J Adv Prosthodont.

2015 Aug;7(4):312-316. 10.4047/jap.2015.7.4.312.

In vitro evaluation of the bond strength between various ceramics and cobalt-chromium alloy fabricated by selective laser sintering

- Affiliations

-

- 1Department of Dental Laboratory Science and Engineering, Korea University, Seoul, Republic of Korea. kjh2804@korea.ac.kr

- KMID: 2118267

- DOI: http://doi.org/10.4047/jap.2015.7.4.312

Abstract

- PURPOSE

This study aimed to present the clinical applicability of restorations fabricated by a new method, by comparing the bond strength of between ceramic powder with different coefficient of thermal expansion and alloys fabricated by Selective laser sintering (SLS).

MATERIALS AND METHODS

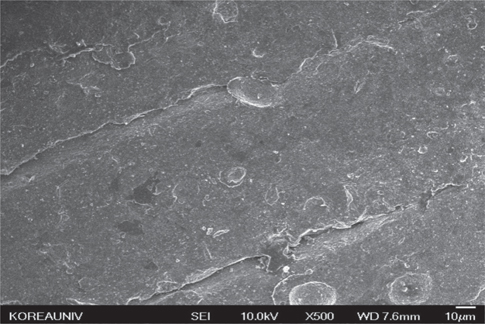

Fifty Co-Cr alloy specimens (25.0 x 3.0 x 0.5 mm) were prepared by SLS and fired with the ceramic (8.0 x 3.0 x 0.5 mm) (ISO 9693:1999). For comparison, ceramics with different coefficient of thermal expansion were used. The bond strength was measured by three-point bending testing and surfaces were observed with FE-SEM. Results were analyzed with a one-way ANOVA (alpha=.05).

RESULTS

The mean values of Duceram Kiss (61.18 +/- 6.86 MPa), Vita VM13 (60.30 +/- 7.14 MPa), Ceramco 3 (58.87 +/- 5.33 MPa), Noritake EX-3 (55.86 +/- 7.53 MPa), and Vintage MP (55.15 +/- 7.53 MPa) were found. No significant difference was observed between the bond strengths of the various metal-ceramics. The surfaces of the specimens possessed minute gaps between the additive manufactured layers.

CONCLUSION

All the five powders have bond strengths higher than the required 25 MPa minimum (ISO 9693); therefore, various powders can be applied to metal structures fabricated by SLS.

