J Adv Prosthodont.

2018 Jun;10(3):236-244. 10.4047/jap.2018.10.3.236.

Comparison of the marginal fit of milled yttrium stabilized zirconium dioxide crowns obtained by scanning silicone impressions and by scanning stone replicas

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, Medicine Doctorate and Translational Research, University of Barcelona, Spain. earandayus@gmail.com

- 2Department of Prosthodontics, Faculty of Dentistry, University of Barcelona, Spain.

- 3Department of Genetics, Microbiology and Stadistics, Faculty of Biology, University of Barcelona, Spain.

- KMID: 2413493

- DOI: http://doi.org/10.4047/jap.2018.10.3.236

Abstract

- PURPOSE

To determine the discrepancy in monolithic zirconium dioxide crowns made with computer-aided design and computer-aided manufacturing (CAD/CAM) systems by comparing scans of silicone impressions and of master casts.

MATERIALS AND METHODS

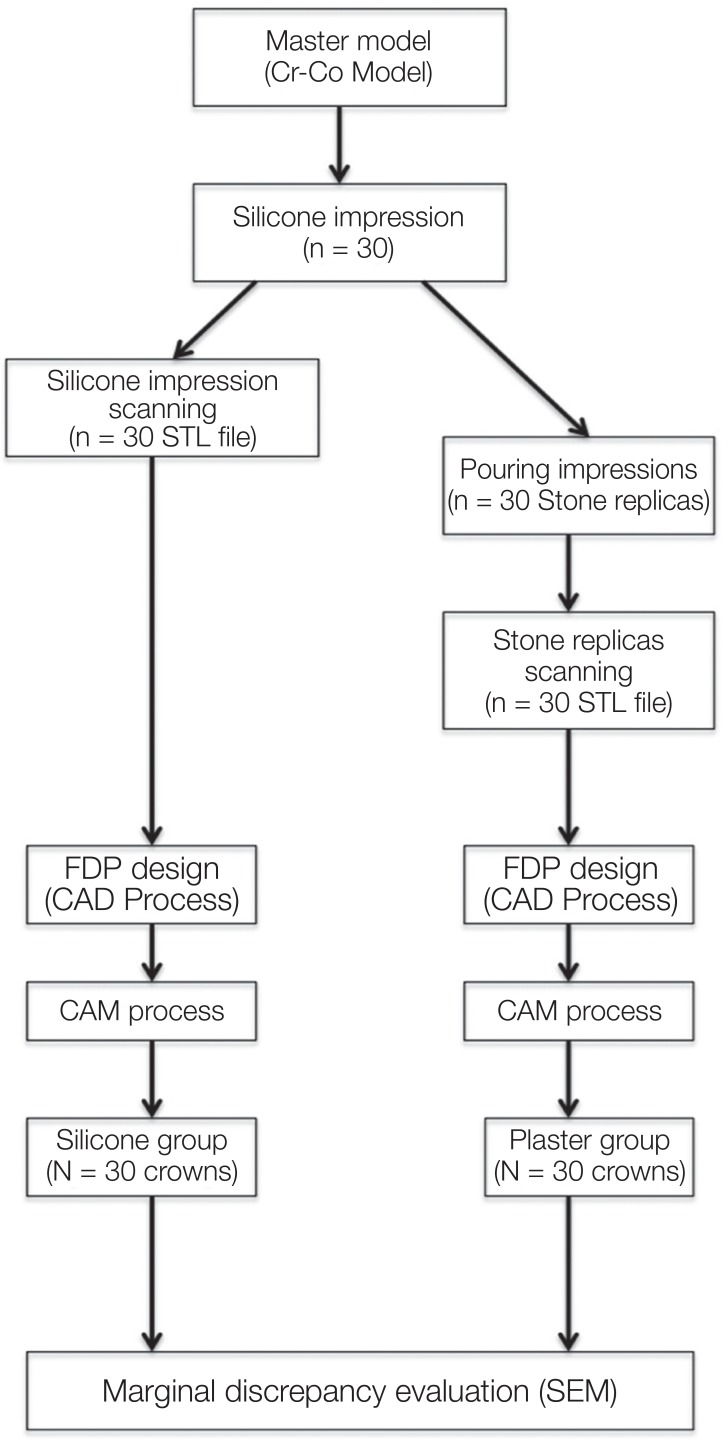

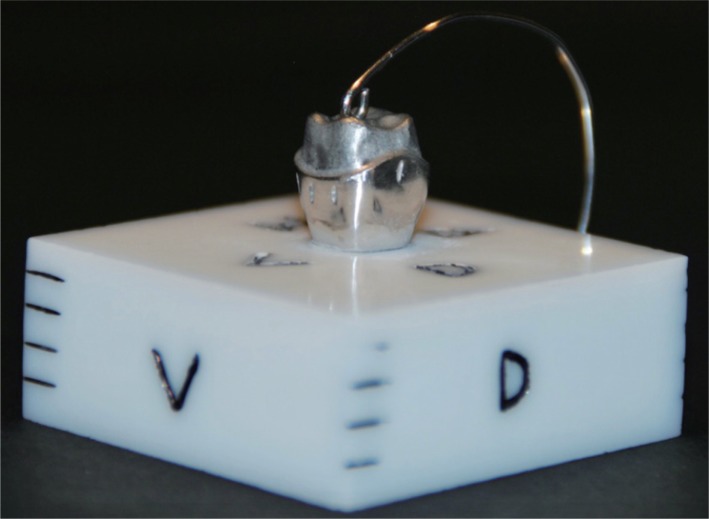

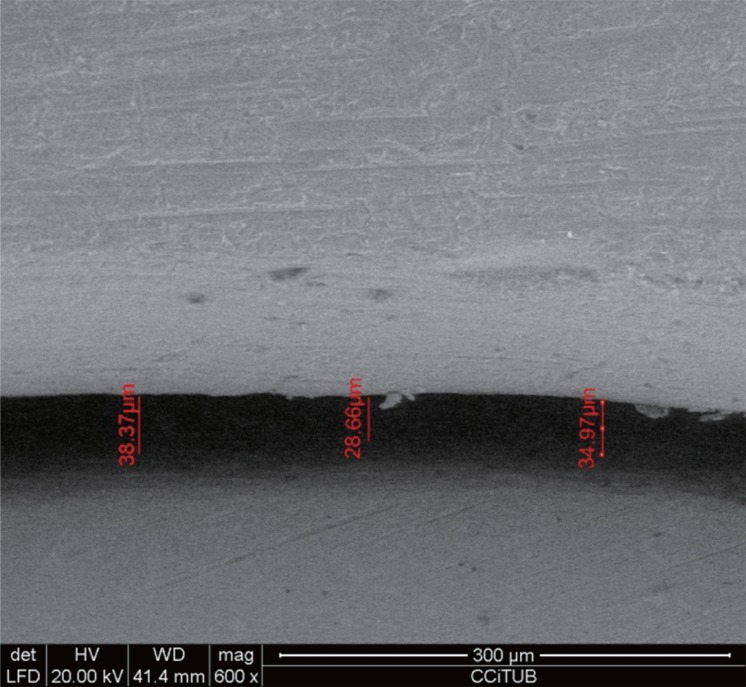

From a Cr-Co master die of a first upper left molar, 30 silicone impressions were taken. The 30 silicone impressions were scanned with the laboratory scanner, thus obtaining 30 milled monolithic yttrium stabilized zirconium dioxide (YSZD) crowns (the silicone group). They were poured and the working models were scanned, obtaining 30 milled monolithic yttrium stabilized zirconium dioxide (YSZD) crowns (the plaster group). Three predetermined points were analyzed in each side of the crown (Mesial, Distal ,Vestibular and Palatal), and the marginal fit was evaluated with SEM (×600). The response variable is the discrepancy from the master model. A repeated measures ANOVA with two within subject factors was performed to study significance of main factors and interaction.

