J Dent Rehabil Appl Sci.

2020 Jun;36(2):95-103. 10.14368/jdras.2020.36.2.95.

Joint stability of internal conical connection abutments with or without hexagon indexes: an in vitro study

- Affiliations

-

- 1Department of Dentistry, Gangneung Asan Hospital, University of Ulsan, College of Medicine, Gangneung, Republic of Korea

- 2Department of Prosthodontics and Research Institute of Oral Science, Gangneung-Wonju National University, Gangneung, Republic of Korea

- KMID: 2503805

- DOI: http://doi.org/10.14368/jdras.2020.36.2.95

Abstract

- Purpose

The purpose of this study was to compare the axial displacement of the hexagonal and conical abutment in internal conical connection implant after screw tightening and cyclic loading.

Materials and Methods

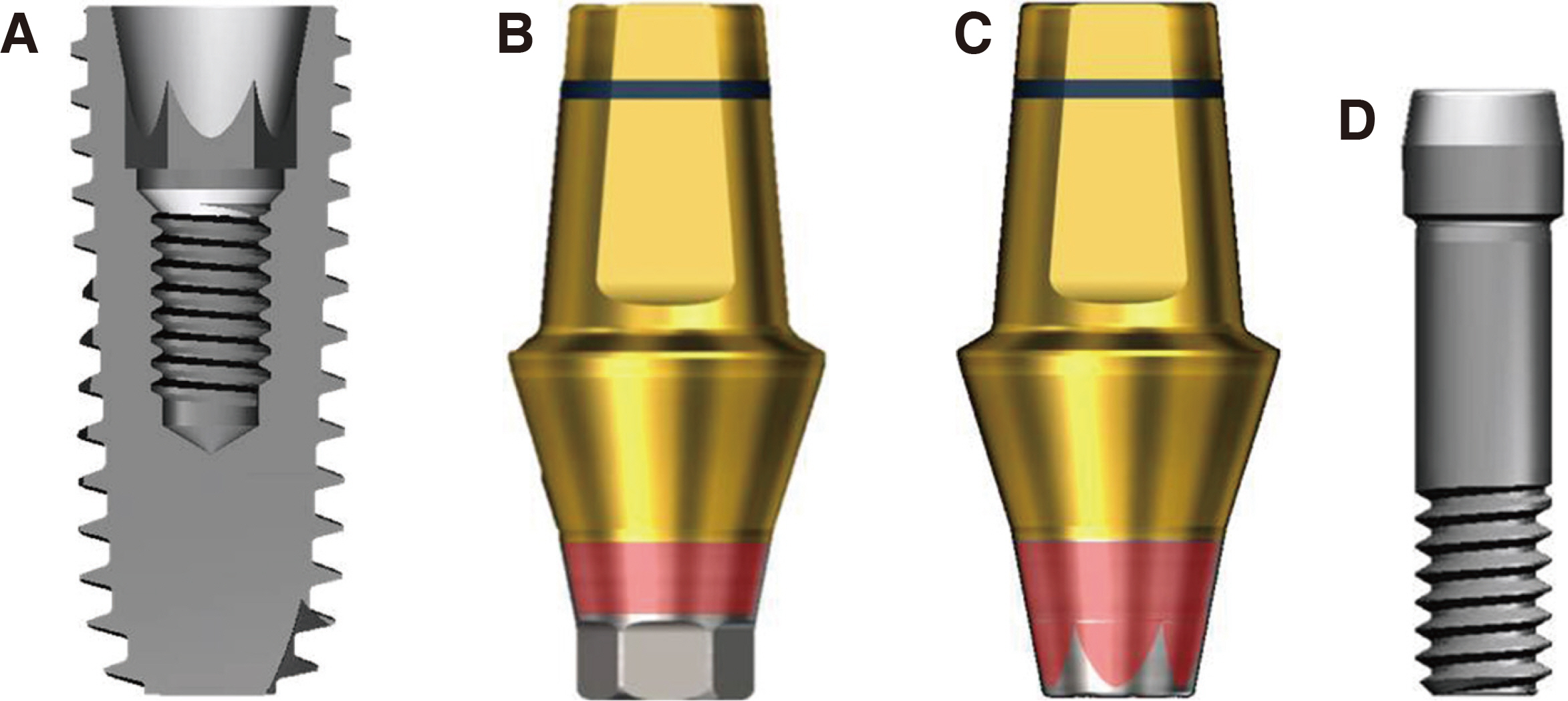

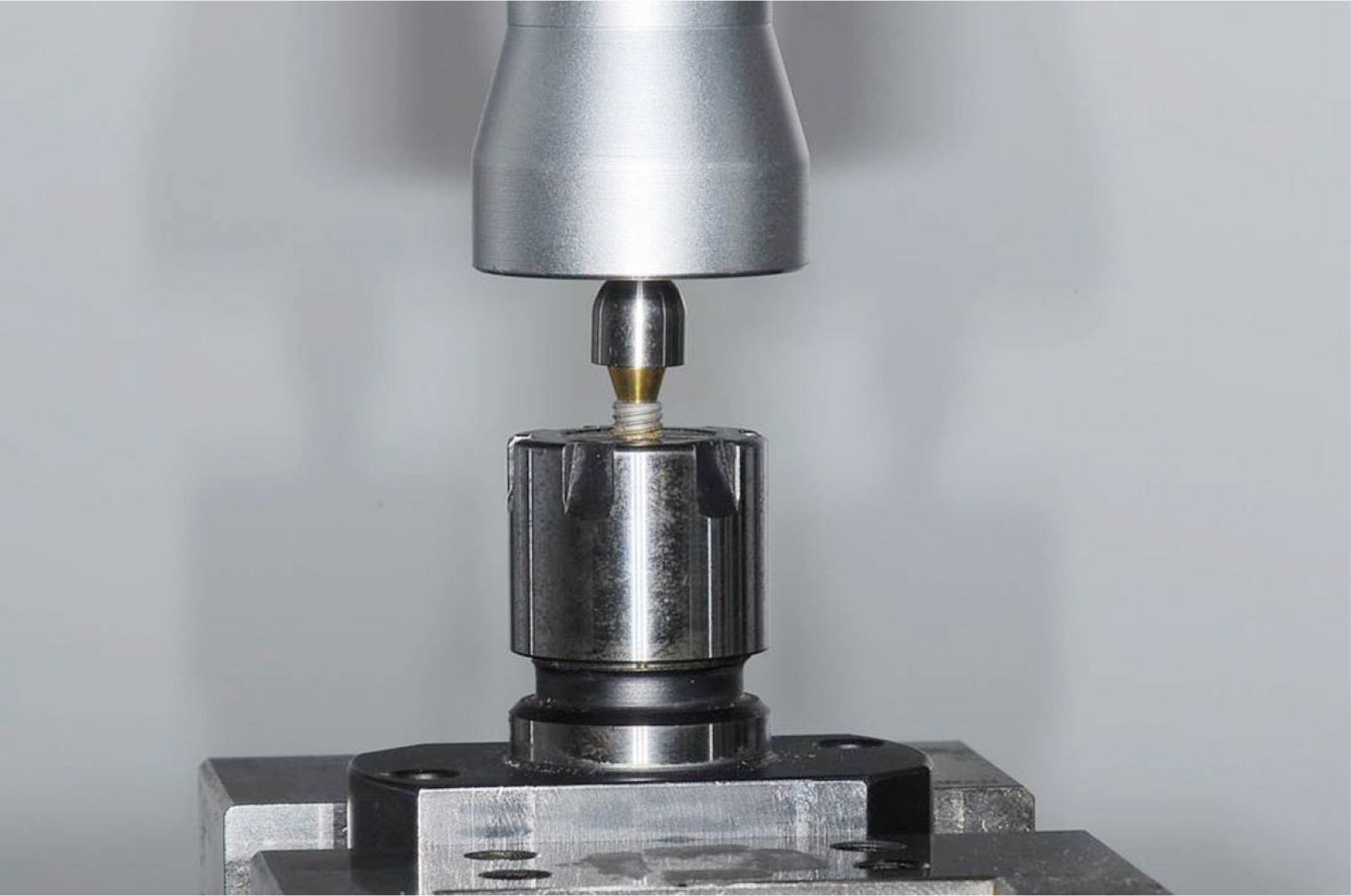

Internal conical connection implants were divided into two groups (n = 10): group HEX, hexagonal abutment; and group CON, conical 2-piece abutments. The axial displacement and removal torque values were measured after 30 Ncm torque tightening and 250N loading test of 100,000 cycles. The Student t test with 5% significance level was used to evaluate the data.

