J Adv Prosthodont.

2018 Feb;10(1):25-31. 10.4047/jap.2018.10.1.25.

Metal-ceramic bond strength between a feldspathic porcelain and a Co-Cr alloy fabricated with Direct Metal Laser Sintering technique

- Affiliations

-

- 1Department of Biomaterials, Dental School, National and Kapodistrian University of Athens, Greece. trpapad@dent.uoa.gr

- 2Department of Dental Technology, Technological Institute of Athens, Greece.

- KMID: 2403995

- DOI: http://doi.org/10.4047/jap.2018.10.1.25

Abstract

- PURPOSE

The aim of the present study was to record the metal-ceramic bond strength of a feldspathic dental porcelain and a Co-Cr alloy, using the Direct Metal Laser Sintering technique (DMLS) for the fabrication of metal substrates.

MATERIALS AND METHODS

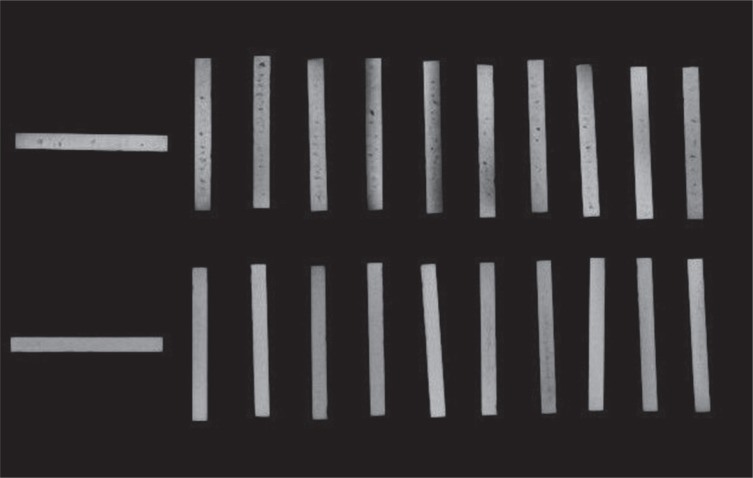

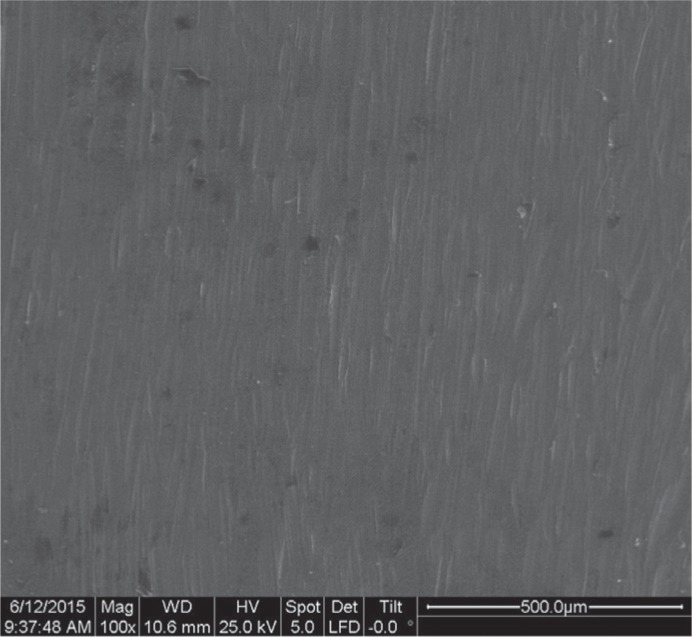

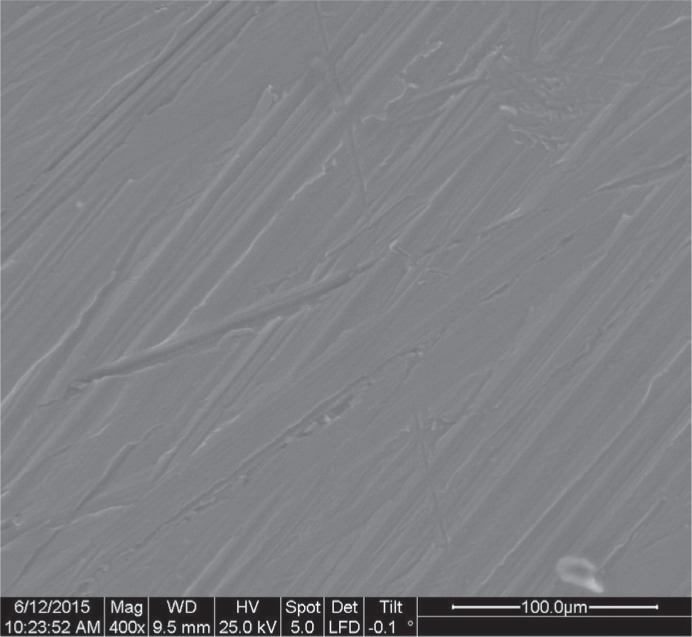

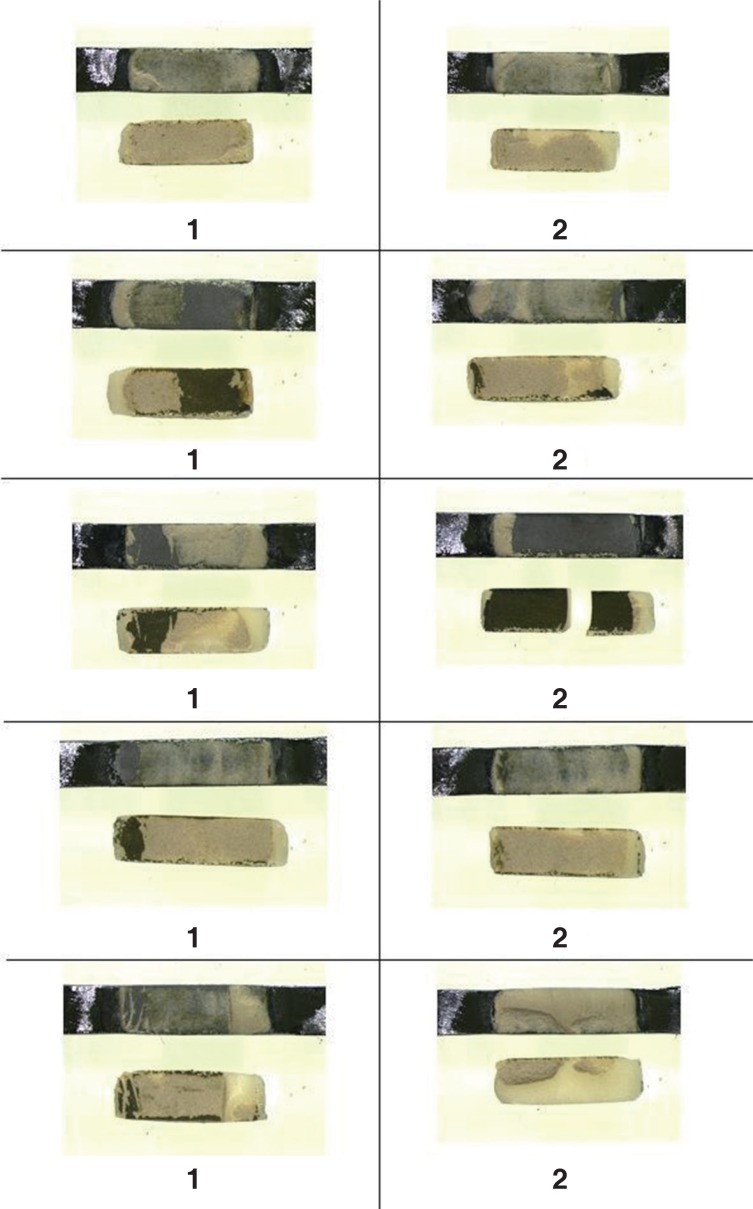

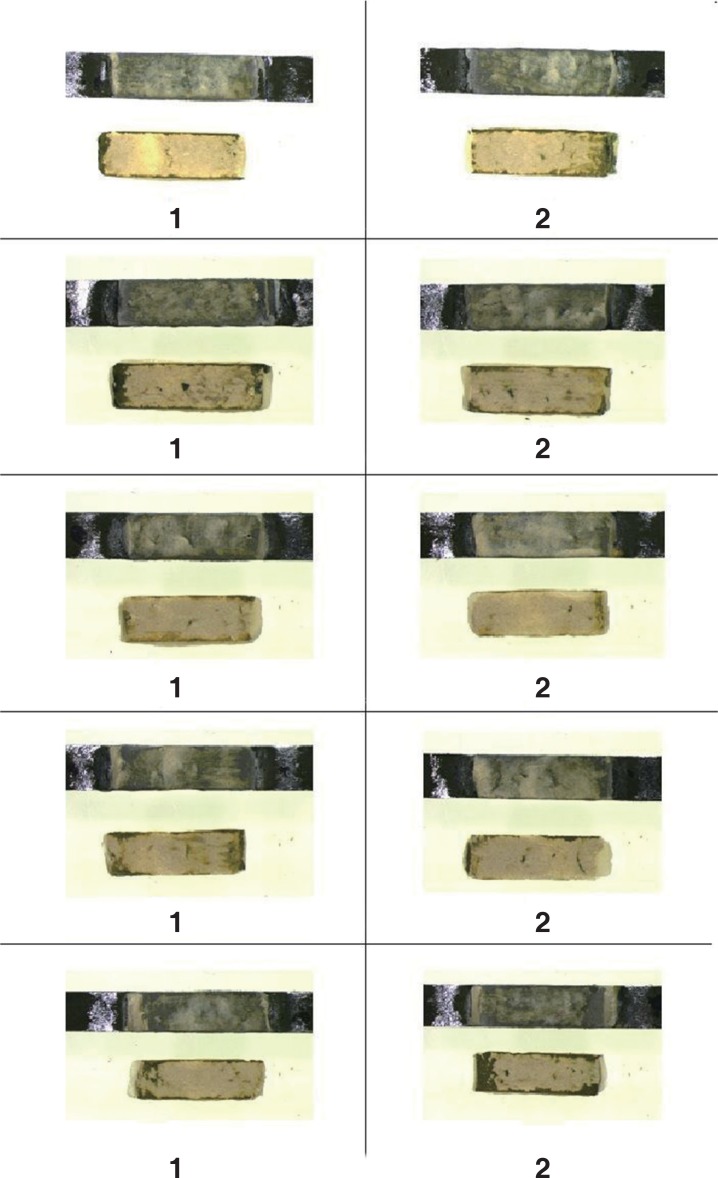

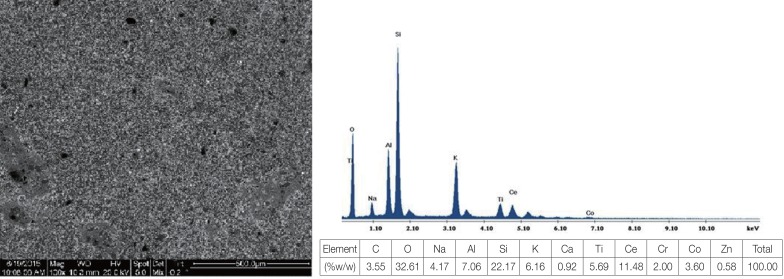

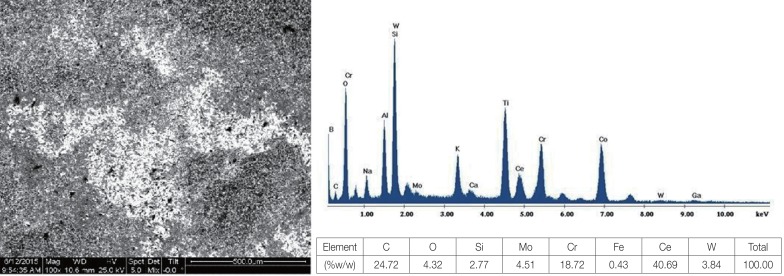

