J Dent Rehabil Appl Sci.

2021 Jun;37(2):73-80. 10.14368/jdras.2021.37.2.73.

Comparative evaluation of the subtractive and additive manufacturing on the color stability of fixed provisional prosthesis materials

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Wonkwang University, Iksan, Republic of Korea

- KMID: 2525980

- DOI: http://doi.org/10.14368/jdras.2021.37.2.73

Abstract

- Purpose

The purpose of this study is to compare the color stability of provisional restorative materials fabricated by subtractive and additive manufacturing.

Materials and Methods

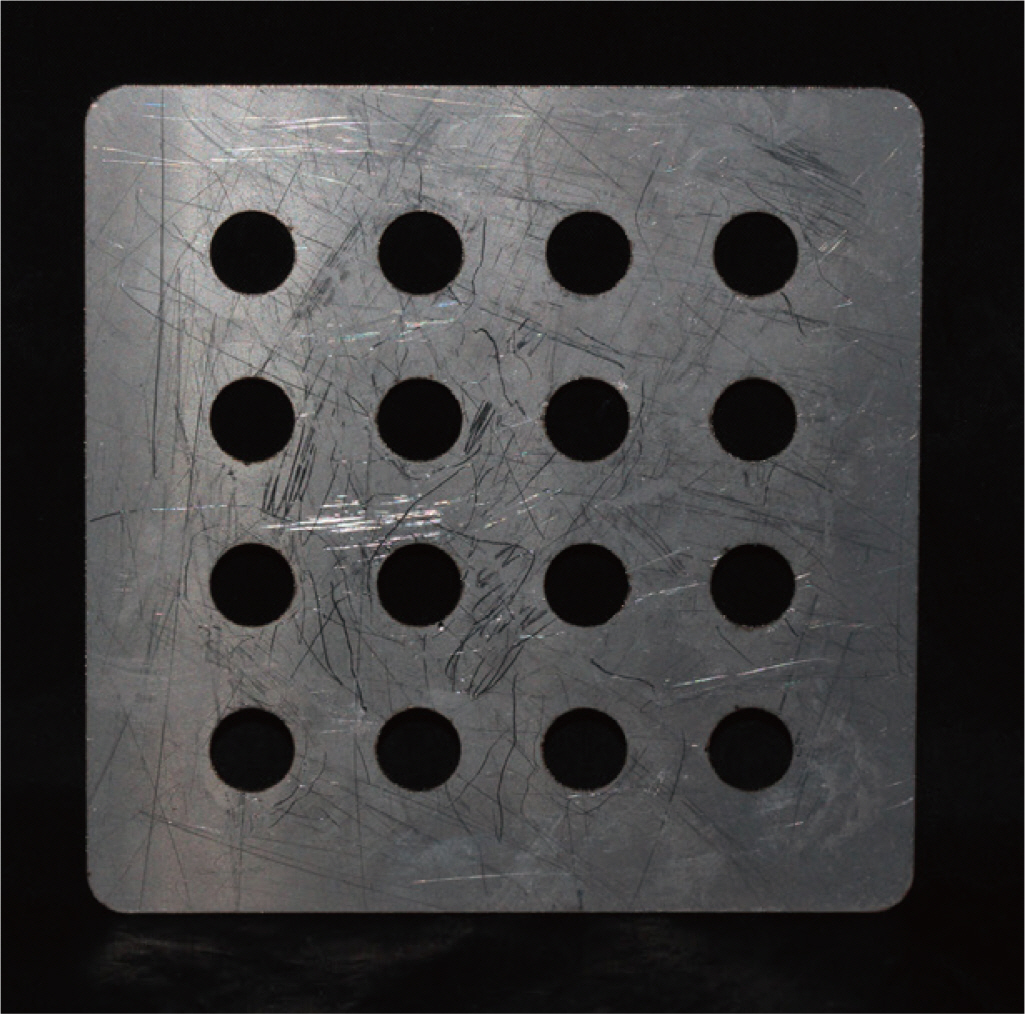

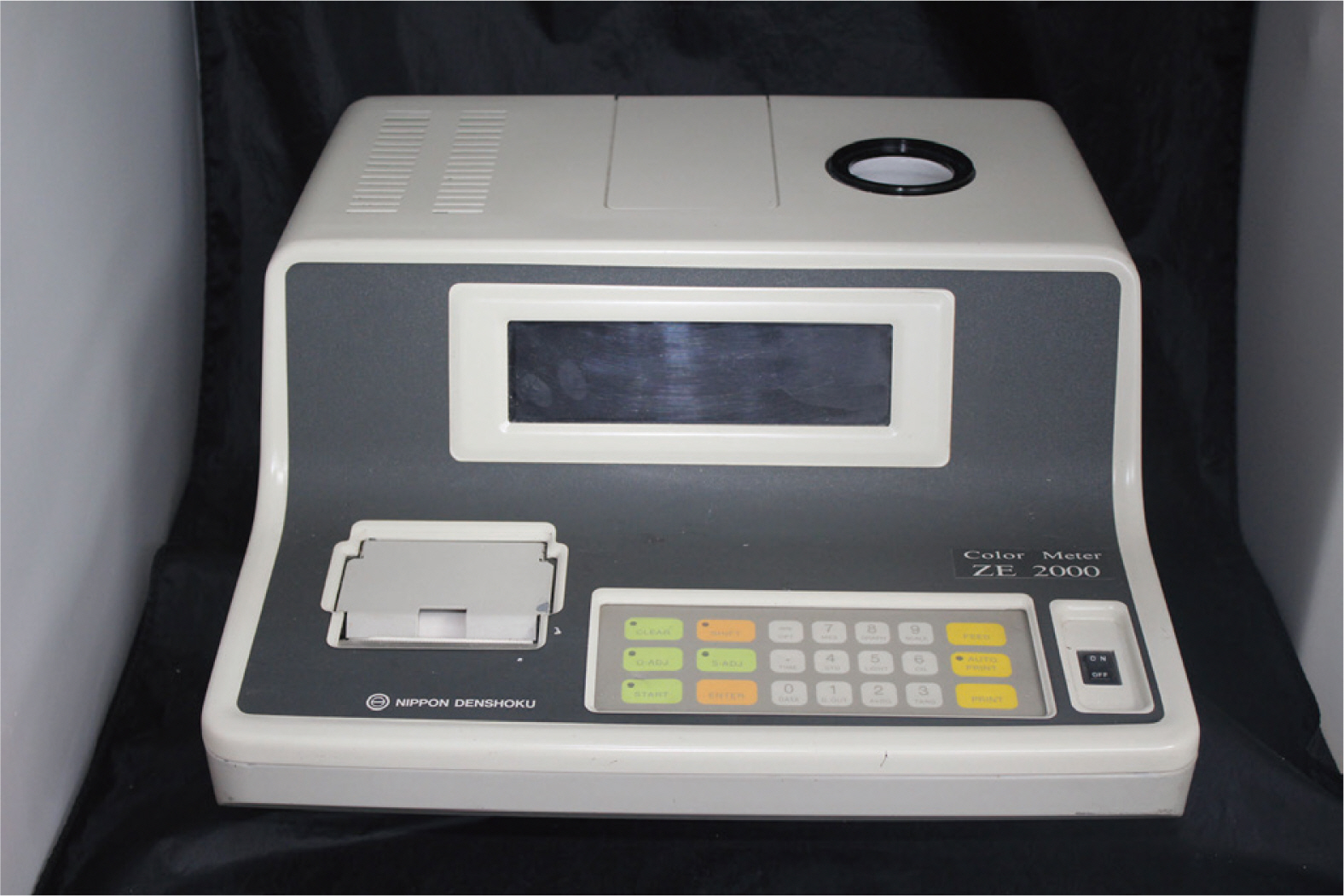

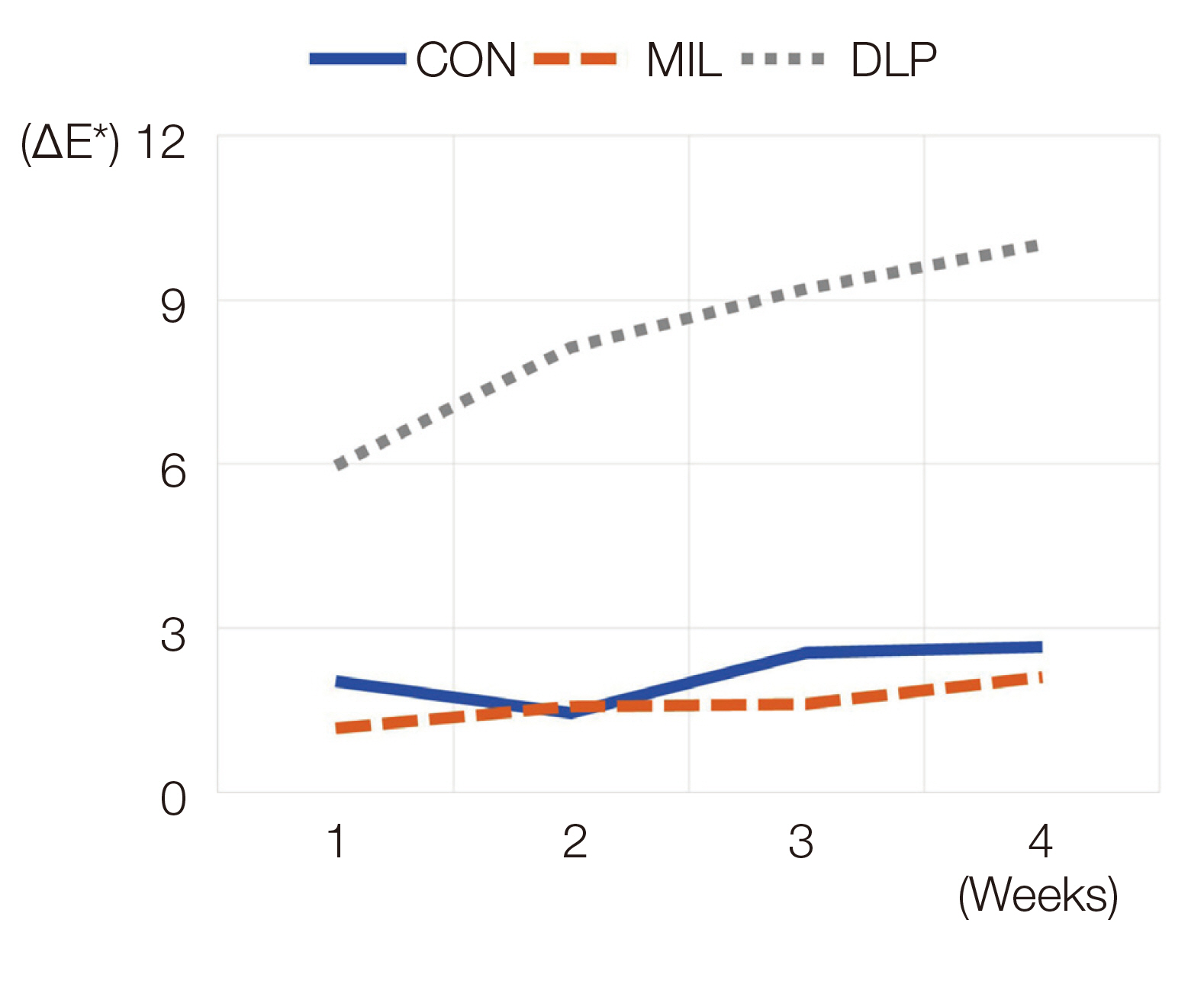

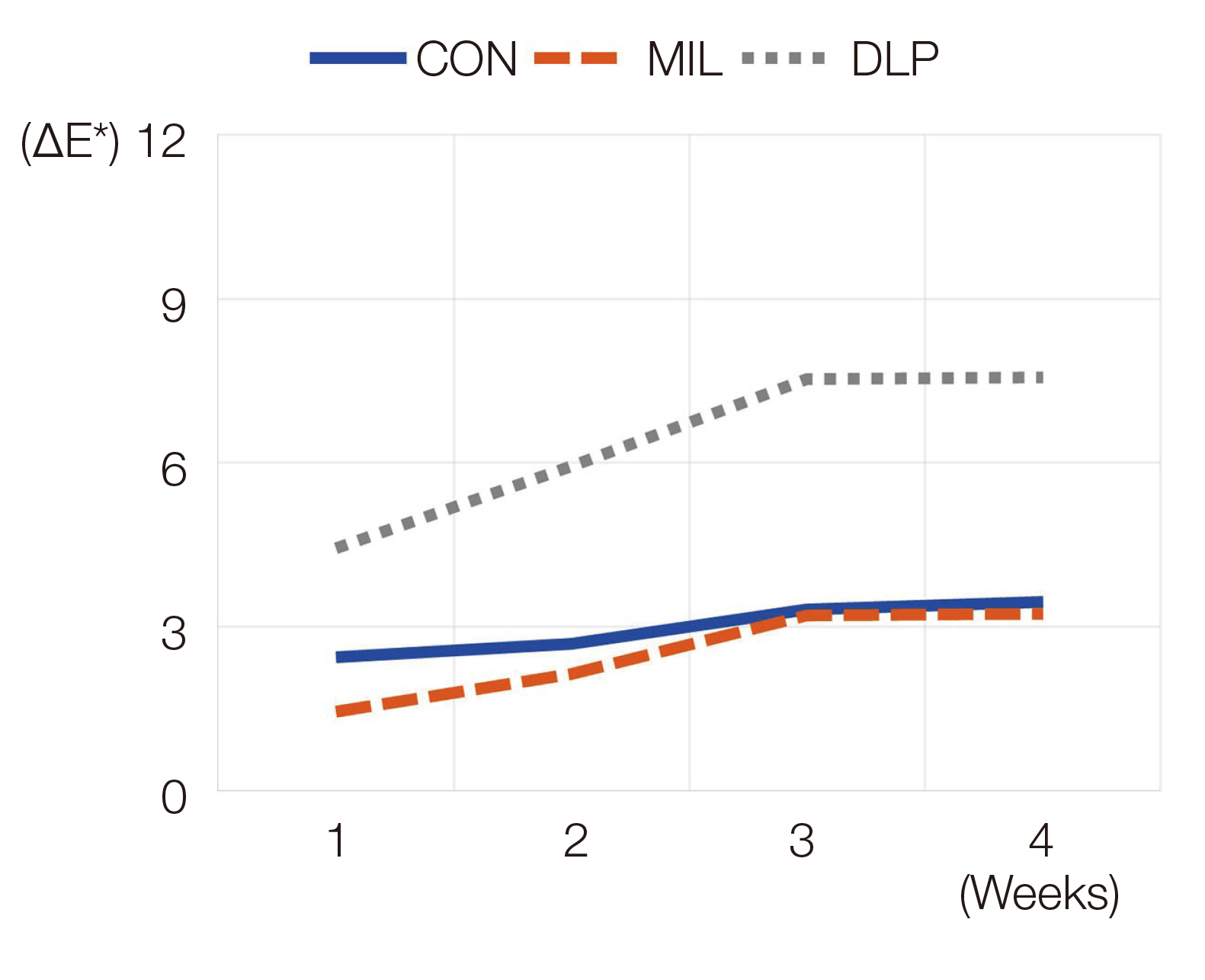

PMMA specimens by subtractive manufacturing and conventional method and bis-acryl specimens by additive manufacturing were fabricated each 20. After immersing specimens in the coffee solution and the wine solution, the color was measured as CIE Lab with a colorimeter weekly for 4 weeks. Color change was calculated and data were analyzed with one-way ANOVA and the Tukey multiple comparisons test (α = 0.05).

Results

PMMA provisional prosthetic materials by subtractive manufacturing showed superior color stability compared to bis-acryl provisional prosthetic materials by additive manufacturing (P < 0.05), and showed similar color stability to the PMMA provisional prosthetic materials by conventional method (P > 0.05).

Conclusion

It is recommended to fabricate provisional restorations by subtractive manufacturing in areas where esthetics is important, such as anterior teeth, and consideration of the color stability will be required when making provisional prosthetic using additive manufacturing.