Results

HEX group demonstrated significantly higher axial displacement values after 30 Ncm tightening in comparison to the CON group (P < 0.05). No significant difference was found in axial displacement after cyclic loading (P = 0.052). Removal torque loss before and after the cyclic loading both revealed no significant difference between groups (P = 0.057 and P = 0.138). Removal torque value decreased after cyclic loading in both groups (P < 0.05).

Conclusion

Overall, both abutment with or without hexagon index presented similar biomechanical performance except HEX group demonstrated significantly more axial displacement after applying tightening torque.

Keyword

Figure

Reference

-

References

1. Cehreli MC, Akça K, Iplikçioğlu H, Sahin S. 2004; Dynamic fatigue resistance of implant-abutment junction in an internally notched morse-taper oral implant: influence of abutment design. Clin Oral Implants Res. 15:459–65. DOI: 10.1111/j.1600-0501.2004.01023.x. PMID: 15248881.2. Norton MR. 1997; An in vitro evaluation of the strength of an internal conical interface compared to a butt joint interface in implant design. Clin Oral Implants Res. 8:290–8. DOI: 10.1034/j.1600-0501.1997.080407.x. PMID: 9586476.3. Norton MR. 1999; Assessment of cold welding properties of the internal conical interface of two commercially available implant systems. J Prosthet Dent. 81:159–66. DOI: 10.1016/S0022-3913(99)70243-X.4. Norton MR. 2000; An in vitro evaluation of the strength of a 1-piece and 2-piece conical abutment joint in implant design. Clin Oral Implants Res. 11:458–64. DOI: 10.1034/j.1600-0501.2000.011005458.x. PMID: 11168238.5. Budynas RG, Nisbett JK. 2011. Shigley's mechanical engineering design. 9th ed. McGraw-Hill;New York:6. Schmitt CM, Nogueira-Filho G, Tenenbaum HC, Lai JY, Brito C, Döring H, Nonhoff J. 2014; Performance of conical abutment (Morse Taper) connection implants: a systematic review. J Biomed Mater Res A. 102:552–74. DOI: 10.1002/jbm.a.34709. PMID: 23533139.7. Lee JH, Lee W, Huh YH, Park CJ, Cho LR. 2019; Impact of intentional overload on joint stability of internal implant-abutment connection system with different diameter. J Prosthodont. 28:e649–e56. DOI: 10.1111/jopr.12661. PMID: 28872722.8. Lee JH, Kim DG, Park CJ, Cho LR. 2014; Axial displacements in external and internal implant-abutment connection. Clin Oral Implants Res. 25:e83–9. DOI: 10.1111/clr.12062. PMID: 23088616.9. Seol HW, Heo SJ, Koak JY, Kim SK, Kim SK. 2015; Axial displacement of external and internal implant-abutment connection evaluated by linear mixed model analysis. Int J Oral Maxillofac Implants. 30:1387–99. DOI: 10.11607/jomi.3857. PMID: 26574863.10. Schwarz MS. 2000; Mechanical complications of dental implants. Clin Oral Implants Res. 11(Suppl 1):156–8. DOI: 10.1034/j.1600-0501.2000.011S1156.x. PMID: 11168264.11. Guzaitis KL, Knoernschild KL, Viana MA. 2011; Effect of repeated screw joint closing and opening cycles on implant prosthetic screw reverse torque and implant and screw thread morphology. J Prosthet Dent. 106:159–69. DOI: 10.1016/S0022-3913(11)60115-7. PMID: 21889002.12. Xia D, Lin H, Yuan S, Bai W, Zheng G. 2014; Dynamic fatigue performance of implant-abutment assemblies with different tightening torque values. Biomed Mater Eng. 24:2143–9. DOI: 10.3233/BME-141025. PMID: 25226912.13. Bernardes SR, da Gloria Chiarello de Mattos M, Hobkirk J, Ribeiro RF. 2014; Loss of preload in screwed implant joints as a function of time and tightening/untightening sequences. Int J Oral Maxillofac Implants. 