J Adv Prosthodont.

2018 Apr;10(2):93-100. 10.4047/jap.2018.10.2.93.

What is the changing frequency of diamond burs?

- Affiliations

-

- 1Department of Prosthodontics, Gülhane Faculty of Dentistry, University of Health Sciences, Ankara, Turkey. emirfaruk@gmail.com

- 2Department of Prosthodontics, Faculty of Dentistry, Hacettepe University, Ankara, Turkey.

- KMID: 2409628

- DOI: http://doi.org/10.4047/jap.2018.10.2.93

Abstract

- PURPOSE

The purpose of this study was to determine the changing frequency of a diamond bur after multiple usages on 3 different surfaces.

MATERIALS AND METHODS

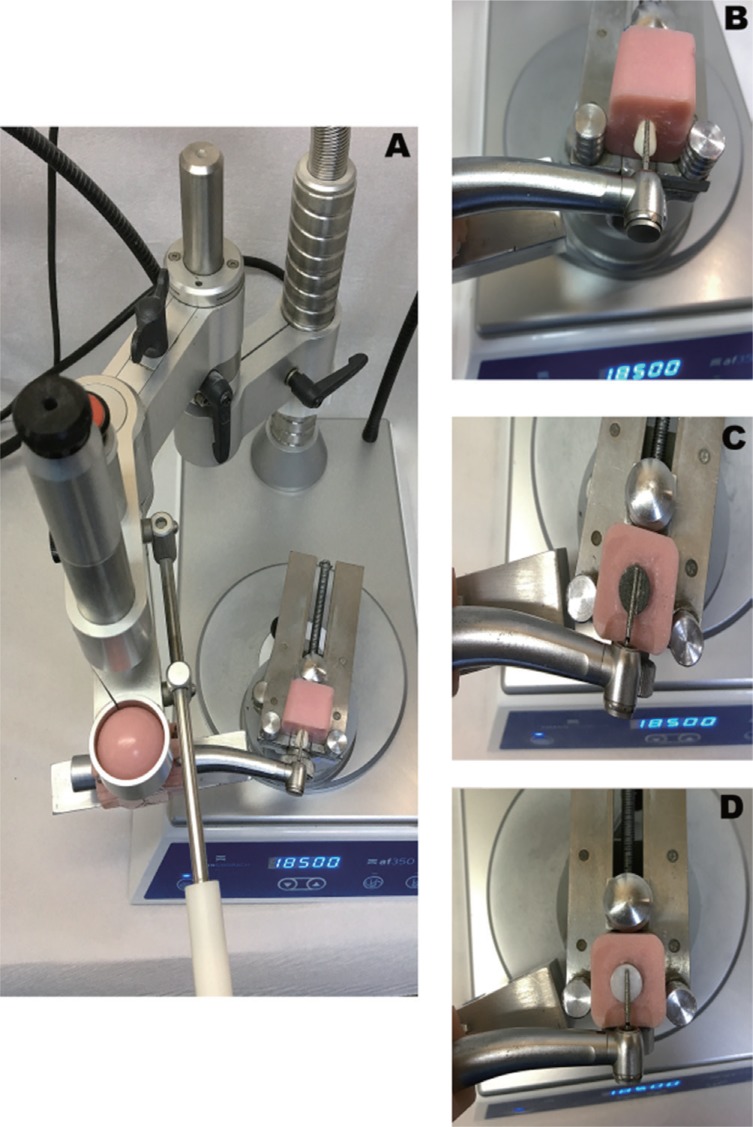

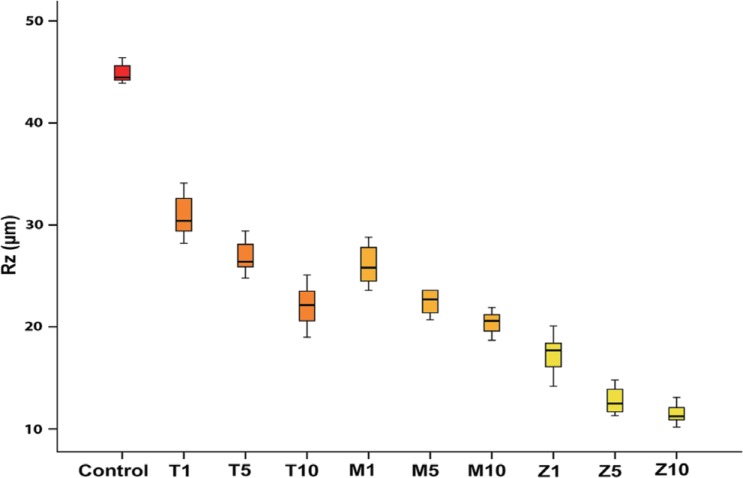

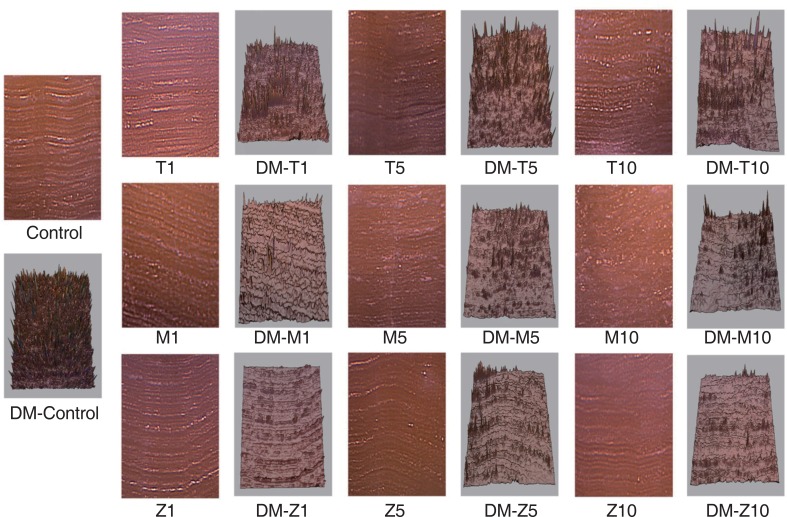

Human premolar teeth (N = 26), disc shaped direct metal laser sintered CoCr (N = 3) and zirconia specimens (N = 3) were used in this study. Groups named basically as Group T for teeth, Group M for CoCr, and Group Z for zirconia. Round tapered black-band diamond bur was used. The specimens were randomly divided into three groups and placed with a special assembly onto the surveyor. 1, 5, and 10 preparation protocols were performed to the first, second, and third sub-groups, respectively. The subgroups were named according to preparation numbers (1, 5, 10). The mentioned bur of each group was then used at another horizontal preparation on a new tooth sample. The same procedure was used for CoCr and zirconia disc specimens. All of the bur surfaces were evaluated using roughness analysis. Then, horizontal tooth preparation surfaces were examined under both stereomicroscope and SEM. The depth maps of tooth surfaces were also obtained from digital stereomicroscopic images. The results were statistically analyzed using One-Way ANOVA, and the Tukey HSD post-hoc tests (α=.05).

RESULTS

All of the groups were significantly different from the control group (P < .001). There was no significant difference between groups Z5 and Z10 (P=.928). Significant differences were found among groups T5, M5, and Z5 (P < .001).

CONCLUSION

Diamond burs wear after multiple use and they should be changed after 5 teeth preparations at most. A diamond bur should not be used for teeth preparation after try-in procedures of metal or zirconia substructures.

Figure

Reference

-

1. Sharma S, Shankar R, Srinivas K. An epidemiological study on the selection, usage and disposal of dental burs among the dental practioner's. J Clin Diagn Res. 2014; 8:250–254.

Article2. Siegel SC, von Fraunhofer JA. Dental cutting with diamond burs: heavy-handed or light-touch? J Prosthodont. 1999; 8:3–9. PMID: 10356549.

