J Adv Prosthodont.

2013 May;5(2):161-166. 10.4047/jap.2013.5.2.161.

Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency

- Affiliations

-

- 1Department of Dental Laboratory Science and Engineering, College of Health Science, Korea University, Seoul, Republic of Korea. kuc2842@korea.ac.kr

- 2Dental Research Institute and Department of Dental Biomaterials Science, School of Dentistry, Seoul National University, Seoul, Republic of Korea. ahnjin@snu.ac.kr

- KMID: 2284756

- DOI: http://doi.org/10.4047/jap.2013.5.2.161

Abstract

- PURPOSE

This study aimed to identify the effects of the sintering conditions of dental zirconia on the grain size and translucency.

MATERIALS AND METHODS

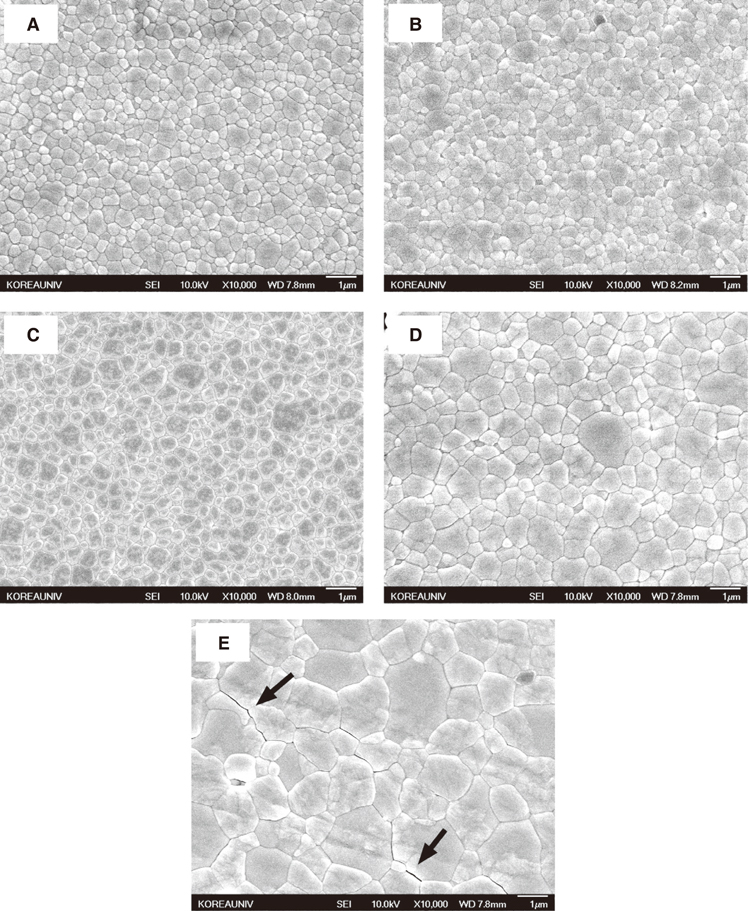

Ten specimens of each of two commercial brands of zirconia (Lava and KaVo) were made and sintered under five different conditions. Microwave sintering (MS) and conventional sintering (CS) methods were used to fabricate zirconia specimens. The dwelling time was 20 minutes for MS and 20 minutes, 2, 10, and 40 hours for CS. The density and the grain size of the sintered zirconia blocks were measured. Total transmission measurements were taken using a spectrophotometer. Two-way analysis of variance model was used for the analysis and performed at a type-one error rate of 0.05.

RESULTS

There was no significant difference in density between brands and sintering conditions. The mean grain size increased according to sintering conditions as follows: MS-20 min, CS-20 min, CS-2 hr, CS-10 hr, and CS-40 hr for both brands. The mean grain size ranged from 347-1,512 nm for Lava and 373-1,481 nm for KaVo. The mean light transmittance values of Lava and KaVo were 28.39-34.48% and 28.09-30.50%, respectively.