29:89–96. DOI: 10.11607/jomi.3344. PMID: 24451858.14. Cho WR, Huh YH, Park CJ, Cho LR. 2015; Effect of cyclic loading and retightening on reverse torque value in external and internal implants. J Adv Prosthodont. 7:288–93. DOI: 10.4047/jap.2015.7.4.288. PMID: 26330975. PMCID: PMC4551784.15. Pintinha M, Camarini ET, Sábio S, Pereira JR. 2013; Effect of mechanical loading on the removal torque of different types of tapered connection abutments for dental implants. J Prosthet Dent. 110:383–8. DOI: 10.1016/j.prosdent.2013.06.007. PMID: 24070863.16. Ding TA, Woody RD, Higginbottom FL, Miller BH. 2003; Evaluation of the ITI Morse taper implant/abutment design with an internal modification. Int J Oral Maxillofac Implants. 18:865–72.17. Ricciardi Coppede A, de Mattos Mda G, Rodrigues RC, Ribeiro RF. 2009; Effect of repeated torque/mechanical loading cycles on two different abutment types in implants with internal tapered connections: an in vitro study. Clin Oral Implants Res. 20:624–32. DOI: 10.1111/j.1600-0501.2008.01690.x. PMID: 19281502.18. Kim KS, Han JS, Lim YJ. 2014; Settling of abutments into implants and changes in removal torque in five different implant-abutment connections. Part 1: Cyclic loading. Int J Oral Maxillofac Implants. 29:1079–84. DOI: 10.11607/jomi.3383. PMID: 25216133.19. Martins CM, Ramos EV, Kreve S, de Carvalho GAP, Franco ABG, de Macedo LGS, de Moura Silva A, Dias SC. 2019; Reverse torque evaluation in indexed and nonindexed abutments of Morse Taper implants in a mechanical fatigue test. Dent Res J (Isfahan). 16:110–16. DOI: 10.4103/1735-3327.250967.20. Piermatti J, Yousef H, Luke A, Mahevich R, Weiner S. 2006; An in vitro analysis of implant screw torque loss with external hex and internal connection implant systems. Implant Dent. 15:427–35. DOI: 10.1097/01.id.0000245440.09464.48. PMID: 17172962.21. de Oliveira Silva TS, Mendes Alencar SM, da Silva Valente V, de Moura C. 2017; Effect of internal hexagonal index on removal torque and tensile removal force of different Morse taper connection abutments. J Prosthet Dent. 117:621–27. DOI: 10.1016/j.prosdent.2016.07.024. PMID: 27881313.22. Perriard J, Wiskott WA, Mellal A, Scherrer SS, Botsis J, Belser UC. 2002; Fatigue resistance of ITI implant-abutment connectors - a comparison of the standard cone with a novel internally keyed design. Clin Oral Implants Res. 13:542–9. DOI: 10.1034/j.1600-0501.2002.130515.x. PMID: 12453133.23. Cho SY, Huh YH, Park CJ, Cho LR. 2018; Three-dimensional finite element analysis on stress distribution of internal implant-abutment engagement features. Int J Oral Maxillofac Implants. 33:319–27. DOI: 10.11607/jomi.5789. PMID: 29534119.24. Cho SY, Huh YH, Park CJ, Cho LR. 2016; Three-dimensional finite element analysis of the stress distribution at the internal implant-abutment connection. Int J Periodontics Restorative Dent. 36:e49–58. DOI: 10.11607/prd.2351. PMID: 27100815.25. Anami LC, da Costa Lima JM, Takahashi FE, Neisser MP, Noritomi PY, Bottino MA. 2015; Stress distribution around osseointegrated implants with different internal-cone connections: photoelastic and finite element analysis. J Oral Implantol. 