Korea.

- 3Department of Prosthodontics, School of Dentistry, Kyung Hee University, Seoul, Republic of Korea. nhokt@naver.com

- KMID: 2438932

- DOI: http://doi.org/10.4047/jap.2019.11.1.55

Abstract

- PURPOSE

The accuracy of denture bases was compared among injection molding, milling, and rapid prototyping (RP) fabricating method.

MATERIALS AND METHODS

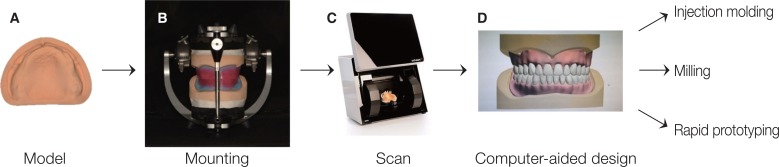

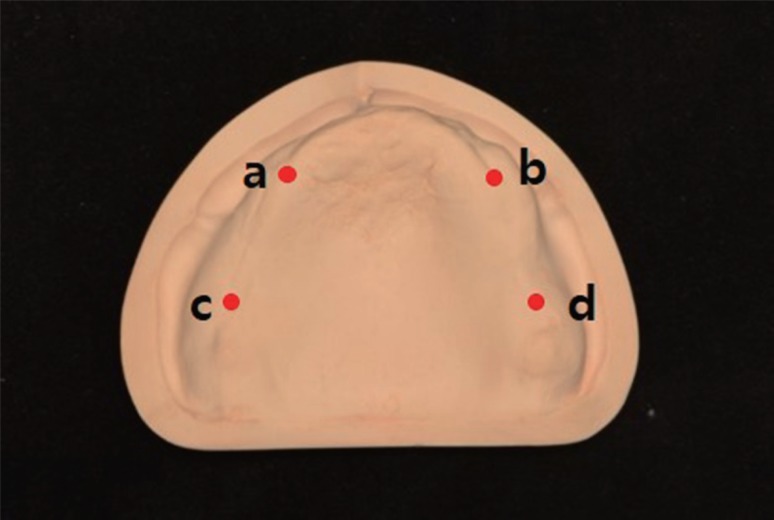

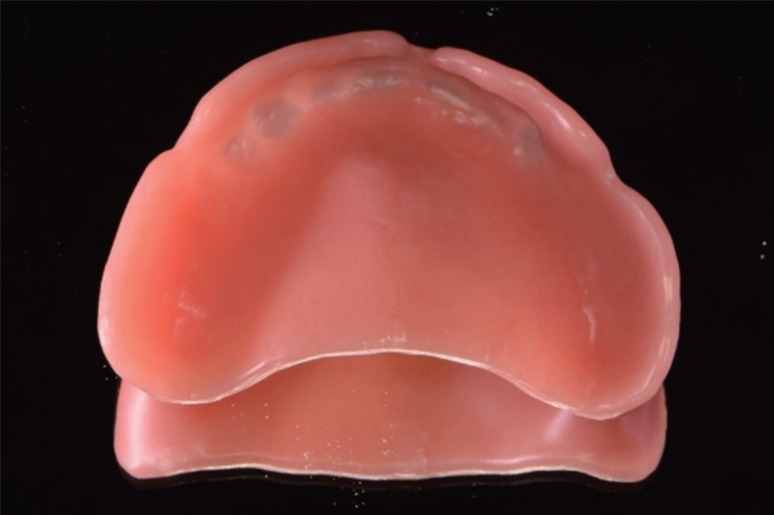

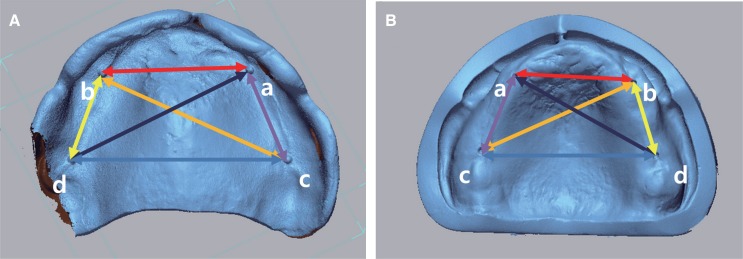

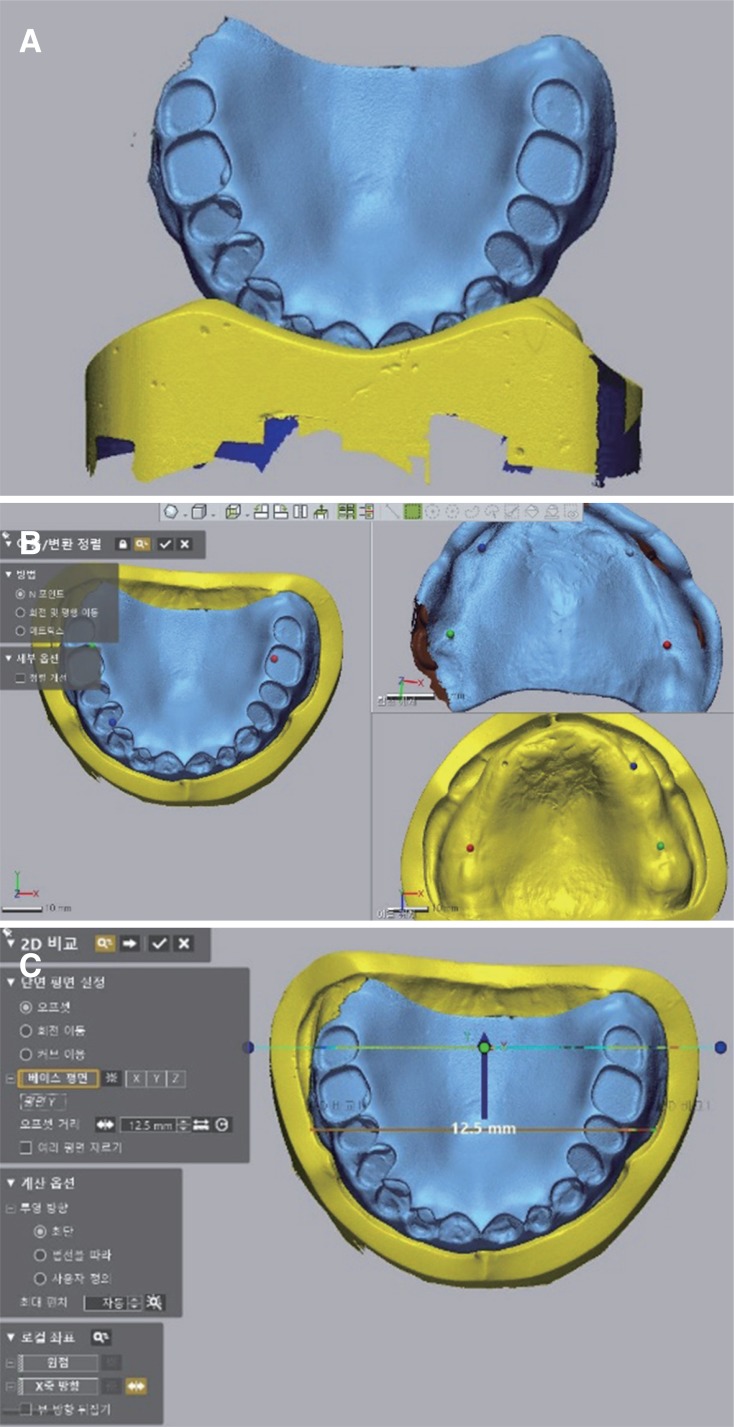

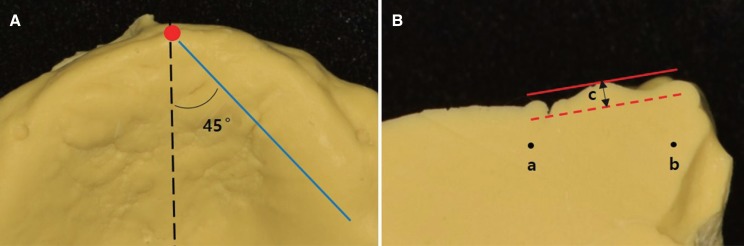

The maxillary edentulous master cast was fabricated and round shaped four notches were formed. The cast was duplicated to ten casts and scanned. In the injection molding method, designed denture bases were milled from a wax block and fabricated using SR Ivocap injection system. Denture bases were milled from a pre-polymerized block in