CONCLUSION

Different sintering conditions resulted in differences in grain size and light transmittance. To obtain more translucent dental zirconia restorations, shorter sintering times should be considered.

Keyword

Figure

Cited by 2 articles

-

Influence of heating rate on the flexural strength of monolithic zirconia

Caner Öztürk, Ersan Çelik

J Adv Prosthodont. 2019;11(4):202-208. doi: 10.4047/jap.2019.11.4.202.Evaluation of translucency of monolithic zirconia and framework zirconia materials

İlkin Tuncel, Işıl Turp, Aslıhan Üşümez

J Adv Prosthodont. 2016;8(3):181-186. doi: 10.4047/jap.2016.8.3.181.

Reference

-

1. Kelly JR, Nishimura I, Campbell SD. Ceramics in dentistry: historical roots and current perspectives. J Prosthet Dent. 1996; 75:18–32.2. Fischer H, Weber M, Marx R. Lifetime prediction of all-ceramic bridges by computational methods. J Dent Res. 2003; 82:238–242.3. Conrad HJ, Seong WJ, Pesun IJ. Current ceramic materials and systems with clinical recommendations: a systematic review. J Prosthet Dent. 2007; 98:389–404.4. Tinschert J, Natt G, Mautsch W, Augthun M, Spiekermann H. Fracture resistance of lithium disilicate-, alumina-, and zirconia-based three-unit fixed partial dentures: a laboratory study. Int J Prosthodont. 2001; 14:231–238.5. Chen YM, Smales RJ, Yip KH, Sung WJ. Translucency and biaxial flexural strength of four ceramic core materials. Dent Mater. 2008; 24:1506–1511.6. Akagawa Y, Hosokawa R, Sato Y, Kamayama K. Comparison between freestanding and tooth-connected partially stabilized zirconia implants after two years' function in monkeys: a clinical and histologic study. J Prosthet Dent. 1998; 80:551–558.7. Ichikawa Y, Akagawa Y, Nikai H, Tsuru H. Tissue compatibility and stability of a new zirconia ceramic in vivo. J Prosthet Dent. 1992; 68:322–326.8. Scarano A, Di Carlo F, Quaranta M, Piattelli A. Bone response to zirconia ceramic implants: an experimental study in rabbits. J Oral Implantol. 2003; 29:8–12.9. Rosenstiel SF, Land MF, Fujimoto J. Contemporary Fixed Prosthodontics. 4th ed. St. Louis: Mosby;2006. p. 262. p. 643.10. Yu B, Ahn JS, Lee YK. Measurement of translucency of tooth enamel and dentin. Acta Odontol Scand. 2009; 67:57–64.11. Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. Relative translucency of six all-ceramic systems. Part I: core materials. J Prosthet Dent. 2002; 88:4–9.12. Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. Relative translucency of six all-ceramic systems. Part II: core and veneer materials. J Prosthet Dent. 2002; 88:10–15.13. Vichi A, Louca C, Corciolani G, Ferrari M. Color related to ceramic and zirconia restorations: a review. Dent Mater. 2011; 27:97–108.14. Brodbelt RH, O'Brien WJ, Fan PL. Translucency of dental porcelains. J Dent Res. 1980; 59:70–75.15. Peelen JGJ, Metselaar R. Light-scattering by pores in polycrystalline materials: transmission properties of alumina. J Appl Phys. 1974; 45:216–220.16. Zhang HB, Kim BN, Morita K, Yoshida H, Lim JH, Hiraga K. Optimization of high-pressure sintering of transparent zirconia with nano-sized grains. J Alloys Compd. 2010; 508:196–199.17. Clarke FJ. McLean JW, editor. Measurement of color of human teeth. Proceedings of the First International Symposium on Ceramics. 1983. Chicago: Quintessence;p. 441–490.18. Casolco SR, Xu J, Garay JE. Transparent/translucent polycrystalline nanostructured yttria stabilized zirconia with varying colors. Scr Mater. 