J Dent Rehabil Appl Sci.

2023 Jun;39(2):79-88. 10.14368/jdras.2023.39.2.79.

Comparison of shear bond strength between hard relining material and 3D-printing denture base resin containing silica micro-gel

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Dankook University, Cheonan, Republic of Korea

- KMID: 2549275

- DOI: http://doi.org/10.14368/jdras.2023.39.2.79

Abstract

- Purpose

Various methods have been attempted to overcome limitations of physical characteristics of 3D-printed dentures; among them a novel method of increasing fracture strength by adding fine particles into the resin has been found to be effective. However, there are still limited research on the effect of these particles on the bond strength between the printed resin and denture relining materials. The purpose of this study is to compare the shear bond strength between the 3D-printing denture base resin and various relining materials when micro-particles on the surface of the resin are removed.

Materials and Methods

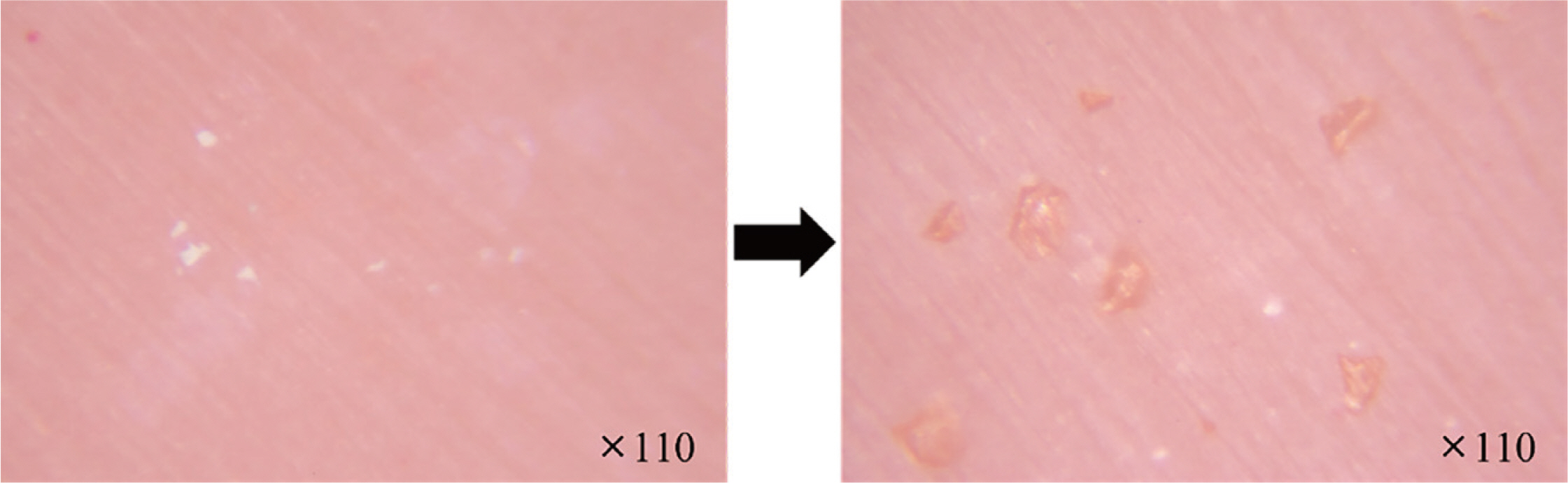

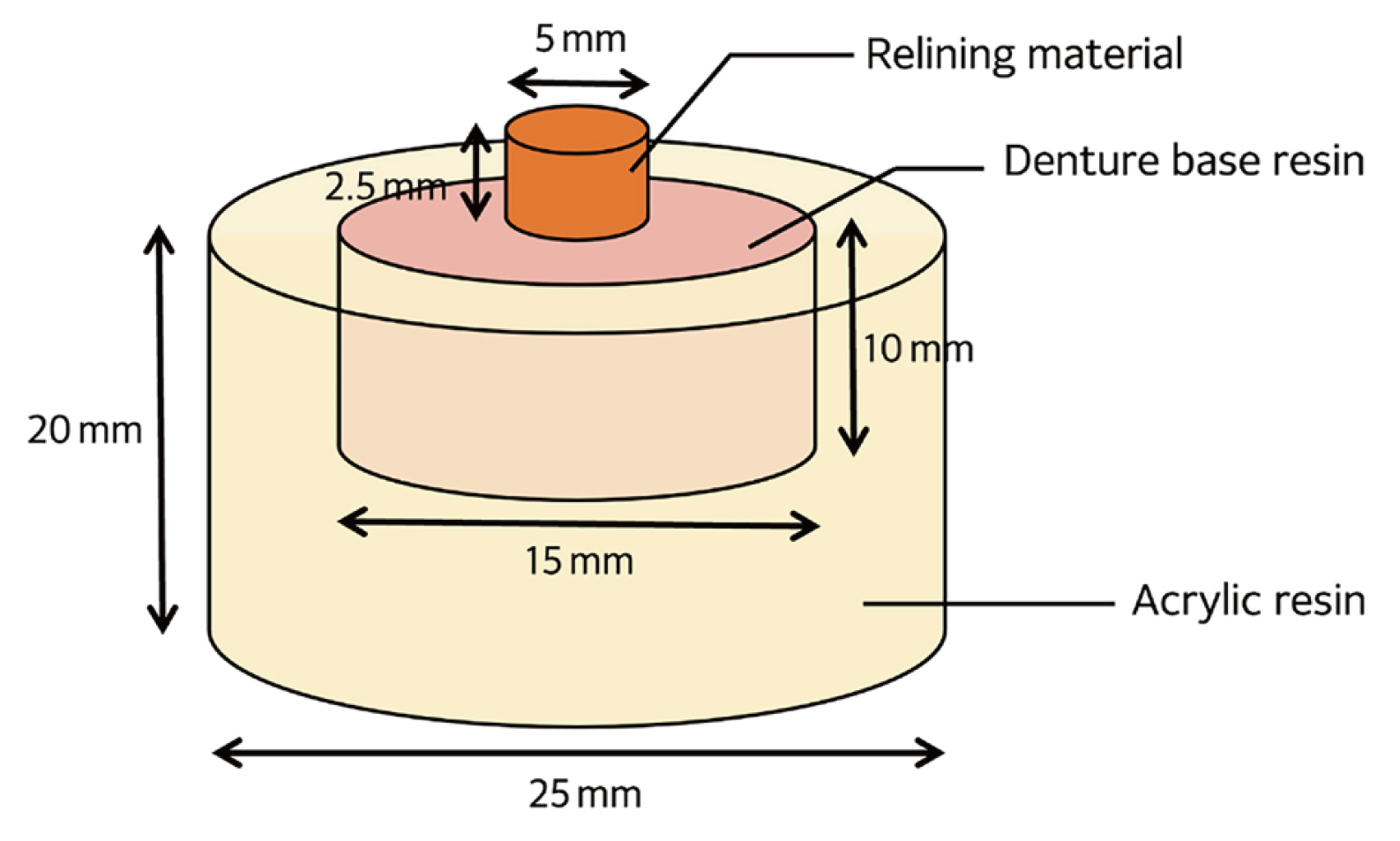

63 µm-sized silica microgels were mixed into 3D-printing denture base resin to make groups of weight ratio of 2 wt% and 3 wt%. After printing all 3 groups, including the control group, an HF etching solution was applied to dissolve the silica micro-particles on the surface. Three kinds of relining materials, Tokuyama Rebase II normal, KOOLINER, and ProBase Cold were attached to the surface. The shear bond strength values and the failure modes for each group were analyzed.

