J Adv Prosthodont.

2018 Oct;10(5):388-394. 10.4047/jap.2018.10.5.388.

Digital evaluation of axial displacement by implant-abutment connection type: An in vitro study

- Affiliations

-

- 1Department of Dentistry, Graduate School, Kyungpook National University, Daegu, Republic of Korea. kblee@knu.ac.kr

- 2Department of Dental Science, Graduate School, Kyungpook National University, Daegu, Republic of Korea.

- 3Advanced Dental Device Development Institute, Kyungpook National University, Daegu, Republic of Korea.

- KMID: 2422876

- DOI: http://doi.org/10.4047/jap.2018.10.5.388

Abstract

- PURPOSE

To measure axial displacement of different implant-abutment connection types and materials during screw tightening at the recommended torque by using a contact scanner for two-dimensional (2D) and three-dimensional (3D) analyses.

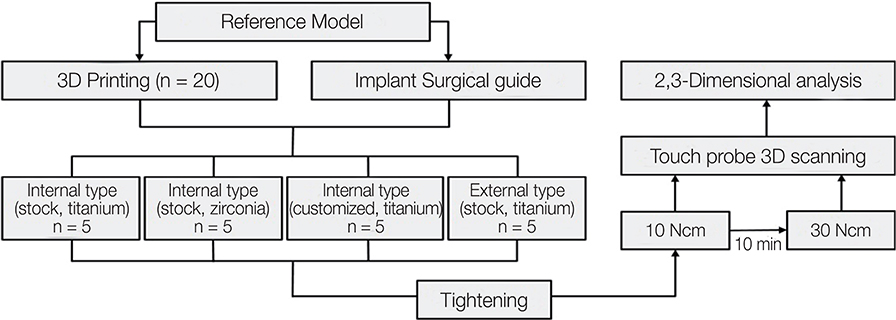

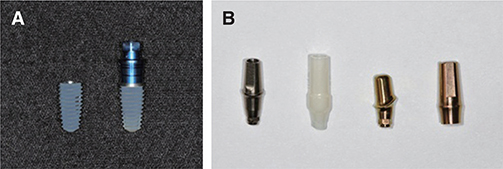

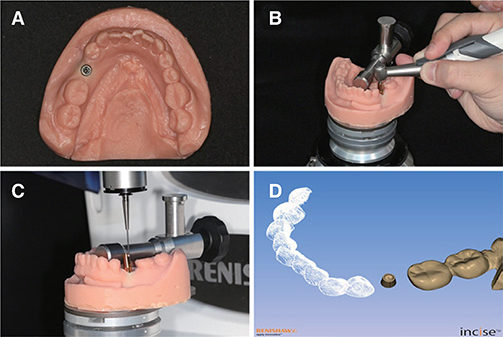

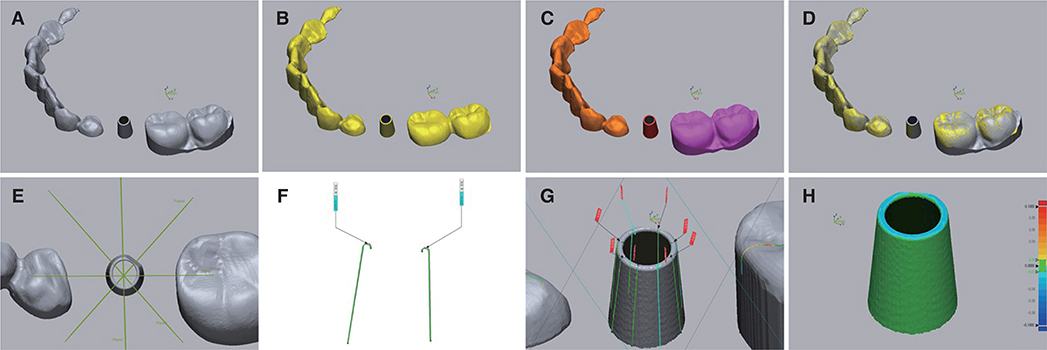

MATERIALS AND METHODS

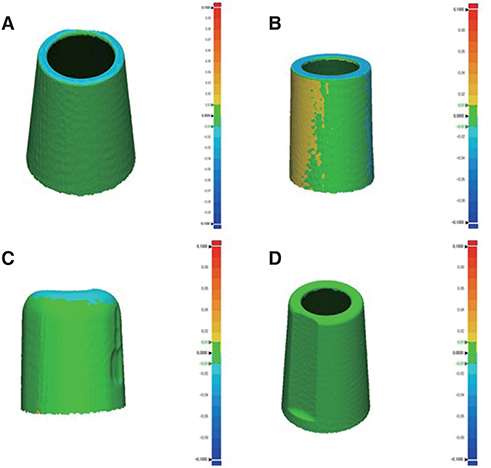

Twenty models of missing mandibular left second premolars were 3D-printed and implant fixtures were placed at the same position by using a surgical guide. External and internal fixtures were used. Three implant-abutment internal connection (INT) types and one implant-abutment external connection (EXT) type were prepared. Two of the INT types used titanium abutment and zirconia abutment; the other INT type was a customized abutment, fabricated by using a computer-controlled milling machine. The EXT type used titanium abutment. Screws were tightened at 10 N·cm, simulating hand tightening, and then at the manufacturers' recommended torque (30 N·cm) 10 min later. Abutments and adjacent teeth were subsequently scanned with a contact scanner for 2D and 3D analyses using a 3D inspection software.