Article3. Borges CF, Magne P, Pfender E, Heberlein J. Dental diamond burs made with a new technology. J Prosthet Dent. 1999; 82:73–79. PMID: 10384166.

Article4. Bae JH, Yi J, Kim S, Shim JS, Lee KW. Changes in the cutting efficiency of different types of dental diamond rotary instrument with repeated cuts and disinfection. J Prosthet Dent. 2014; 111:64–70. PMID: 24231434.

Article5. Nakamura K, Katsuda Y, Ankyu S, Harada A, Tenkumo T, Kanno T, Niwano Y, Egusa H, Milleding P, Örtengren U. Cutting efficiency of diamond burs operated with electric high-speed dental handpiece on zirconia. Eur J Oral Sci. 2015; 8. 28.

Article6. Klimek L, Banaszek K. The mechanisms of wear in burs with diamond grits. J Superhard Mater. 2007; 29:185–188.

Article7. Heymann HO, Swift EJ Jr, Ritter AV. Sturdevant's arts and science of operative dentistry. 6th ed. St. Louis: Mosby;2013. p. 164–185.8. Bhagat TV, Thombare R. A comparative evaluation of functional efficiency of diamond bur used with distilled water, distilled water modified by addition of mouthwash and lactated ringer solution as coolants. An in-vitro study. Inter J Dent Clin. 2012; 4:6–9.9. Leonard DL, Charlton DG. Performance of high-speed dental handpieces subjected to simulated clinical use and sterilization. J Am Dent Assoc. 1999; 130:1301–1311. PMID: 10492537.

Article10. Waqar A, Sein H, Jackson MJ, Rego C, Phoenix DA, Elhissi A, Crean J. Chemical vapour deposition of diamond for dental tools and burs springer brief in materials. 1st ed. London: Springer;2014. p. 19–48.11. Siegel SC, von Fraunhofer JA. Effect of handpiece load on the cutting efficiency of dental burs. Machining Sci Technol. 1997; 1:1–13.

Article12. Galindo DF, Ercoli C, Funkenbusch PD, Greene TD, Moss ME, Lee HJ, Ben-Hanan U, Graser GN, Barzilay I. Tooth preparation: a study on the effect of different variables and a comparison between conventional and channeled diamond burs. J Prosthodont. 2004; 13:3–16. PMID: 15032891.

Article13. Laforgia PD, Milano V, Morea C, Desiate A. Temperature change in the pulp chamber during complete crown preparation. J Prosthet Dent. 1991; 65:56–61. PMID: 1851842.

Article14. Kiran J, Chiranjeevi R, Vahini R, Chandrasekharan NK. Changes in the Diamond bur before and after tooth preparation. Trends Prosthodont Dent Implantol. 2014; 5:18–21.15. Ayad MF, Rosenstiel SF, Salama M. Influence of tooth surface roughness and type of cement on retention of complete cast crowns. J Prosthet Dent. 1997; 77:116–121. PMID: 9051596.

Article16. Oilo G, Jørgensen KD. The influence of surface roughness on the retentive ability of two dental luting cements. J Oral Rehabil. 1978; 5:377–389. PMID: 361933.

Article17. Koodaryan R, Hafezeqoran A, Poursoltan S. Effect of dentin surface roughness on the shear bond strength of resin bonded restorations. J Adv Prosthodont. 2016; 8:224–228. PMID: 27350858.

Article18. McInnes PM, Wendt SL Jr, Retief DH, Weinberg R. Effect of dentin surface roughness on shear bond strength. Dent Mater. 1990; 6:204–207. PMID: 2086296.

Article19. Solá-Ruiz MF, Faus-Matoses I, Del Rio Highsmith J, Fons-Font A. Study of surface topography, roughness, and microleakage after dental preparation with different instrumentation. Int J Prosthodont. 2014; 27:530–533. PMID: 25390866.

Article20. Siegel SC, Von Fraunhofer JA. Dental cutting: the historical development of diamond burs. J Am Dent Assoc. 1998; 129:740–745. PMID: 9631615.