2008; 58:516–519.19. Jiang L, Liao Y, Wan Q, Li W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med. 2011; 22:2429–2435.20. Anselmi-Tamburini U, Woolman JN, Munir ZA. Transparent nanometric cubic and tetragonal zirconia obtained by high-pressure pulsed electric current sintering. Adv Funct Mater. 2007; 17:3267–3273.21. Yang D, Raj R, Conrad H. Enhanced sintering rate of Zirconia (3Y-TZP) through the effect of a weak dc electric field on grain growth. J Am Ceram Soc. 2010; 93:2935–2937.22. Janney MA, Calhoun CL, Kimrey HD. Microwave sintering of solid oxide fuel cell materials: I, Zirconia-8 mol% Yttria. J Am Ceram Soc. 1992; 75:341–346.23. Li JF, Watanabe R. Phase Transformation in Y2O3-Partially-Stabilized ZrO2 Polycrystals of Various Grain Sizes during Low-Temperature Aging in Water. J Am Ceram Soc. 1998; 81:2687–2691.24. Ebadzadeh T, Valefi M. Microwave-assisted sintering of zircon. J Alloys Compd. 2008; 448:246–249.25. Cheng J, Agrawal D, Zhang Y, Roy R. Microwave sintering of transparent alumina. Mater Lett. 2002; 56:587–592.26. Luo J, Adak S, Stevens R. Microstructure evolution and grain growth in the sintering of 3Y-TZP ceramics. J Mater Sci. 1998; 33:5301–5309.27. ISO 18754 - Fine ceramics-advanced ceramics, advanced technical ceramics-Determination of density and apparent porosity. Geneva; Switzerland: ISO;2008.28. ASTM. Standard test method for determining average grain size E112-96. Part 301. 2003. p. 243–266.29. Mendelson MI. Average Grain Size in Polycrystalline Ceramics. J Am Ceram Soc. 1969; 52:443–446.30. Cook WD, McAree DC. Optical properties of esthetic restorative materials and natural dentition. J Biomed Mater Res. 1985; 19:469–488.31. Lee YK. Influence of scattering/absorption characteristics on the color of resin composites. Dent Mater. 2007; 23:124–131.32. O'Brien WJ, Johnston WM, Fanian F. Double-layer color effects in porcelain systems. J Dent Res. 1985; 64:940–943.33. Hayashi K, Kobayashi O, Toyoda S, Morinaga K. Transmission optical properties of polycrystalline alumina with submicron grains. Mater Trans JIM. 1991; 32:1024–1029.34. O YT, Koo JB, Hong KJ, Park JS, Shin DC. Effect of grain size on transmittance and mechanical strength of sintered alumina. Mat Sci Eng A. 2004; 374:191–195.35. Apetz R, van Bruggen MPB. Transparent alumina: A light scattering model. J Am Ceram Soc. 2003; 86:480–486.36. Alaniz JE, Perez-Gutierrez FG, Aguilar G, Garay JE. Optical properties of transparent nanocrystalline yttria stabilized zirconia. Opt Mater. 2009; 32:62–68.37. ISO 13356 - Implants for surgery-Ceramic materials based on yttria-stabilized tetragonal zirconia (Y-TZP). Geneva; Switzerland: ISO;2008.38. Tekeli S, Erdogan M. A quantitative assessment of cavities in 3 mol% yttria-stabilized tetragonal zirconia specimens containing various grain size. Ceram Int. 2002; 28:785–789.39. Hjerppe J, Vallittu PK, Fröberg K, Lassila LV. Effect of sintering time on biaxial strength of zirconium dioxide. Dent Mater. 2009; 25:166–171.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of the optical properties of pre-colored dental monolithic zirconia ceramics sintered in a conventional furnace versus a microwave oven

- Evaluation of translucency of monolithic zirconia and framework zirconia materials

- Review on factors affecting the optical properties of dental zirconia

- Grain size, crystalline phase and fracture toughness of the monolithic zirconia

- Comparison of the translucency of shaded zirconia all-ceramic systems