the milling method. In the RP method, denture bases were printed and post-cured. The intaglio surface of the base was scanned and surface matching software was used to measure inaccuracy. Measurements were performed between four notches and two points in the mid-palatal suture to evaluate inaccuracy. The palatine rugae resolution was evaluated. One-way analysis of variance was used for statistical analysis at α=.05.

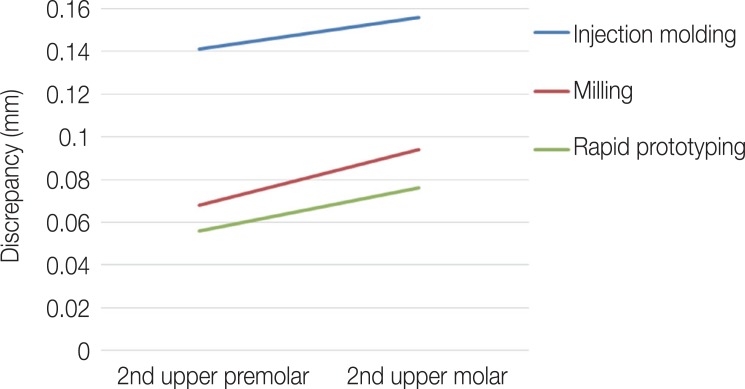

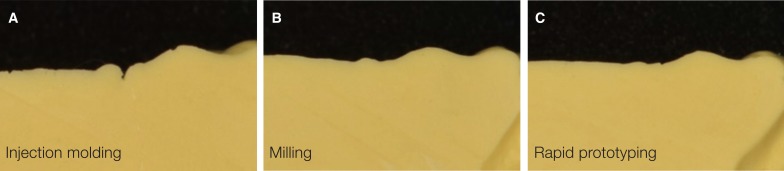

RESULTS

No statistically significant differences in distances among four notches (P>.05). The accuracy of the injection molding method was lower than those of the other methods in two points of the mid-palatal suture significantly (P < .05). The degree of palatine rugae resolution was significantly higher in the injection molding method than that in other methods (P < .05).

CONCLUSION

The overall accuracy of the denture base is higher in milling and RP method than the injection molding method. The degree of fine reproducibility is higher in the injection molding method than the milling or RP method.

Keyword

Figure

Cited by 2 articles

-

Fabrication of complete dentures by conventional method and CAD/CAM milling: A case report

Youngchul Jung, Junsuk Lee, Seoung-Jin Hong, Kwantae Noh, Hyeong-Seob Kim, Ahran Pae

J Korean Acad Prosthodont. 2019;57(3):296-303. doi: 10.4047/jkap.2019.57.3.296.Evaluation of the dimensional change of 3D-printed complete denture after post-curing

Suyeon Lee, Younghun Kwak, Eunchul Park, Heejung Kim

J Dent Rehabil Appl Sci. 2022;38(4):233-241. doi: 10.14368/jdras.2022.38.4.233.

Reference

-

1. Kawara M, Komiyama O, Kimoto S, Kobayashi N, Kobayashi K, Nemoto K. Distortion behavior of heat-activated acrylic denture-base resin in conventional and long, low-temperature processing methods. J Dent Res. 1998; 77:1446–1453. PMID: 9649173.

