Restor Dent Endod.

2016 Feb;41(1):37-43. 10.5395/rde.2016.41.1.37.

Marginal and internal fit of nano-composite CAD/CAM restorations

- Affiliations

-

- 1Seoul National University Dental Hospital, Seoul, Korea.

- 2Department of Conservative Dentistry, Seoul National University School of Dentistry and Dental Research Institute, Seoul, Korea. shbaek@snu.ac.kr

- KMID: 2316962

- DOI: http://doi.org/10.5395/rde.2016.41.1.37

Abstract

OBJECTIVES

The purpose of this study was to compare the marginal and internal fit of nano-composite CAD-CAM restorations.

MATERIALS AND METHODS

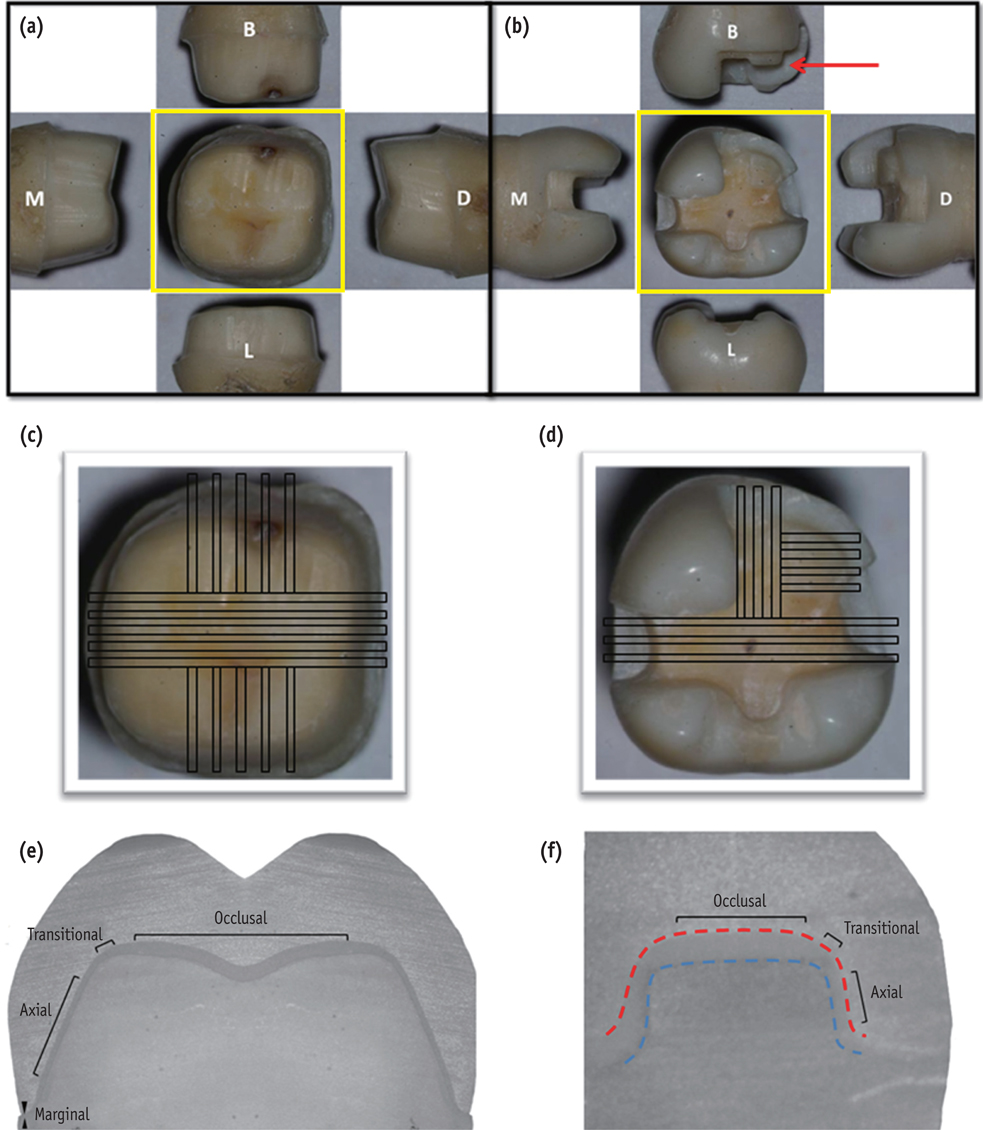

A full veneer crown and an mesio-occluso-distal (MOD) inlay cavity, which were prepared on extracted human molars, were used as templates of epoxy resin replicas. The prepared teeth were scanned and CAD-CAM restorations were milled using Lava Ultimate (LU) and experimental nano-composite CAD/CAM blocks (EB) under the same milling parameters. To assess the marginal and internal fit, the restorations were cemented to replicas and were embedded in an acrylic mold for sectioning at 0.5 mm intervals. The measured gap data were pooled according to the block types and measuring points for statistical analysis.

RESULTS

Both the block type and measuring point significantly affected gap values, and their interaction was significant (p = 0.000). In crowns and inlays made from the two blocks, gap values were significantly larger in the occlusal area than in the axial area, while gap values in the marginal area were smallest (p < 0.001). Among the blocks, the restorations milled from EB had a significantly larger gap at all measuring points than those milled from LU (p = 0.000).

CONCLUSIONS

The marginal and internal gaps of the two nano-composite CAD/CAM blocks differed according to the measuring points. Among the internal area of the two nano-composite CAD/CAM restorations, occlusal gap data were significantly larger than axial gap data. The EB crowns and inlays had significantly larger gaps than LU restorations.

Figure

Cited by 1 articles

-

