J Adv Prosthodont.

2012 May;4(2):89-92.

Prosthetic misfit of implant-supported prosthesis obtained by an alternative section method

- Affiliations

-

- 1Department of Dental Materials and Prosthodontics, Dental School of Ribeirao Preto, University of Sao Paulo, Ribeirao Preto, SP, Brazil. rtiossi@yahoo.com

- 2Department of Occlusion and Prosthodontics, Dental School of Sobral, University of Ceara, Sobral, CE, Brazil.

Abstract

- PURPOSE

Adequate passive-fitting of one-piece cast 3-element implant-supported frameworks is hard to achieve. This short communication aims to present an alternative method for section of one-piece cast frameworks and for casting implant-supported frameworks.

MATERIALS AND METHODS

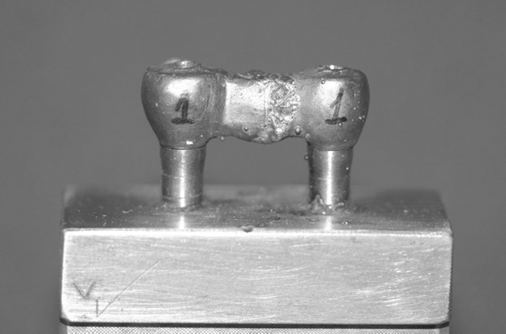

Three-unit implant-supported nickel-chromium (Ni-Cr) frameworks were tested for vertical misfit (n = 6). The frameworks were cast as one-piece (Group A) and later transversally sectioned through a diagonal axis (Group B) and compared to frameworks that were cast diagonally separated (Group C). All separated frameworks were laser welded. Only one side of the frameworks was screwed.

RESULTS

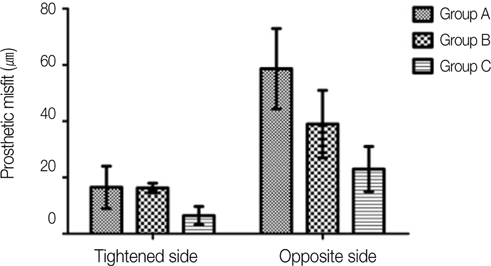

The results on the tightened side were significantly lower in Group C (6.43 +/- 3.24 microm) when compared to Groups A (16.50 +/- 7.55 microm) and B (16.27 +/- 1.71 microm) (P<.05). On the opposite side, the diagonal section of the one-piece castings for laser welding showed significant improvement in the levels of misfit of the frameworks (Group A, 58.66+/-14.30 microm; Group B, 39.48+/-12.03 microm; Group C, 23.13+/-8.24 microm) (P<.05).

CONCLUSION

Casting diagonally sectioned frameworks lowers the misfit levels. Lower misfit levels for the frameworks can be achieved by diagonally sectioning one-piece frameworks.