RESULTS

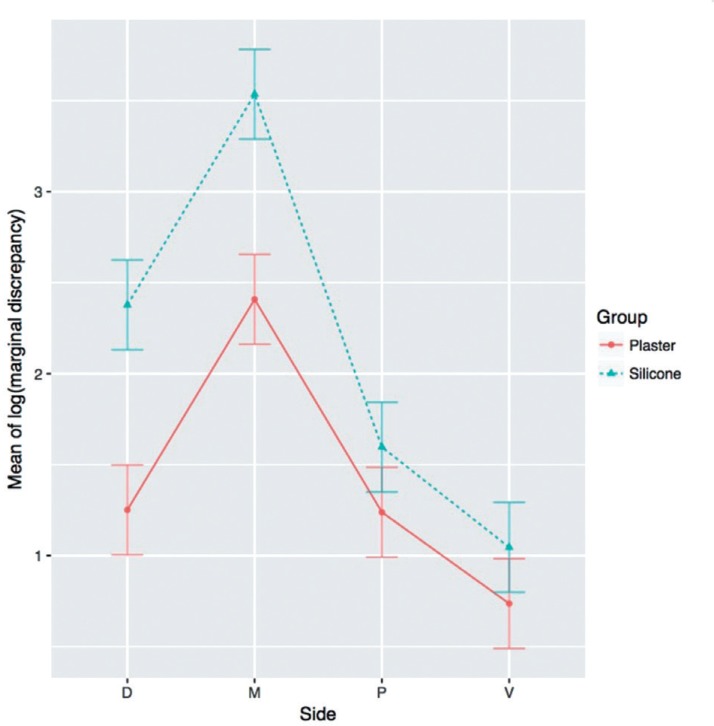

Mean marginal discrepancy was 22.42±35.65 µm in the silicone group and 8.94±14.69 µm in the plaster group. The statistical analysis showed significant differences between the two groups and also among the four aspects. Interaction was also significant (P=.02).

CONCLUSION

The mean marginal fit values of the two groups were within the clinically acceptable values. Significant differences were found between the groups according to the aspects studied. Various factors influenced the accuracy of digitizing, such as the design, the geometry, and the preparation guidance, as well as the texture, roughness and the color of the scanned material.

Keyword

MeSH Terms

Figure

Reference

-

1. Caparroso CB, Marin DV, Echavarria A. Marginal adaptation and internal fit of zirconia-ytrya frameworks fabricated with Procera® and Cerec in-Lab® CAD/CAM systems. Rev Fac Odontol Univ Antioq. 2011; 22:186–197.2. An S, Kim S, Choi H, Lee JH, Moon HS. Evaluating the marginal fit of zirconia copings with digital impressions with an intraoral digital scanner. J Prosthet Dent. 2014; 112:1171–1175. PMID: 24951386.

Article3. Alghazzawi TF, Al-Samadani KH, Lemons J, Liu PR, Essig ME, Bartolucci AA, Janowski GM. Effect of imaging powder and CAD/CAM stone types on the marginal gap of zirconia crowns. J Am Dent Assoc. 2015; 146:111–120. PMID: 25637209.

Article4. Pradíes G, Zarauz C, Valverde A, Ferreiroa A, Martínez-Rus F. Clinical evaluation comparing the fit of all-ceramic crowns obtained from silicone and digital intraoral impressions based on wavefront sampling technology. J Dent. 2015; 43:201–208. PMID: 25527248.

Article5. Reich S, Wichmann M, Nkenke E, Proeschel P. Clinical fit of all-ceramic three-unit fixed partial dentures,generated with three different CAD/CAM systems. Eur J Oral Sci. 2005; 113:174–179. PMID: 15819826.6. Ting-Shu S, Jian S. Intraoral digital impression technique: A review. J Prosthodont. 2015; 24:313–321. PMID: 25220390.

Article7. Keul C, Stawarczyk B, Erdelt KJ, Beuer F, Edelhoff D, Güth JF. Fit of 4-unit FDPs made of zirconia and CoCr-alloy after chairside and labside digitalization-a laboratory study. Dent Mater. 2014; 30:400–407. PMID: 24522150.8. Syrek A, Reich G, Ranftl D, Klein C, Cerny B, Brodesser J. Clinical evaluation of all-ceramic crowns fabricated from intraoral digital impressions based on the principle of active wavefront sampling. J Dent. 2010; 38:553–559. PMID: 20381576.

Article9. Ng J, Ruse D, Wyatt C. A comparison of the marginal fit of crowns fabricated with digital and conventional methods. J Prosthet Dent. 2014; 112:555–560. PMID: 24630399.

Article10. Flügge TV, Schlager S, Nelson K, Nahles S, Metzger MC. Precision of intraoral digital dental impressions with iTero and extraoral digitization with the iTero and a model scanner. Am J Orthod Dentofacial Orthop. 2013; 144:471–478. PMID: 23992820.