41:155–62. DOI: 10.1563/AAID-JOI-D-12-00260. PMID: 23750560.26. Saidin S, Abdul Kadir MR, Sulaiman E, Abu Kasim NH. 2012; Effects of different implant-abutment connections on micromotion and stress distribution: prediction of microgap formation. J Dent. 40:467–74. DOI: 10.1016/j.jdent.2012.02.009. PMID: 22366313.27. Squier RS, Psoter WJ, Taylor TD. 2002; Removal torques of conical, tapered implant abutments: the effects of anodization and reduction of surface area. Int J Oral Maxillofac Implants. 17:24–7.28. Kwon TK, Yang JH, Kim SH, Han JS, Lee JB. 2007; A comparative study of the 1-piece and 2-piece conical abutment joint: the strength and the fatigue resistance. J Korean Acad Prosthodont. 45:780–86.29. Cerutti-Kopplin D, Rodrigues Neto DJ, Lins do Valle A, Pereira JR. 2014; Influence of reverse torque values in abutments with or without internal hexagon indexes. J Prosthet Dent. 112:824–7. DOI: 10.1016/j.prosdent.2014.03.004. PMID: 24787130.30. Villarinho EA, Cervieri A, Shinkai RS, Grossi ML, Teixeira ER. 2015; The effect of a positioning index on the biomechanical stability of tapered implant-abutment connections. J Oral Implantol. 41:139–43. DOI: 10.1563/AAID-JOI-D-12-00245. PMID: 23641735.31. Siamos G, Winkler S, Boberick KG. 2002; Relationship between implant preload and screw loosening on implant-supported prostheses. J Oral Implantol. 28:67–73. DOI: 10.1563/1548-1336(2002)028<0067:TRBIPA>2.3.CO;2. PMID: 12498448.32. Bozkaya D, Müftü S. 2003; Mechanics of the tapered interference fit in dental implants. J Biomech. 36:1649–58. DOI: 10.1016/S0021-9290(03)00177-5.33. Bozkaya D, Müftü S. 2005; Mechanics of the taper integrated screwed-in (TIS) abutments used in dental implants. J Biomech. 38:87–97. DOI: 10.1016/j.jbiomech.2004.03.006. PMID: 15519343.34. Binon PP. 1998; Evaluation of the effectiveness of a technique to prevent screw loosening. J Prosthet Dent. 79:430–2. DOI: 10.1016/S0022-3913(98)70157-X.35. Haack JE, Sakaguchi RL, Sun T, Coffey JP. 1995; Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 10:529–36. PMID: 7590997.36. da Silva Prado L, da Silva J, Garcia ALH, Boaretto FBM, Grivicich I, Conter LU, de Oliveira Salvi A, Reginatto FH, Vencato SB, de Barros Falcão Ferraz A, Picada JN. 2017; Evaluation of DNA damage in HepG2 cells and mutagenicity of garcinielliptone FC, a bioactive benzophenone. Basic Clin Pharmacol Toxicol. 120:621–27. DOI: 10.1111/bcpt.12753. PMID: 28054742.37. Lee JH, Huh YH, Park CJ, Cho LR. 2016; Effect of the coronal wall thickness of dental implants on the screw joint stability in the internal implant-abutment connection. Int J Oral Maxillofac Implants. 31:1058–65. DOI: 10.11607/jomi.4600. PMID: 27632260.38. Karl M, Taylor TD. 2016; Effect of cyclic loading on micromotion at the implant-abutment interface. Int J Oral Maxillofac Implants. 31:1292–7. DOI: 10.11607/jomi.5116. PMID: 27525518.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of a counter-torque device and the internal hexagon of abutment on the tightening torque transmitted to the implant

- Influence of abutment materials on the implant-abutment joint stability in internal conical connection type implant systems

- Rotational tolerances of a titanium abutment in the as-received condition and after screw tightening in a conical implant connection

- Effect of casting procedure on screw loosening of UCLA abutment in two implant-abutment connection systems

- Comparison of fit accuracy and torque maintenance of zirconia and titanium abutments for internal tri-channel and external-hex implant connections