Article2. Parvizi A, Lindquist T, Schneider R, Williamson D, Boyer D, Dawson DV. Comparison of the dimensional accuracy of injection-molded denture base materials to that of conventional pressure-pack acrylic resin. J Prosthodont. 2004; 13:83–89. PMID: 15210003.

Article3. Darvell BW, Clark RK. The physical mechanisms of complete denture retention. Br Dent J. 2000; 189:248–252. PMID: 11048392.

Article4. Jacob RF. The traditional therapeutic paradigm: complete denture therapy. J Prosthet Dent. 1998; 79:6–13. PMID: 9474534.

Article5. Jacobson TE, Krol AJ. A contemporary review of the factors involved in complete denture retention, stability, and support. Part I: retention. J Prosthet Dent. 1983; 49:5–15. PMID: 6337253.

Article6. Jacobson TE, Krol AJ. A contemporary review of the factors involved in complete dentures. Part II: stability. J Prosthet Dent. 1983; 49:165–172. PMID: 6338210.

Article7. Jacobson TE, Krol AJ. A contemporary review of the factors involved in complete dentures. Part III: support. J Prosthet Dent. 1983; 49:306–313. PMID: 6341544.

Article8. Pryor WJ. Injection molding of plastics for dentures. J Am Dent Assoc. 1942; 29:1400–1408.

Article9. Huggett R, Zissis A, Harrison A, Dennis A. Dimensional accuracy and stability of acrylic resin denture bases. J Prosthet Dent. 1992; 68:634–640. PMID: 1403942.

Article10. Goodacre CJ, Garbacea A, Naylor WP, Daher T, Marchack CB, Lowry J. CAD/CAM fabricated complete dentures: concepts and clinical methods of obtaining required morphological data. J Prosthet Dent. 2012; 107:34–46. PMID: 22230914.

Article11. Bidra AS, Taylor TD, Agar JR. Computer-aided technology for fabricating complete dentures: systematic review of historical background, current status, and future perspectives. J Prosthet Dent. 2013; 109:361–366. PMID: 23763779.

Article12. Infante L, Yilmaz B, McGlumphy E, Finger I. Fabricating complete dentures with CAD/CAM technology. J Prosthet Dent. 2014; 111:351–355. PMID: 24461946.

Article13. Maeda Y, Minoura M, Tsutsumi S, Okada M, Nokubi T. A CAD/CAM system for removable denture. Part I: Fabrication of complete dentures. Int J Prosthodont. 1994; 7:17–21. PMID: 8179777.14. Matsuda T, Goto T, Yagi K, Kashiwabara T, Ichikawa T. Part-digitizing system of impression and interocclusal record for complete denture fabrication. J Prosthodont. 2016; 25:503–509. PMID: 26619371.

Article15. Kuesel AC, Graschew G, Hull WE, Lorenz W, Thielmann HW. 31P NMR studies of cultured human tumor cells. Influence of pH on phospholipid metabolite levels and the detection of cytidine 5'-diphosphate choline. NMR Biomed. 1990; 3:78–89. PMID: 2390457.

Article16. Wimmer T, Gallus K, Eichberger M, Stawarczyk B. Complete denture fabrication supported by CAD/CAM. J Prosthet Dent. 2016; 115:541–546. PMID: 26774323.

Article17. Munari LS, Cornacchia TP, Moreira AN, Gonçalves JB, De Las Casas EB, Magalhães CS. Stress distribution in a premolar 3D model with anisotropic and isotropic enamel. Med Biol Eng Comput. 2015; 53:751–758. PMID: 25850984.

Article18. Goodacre BJ, Goodacre CJ, Baba NZ, Kattadiyil MT. Comparison of denture base adaptation between CAD-CAM and conventional fabrication techniques. J Prosthet Dent. 2016; 116:249–256. PMID: 27112416.

Article19. McLaughlin JB, Ramos V Jr, Dickinson DP. Comparison of fit of dentures fabricated by traditional techniques versus CAD/CAM technology. J Prosthodont. 2017; 11. 14.

