J Adv Prosthodont.

2017 Apr;9(2):124-129. 10.4047/jap.2017.9.2.124.

Role of span length in the adaptation of implant-supported cobalt chromium frameworks fabricated by three techniques

- Affiliations

-

- 1Department of Prosthodontics, School and Hospital of Stomatology, Wuhan University, Wuhan, P.R.China. willowlovely@qq.com

- KMID: 2376300

- DOI: http://doi.org/10.4047/jap.2017.9.2.124

Abstract

- PURPOSE

This study evaluated the effect of span length on the adaptation of implant-supported cobalt chromium frameworks fabricated by three techniques.

MATERIALS AND METHODS

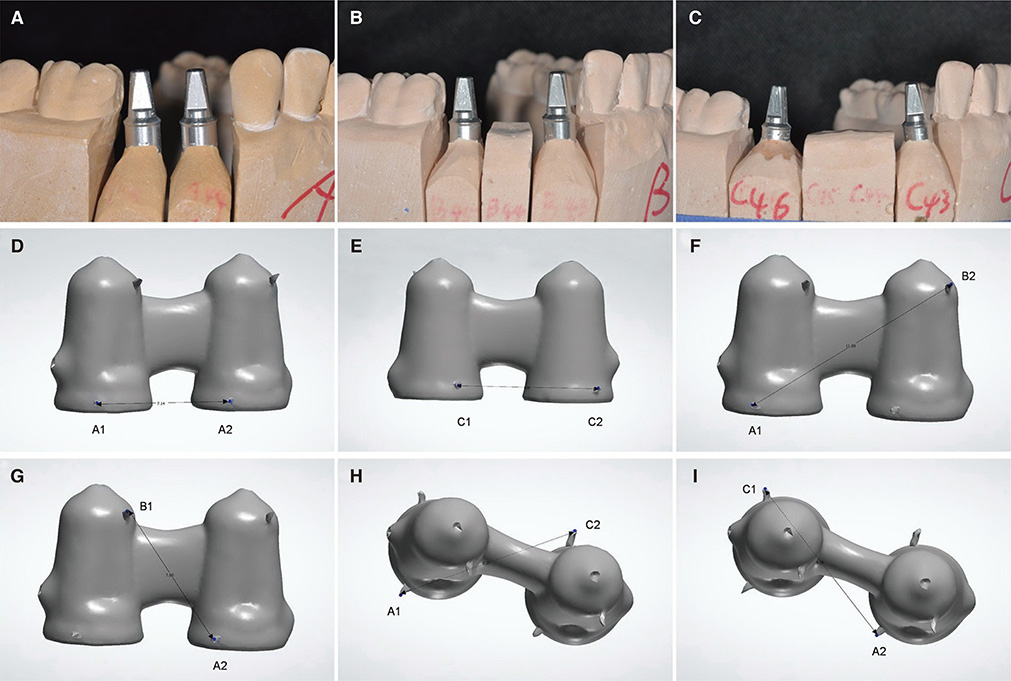

Models with two solid abutment analogs at different inter-abutment distances were digitized using a laboratory scanner. Frameworks of two-, three-, and four-unit fixed prostheses were designed by a computer. Six dots with a diameter of 0.2 mm were preset on the surface of each framework. A total of 54 implant-supported cobalt chromium frameworks were fabricated by milling, selective laser melting (SLM), and cast techniques. The frameworks were scanned and exported as Stereolithography files. Distances between two dots in X, Y, and Z coordinates were measured in both the designed and fabricated frameworks. Marginal gaps between the framework and the abutments were also evaluated by impression replica method.

RESULTS

In terms of distance measurement, significant differences were found between three- and four-unit frameworks, as well as between two- and four-unit frameworks prepared by milling technique (P<.05). Significant differences were also noted between two- and three-unit frameworks, as well as between two- and four-unit frameworks prepared by cast technique (P<.05). The milling technique presented smaller differences than the SLM technique, and the SLM technique showed smaller differences than the cast technique at any unit prostheses (P<.05). Evaluation with the impression replica method indicated significant differences among the span lengths for any fabrication method (P<.05), as well as among the fabrication methods at any unit prostheses (P<.05).

CONCLUSION

The adaptation of implant-supported cobalt chromium frameworks was affected by the span length and fabrication method.

Keyword

- Milling; SLM; Cast; Span; Adaptation

Figure

Cited by 1 articles

-

Precision of the milled full-arch framework fabricated using pre-sintered soft alloy: A pilot study

Hyun-Wook Woo, Sung-Am Cho, Cheong-Hee Lee, Kyu-Bok Lee, Jin-Hyun Cho, Du-Hyeong Lee

J Adv Prosthodont. 2018;10(2):128-131. doi: 10.4047/jap.2018.10.2.128.

