J Korean Acad Prosthodont.

2012 Apr;50(2):92-98. 10.4047/jkap.2012.50.2.92.

Effect of various abutment systems on the removal torque and the abutment settling in the conical connection implant systems

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Dankook University, Cheonan, Korea. joon322@dku.edu

- KMID: 2195496

- DOI: http://doi.org/10.4047/jkap.2012.50.2.92

Abstract

- PURPOSE

The aim of this study was to evaluate the effects of different abutment materials on abutment screw loosening and settling-down effect in conical connection type implant system.

MATERIALS AND METHODS

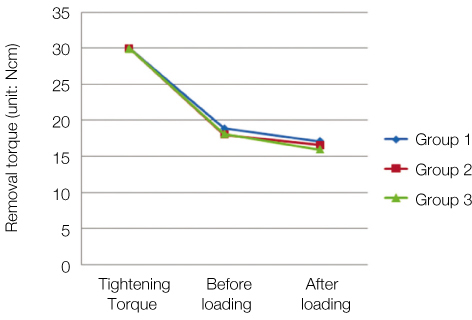

Three types of abutment, cementation, gold UCLA, and metal UCLA abutment were used. Two UCLA groups were fabricated in a similar pattern to cementation abutment. Type III gold alloy and Nickel-Chromium alloy was used for casting gold UCLA abutment and metal UCLA abutment, respectively. Fixture and abutment were tightened to 30 Ncm by using digital torque controller and re-tightening was conducted with same force after 10 minutes. Digital torque gauge was used to measure loosening torque and fixture/abutment length was measured by digital micrometer. Dynamic loads between 25 N and 250 N were applied with 0degreesangle to the abutment axis. After loading, fixture/abutment length was re-measured and amount of settlement was calculated. Loosening torque value was also measured for comparison.

RESULTS

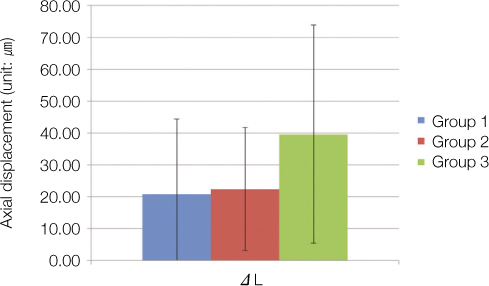

All three groups showed significant differences of length when comparing before and after loading, but there was no significant difference of settling amount in all groups. Loosening torque values were significantly decreased when comparing before and after loading in all groups(P<.05). However, there was no significant difference in loss of loosening torque values when compared to groups.

CONCLUSION

In internal conical connection type implants, dynamic load affected on settlement and loosening torque of implant, but there was no differences between abutments materials. Likewise gold UCLA abutment, metal UCLA abutment might be able to withstand functional load.

Figure

Reference

-

1. Adell R, Lekholm U, Rockler B, Brånemark PI. A 15-year study of osseointegrated implants in the treatment of the edentulous jaw. Int J Oral Surg. 1981. 10:387–416.

Article2. Goodacre CJ, Bernal G, Rungcharassaeng K, Kan JY. Clinical complications with implants and implant prostheses. J Prosthet Dent. 2003. 90:121–132.

Article3. Becker W, Becker BE. Replacement of maxillary and mandibular molars with single endosseous implant restorations: a retrospective study. J Prosthet Dent. 1995. 74:51–55.

Article4. Jemt T, Lindén B, Lekholm U. Failures and complications in 127 consecutively placed fixed partial prostheses supported by Brånemark implants: from prosthetic treatment to first annual checkup. Int J Oral Maxillofac Implants. 1992. 7:40–44.

Article5. Quek HC, Tan KB, Nicholls JI. Load fatigue performance of four implant-abutment interface designs: effect of torque level and implant system. Int J Oral Maxillofac Implants. 2008. 23:253–262.6. Simon RL. Single implant-supported molar and premolar crowns: a ten-year retrospective clinical report. J Prosthet Dent. 2003. 90:517–521.

Article7. Jemt T, Laney WR, Harris D, Henry PJ, Krogh PH Jr, Polizzi G, Zarb GA, Herrmann I. Osseointegrated implants for single tooth replacement: a 1-year report from a multicenter prospective study. Int J Oral Maxillofac Implants. 1991. 6:29–36.8. Jörnéus L, Jemt T, Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992. 7:353–359.9. Shigley JE, Mische CR. Standard Handbook of Machine Designs. 1986. New York: McGraw-Hill;16–23.10. Kim KS, Lim YJ, Kim MJ, Kwon HB, Yang JH, Lee JB, Yim SH. Variation in the total lengths of abutment/implant assemblies generated with a function of applied tightening torque in external and internal implant-abutment connection. Clin Oral Implants Res. 2011. 22:834–839.

Article11. Siamos G, Winkler S, Boberick KG. Relationship between implant preload and screw loosening on implant-supported prostheses. J Oral Implantol. 2002. 28:67–73.