Article20. Johnson DL, Holt RA, Duncanson MG Jr. Contours of the edentulous palate. J Am Dent Assoc. 1986; 113:35–40. PMID: 3525644.

Article21. Sykora O, Sutow EJ. Posterior palatal seal adaptation: influence of processing technique, palate shape and immersion. J Oral Rehabil. 1993; 20:19–31. PMID: 8429420.

Article22. Johnson DL, Duncanson MG Jr. The plastic postpalatal denture seal. Quintessence Int. 1987; 18:457–462. PMID: 3333857.23. Lee CJ, Bok SB, Bae JY, Lee HH. Comparative adaptation accuracy of acrylic denture bases evaluated by two different methods. Dent Mater J. 2010; 29:411–417. PMID: 20675954.

Article24. Steinmassl O, Dumfahrt H, Grunert I, Steinmassl PA. CAD/CAM produces dentures with improved fit. Clin Oral Investig. 2018; 22:2829–2835.

Article25. Schaefer O, Decker M, Wittstock F, Kuepper H, Guentsch A. Impact of digital impression techniques on the adaption of ceramic partial crowns in vitro. J Dent. 2014; 42:677–683. PMID: 24508541.

Article26. Ender A, Mehl A. Influence of scanning strategies on the accuracy of digital intraoral scanning systems. Int J Comput Dent. 2013; 16:11–21. PMID: 23641661.27. Petrovic V, Gonzalez JVH, Ferrando OJ, Gordillo JD, Puchades JRB, Griñan LP. Additive layered manufacturing: sectors of industrial application shown through case studies. Int J Prod Res. 2011; 49:1061–1079.

Article28. Groth C, Kravitz ND, Jones PE, Graham JW, Redmond WR. Three-dimensional printing technology. J Clin Orthod. 2014; 48:475–485. PMID: 25226040.29. Alharbi N, Osman R, Wismeijer D. Effects of build direction on the mechanical properties of 3D-printed complete coverage interim dental restorations. J Prosthet Dent. 2016; 115:760–767. PMID: 26803175.

Article30. Braian M, Jimbo R, Wennerberg A. Production tolerance of additive manufactured polymeric objects for clinical applications. Dent Mater. 2016; 32:853–861. PMID: 27118595.

Article31. Allen S, Dutta D. On the computation of part orientation using support structures in layered manufacturing. In : Proceedings of the International Solid Freeform Fabrication Symposium; Austin, TX. 1994. p. 259–269.32. Plooij JM, Maal TJ, Haers P, Borstlap WA, Kuijpers-Jagtman AM, Bergé SJ. Digital three-dimensional image fusion processes for planning and evaluating orthodontics and orthognathic surgery. A systematic review. Int J Oral Maxillofac Surg. 2011; 40:341–352. PMID: 21095103.

Article33. Revilla-León M, Özcan M. Additive manufacturing technologies used for processing polymers: Current status and potential application in prosthetic dentistry. J Prosthodont. 2018; 4. 22.

Article34. Srinivasan M, Cantin Y, Mehl A, Gjengedal H, Müller F, Schimmel M. CAD/CAM milled removable complete dentures: an in vitro evaluation of trueness. Clin Oral Investig. 2017; 21:2007–2019.

Article35. Puebla K, Arcaute K, Quintana R, Wicker RB. Effects of environmental conditions, aging, and build orientations on the mechanical properties of ASTM type I specimens manufactured via stereolithography. Rapid Prototyp J. 2012; 18:374–388.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Fabrication of complete denture using CAD-based vertical dimension increase and monolithic disc: a case report

- Accuracy of CAD-CAM RPD framework according to manufacturing method: A literature review

- RPD framework fabrication using computer-aided design (CAD) and rapid prototyping

- Adherence of Candida to complete denture surfaces in vitro: A comparison of conventional and CAD/CAM complete dentures

- Fabrication of complete denture using conventional method and monolithic digital denture system: a case report