Keyword

Figure

Reference

-

References

1. Nejatidanesh F, Lotfi HR, Savabi O. 2006; Marginal accuracy of interim restorations fabricated from four interim autopolymerizing resins. J Prosthet Dent. 95:364–7. DOI: 10.1016/j.prosdent.2006.02.030. PMID: 16679131.2. Bello A, Jarvis RH. 1997; A review of esthetic alternatives for the restoration of anterior teeth. J Prosthet Dent. 78:437–40. DOI: 10.1016/S0022-3913(97)70056-8. PMID: 9399183.3. Sham AS, Chu FC, Chai J, Chow TW. 2004; Color stability of provisional prosthodontic materials. J Prosthet Dent. 91:447–52. DOI: 10.1016/j.prosdent.2004.03.005. PMID: 15153852.4. Doray PG, Li D, Powers JM. 2001; Color stability of provisional restorative materials after accelerated aging. J Prosthodont. 10:212–6. DOI: 10.1111/j.1532-849X.2001.00212.x. PMID: 11781969.5. Tallarico M. 2020; Computerization and digital workflow in medicine: Focus on digital dentistry. Materials. 13:2172. DOI: 10.3390/ma13092172. PMID: 32397279. PMCID: PMC7254335.6. Rayyan MM, Aboushelib M, Sayed NM, Ibrahim A, Jimbo R. 2015; Comparison of interim restorations fabricated by CAD/CAM with those fabricated manually. J Prosthet Dent. 114:414–9. DOI: 10.1016/j.prosdent.2015.03.007. PMID: 26001490.7. Almohareb T, Alkatheeri MS, Vohra F, Alrahlah A. 2018; Influence of experimental staining on the color stability of indirect computer-aided design/computeraided manufacturing dental provisional materials. Eur J Dent. 12:269–74. DOI: 10.4103/ejd.ejd_1_18. PMID: 29988258. PMCID: PMC6004811.8. Elagra MI, Rayyan MR, Alhomaidhi MM, Alanaziy AA, Alnefaie MO. 2017; Color stability and marginal integrity of interim crowns: An in vitro study. Eur J Dent. 11:330–4. DOI: 10.4103/ejd.ejd_66_17. PMID: 28932142. PMCID: PMC5594961.9. Shin JW, Kim JE, Choi YJ, Shin SH, Nam NE, Shim JS, Lee KW. 2020; Evaluation of the color stability of 3D-printed crown and bridge materials against various sources of discoloration: An in vitro study. Materials. 13:5359. DOI: 10.3390/ma13235359. PMID: 33255922. PMCID: PMC7731151.10. Gruber S, Kamnoedboon P, Özcan M, inivasan M Sr. 2020; Aug. 31. CAD/CAM complete denture resins: An in vitro evaluation of color stability. J Prosthodont. doi: 10.1111/jopr.13246. DOI: 10.1111/jopr.13246. PMID: 32864812.11. Revilla-León M, Umorin M, Özcan M, Piedra-Cascón W. 2020; Color dimensions of additive manufactured interim restorative dental material. J Prosthet Dent. 123:754–60. DOI: 10.1016/j.prosdent.2019.06.001. PMID: 31653404.12. Rosentritt M, Esch J, Behr M, Leibrock A, Handel G. 1998; In vivo color stability of resin composite veneers and acrylic resin teeth in removable partial dentures. Quintessence Int. 29:517–22. PMID: 9807133.13. Park JS, Park MG. 2013; Effect of aging treatment on the flexural properties of polymer provisional restoration materials. Korean J Dent Mater. 40:215–21.14. Wyszecki G, Stiles WS. 2000. Color Science: Concepts and Methods, Quantitative Data and Formulae. 2nd ed. John Wiley and Sons;New York: p. 83–116.15. Schulze KA, Marshall SJ, Gansky SA, Marshall GW. 2003; Color stability and hardness in dental composites after accelerated aging. Dent Mater. 19:612–9. DOI: 10.1016/S0109-5641(03)00003-4. PMID: 12901985.16. Ruyter IE, Nilner K, Möller B. 1987; Color stability of dental composite resin materials for crown and bridge veneers. Dent Mater. 