RESULTS

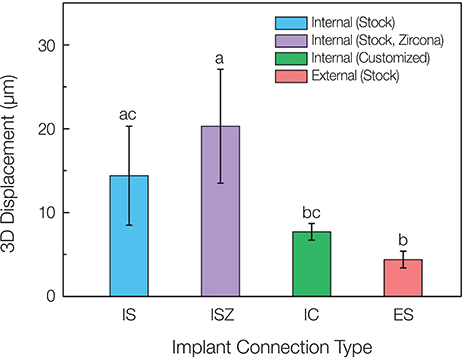

Significant differences were observed in axial displacement according to the type of implant-abutment connection (P < .001). Vertical displacement of abutments was greater than overall displacement, and significant differences in vertical and overall displacement were observed among the four connection types (P < .05).

CONCLUSION

Displacement according to connection type and material should be considered in choosing an implant abutment. When adjusting a prosthesis, tightening the screw at the manufacturers' recommended torque is advisable, rather than the level of hand tightening.

MeSH Terms

Figure

Reference

-

1. Brånemark PI, Adell R, Breine U, Hansson BO, Lindström J, Ohlsson A. Intra-osseous anchorage of dental prostheses. I. Experimental studies. Scand J Plast Reconstr Surg. 1969; 3:81–100.2. Brånemark PI. Osseointegration and its experimental background. J Prosthet Dent. 1983; 50:399–410.3. Brånemark PI, Svensson B, van Steenberghe D. Ten-year survival rates of fixed prostheses on four or six implants ad modum Brånemark in full edentulism. Clin Oral Implants Res. 1995; 6:227–231.

Article4. Sutter F, Weber HP, Sorensen J, Belser U. The new restorative concept of the ITI dental implant system: design and engineering. Int J Periodontic Restor Dent. 1993; 13:408–431.5. Ugurel CS, Steiner M, Isik-Ozkol G, Kutay O, Kern M. Mechanical resistance of screwless morse taper and screw-retained implant-abutment connections. Clin Oral Implants Res. 2015; 26:137–142.

Article6. Brånemark PI, Hansson BO, Adell R, Breine U, Lindström J, Hallén O, Ohman A. Osseointegrated implants in the treatment of the edentulous jaw. Experience from a 10-year period. Scand J Plast Reconstr Surg Suppl. 1977; 16:1–132.7. Norton MR. An in vitro evaluation of the strength of an internal conical interface compared to a butt joint interface in implant design. Clin Oral Implants Res. 1997; 8:290–298.

Article8. Maeda Y, Satoh T, Sogo M. In vitro differences of stress concentrations for internal and external hex implant-abutment connections: a short communication. J Oral Rehabil. 2006; 33:75–78.

Article9. Schwarz MS. Mechanical complications of dental implants. Clin Oral Implants Res. 2000; 11:156–158.

Article10. Dailey B, Jordan L, Blind O, Tavernier B. Axial displacement of abutments into implants and implant replicas, with the tapered cone-screw internal connection, as a function of tightening torque. Int J Oral Maxillofac Implants. 2009; 24:251–256.11. Yilmaz B, Seidt JD, McGlumphy EA, Clelland NL. Displacement of screw-retained single crowns into implants with conical internal connections. Int J Oral Maxillofac Implants. 2013; 28:803–806.

Article12. Winkler S, Ring K, Ring JD, Boberick KG. Implant screw mechanics and the settling effect: overview. J Oral Implantol. 2003; 29:242–245.13. Lee JH, Kim DG, Park CJ, Cho LR. Axial displacements in external and internal implant-abutment connection. Clin Oral Implants Res. 2014; 25:e83–e89.

Article14. Spector MR, Donovan TE, Nicholls JI. An evaluation of impression techniques for osseointegrated implants. J Prosthet Dent. 1990; 63:444–447.

Article15. Liu DY, Cader FN, Abduo J, Palamara J. Accuracy of different implant impression techniques: Evaluation of new tray design concept. J Prosthodont. 2017; 12. 29. [Epub ahead of print]. DOI: 10.1111/jopr.12733.

Article16. Tan KB, Nicholls JI. The effect of 3 torque delivery systems on gold screw preload at the gold cylinder-abutment screw joint. Int J Oral Maxillofac Implants. 2002; 17:175–183.17. Dellinges MA, Tebrock OC. A measurement of torque values obtained with hand-held drivers in a simulated clinical setting. J Prosthodont. 1993; 2:212–214.

