J Adv Prosthodont.

2014 Aug;6(4):266-271. 10.4047/jap.2014.6.4.266.

Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering

- Affiliations

-

- 1Department of Dental Laboratory Science and Engineering, Korea University, Seoul, Republic of Korea. kjh2804@korea.ac.kr

- KMID: 1974845

- DOI: http://doi.org/10.4047/jap.2014.6.4.266

Abstract

- PURPOSE

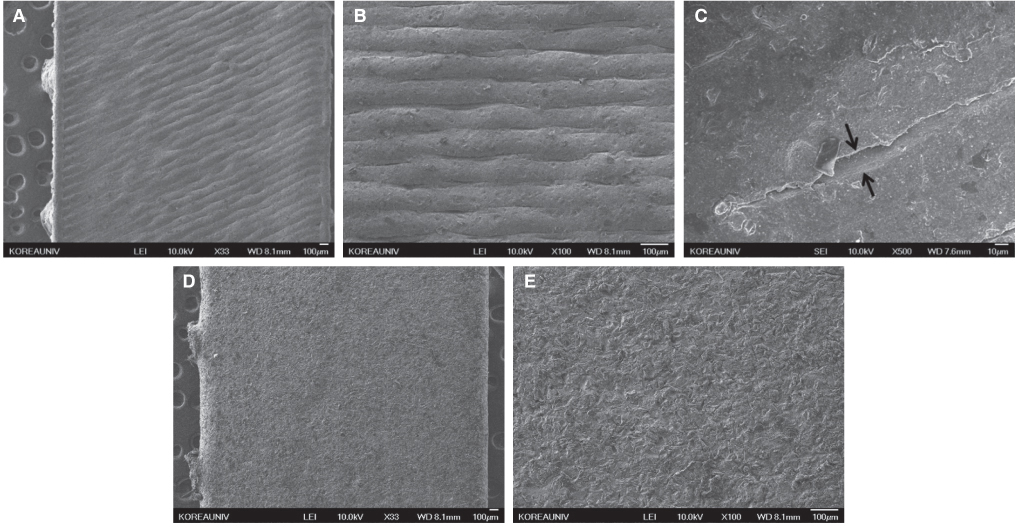

The purpose of this study was to compare the fracture strength of the metal and the bond strength in metal-ceramic restorations produced by selective laser sintering (SLS) and by conventional casting (CAST).

MATERIALS AND METHODS

Non-precious alloy (StarLoy C, DeguDent, Hanau, Germany) was used in CAST group and metal powder (SP2, EOS GmbH, Munich, Germany) in SLS group. Metal specimens in the form of sheets (25.0 x 3.0 x 0.5 mm) were produced in accordance with ISO 9693:1999 standards (n=30). To measure the bond strength, ceramic was fired on a metal specimen and then three-point bending test was performed. In addition, the metal fracture strength was measured by continuing the application of the load. The values were statistically analyzed by performing independent t-tests (alpha=0.05).

RESULTS

The mean bond strength of the SLS group (50.60 MPa) was higher than that of the CAST group (46.29 MPa), but there was no statistically significant difference. The metal fracture strength of the SLS group (1087.2 MPa) was lower than that of the CAST group (2399.1 MPa), and this difference was statistically significant.

CONCLUSION

In conclusion the balling phenomenon and the gap formation of the SLS process may increase the metal-ceramic bond strength.

Keyword

Figure

Cited by 2 articles

-

Metal-ceramic bond strength between a feldspathic porcelain and a Co-Cr alloy fabricated with Direct Metal Laser Sintering technique

Konstantinos Dimitriadis, Konstantinos Spyropoulos, Triantafillos Papadopoulos

J Adv Prosthodont. 2018;10(1):25-31. doi: 10.4047/jap.2018.10.1.25.A study on the machining accuracy of dental digital method focusing on dental inlay

Eun-Jeong Bae, Il-Do Jeong, Woong-Chul Kim, Ji-Hwan Kim

J Adv Prosthodont. 2018;10(4):321-327. doi: 10.4047/jap.2018.10.4.321.