Keyword

MeSH Terms

Figure

Reference

-

1. Sahin S, Cehreli MC. The significance of passive framework fit in implant prosthodontics: current status. Implant Dent. 2001. 10:85–92.2. Kohorst P, Brinkmann H, Li J, Borchers L, Stiesch M. Marginal accuracy of four-unit zirconia fixed dental prostheses fabricated using different computer-aided design/computer-aided manufacturing systems. Eur J Oral Sci. 2009. 117:319–325.3. Jemt T. Failures and complications in 391 consecutively inserted fixed prostheses supported by Brånemark implants in edentulous jaws: a study of treatment from the time of prosthesis placement to the first annual checkup. Int J Oral Maxillofac Implants. 1991. 6:270–276.4. Tiossi R, Rodrigues RC, de Mattos Mda G, Ribeiro RF. Comparative analysis of the fit of 3-unit implant-supported frameworks cast in nickel-chromium and cobalt-chromium alloys and commercially pure titanium after casting, laser welding, and simulated porcelain firings. Int J Prosthodont. 2008. 21:121–123.5. Clelland NL, Carr AB, Gilat A. Comparison of strains transferred to a bone simulant between as-cast and postsoldered implant frameworks for a five-implant-supported fixed prosthesis. J Prosthodont. 1996. 5:193–200.6. Koke U, Wolf A, Lenz P, Gilde H. In vitro investigation of marginal accuracy of implant-supported screw-retained partial dentures. J Oral Rehabil. 2004. 31:477–482.7. Silva TB, De Arruda Nobilo MA, Pessanha Henriques GE, Mesquita MF, Guimaraes MB. Influence of laser-welding and electroerosion on passive fit of implant-supported prosthesis. Stomatologija. 2008. 10:96–100.8. de Sousa SA, de Arruda Nobilo MA, Henriques GE, Mesquita MF. Passive fit of frameworks in titanium and palladium-silver alloy submitted the laser welding. J Oral Rehabil. 2008. 35:123–127.9. Tiossi R, Falcão-Filho H, Aguiar Júnior FA, Rodrigues RC, Mattos Mda G, Ribeiro RF. Modified section method for laser-welding of ill-fitting cp Ti and Ni-Cr alloy one-piece cast implant-supported frameworks. J Oral Rehabil. 2010. 37:359–363.10. de Aguiar FA Jr, Tiossi R, Rodrigues RC, Mattos Mde G, Ribeiro RF. An alternative section method for casting and posterior laser welding of metallic frameworks for an implantsupported prosthesis. J Prosthodont. 2009. 18:230–234.11. Kikuchi H, Kurotani T, Kaketani M, Hiraguchi H, Hirose H, Yoneyama T. Effect of laser irradiation conditions on the laser welding strength of cobalt-chromium and gold alloys. J Oral Sci. 2011. 53:301–305.12. Sartori IA, Ribeiro RF, Francischone CE, de Mattos Mda G. In vitro comparative analysis of the fit of gold alloy or commercially pure titanium implant-supported prostheses before and after electroerosion. J Prosthet Dent. 2004. 92:132–138.13. Watanabe I, Watanabe E, Atsuta M, Okabe T. Tensile strength of soldered gold alloy joints. J Prosthet Dent. 1997. 78:260–266.14. Fonseca JC, Henriques GE, Sobrinho LC, de Góes MF. Stress-relieving and porcelain firing cycle influence on marginal fit of commercially pure titanium and titanium-aluminum-vanadium copings. Dent Mater. 2003. 19:686–691.15. Wettstein F, Sailer I, Roos M, Hämmerle CH. Clinical study of the internal gaps of zirconia and metal frameworks for fixed partial dentures. Eur J Oral Sci. 2008. 116:272–279.16. Jemt T, Book K. Prosthesis misfit and marginal bone loss in edentulous implant patients. Int J Oral Maxillofac Implants. 1996. 11:620–625.17. Shimakura M, Yamada S, Takeuchi M, Miura K, Ikeyama J. Influence of irradiation conditions on the deformation of pure titanium frames in laser welding. Dent Mater J. 2009. 28:243–247.18. Nuñez-Pantoja JM, Vaz LG, Nóbilo MA, Henriques GE, Mesquita MF. Effects of laser-weld joint opening size on fatigue strength of Ti-6Al-4V structures with several diameters. J Oral Rehabil. 2011. 38:196–201.19. Zupancic R, Legat A, Funduk N. Tensile strength and corrosion resistance of brazed and laser-welded cobalt-chromium alloy joints. J Prosthet Dent. 2006. 96:273–282.20. Gemalmaz D, Berksun S, Alkumru HN, Kasapoglu C. Thermal cycling distortion of porcelain fused to metal fixed partial dentures. J Prosthet Dent. 1998. 80:654–660.21. Bridger DV, Nicholls JI. Distortion of ceramometal fixed partial dentures during the firing cycle. J Prosthet Dent. 1981. 45:507–514.22. Campbell SD, Pelletier LB. Thermal cycling distortion of metal ceramics: Part I-Metal collar width. J Prosthet Dent. 1992. 67:603–608.23. Campbell SD, Sirakian A, Pelletier LB, Giordano RA. Effects of firing cycle and surface finishing on distortion of metal ceramic castings. J Prosthet Dent. 1995. 74:476–481.24. Twiggs SW, Searle JR, Ringle RD, Fairhurst CW. A rapid heating and cooling rate dilatometer for measuring thermal expansion in dental porcelain. J Dent Res. 1989. 68:1316–1318.25. Bryant RA, Nicholls JI. Measurement of distortions in fixed partial dentures resulting from degassing. J Prosthet Dent. 1979. 42:515–520.26. Ziebert GJ, Hurtado A, Glapa C, Schiffleger BE. Accuracy of one-piece castings, preceramic and postceramic soldering. J Prosthet Dent. 1986. 55:312–317.27. Zervas PJ, Papazoglou E, Beck FM, Carr AB. Distortion of three-unit implant frameworks during casting, soldering, and simulated porcelain firings. J Prosthodont. 1999. 8:171–179.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Implant supported prosthetic rehabilitation of severely atrophic mandible with fixed detachable prosthesis

- Clinical cases of implant-supported fixed dental prosthesis using modified lingual screw system (T-screw system)

- Full mouth rehabilitation of fully edentulous patient with implant-supported fixed prosthesis preceding bone graft: A case report

- Burnishing effect on marginal misfit of implant-supported screw-and-cement retained prostheses: A case report

- Implant-supported fixed prosthesis in patient with severe defects using staged GBR via 2-step augmentations: A case report