Article12. Ricciardi Coppedê A, de Mattos Mda G, Rodrigues RC, Ribeiro RF. Effect of repeated torque/mechanical loading cycles on two different abutment types in implants with internal tapered connections: an in vitro study. Clin Oral Implants Res. 2009. 20:624–632.13. Weiss EI, Kozak D, Gross MD. Effect of repeated closures on opening torque values in seven abutment-implant systems. J Prosthet Dent. 2000. 84:194–199.

Article14. Lewis S, Avera S, Engleman M, Beumer J 3rd. The restoration of improperly inclined osseointegrated implants. Int J Oral Maxillofac Implants. 1989. 4:147–152.15. Lewis SG, Llamas D, Avera S. The UCLA abutment: a four-year review. J Prosthet Dent. 1992. 67:509–515.

Article16. Carotenuto G, Palumbo M, Zarone F, Nicolais L. Characterization of the interface between prefabricated gold copings and cast dental alloy in implant restorations. Clin Oral Implants Res. 1999. 10:131–138.

Article17. O'Brien WJ. O'Brien WJ, editor. Base metal casting alloys. Dental material and their selection. 1997. Quintessence;259–268.18. Kano SC, Bonfante G, Hussne R, Siqueira AF. Use of base metal casting alloys for implant framework: marginal accuracy analysis. J Appl Oral Sci. 2004. 12:337–343.

Article19. Lim JH, Lee MR, Cho IH. A study on the photoelastic analysis of stresses induced by the connection modalities between natural tooth abutment and dental implant. J Dankook Dent Res Inst. 1992. 4:141–151.20. Artzi Z, Dreiangel A. A screw lock for single-tooth implant superstructures. J Am Dent Assoc. 1999. 130:677–682.

Article21. Schwarz MS. Mechanical complications of dental implants. Clin Oral Implants Res. 2000. 11:156–158.

Article22. Cavazos E, Bell FA. Preventing loosening of implant abutment screws. J Prosthet Dent. 1996. 75:566–569.

Article23. Kang YM, Lim JH, Cho IH. A study on the abutment screw loosening of dental implants. J Korean Acad Prosthodont. 1996. 34:1–14.24. Im SM, Kim DG, Park CJ, Cha MS, Cho LR. Biomechanical considerations for the screw of implant prosthesis: A literature review. J Korean Acad Prosthodont. 2010. 48:61–68.

Article25. Dailey B, Jordan L, Blind O, Tavernier B. Axial displacement of abutments into implants and implant replicas, with the tapered cone-screw internal connection, as a function of tightening torque. Int J Oral Maxillofac Implants. 2009. 24:251–256.26. Sutter F, Weber HP, Sorensen J, Belser U. The new restorative concept of the ITI dental implant system: design and engineering. Int J Periodont Rest Dent. 1993. 13:409–431.27. Choi JU, Jeong CM, Jeon YC, Lim JS, Jeong HC, Eom TG. Influence of tungsten carbide/carbon coating on the preload of implant abutment screws. J Korean Acad Prosthodont. 2006. 44:229–242.28. Norton MR. An in vitro evaluation of the strength of a 1-piece and 2-piece conical abutment joint in implant design. Clin Oral Implants Res. 2000. 11:458–464.

Article29. Mericske-Stern R, Zarb GA. In vivo measurements of some functional aspects with mandibular fixed prostheses supported by implants. Clin Oral Implants Res. 1996. 7:153–161.

Article30. Richter EJ. In vivo vertical forces on implants. Int J Oral Maxillofac Implants. 1995. 10:99–108.31. Wataha JC. Biocompatibility of dental casting alloys: a review. J Prosthet Dent. 2000. 83:223–234.

Article32. White GE. Osseointegrated dental technology. 1993. Carol Stream, IL: Quintessence;70–83.33. Hulterström M, Nilsson U. Cobalt-chromium as a framework material in implant-supported fixed prostheses: a preliminary report. Int J Oral Maxillofac Implants. 1991. 6:475–480.34. Geis-Gerstorfer J, Weber H, Sauer KH. In vitro substance loss due to galvanic corrosion in Ti implant/Ni-Cr supraconstruction systems. Int J Oral Maxillofac Implants. 1989. 4:119–123.35. Lee JJ, Song KY, Ahn SK, Park JM. Surface roughness changes caused by the galvanic corrosion between a titanium abutment and base metal alloy. J Korean Acad Prosthodont. 2011. 49:65–72.

Article36. Oh KT, Kim KN. Electrochemical properties of suprastructures galvanically coupled to a titanium implant. J Biomed Mater Res B Appl Biomater. 2004. 70:318–331.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of a counter-torque device and the internal hexagon of abutment on the tightening torque transmitted to the implant

- The influence of abutment screw tightening timing and DLC coating of conical connection implant system

- Influence of abutment materials on the implant-abutment joint stability in internal conical connection type implant systems

- Screw Joint Stability under Cyclic Loading of Zirconia Implant Abutments

- Influence of Tightening Torque on Implant-Abutment Screw Joint Stability