Ten metal substrates were fabricated with powder of a dental Co-Cr alloy using DMLS technique (test group) in dimensions according to ISO 9693. Another ten substrates were fabricated with a casing dental Co-Cr alloy using classic casting technique (control group) for comparison. Another three substrates were fabricated using each technique to record the Modulus of Elasticity (E) of the used alloys. All substrates were examined to record external and internal porosity. Feldspathic porcelain was applied on the substrates. Specimens were tested using the three-point bending test. The failure mode was determined using optical and scanning electron microscopy. The statistical analysis was performed using t-test.

RESULTS

Substrates prepared using DMLS technique did not show internal porosity as compared to those produced using the casting technique. The E of control and test group was 222 ± 5.13 GPa and 227 ± 3 GPa, respectively. The bond strength was 51.87 ± 7.50 MPa for test group and 54.60 ± 6.20 MPa for control group. No statistically significant differences between the two groups were recorded. The mode of failure was mainly cohesive for all specimens.

CONCLUSION

Specimens produced by the DMLS technique cover the lowest acceptable metal-ceramic bond strength of 25 MPa specified in ISO 9693 and present satisfactory bond strength for clinical use.

Keyword

MeSH Terms

Figure

Reference

-

1. Bezzon OL, de Mattos Mda G, Ribeiro RF, Rollo JM. Effect of beryllium on the castability and resistance of ceramometal bonds in nickel-chromium alloys. J Prosthet Dent. 1998; 80:570–574. PMID: 9813808.

Article2. Willis HH, Florig HK. Potential exposures and risks from beryllium-containing products. Risk Anal. 2002; 22:1019–1033. PMID: 12442995.

Article3. Al Jabbari YS. Physico-mechanical properties and prosthodontic applications of Co-Cr dental alloys: a review of the literature. J Adv Prosthodont. 2014; 6:138–145. PMID: 24843400.