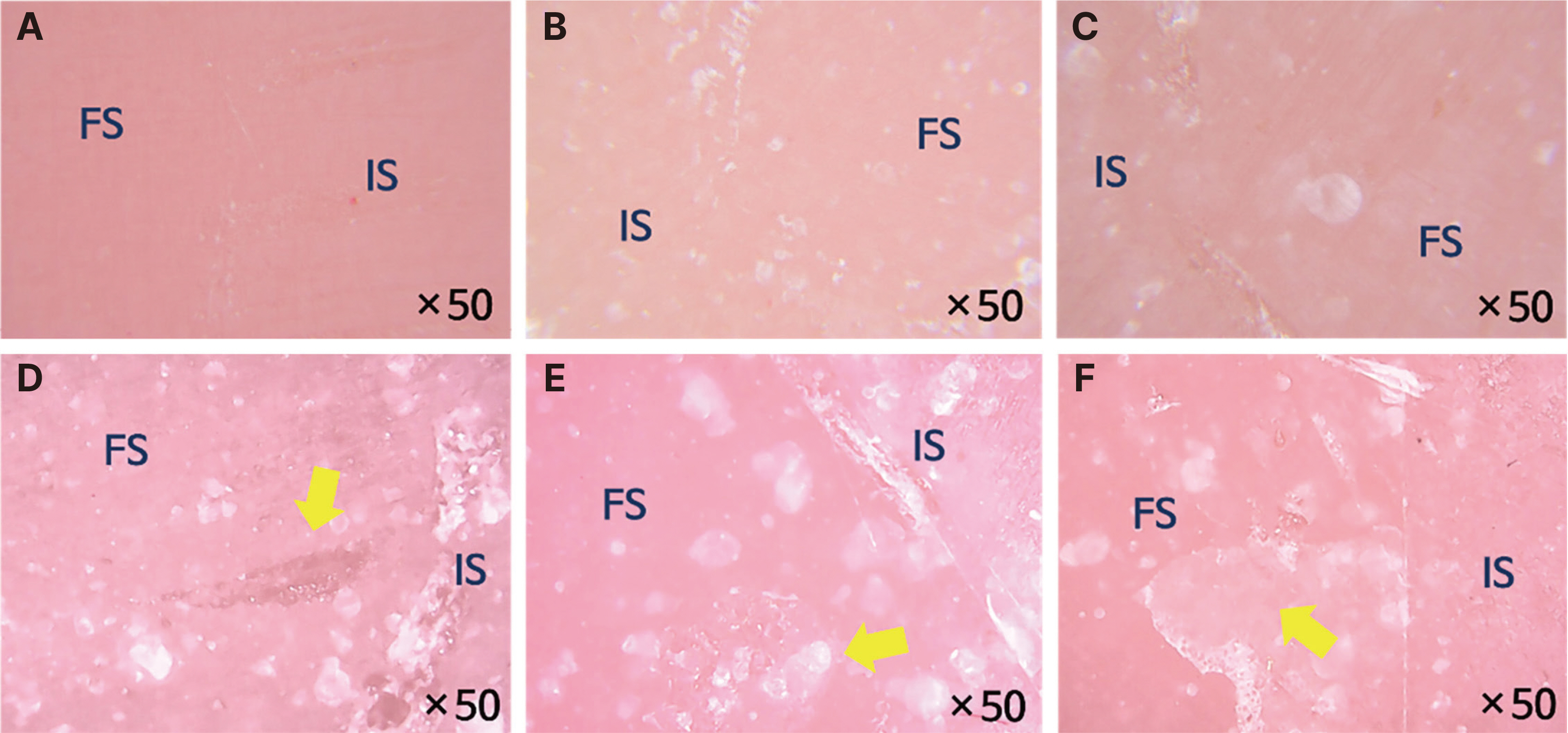

Results

The shear bond strength showed the largest average value in the control group, in which silica was not mixed, among all three relining materials. Also, there were significant differences between specimens with different weight ratios. The largest value was measured in ProBase Cold, and the main failure mode was adhesive failure in all groups.

Conclusion

The shear bond strength was significantly reduced when the silica micro-particles on the surface were removed from the 3D printing denture base resin.

Keyword

Figure

Reference

-

References

1. Faty MA, Sabet ME, Thabet YG. 2022; Sep. 22. A comparison of denture base retention and adaptation between CAD-CAM and conventional fabrication techniques. Int J Prosthodont. doi: 10.11607/ijp.7193. Online ahead of print. DOI: 10.11607/ijp.7193. PMID: 33662053.

Article2. Goodacre CJ, Garbacea A, Naylor WP, Daher T, Marchack CB, Lowry J. 2012; CAD/CAM fabricated complete dentures: concepts and clinical methods of obtaining required morphological data. J Prosthet Dent. 107:34–46. DOI: 10.1016/S0022-3913(12)60015-8. PMID: 22230914.

Article3. Kattadiyil MT, AlHelal A. 2017; An update on computer-engineered complete dentures: A systematic review on clinical outcomes. J Prosthet Dent. 117:478–85. DOI: 10.1016/j.prosdent.2016.08.017. PMID: 27881317.4. Dimitrova M, Corsalini M, Kazakova R, Vlahova A, Chuchulska B, Barile G, Capodiferro S, Kazakov S. 2022; Comparison between Conventional PMMA and 3D Printed Resins for Denture Bases: A Narrative Review. J Compos Sci. 6:87. DOI: 10.3390/jcs6030087. PMID: d8367d2e9d3c48cbaef94c7050e362dc.