3:246–51. DOI: 10.1016/S0109-5641(87)80081-7. PMID: 3479360.17. Ruyter IE, Svendsen SA. 1978; Remaining methacrylate groups in composite restorative materials. Acta Odontol Scand. 36:75–82. DOI: 10.3109/00016357809027569. PMID: 274063.18. Garcia CR, Rumpf RC, Tsang HH, Barton JH. 2013; Effects of extreme surface roughness on 3D printed horn antenna. Electron Lett. 49:734–6. DOI: 10.1049/el.2013.1528.19. Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D. 2018; Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos B Eng. 143:172–96. DOI: 10.1016/j.compositesb.2018.02.012.20. Vaezi M, Seitz H, Yang S. 2013; A review on 3D microadditive manufacturing technologies. Int J Adv Manuf Technol. 67:1721–54. DOI: 10.1007/s00170-012-4605-2.21. Ferracane JL, Moser JB, Greener EH. 1985; Ultraviolet light-induced yellowing of dental restorative resins. J Prosthet Dent. 54:483–7. DOI: 10.1016/0022-3913(85)90418-4. PMID: 2931511.22. Abu-Bakr N, Han L, Okamoto A, Iwaku M. 2000; Color stability of compomer after immersion in various media. J Esthet Dent. 12:258–63. DOI: 10.1111/j.1708-8240.2000.tb00232.x. PMID: 11338492.23. Asmussen E. 1983; Factors affecting the color stability of restorative resins. Acta Odontol Scand. 41:11–8. DOI: 10.3109/00016358309162298. PMID: 6575570.24. Park SJ, Lee HA, Lee SH, Seok S, Lim BS, Kwon JS, Kim KM. 2019; Comparison of physical properties of the various 3D printing temporary crown and bridge resin. Korean J Dent Mater. 46:139–52. DOI: 10.14815/kjdm.2019.46.3.139.25. Bertolo MV, Moraes RC, Pfeifer C, Salgado VE, Correr AR, Schneider LF. 2017; Influence of Photoinitiator System on Physical-Chemical Properties of Experimental Self-Adhesive Composites. Braz Dent J. 28:35–9. DOI: 10.1590/0103-6440201700841. PMID: 28301015.26. Hadis MA, Shortall AC, Palin WM. 2012; Competitive light absorbers in photoactive dental resin-based materials. Dent Mater. 28:831–41. DOI: 10.1016/j.dental.2012.04.029. PMID: 22578661.27. Kim JE, Choi WH, Lee D, Shin Y, Park SH, Roh BD, Kim D. 2021; Color and Translucency Stability of Three-Dimensional Printable Dental Materials for Crown and Bridge Restorations. Materials. 14:650. DOI: 10.3390/ma14030650. PMID: 33572545. PMCID: PMC7866796.28. Mazaro JVQ, Minani LM, Zavanelli AC, Mello CCD, Lemos CAA. 2015; Evaluation of color stability of different temporary restorative materials. Rev Odontol UNESP. 44:262–7. DOI: 10.1590/1807-2577.0017.29. Berli C, Thieringer FM, Sharma N, Müller JA, Dedem P, Fischer J, Rohr N. 2020; Comparing the mechanical properties of pressed, milled, and 3Dprinted resins for occlusal devices. J Prosthet Dent. 124:780–6. DOI: 10.1016/j.prosdent.2019.10.024. PMID: 31955837.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Marginal and internal discrepancy of 3-unit fixed dental prostheses fabricated by subtractive and additive manufacturing

- Comparison analysis of fracture load and flexural strength of provisional restorative resins fabricated by different methods

- Evaluation of marginal and internal gap of three-unit metal framework according to subtractive manufacturing and additive manufacturing of CAD/CAM systems

- Comparison of shear bond strength between various temporary prostheses resin blocks fabricated by subtractive and additive manufacturing methods bonded to self-curing reline resin

- Reinforcing the retention of provisional restoration using provisional implant on maxillary anterior region: clinical case report