J Adv Prosthodont.

2018 Oct;10(5):354-360. 10.4047/jap.2018.10.5.354.

Accuracy of provisional crowns made using stereolithography apparatus and subtractive technique

- Affiliations

-

- 1Department of Dental Laboratory Science and Engineering, College of Health Science, Korea University, Seoul, Republic of Korea. kuc2842@korea.ac.kr

- KMID: 2422871

- DOI: http://doi.org/10.4047/jap.2018.10.5.354

Abstract

- PURPOSE

To compare and analyze trueness and precision of provisional crowns made using stereolithography apparatus and subtractive technology.

MATERIALS AND METHODS

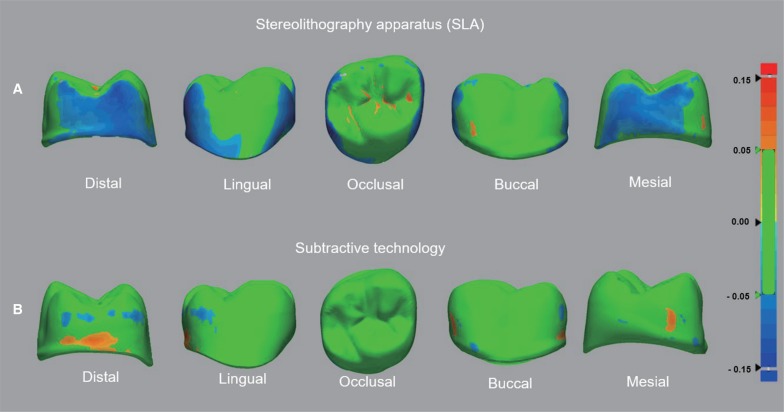

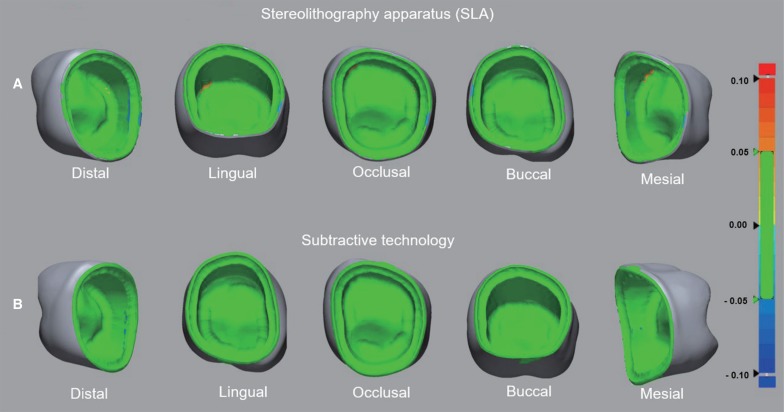

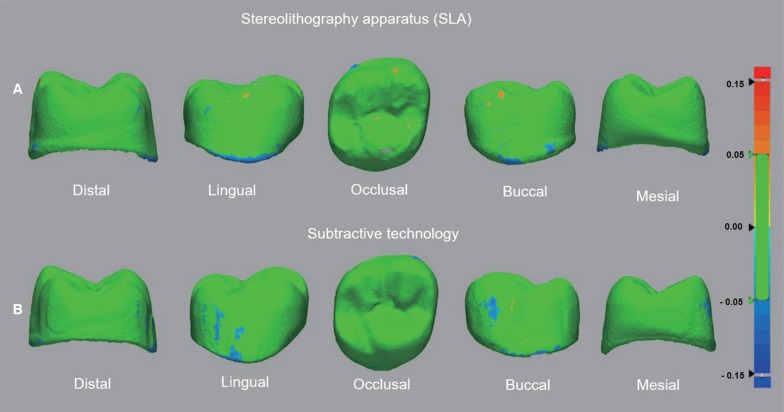

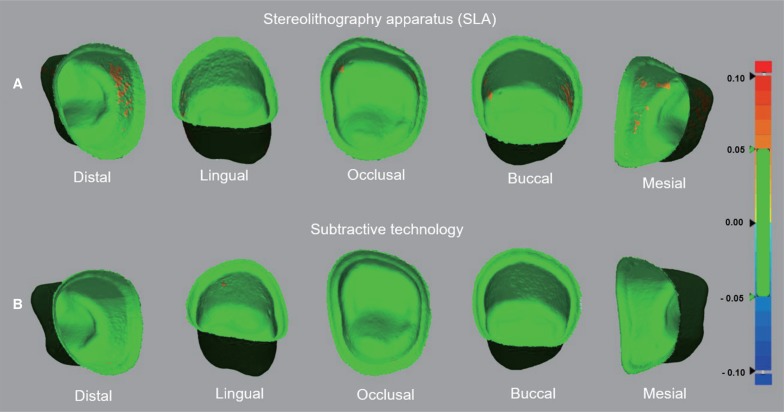

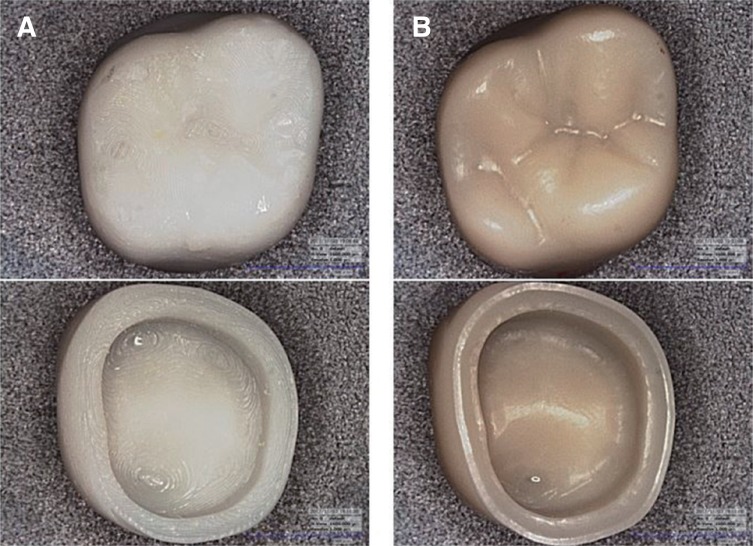

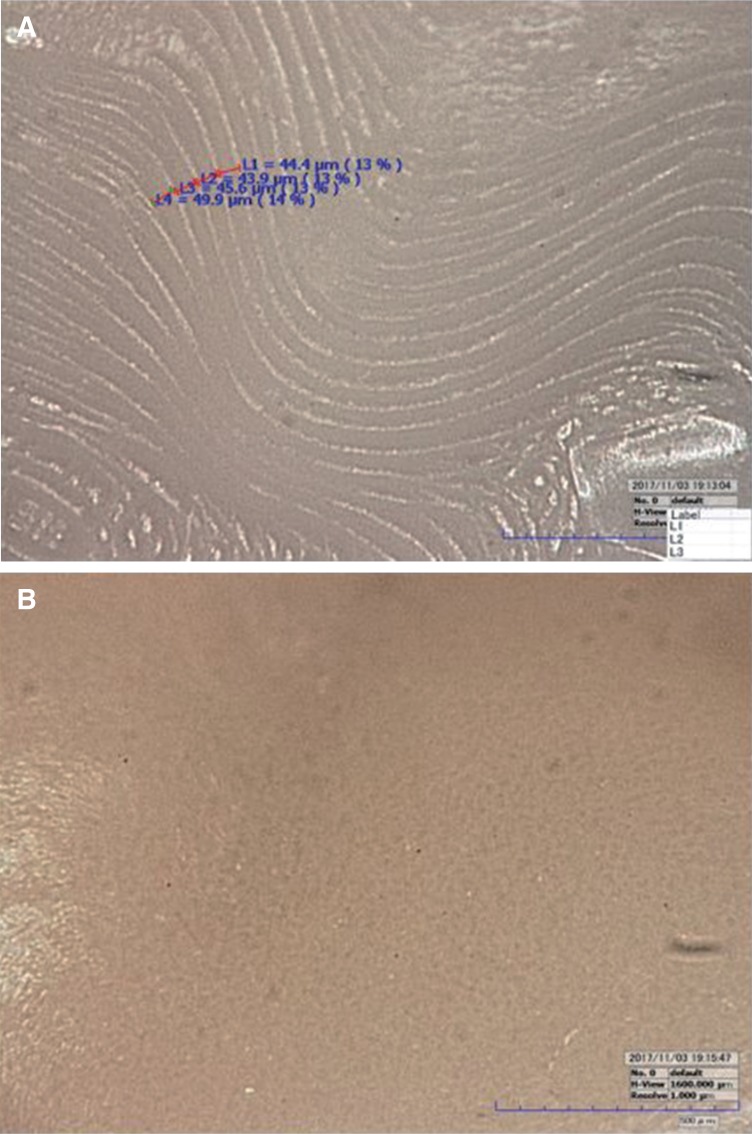

Digital impressions were made using a master model and an intraoral scanner and the crowns were designed with CAD software; in total, 22 crowns were produced. After superimposing CAD design data and scan data using a 3D program, quantitative and qualitative data were obtained for analysis of trueness and precision. Statistical analysis was performed using normality test combined with Levene test for equal variance analysis and independent sample t-test. Type 1 error was set at 0.05.

RESULTS

Trueness for the outer and inner surfaces of the SLA crown (SLAC) were 49.6±9.3 µm and 22.5±5.1 µm, respectively, and those of the subtractive crown (SUBC) were 31.8±7.5 µm and 14.6±1.2 µm, respectively. Precision values for the outer and inner surfaces of the SLAC were 18.7±6.2 µm and 26.9±8.5 µm, and those of the SUBC were 25.4±3.1 µm and 13.8±0.6 µm, respectively. Trueness values for the outer and inner surfaces of the SLAC and SUBC showed statistically significant differences (P < .001). Precision for the inner surface showed significance (P < .03), whereas that for the outer surface showed no significance (P < .58).

CONCLUSION

The study demonstrates that provisional crowns produced by subtractive technology are superior to crowns fabricated by stereolithography in terms of accuracy.