Article5. Totu EE, Nechifor AC, Nechifor G, Aboul-Enein HY, Cristache CM. 2017; Poly(methyl methacrylate) with TiO2 nanoparticles inclusion for stereolitographic complete denture manufacturing - the fututre in dental care for elderly edentulous patients? J Dent. 59:68–77. DOI: 10.1016/j.jdent.2017.02.012. PMID: 28223199.

Article6. Tallgren A. 2003; The continuing reduction of the residual alveolar ridges in complete denture wearers: a mixed-longitudinal study covering 25 years. J Prosthet Dent. 89:427–35. DOI: 10.1016/S0022-3913(03)00158-6. PMID: 12806317.

Article7. Cho SY, Song YG. 2021; A comparison study on shear bond strength of 3D printed resin and conventional heat-cured denture base resin to denture relining materials. J Dent Rehabil Appl Sci. 37:232–43. DOI: 10.14368/jdras.2021.37.4.232.

Article8. Koseoglu M, Tugut F, Akin H. 2023; Tensile bond strength of soft and hard relining materials to conventional and additively manufactured denture-base materials. J Prosthodont. 32:74–80. DOI: 10.1111/jopr.13608. PMID: 36111532.

Article9. Kim HS, Jung JH, Bae JM, Kim JM, Kim YL. 2020; Tensile bond strength of chairside reline resin to denture bases fabricated by subtractive and additive manufacturing. J Korean Acad Prosthodont. 58:177–84. DOI: 10.4047/jkap.2020.58.3.177.

Article10. Gad MM, Rahoma A, Abualsaud R, Al-Thobity AM, Akhtar S, Helal MA, Al-Harbi FA. 2020; Impact of different surface treatments and repair material reinforcement on the flexural strength of repaired PMMA denture base material. Dent Mater J. 39:471–82. DOI: 10.4012/dmj.2018-436. PMID: 32092720.

Article11. Jeong JW, Song YG. 2021; Investigation of effect of zirconia on osseointegration by surface treatments. J Dent Rehabil Appl Sci. 37:23–30. DOI: 10.14368/jdras.2021.37.1.23.

Article12. Wang C, Shi YF, Xie PJ, Wu JH. 2021; Accuracy of digital complete dentures: A systematic review of in vitro studies. J Prosthet Dent. 125:249–56. DOI: 10.1016/j.prosdent.2020.01.004. PMID: 32115218.13. Awad AN, Cho SH, Kesterke MJ, Chen JH. 2023; Comparison of tensile bond strength of denture reline materials on denture bases fabricated with CAD-CAM technology. J Prosthet Dent. 129:616–22. DOI: 10.1016/j.prosdent.2021.06.047. PMID: 34373111.

Article14. Mutluay MM, Ruyter IE. 2005; Evaluation of adhesion of chairside hard relining materials to denture base polymers. J Prosthet Dent. 94:445–52. DOI: 10.1016/j.prosdent.2005.08.011. PMID: 16275305.

Article15. Palitsch A, Hannig M, Ferger P, Balkenhol M. 2012; Bonding of acrylic denture teeth to MMA/PMMA and light-curing denture base materials: the role of conditioning liquids. J Dent. 40:210–21. DOI: 10.1016/j.jdent.2011.12.010. PMID: 22207164.

Article16. Wemken G, Burkhardt F, Spies BC, Kleinvogel L, Adali U, Sterzenbach G, Beuer F, Wesemann C. 2021; Bond strength of conventional, subtractive, and additive manufactured denture bases to soft and hard relining materials. Dent Mater. 37:928–38. DOI: 10.1016/j.dental.2021.02.018. PMID: 33722400.

Article17. Khaled SM, Sui R, Charpentier PA, Rizkalla AS. 2007; Synthesis of TiO2-PMMA Nanocomposite: Using Methacrylic Acid as a Coupling Agent. Langmuir. 23:3988–95. DOI: 10.1021/la062879n. PMID: 17316031.

Article18. Alshaikh AA, Khattar A, Almindil IA, Alsaif MH, Akhtar S, Khan SQ, Gad MM. 2022; 3D-Printed Nanocomposite Denture-Base Resins: Effect of ZrO2 Nanoparticles on the Mechanical and Surface Properties In Vitro. Nanomaterials (Basel). 12:2451. DOI: 10.3390/nano12142451. PMID: 35889675. PMCID: PMC9315924. PMID: 38502d1014384a459632fccc2ebd4e44.