Reference

-

1. Traini T, Mangano C, Sammons RL, Mangano F, Macchi A, Piattelli A. Direct laser metal sintering as a new approach to fabrication of an isoelastic functionally graded material for manufacture of porous titanium dental implants. Dent Mater. 2008; 24:1525–1533.2. Hull CW. Apparatus for production of three-dimensional objects by stereolithography. US Patent. US4575330 A. 1984.3. Feygin M, Shkolnik A, Diamond MN, Dvorskiy E. Laminated object manufacturing system. Torrance, CA: Helisys, Inc.;1998.4. Deckard CR. Part generation by layerwise selective sintering. Austin, TX; USA: University of Texas at Austin;1986. Thesis (M.S. in Engin.).5. Feygin M. Apparatus and method for forming an integral object from laminations. US Patent. EP0272305 B1. 1988.6. Olakanmi EO. Selective laser sintering/melting (SLS/SLM) of pure Al, Al-Mg, and Al-Si powders: Effect of processing conditions and powder properties. J Mater Process Technol. 2013; 213:1387–1405.7. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12.8. Khaing MW, Fuh JYH, Lu L. Direct metal laser sintering for rapid tooling: processing and characterisation of EOS parts. J Mater Process Technol. 2001; 113:269–272.9. Bremen S, Meiners W, Diatlov A. Selective Laser Melting. Laser Tech J. 2012; 9:33–38.10. Wataha JC. Predicting clinical biological responses to dental materials. Dent Mater. 2012; 28:23–40.11. Friebel M, Pernell O, Cappius HJ, Helfmann J, Meinke MC. Simulation of color perception of layered dental composites using optical properties to evaluate the benefit of esthetic layer preparation technique. Dent Mater. 2012; 28:424–432.12. Ucar Y, Brantley WA, Johnston WM, Dasgupta T. Mechanical properties, fracture surface characterization, and microstructural analysis of six noble dental casting alloys. J Prosthet Dent. 2011; 105:394–402.13. Manaranche C, Hornberger H. A proposal for the classification of dental alloys according to their resistance to corrosion. Dent Mater. 2007; 23:1428–1437.14. Sturdevant JR, Sturdevant CM, Taylor DF, Bayne SC. The 8-year clinical performance of 15 low-gold casting alloys. Dent Mater. 1987; 3:347–352.15. de Melo RM, Travassos AC, Neisser MP. Shear bond strengths of a ceramic system to alternative metal alloys. J Prosthet Dent. 2005; 93:64–69.16. Salazar M SM, Pereira SM, Ccahuana V VZ, Passos SP, Vanderlei AD, Pavanelli CA, Bottino MA. Shear bond strength between metal alloy and a ceramic system, submitted to different thermocycling immersion times. Acta Odontol Latinoam. 2007; 20:97–102.17. Watanabe K, Miyakawa O, Takada Y, Okuno O, Okabe T. Casting behavior of titanium alloys in a centrifugal casting machine. Biomaterials. 2003; 24:1737–1743.18. Childs THC, Hauser C, Badrossamay M. Selective laser sintering (melting) of stainless and tool steel powders: Experiments and modelling. Proc Inst Mech Eng Part B. 2005; 219:339–357.19. Gu D, Shen Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater Des. 2009; 30:2903–2910.20. Gusarov AV, Laoui T, Froyen L, Titov VI. Contact thermal conductivity of a powder bed in selective laser sintering. Int J Heat Mass Transf. 2003; 46:1103–1109.21. Gu D, Shen Y. Effects of dispersion technique and component ratio on densification and microstructure of multi-component Cu-based metal powder in direct laser sintering. J Mater Process Technol. 2007; 182:564–573.22. Li R, Liu J, Shi Y, Wang L. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int J Adv Manuf Technol. 2012; 59:1025–1035.23. Basile N, Gonon M, Petit F, Cambier F. Interaction between laser beam and BaTiO3 powders in selective laser sintering treatments. J Eur Ceram Soc. 2012; 32:3303–3311.24. Su X, Yang Y. Research on track overlapping during selective laser melting of powders. J Mater Process Technol. 2012; 212:2074–2079.25. Akova T, Ucar Y, Tukay A, Balkaya MC, Brantley WA. Comparison of the bond strength of laser-sintered and cast base metal dental alloys to porcelain. Dent Mater. 2008; 24:1400–1404.26. Xiang N, Xin XZ, Chen J, Wei B. Metal-ceramic bond strength of Co-Cr alloy fabricated by selective laser melting. J Dent. 2012; 40:453–457.27. Reyes MJ, Oshida Y, Andres CJ, Barco T, Hovijitra S, Brown D. Titanium-porcelain system. Part III: effects of surface modification on bond strengths. Biomed Mater Eng. 2001; 11:117–136.28. ISO 9693. Metal-ceramic dental restorative systems. 2nd ed. Geneva, Switzerland: International Organization for Standardization;1999.29. Kontonasaki E, Kantiranis N, Papadopoulou L, Chatzistavrou X, Kavouras P, Zorba T, Sivropoulou A, Chrissafis K, Paraskevopoulos KM, Koidis PT. Microstructural characterization and comparative evaluation of physical, mechanical and biological properties of three ceramics for metal-ceramic restorations. Dent Mater. 2008; 24:1362–1373.30. Uusalo EK, Lassila VP, Yli-Urpo AU. Bonding of dental porcelain to ceramic-metal alloys. J Prosthet Dent. 1987; 57:26–29.31. Zinelis S, Tsetsekou A, Papadopoulos T. Thermal expansion and microstructural analysis of experimental metal-ceramic titanium alloys. J Prosthet Dent. 2003; 90:332–338.32. Gu D, Shen Y. Balling phenomena during direct laser sintering of multi-component Cu-based metal powder. J Alloys Compd. 2007; 432:163–166.33. Korkmaz T, Asar V. Comparative evaluation of bond strength of various metal-ceramic restorations. Mater Des. 2009; 30:445–451.34. Nieva N, Arreguez C, Carrizo RN, Molé CS, Lagarrigue GM. Bonding Strength Evaluation on metal/ceramic interfaces in dental materials. Proc Mater Sci. 2012; 1:475–482.35. Esquivel-Upshaw JF, Anusavice KJ, Young H, Jones J, Gibbs C. Clinical performance of a lithia disilicate-based core ceramic for three-unit posterior FPDs. Int J Prosthodont. 2004; 17:469–475.36. Fischer J, Stawarczyk B, Trottmann A, Hämmerle CHF. Festigkeit lasergesinterter Brückengerüste aus einer CoCr-Legierung. Quintessenz Zahntech. 2008; 34:140–149.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- In vitro evaluation of the bond strength between various ceramics and cobalt-chromium alloy fabricated by selective laser sintering

- Fabricating a Ceramic-Pressed-to-Metal Restoration with Computer-Aided Design, Computer-Aided Manufacturing and Selective Laser Sintering: A Case Report

- Metal-ceramic bond strength between a feldspathic porcelain and a Co-Cr alloy fabricated with Direct Metal Laser Sintering technique

- Comparison of the bond strength of ceramics to Co-Cr alloys made by casting and selective laser melting

- Effect of Degassing Condition on Ceramic Bond Strength of Ni-Cr Alloys