Keyword

Figure

Reference

-

1. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12.2. Moldovan O, Luthardt RG, Corcodel N, Rudolph H. Three-dimensional fit of CAD/CAM-made zirconia copings. Dent Mater. 2011; 27:1273–1278.3. Wu L, Zhu H, Gai X, Wang Y. Evaluation of the mechanical properties and porcelain bond strength of cobalt-chromium dental alloy fabricated by selective laser melting. J Prosthet Dent. 2014; 111:51–55.4. CR Deckard . Method and apparatus for producing parts by selective sintering. United States Patent. US4863538 A. 1989. 09. 05.5. M Feygin . Apparatus and method for forming an integral object from laminations. United States Patent. US5354414 A. 1994. 10. 11.6. Nieva N, Arreguez C, Carrizo R, Molé CS, Lagarrigue GM. Bonding strength evaluation on metal/ceramic interfaces in dental materials. Proc Mater Sci. 2012; 1:475–482.7. Donovan TE. Porcelain-fused-to-metal (PFM) alternatives. J Esthet Restor Dent. 2009; 21:4–6.8. Wataha JC. Alloys for prosthodontic restorations. J Prosthet Dent. 2002; 87:351–363.9. Zinelis S, Tsetsekou A, Papadopoulos T. Thermal expansion and microstructural analysis of experimental metal-ceramic titanium alloys. J Prosthet Dent. 2003; 90:332–338.10. Reyes MJ, Oshida Y, Andres CJ, Barco T, Hovijitra S, Brown D. Titanium-porcelain system. Part III: effects of surface modification on bond strengths. Biomed Mater Eng. 2001; 11:117–136.11. Steiner PJ, Kelly JR, Giuseppetti AA. Compatibility of ceramic-ceramic systems for fixed prosthodontics. Int J Prosthodont. 1997; 10:375–380.12. Craig RG, Ward ML. Restorative dental materials. 10th ed. St. Louis, MO: Mosby;1997.13. Al Amri MD, Hammad IA. Shear bond strength of two forms of opaque porcelain to the metal substructure. King Saud Univ J Dent Sci. 2012; 3:41–48.14. Barizon KT, Bergeron C, Vargas MA, Qian F, Cobb DS, Gratton DG, Geraldeli S. Ceramic materials for porcelain veneers: part II. Effect of material, shade, and thickness on translucency. J Prosthet Dent. 2014; 112:864–870.15. Wang CH, Wu JH, Li HY, Wang PP, Lee HE, Du JK. Fracture resistance of different metal substructure designs for implant-supported porcelain-fused-to-metal (PFM) crowns. J Dent Sci. 2013; 8:314–320.16. Souza JC, Henriques B, Ariza E, Martinelli AE, Nascimento RM, Silva FS, Rocha LA, Celis JP. Mechanical and chemical analyses across dental porcelain fused to CP titanium or Ti6Al4V. Mater Sci Eng C Mater Biol Appl. 2014; 37:76–83.17. e-Manufacturing Solutions. Instructions for use: EOS Cobalt Chrome SP2. 2011. Available from: http://ip-saas-eos-cms.s3.amazonaws.com/public/32ff6c9b7964c1c9/7c73a9305d8007c47dec2e65196f09e5/EOS_CobaltChrome_SP2_en.pdf.18. ISO 9693. Metal-ceramic dental restorative systems. 2nd ed. Geneva, Switzerland: International Organization for Standardization;1999.19. Lei YC. The influence of different thermal expansion coefficient (TEC) between ceramic and metal on thermal stability of porcelain-fused-to-metal (PFM) crown. Zhonghua Kou Qiang Yi Xue Za Zhi. 1991; 26:329–332. 38820. Korkmaz T, Asar V. Comparative evaluation of bond strength of various metal-ceramic restorations. Mater Des. 2009; 30:445–451.21. Joias RM, Tango RN, Junho de Araujo JE, Junho de Araujo MA, Ferreira Anzaloni Saavedra Gde S, Paes-Junior TJ, Kimpara ET. Shear bond strength of a ceramic to Co-Cr alloys. J Prosthet Dent. 2008; 99:54–59.22. Külünk T, Kurt M, Ural Ç, Külünk Ş, Baba S. Effect of different air-abrasion particles on metal-ceramic bond strength. J Dent Sci. 2011; 6:140–146.23. Bae EJ, Kim JH, Kim WC, Kim HY. Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering. J Adv Prosthodont. 2014; 6:266–271.24. Liu Y, Wang Z, Gao B, Zhao X, Lin X, Wu J. Evaluation of mechanical properties and porcelain bonded strength of nickel-chromium dental alloy fabricated by laser rapid forming. Lasers Med Sci. 2010; 25:799–804.25. de Melo RM, Travassos AC, Neisser MP. Shear bond strengths of a ceramic system to alternative metal alloys. J Prosthet Dent. 2005; 93:64–69.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- BOND STRENGTH BETWEEN COBALT-CHROMIUM ALLOY AND DENTURE BASE RESIN ACCORDING TO ADHESIVE PRIMERS

- Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering

- Comparison of the bond strength of ceramics to Co-Cr alloys made by casting and selective laser melting

- Metal-ceramic bond strength between a feldspathic porcelain and a Co-Cr alloy fabricated with Direct Metal Laser Sintering technique

- A STDUY ON THE SURFACE MORPHOLOGY AND BOND STRENGTH OF DENTURE BASE RESIN TO COBALT-CHROMIUM ALLOY AFTER VARYING MODES OF SURFACE TREATMENT