Marginal fit of three different nanocomposite inlays fabricated with computer-aided design/computer-aided manufacturing (CAD/CAM) technology: a comparative study

Hyunsuk Choi, Jae-Young Jo, Min-Ho Hong

J Yeungnam Med Sci. 2024;41(2):80-85. doi: 10.12701/jyms.2023.00934.

Reference

-

1. Nguyen JF, Migonney V, Ruse ND, Sadoun M. Resin composite blocks via high-pressure high-temperature polymerization. Dent Mater. 2012; 28:529–534.

Article2. Stawarczyk B, Sener B, Trottmann A, Roos M, Ozcan M, Hämmerle CH. Discoloration of manually fabricated resins and industrially fabricated CAD/CAM blocks versus glass-ceramic: effect of storage media, duration,and subsequent polishing. Dent Mater J. 2012; 31:377–383.

Article3. Lauvahutanon S, Takahashi H, Shiozawa M, Iwasaki N, Asakawa Y, Oki M, Finger WJ, Arksornnukit M. Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J. 2014; 33:705–710.

Article4. Rocca GT, Bonnafous F, Rizcalla N, Krejci I. A technique to improve the esthetic aspects of CAD/CAM composite resin restorations. J Prosthet Dent. 2010; 104:273–275.

Article5. 3M ESPE M: Lava Ultimate CAD/CAM restorativetechnical product profile. 2011. updated 2016 Jan 2. Available from: http://www.d-way.cz/data/product/13/23/files/Lava_Ult_TPP.pdf.6. Molin M, Karlsson S. The fit of gold inlays and three ceramic inlay systems. A clinical and in vitro study. Acta Odontol Scand. 1993; 51:201–206.

Article7. Wang WC, McDonald A, Petrie A, Setchell D. Interface dimensions of CEREC-3 MOD onlays. Eur J Prosthodont Restor Dent. 2007; 15:183–189.8. Martin N, Jedynakiewicz NM. Interface dimensions of CEREC-2 MOD inlays. Dent Mater. 2000; 16:68–74.

Article9. Sjögren G. Marginal and internal fit of four different types of ceramic inlays after luting. An in vitro study. Acta Odontol Scand. 1995; 53:24–28.

Article10. Reich S, Gozdowski S, Trentzsch L, Frankenberger R, Lohbauer U. Marginal fit of heat-pressed vs. CAD/CAM processed all-ceramic onlays using a milling unit prototype. Oper Dent. 2008; 33:644–650.

Article11. Baig MR, Tan KB, Nicholls JI. Evaluation of the marginal fit of a zirconia ceramic computer-aided machined (CAM) crown system. J Prosthet Dent. 2010; 104:216–227.