Article11. Lee WS, Kim WC, Kim HY, Kim WT, Kim JH. Evaluation of different approaches for using a laser scanner in digitization of dental impressions. J Adv Prosthodont. 2014; 6:22–29. PMID: 24605202.

Article12. Schillingburg HT, Hobo S, Whitsett LD, et al. Fundamentals of Fixed Prosthodontics. 3rd ed. London: Ed Quintessence Books;2006. p. 130–132.13. Renne W, McGill ST, Forshee KV, DeFee MR, Mennito AS. Predicting marginal fit of CAD/CAM crowns based on the presence or absence of common preparation errors. J Prosthet Dent. 2012; 108:310–315. PMID: 23107239.

Article14. Tsitrou EA, Northeast SE, van Noort R. Evaluation of the marginal fit of three margin designs of resin composite crowns using CAD/CAM. J Dent. 2007; 35:68–73. PMID: 16781043.15. Rinke S, Fischer C. Range of indications for translucent zirconia modifications: clinical and technical aspects. Quintessence Int. 2013; 44:557–566. PMID: 23772439.16. Lawrence MA. ez: Easy analysis and visualization of factorial experiments. Computer software manual. (R package version 3.0-0). 2011.17. Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989; 62:405–408. PMID: 2685240.

Article18. Persson AS, Odén A, Andersson M, Sandborgh-Englund G. Digitization of simulated clinical dental impressions: virtual three-dimensional analysis of exactness. Dent Mater. 2009; 25:929–936. PMID: 19264353.

Article19. Patzelt SB, Bishti S, Stampf S, Att W. Accuracy of computer-aided design/computer-aided manufacturing-generated dental casts based on intraoral scanner data. J Am Dent Assoc. 2014; 145:1133–1140. PMID: 25359645.

Article20. Anami LC, Lima JM, Corazza PH, Yamamoto ET, Bottino MA, Borges AL. Finite element analysis of the influence of geometry and design of zirconia crowns on stress distribution. J Prosthodont. 2015; 24:146–151. PMID: 24975118.

Article21. DeLong R, Knorr S, Anderson GC, Hodges J, Pintado MR. Accuracy of contacts calculated from 3D images of occlusal surfaces. J Dent. 2007; 35:528–534. PMID: 17418474.

Article22. Rudolph H, Luthardt RG, Walter MH. Computer-aided analysis of the influence of digitizing and surfacing on the accuracy in dental CAD/CAM technology. Comput Biol Med. 2007; 37:579–587. PMID: 16844107.

Article23. Persson AS, Andersson M, Odén A, Sandborgh-Englund G. Computer aided analysis of digitized dental stone replicas by dental CAD/CAM technology. Dent Mater. 2008; 24:1123–1130. PMID: 18336900.

Article24. Schaefer O, Decker M, Wittstock F, Kuepper H, Guentsch A. Impact of digital impression techniques on the adaption of ceramic partial crowns in vitro. J Dent. 2014; 42:677–683. PMID: 24508541.

Article25. Quaas S, Rudolph H, Luthardt RG. Direct mechanical data acquisition of dental impressions for the manufacturing of CAD/CAM restorations. J Dent. 2007; 35:903–908. PMID: 17980951.

Article26. Schaefer O, Kuepper H, Sigusch BW, Thompson GA, Hefti AF, Guentsch A. Three-dimensional fit of lithium disilicate partial crowns in vitro. J Dent. 2013; 41:271–277. PMID: 23228498.

Article27. Syrek A, Reich G, Ranftl D, Klein C, Cerny B, Brodesser J. Clinical evaluation of all-ceramic crowns fabricated from intraoral digital impressions based on the principle of active wavefront sampling. J Dent. 2010; 38:553–559. PMID: 20381576.

Article28. DeLong R, Pintado MR, Ko CC, Hodges JS, Douglas WH. Factors influencing optical 3D scanning of vinyl polysiloxane impression materials. J Prosthodont. 2001; 10:78–85. PMID: 11512112.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A STUDY ON THE MARGINAL FIT OF ALL-CERAMIC CROWN USING CCD CAMERA

- Clinical comparison of marginal fit of ceramic inlays between digital and conventional impressions

- In vitro marginal fit of the computer-aided milled cercon crowns

- Marginal and internal fit of nano-composite CAD/CAM restorations

- Comparison of micro CT and cross-section technique for evaluation of marginal and internal fit of lithium disilicate crowns