Reference

-

1. Att W, Hoischen T, Gerds T, Strub JR. Marginal adaptation of all-ceramic crowns on implant abutments. Clin Implant Dent Relat Res. 2008; 10:218–225.2. Abduo J, Bennani V, Waddell N, Lyons K, Swain M. Assessing the fit of implant fixed prostheses: a critical review. Int J Oral Maxillofac Implants. 2010; 25:506–515.3. Sahin S, Cehreli MC. The significance of passive framework fit in implant prosthodontics: current status. Implant Dent. 2001; 10:85–92.4. Takahashi T, Gunne J. Fit of implant frameworks: an in vitro comparison between two fabrication techniques. J Prosthet Dent. 2003; 89:256–260.5. de França DG, Morais MH, das Neves FD, Barbosa GA. Influence of CAD/CAM on the fit accuracy of implant-supported zirconia and cobalt-chromium fixed dental prostheses. J Prosthet Dent. 2015; 113:22–28.6. Sun J, Zhang FQ. The application of rapid prototyping in prosthodontics. J Prosthodont. 2012; 21:641–644.7. de Araújo GM, de França DG, Silva Neto JP, Barbosa GA. Passivity of conventional and CAD/CAM fabricated implant frameworks. Braz Dent J. 2015; 26:277–283.8. Witkowski S, Komine F, Gerds T. Marginal accuracy of titanium copings fabricated by casting and CAD/CAM techniques. J Prosthet Dent. 2006; 96:47–52.9. Fernández M, Delgado L, Molmeneu M, García D, Rodríguez D. Analysis of the misfit of dental implant-supported prostheses made with three manufacturing processes. J Prosthet Dent. 2014; 111:116–123.10. Nesse H, Ulstein DM, Vaage MM, Øilo M. Internal and marginal fit of cobalt-chromium fixed dental prostheses fabricated with 3 different techniques. J Prosthet Dent. 2015; 114:686–692.11. Xu D, Xiang N, Wei B. The marginal fit of selective laser melting-fabricated metal crowns: an in vitro study. J Prosthet Dent. 2014; 112:1437–1440.12. Rahme HY, Tehini GE, Adib SM, Ardo AS, Rifai KT. In vitro evaluation of the “replica technique” in the measurement of the fit of Procera crowns. J Contemp Dent Pract. 2008; 9:25–32.13. Lee JY, Choi SJ, Kim MS, Kim HY, Kim YS, Shin SW. Effect of span length on the fit of zirconia framework fabricated using CAD/CAM system. J Adv Prosthodont. 2013; 5:118–125.14. Anunmana C, Charoenchitt M, Asvanund C. Gap comparison between single crown and three-unit bridge zirconia substructures. J Adv Prosthodont. 2014; 6:253–258.15. Tiossi R, Gomes EA, Lapria Faria AC, Silveira Rodrigues RC, Ribeiro RF. Effect of cyclic loading on the vertical microgap of long-span zirconia frameworks supported by 4 or 6 implants. J Prosthet Dent. 2014; 112:828–833.16. Strub JR, Rekow ED, Witkowski S. Computer-aided design and fabrication of dental restorations: current systems and future possibilities. J Am Dent Assoc. 2006; 137:1289–1296.17. Sundar MK, Chikmagalur SB, Pasha F. Marginal fit and microleakage of cast and metal laser sintered copings-an in vitro study. J Prosthodont Res. 2014; 58:252–258.18. Rosentritt M, Behr M, Kolbeck C, Handel G. Marginal integrity of CAD/CAM fixed partial dentures. Eur J Dent. 2007; 1:25–30.19. Karl M, Graef F, Wichmann M, Krafft T. Passivity of fit of CAD/CAM and copy-milled frameworks, veneered frameworks, and anatomically contoured, zirconia ceramic, implant-supported fixed prostheses. J Prosthet Dent. 2012; 107:232–238.20. Zeng L, Zhang Y, Liu Z, Wei B. Effects of repeated firing on the marginal accuracy of Co-Cr copings fabricated by selective laser melting. J Prosthet Dent. 2015; 113:135–139.21. Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent. 2009; 102:253–259.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Considerations for the Survival of Complete Arch Implant-Supported Zirconia Restorations; Status of Antagonistic Arches and Stress Distribution on Frameworks: A Case Report

- Implant-supported prosthetic rehabilitation for the edentulous maxilla using the additive manufacturing technology: A case report

- Prosthetic misfit of implant-supported prosthesis obtained by an alternative section method

- Biomechanical behavior of CAD/CAM cobaltchromium and zirconia full-arch fixed prostheses

- Effect of span length on the fit of zirconia framework fabricated using CAD/CAM system