Article21. Pilcher ES, Tietge JD, Draughn RA. Comparison of cutting rates among single-patient-use and multiple-patient-use diamond burs. J Prosthodont. 2000; 9:66–70. PMID: 11070132.

Article22. Siegel SC, von Fraunhofer JA. Assessing the cutting efficiency of dental diamond burs. J Am Dent Assoc. 1996; 127:763–772. PMID: 8708278.

Article23. Siegel SC, von Fraunhofer JA. Comparison of sectioning rates among carbide and diamond burs using three casting alloys. J Prosthodont. 1999; 8:240–244. PMID: 10895675.

Article24. Siegel SC, von Fraunhofer JA. Cutting efficiency of three diamond bur grit sizes. J Am Dent Assoc. 2000; 131:1706–1710. PMID: 11143734.

Article25. Sein H, Ahmed W, Jackson M, Woodwards R, Polini R. Performance and characterisation of CVD diamond coated, sintered diamond and WC-Co cutting tools for dental and micromachining applications. Thin Solid Films. 2004; 447-8:455–461.

Article26. Taylor DF, Perkins RR, Kumpula JW. Characteristics of some air-turbine handpieces. J Am Dent Assoc. 1962; 64:794–805. PMID: 13919933.

Article27. Brockhurst PJ, Shams R. Dynamic measurement of the torque-speed characteristics of dental high speed air turbine handpieces. Aust Dent J. 1994; 39:33–38. PMID: 8185538.

Article28. Choi C, Driscoll CF, Romberg E. Comparison of cutting efficiencies between electric and air-turbine dental handpieces. J Prosthet Dent. 2010; 103:101–107. PMID: 20141814.

Article29. Ottl P, Lauer HC. Temperature response in the pulpal chamber during ultrahigh-speed tooth preparation with diamond burs of different grit. J Prosthet Dent. 1998; 80:12–19. PMID: 9656172.

Article30. Oztürk B, Uşümez A, Oztürk AN, Ozer F. In vitro assessment of temperature change in the pulp chamber during cavity preparation. J Prosthet Dent. 2004; 91:436–440. PMID: 15153850.31. Ercoli C, Rotella M, Funkenbusch PD, Russell S, Feng C. In vitro comparison of the cutting efficiency and temperature production of 10 different rotary cutting instruments. Part I: Turbine. J Prosthet Dent. 2009; 101:248–261. PMID: 19328278.

Article32. Yin L, Jahanmir S, Ives LK. Abrasive machining of porcelain and zirconia with a dental handpiece. Wear. 2003; 975–989.

Article33. Ayad MF, Rosenstiel SF, Hassan MM. Surface roughness of dentin after tooth preparation with different rotary instrumentation. J Prosthet Dent. 1996; 75:122–128. PMID: 8667268.

Article34. Al-Omari WM, Mitchell CA, Cunningham JL. Surface roughness and wettability of enamel and dentine surfaces prepared with different dental burs. J Oral Rehabil. 2001; 28:645–650. PMID: 11422697.

Article35. Ayyıldız S, Soylu EH, Ide S, Kılıç S, Sipahi C, Pişkin B, Gökçe HS. Annealing of Co-Cr dental alloy: effects on nanostructure and Rockwell hardness. J Adv Prosthodont. 2013; 5:471–478. PMID: 24353888.

Article36. Gutiérrez-Salazar M, Reyes-Gasga J. Microhardness and chemical composition of human tooth. Mat Res. 2003; 6:367–373.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of cutting instruments on the dentin bond strength of a self-etch adhesive

- Effects of dentin surface preparations on bonding of self-etching adhesives under simulated pulpal pressure

- An experimental study of cutting efficiency of air-driven diamond burs on human tooth

- Sterilization effect of atmospheric pressure non-thermal air plasma on dental instruments

- Microshear bond strength of a self-etching primer adhesive to enamel according to the type of bur