MeSH Terms

Figure

Cited by 1 articles

-

Marginal and internal discrepancy of 3-unit fixed dental prostheses fabricated by subtractive and additive manufacturing

Jae-Won Choi

J Korean Acad Prosthodont. 2020;58(1):7-13. doi: 10.4047/jkap.2020.58.1.7.

Reference

-

1. Nejatidanesh F, Lotfi HR, Savabi O. Marginal accuracy of interim restorations fabricated from four interim autopolymerizing resins. J Prosthet Dent. 2006; 95:364–367. PMID: 16679131.

Article2. Karaokutan I, Sayin G, Kara O. In vitro study of fracture strength of provisional crown materials. J Adv Prosthodont. 2015; 7:27–31. PMID: 25722834.3. Ferracane J. Elution of leachable components from composites. J Oral Rehabil. 1994; 21:441–452. PMID: 7965355.

Article4. Young HM, Smith CT, Morton D. Comparative in vitro evaluation of two provisional restorative materials. J Prosthet Dent. 2001; 85:129–132. PMID: 11208201.

Article5. Poticny DJ, Klim J. CAD/CAM in-office technology: Innovations after 25 years for predictable, esthetic outcomes. J Am Dent Assoc. 2010; 141:5S–9S. PMID: 20516108.6. Ng J, Ruse D, Wyatt C. A comparison of the marginal fit of crowns fabricated with digital and conventional methods. J Prosthet Dent. 2014; 112:555–560. PMID: 24630399.

Article7. Kim CM, Kim SR, Kim JH, Kim HY, Kim WC. Trueness of milled prostheses according to number of ball-end mill burs. J Prosthet Dent. 2016; 115:624–629. PMID: 26774318.

Article8. Kim DY, Lee HN, Kim JH, Kim HY, Kim WC. Evaluation of marginal and internal gaps in single and three-unit metal frameworks made by micro-stereolithography. J Adv Prosthodont. 2017; 9:239–243. PMID: 28874989.

Article9. Van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12. PMID: 22119539.

Article10. Braian M, Jimbo R, Wennerberg A. Production tolerance of additive manufactured polymeric objects for clinical applications. Dent Mater. 2016; 32:853–861. PMID: 27118595.

Article11. Koch GK, Gallucci GO, Lee SJ. Accuracy in the digital workflow: From data acquisition to the digitally milled cast. J Prosthet Dent. 2016; 115:749–754. PMID: 26803173.

Article12. ISO-12836. Digitizing devices for CAD/CAM systems for indirect dental restorations - Test methods for assessing accuracy. Geneva, Switzerland: International Standards for Organization (ISO);2012. Available at: https://www.iso.org/iso/store.html.13. ISO-5725-1. Accuracy (trueness and precision) of measurement methods and results. Part 1: General principles and definitions. Geneva, Switzerland: International Standards for Organization (ISO);1994. Available at: https://www.iso.org/iso/store.html.14. Kirsch C, Ender A, Attin T, Mehl A. Trueness of four different milling procedures used in dental CAD/CAM systems. Clin Oral Investig. 2017; 21:551–558.

Article15. Bosch G, Ender A, Mehl A. A 3-dimensional accuracy analysis of chairside CAD/CAM milling processes. J Prosthet Dent. 2014; 112:1425–1431. PMID: 24993373.

Article16. Schaefer O, Watts DC, Sigusch BW, Kuepper H, Guentsch A. Marginal and internal fit of pressed lithium disilicate partial crowns in vitro: A three-dimensional analysis of accuracy and reproducibility. Dent Mater. 2012; 28:320–326. PMID: 22265824.

Article17. Jeong ID, Kim WC, Park J, Kim CM, Kim JH. Ceramic molar crown reproducibility by digital workflow manufacturing: An in vitro study. J Adv Prosthodont. 2017; 9:252–256. PMID: 28874991.

Article18. Lee WS, Lee DH, Lee KB. Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system. J Adv Prosthodont. 2017; 9:265–270. PMID: 28874993.

Article19. Kim KB, Kim JH, Kim WC, Kim JH. In vitro evaluation of marginal and internal adaptation of three-unit fixed dental prostheses produced by stereolithography. Dent Mater J. 2014; 33:504–509. PMID: 25087659.

Article20. Park JY, Bae SY, Lee JJ, Kim JH, Kim HY, Kim WC. Evaluation of the marginal and internal gaps of three different dental prostheses: Comparison of the silicone replica technique and three-dimensional superimposition analysis. J Adv Prosthodont. 2017; 9:159–169. PMID: 28680546.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison analysis of fracture load and flexural strength of provisional restorative resins fabricated by different methods

- Comparative evaluation of the subtractive and additive manufacturing on the color stability of fixed provisional prosthesis materials

- Effect of shell thickness on fracture strength of single implant provisional crowns fabricated by indirect-direct technique using 3D printing

- Evaluation of marginal and internal gap of three-unit metal framework according to subtractive manufacturing and additive manufacturing of CAD/CAM systems

- The use of definitive implant abutments for the fabrication of provisional crowns: a case series