Article19. Aati S, Aneja S, Kassar M, Leung R, Nguyen A, Tran S, Shrestha B, Fawzy A. 2022; Silver-loaded mesoporous silica nanoparticles enhanced the mechanical and antimicrobial properties of 3D printed denture base resin. J Mech Behav Biomed Mater. 134:105421. DOI: 10.1016/j.jmbbm.2022.105421. PMID: 36037709.

Article20. Gad MM, Al-Harbi FA, Akhtar S, Fouda SM. 2022; 3D-Printable Denture Base Resin Containing SiO2 Nanoparticles: An In Vitro Analysis of Mechanical and Surface Properties. J Prosthodont. 31:784–90. DOI: 10.1111/jopr.13483. PMID: 35061921.21. Alkurt M, Yeşil Duymuş Z, Gundogdu M. 2014; Effect of repair resin type and surface treatment on the repair strength of heat-polymerized denture base resin. J Prosthet Dent. 111:71–8. DOI: 10.1016/j.prosdent.2013.09.007. PMID: 24161257.

Article22. Park SJ, Lee JS. 2022; Effect of surface treatment on shear bond strength of relining material and 3D-printed denture base. J Adv Prosthodont. 14:262–72. DOI: 10.4047/jap.2022.14.4.262. PMID: 36105879. PMCID: PMC9444486.

Article23. Cevik P, Yildirim-Bicer AZ. 2018; The effect of silica and prepolymer nanoparticles on the mechanical properties of denture base acrylic resin. J Prosthodont. 27:763–70. DOI: 10.1111/jopr.12573. PMID: 27898997.

Article24. Qi DM, Bao YZ, Weng ZX, Huang ZM. 2006; Preparation of acrylate polymer/silica nanocomposite particles with high silica encapsulation efficiency via miniemulsion polymerization. Polymer. 47:4622–9. DOI: 10.1016/j.polymer.2006.04.024.

Article25. Spierings G. 1993; Wet chemical etching of silicate glasses in hydrofluoric acid based solutions. J Mater Sci. 28:6261–73. DOI: 10.1007/BF01352182.

Article26. Donmez MB, Okutan Y, Yucel MT. 2020; Effect of prolonged application of single-step self-etching primer and hydrofluoric acid on the surface roughness and shear bond strength of CAD/CAM materials. Eur J Oral Sci. 128:542–9. DOI: 10.1111/eos.12747. PMID: 33247878.

Article27. Quaas AC, Yang B, Kern M. 2007; Panavia F 2.0 bonding to contaminated zirconia ceramic after different cleaning procedures. Dent Mater. 23:506–12. DOI: 10.1016/j.dental.2006.03.008. PMID: 16893563.

Article28. Jeong KW, Kim SH. 2019; Influence of surface treatments and repair materials on the shear bond strength of CAD/CAM provisional restorations. J Adv Prosthodont. 11:95–104. DOI: 10.4047/jap.2019.11.2.95. PMID: 31080570. PMCID: PMC6491361.

Article29. Lim NK, Shin SY. 2020; Bonding of conventional provisional resin to 3D printed resin: the role of surface treatments and type of repair resins. J Adv Prosthodont. 12:322–8. DOI: 10.4047/jap.2020.12.5.322. PMID: 33149854. PMCID: PMC7604236.

Article30. Qaw MS, Abushowmi TH, Almaskin DF, AlZaher ZA, Gad MM, Al-Harbi FA, Abualsaud R, Ammar MM. 2020; A Novel Approach to Improve Repair Bond Strength of Repaired Acrylic Resin: An in Vitro Study on the Shear Bond Strength. J Prosthodont. 29:323–33. DOI: 10.1111/jopr.12970. PMID: 30298674.

Article31. Silva Cde S, Machado AL, Chaves Cde A, Pavarina AC, Vergani CE. 2013; Effect of thermal cycling on denture base and autopolymerizing reline resins. J Appl Oral Sci. 21:219–24. DOI: 10.1590/1679-775720130061. PMID: 23857648. PMCID: PMC3881901. PMID: 97f6e0b7bbd14d2bb97c68e8d0524bd2.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A comparison study on shear bond strength of 3D printed resin and conventional heat-cured denture base resin to denture relining materials

- Effect of surface treatment on shear bond strength between artificial resin teeth and 3D printing denture base resin

- Effect of surface treatment on shear bond strength of relining material and 3D-printed denture base

- Nonthermal plasma on the shear bond strength of relining resin to thermoplastic denture base resin

- The Effects Of Thermocycling On The Bond Strength Between Cobalt-Chromium Alloy And Denture Base Resin