Article18. Kanawati A, Richards MW, Becker JJ, Monaco NE. Measurement of clinicians' ability to hand torque dental implant components. J Oral Implantol. 2009; 35:185–188.

Article19. Moon SJ, Kim HJ, Son MK, Chung CH. Sinking and fit of abutment of locking taper implant system. J Adv Prosthodont. 2009; 1:97–101.

Article20. Gilbert AB, Yilmaz B, Seidt JD, McGlumphy EA, Clelland NL, Chien HH. Three-Dimensional Displacement of Nine Different Abutments for an Implant with an Internal Hexagon Platform. Int J Oral Maxillofac Implants. 2015; 30:781–788.

Article21. Siadat H, Beyabanaki E, Mousavi N, Alikhasi M. Comparison of fit accuracy and torque maintenance of zirconia and titanium abutments for internal tri-channel and external-hex implant connections. J Adv Prosthodont. 2017; 9:271–277.

Article22. Goodacre CJ, Kan JY, Rungcharassaeng K. Clinical complications of osseointegrated implants. J Prosthet Dent. 1999; 81:537–552.

Article23. Tagger Green N, Machtei EE, Horwitz J, Peled M. Fracture of dental implants: literature review and report of a case. Implant Dent. 2002; 11:137–143.

Article24. Kim KS, Lim YJ, Kim MJ, Kwon HB, Yang JH, Lee JB, Yim SH. Variation in the total lengths of abutment/implant assemblies generated with a function of applied tightening torque in external and internal implant-abutment connection. Clin Oral Implants Res. 2011; 22:834–839.

Article25. Shim HW, Yang BE. Long-term cumulative survival and mechanical complications of single-tooth Ankylos Implants: focus on the abutment neck fractures. J Adv Prosthodont. 2015; 7:423–430.

Article26. Messias A, Rocha S, Calha N, Neto MA, Nicolau P, Guerra F. Effect of intentional abutment disconnection on the micromovements of the implant-abutment assembly: a 3D digital image correlation analysis. Clin Oral Implants Res. 2017; 28:9–16.

Article27. Rebeeah HA, Yilmaz B, Seidt JD, McGlumphy E, Clelland N, Brantley W. Comparison of 3D displacements of screw-retained zirconia implant crowns into implants with different internal connections with respect to screw tightening. J Prosthet Dent. 2018; 119:132–137.

Article28. Schaefer O, Watts DC, Sigusch BW, Kuepper H, Guentsch A. Marginal and internal fit of pressed lithium disilicate partial crowns in vitro: a three-dimensional analysis of accuracy and reproducibility. Dent Mater. 2012; 28:320–326.

Article29. Rudolph H, Luthardt RG, Walter MH. Computer-aided analysis of the influence of digitizing and surfacing on the accuracy in dental CAD/CAM technology. Comput Biol Med. 2007; 37:579–587.

Article30. Rhee YK, Huh YH, Cho LR, Park CJ. Comparison of intraoral scanning and conventional impression techniques using 3-dimensional superimposition. J Adv Prosthodont. 2015; 7:460–467.

Article31. Park JM. Comparative analysis on reproducibility among 5 intraoral scanners: sectional analysis according to restoration type and preparation outline form. J Adv Prosthodont. 2016; 8:354–362.

Article32. Park HN, Lim YJ, Yi WJ, Han JS, Lee SP. A comparison of the accuracy of intraoral scanners using an intraoral environment simulator. J Adv Prosthodont. 2018; 10:58–64.

Article33. Hayama H, Fueki K, Wadachi J, Wakabayashi N. Trueness and precision of digital impressions obtained using an intraoral scanner with different head size in the partially edentulous mandible. J Prosthodont Res. 2018; 62:347–352.

Article34. Patzelt SB, Emmanouilidi A, Stampf S, Strub JR, Att W. Accuracy of full-arch scans using intraoral scanners. Clin Oral Investig. 2014; 18:1687–1694.

Article35. Persson A, Andersson M, Oden A, Sandborgh-Englund G. A three-dimensional evaluation of a laser scanner and a touchprobe scanner. J Prosthet Dent. 2006; 95:194–200.

Article36. Dimitrova M. A 3D evaluation of the repeatability of accuracy in optical and contact scanners. Cardiff, Wales, UK: Cardiff Metropolitan University;2017. 1–36. Doctor's Thesis.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of cyclic loading on axial displacement of abutment into implant with internal tapered connection: a pilot study

- Axial displacement in single-tooth implant restoration: Case report

- Effects of implant tilting and the loading direction on the displacement and micromotion of immediately loaded implants: an in vitro experiment and finite element analysis

- Concept and application of implant connection systems: Part I. Placement and restoration of internal conical connection implant

- Joint stability of internal conical connection abutments with or without hexagon indexes: an in vitro study