Article4. Alkmina LB, Araújo AA, Silval P. Microstructural evidence of beryllium in commercial dental Ni-Cr alloys. Mat Res. 2014; 17:627–631.5. Chen WC, Teng FY, Hung CC. Characterization of Ni-Cr alloys using different casting techniques and molds. Mater Sci Eng C Mater Biol Appl. 2014; 35:231–238. PMID: 24411373.

Article6. Henriques B, Soares D, Silva FS. Influence of preoxidation cycle on the bond strength of CoCrMoSi–porcelain dental composites. Mater Sci Engin: A. 2012; 32:2374–2380.

Article7. Molina A, Echeverri D, Parra M, Castro IJ, Garzon H, Valencia CH, Olave G. Metallographic characterization of overdentures bars manufactured by over-castting abutments for dental implants. Rev Fac Odontol Univ Antioq. 2013; 25:26–43.8. Atluri KR, Vallabhaneni TT, Tadi DP, Vadapalli SB, Tripuraneni SC, Averneni P. Comparative evaluation of metal-ceramic bond strengths of nickel chromium and cobalt chromium alloys on repeated castings: An in vitro study. J Int Oral Health. 2014; 6:99–103.9. Akova T, Ucar Y, Tukay A, Balkaya MC, Brantley WA. Comparison of the bond strength of laser-sintered and cast base metal dental alloys to porcelain. Dent Mater. 2008; 24:1400–1404. PMID: 18417202.