Article12. Boitelle P, Mawussi B, Tapie L, Fromentin O. A systematic review of CAD/CAM fit restoration evaluations. J Oral Rehabil. 2014; 41:853–874.

Article13. Nakamura T, Dei N, Kojima T, Wakabayashi K. Marginal and internal fit of Cerec 3 CAD/CAM all-ceramic crowns. Int J Prosthodont. 2003; 16:244–248.14. Krasanaki ME, Pelekanos S, Andreiotelli M, Koutayas SO, Eliades G. X-ray microtomographic evaluation of the influence of two preparation types on marginal fit of CAD/CAM alumina copings: a pilot study. Int J Prosthodont. 2012; 25:170–172.15. Pelekanos S, Koumanou M, Koutayas SO, Zinelis S, Eliades G. Micro-CT evaluation of the marginal fit of different In-Ceram alumina copings. Eur J Esthet Dent. 2009; 4:278–292.16. Rungruanganunt P, Kelly JR, Adams DJ. Two imaging techniques for 3D quantification of pre-cementation space for CAD/CAM crowns. J Dent. 2010; 38:995–1000.

Article17. Matta RE, Schmitt J, Wichmann M, Holst S. Circumferential fit assessment of CAD/CAM single crowns-a pilot investigation on a new virtual analytical protocol. Quintessence Int. 2012; 43:801–809.18. Fonseca JC, Henriques GE, Sobrinho LC, de Góes MF. Stress-relieving and porcelain firing cycle influence on marginal fit of commercially pure titanium and titanium-aluminum-vanadium copings. Dent Mater. 2003; 19:686–691.

Article19. Weaver JD, Johnson GH, Bales DJ. Marginal adaptation of castable ceramic crowns. J Prosthet Dent. 1991; 66:747–753.

Article20. McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971; 131:107–111.

Article21. Brunthaler A, König F, Lucas T, Sperr W, Schedle A. Longevity of direct resin composite restorations in posterior teeth. Clin Oral Investig. 2003; 7:63–70.22. Yu H, Wegehaupt FJ, Wiegand A, Roos M, Attin T, Buchalla W. Erosion and abrasion of tooth-colored restorative materials and human enamel. J Dent. 2009; 37:913–922.

Article23. Stawarczyk B, Egli R, Roos M, Ozcan M, Hämmerle CH. The impact of in vitro aging on the mechanical and optical properties of indirect veneering composite resins. J Prosthet Dent. 2011; 106:386–398.

Article24. Tsitrou EA, Northeast SE, van Noort R. Evaluation of the marginal fit of three margin designs of resin composite crowns using CAD/CAM. J Dent. 2007; 35:68–73.

Article25. Akbar JH, Petrie CS, Walker MP, Williams K, Eick JD. Marginal adaptation of Cerec 3 CAD/CAM composite crowns using two different finish line preparation designs. J Prosthodont. 2006; 15:155–163.

Article26. Kim JH, Cho BH, Lee JH, Kwon SJ, Yi YA, Shin Y, Roh BD, Seo DG. Influence of preparation design on fit and ceramic thickness of CEREC 3 partial ceramic crowns after cementation. Acta Odontol Scand. 2015; 73:107–113.

Article27. Seo D, Yi Y, Roh B. The effect of preparation designs on the marginal and internal gaps in Cerec3 partial ceramic crowns. J Dent. 2009; 37:374–382.

Article28. Nam SJ, Yoon MJ, Kim WH, Ryu GJ, Bang MK, Huh JB. Marginal and Internal Fit of Conventional Metal-Ceramic and Lithium Disilicate CAD/CAM Crowns. Int J Prosthodont. 2015; 28:519–521.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Marginal fit of the digident CAD/CAM zirconia ceramic crowns

- Marginal fit of three different nanocomposite inlays fabricated with computer-aided design/computer-aided manufacturing (CAD/CAM) technology: a comparative study

- How adjustment could affect internal and marginal adaptation of CAD/CAM crowns made with different materials

- Comparison of marginal fit before and after porcelain build-up of two kinds of CAD/CAM zirconia all-ceramic restorations

- Color stability of fully- and pre-crystalized chair-side CAD-CAM lithium disilicate restorations after required and additional sintering processes