Article10. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12. PMID: 22119539.

Article11. Koutsoukis T, Zinelis S, Eliades G, Al-Wazzan K, Rifaiy MA, Al Jabbari YS. Selective laser melting technique of Co-Cr dental alloys: A review of structure and properties and comparative analysis with other available techniques. J Prosthodont. 2015; 24:303–312. PMID: 26129918.

Article12. Henriques B, Soares D, Silva FS. Microstructure, hardness, corrosion resistance and porcelain shear bond strength comparison between cast and hot pressed CoCrMo alloy for metal-ceramic dental restorations. J Mech Behav Biomed Mater. 2012; 12:83–92. PMID: 22659369.

Article13. Takaichi A, Suyalatu , Nakamoto T, Joko N, Nomura N, Tsutsumi Y, Migita S, Doi H, Kurosu S, Chiba A, Wakabayashi N, Igarashi Y, Hanawa T. Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications. J Mech Behav Biomed Mater. 2013; 21:67–76. PMID: 23500549.

Article14. Al Jabbari YS, Koutsoukis T, Barmpagadaki X, Zinelis S. Metallurgical and interfacial characterization of PFM Co-Cr dental alloys fabricated via casting, milling or selective laser melting. Dent Mater. 2014; 30:e79–e88. PMID: 24534375.

Article15. Khaing MW, Fuh JYH, Lu L. Direct metal laser sintering for rapid tooling: processing and characterisation of EOS parts. J Mater Proces Technol. 2001; 113:269–272.

Article16. Simchi A. Direct laser sintering of metal powders: Mechanism, kinetics and microstructural features. Mater Sci Engin: A. 2006; 428:148–158.

Article17. Akagi K, Okamoto Y, Matsuura T, Horibe T. Properties of test metal ceramic titanium alloys. J Prosthet Dent. 1992; 68:462–467. PMID: 1432762.

Article18. Ban S, Anusavice KJ. Influence of test method on failure stress of brittle dental materials. J Dent Res. 1990; 69:1791–1799. PMID: 2250083.

Article19. ISO 9693. Metal-ceramic dental restorative systems. Second edition. Geneva, Switzerland: International Organization for Standardization;1999.20. Ritter JE. Critique of test methods for lifetime predictions. Dent Mater. 1995; 11:147–151. PMID: 8621037.

Article21. Pröbster L, Maiwald U, Weber H. Three-point bending strength of ceramics fused to cast titanium. Eur J Oral Sci. 1996; 104:313–319. PMID: 8831067.

Article22. Liu J, Chi S, Xu J, Wang Y, Zhan D. Effect of preparation methods on the metal-porcelain bond strength of Co-Cr alloys. Hua Xi Kou Qiang Yi Xue Za Zhi. 2014; 32:115–118. PMID: 24881202.23. Bae EJ, Kim JH, Kim WC, Kim HY. Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering. J Adv Prosthodont. 2014; 6:266–271. PMID: 25177469.

Article24. Bae EJ, Kim HY, Kim WC, Kim JH. In vitro evaluation of the bond strength between various ceramics and cobalt-chromium alloy fabricated by selective laser sintering. J Adv Prosthodont. 2015; 7:312–316. PMID: 26330978.25. Liu J, Liu Y, Sun R, Zhan DS, Wang YY. Metal-ceramic bond strength of Co-Cr alloy processed by selective laser melting. Zhonghua Kou Qiang Yi Xue Za Zhi. 2013; 48:170–172. PMID: 23751533.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A comparative study on the bond strength of porcelain to the millingable Pd-Ag alloy

- Effect of Degassing Condition on Ceramic Bond Strength of Ni-Cr Alloys

- Bond-strength of several metal-meramic alloys and meneered-porcelain

- Comparison of the bond strength of ceramics to Co-Cr alloys made by casting and selective laser melting

- Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering