J Dent Rehabil Appl Sci.

2022 Dec;38(4):233-241. 10.14368/jdras.2022.38.4.233.

Evaluation of the dimensional change of 3D-printed complete denture after post-curing

- Affiliations

-

- 1Postgraduate School, College of Dentistry, Chosun University, Gwangju, Republic of Korea

- 2Department of Prosthodontics, College of Dentistry, Chosun University, Gwangju, Republic of Korea

- KMID: 2538521

- DOI: http://doi.org/10.14368/jdras.2022.38.4.233

Abstract

- Purpose

The purpose of this study was to assess the dimensional change of 3D-printed dentures after post-curing.

Materials and Methods

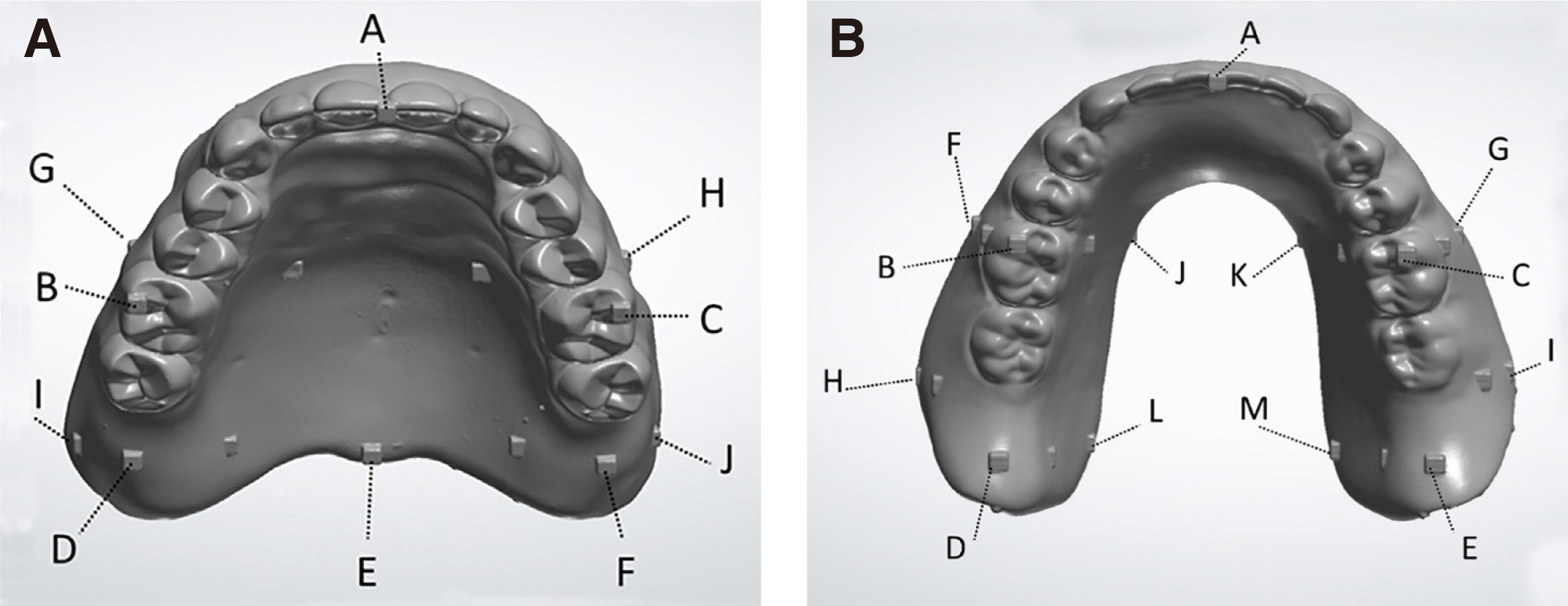

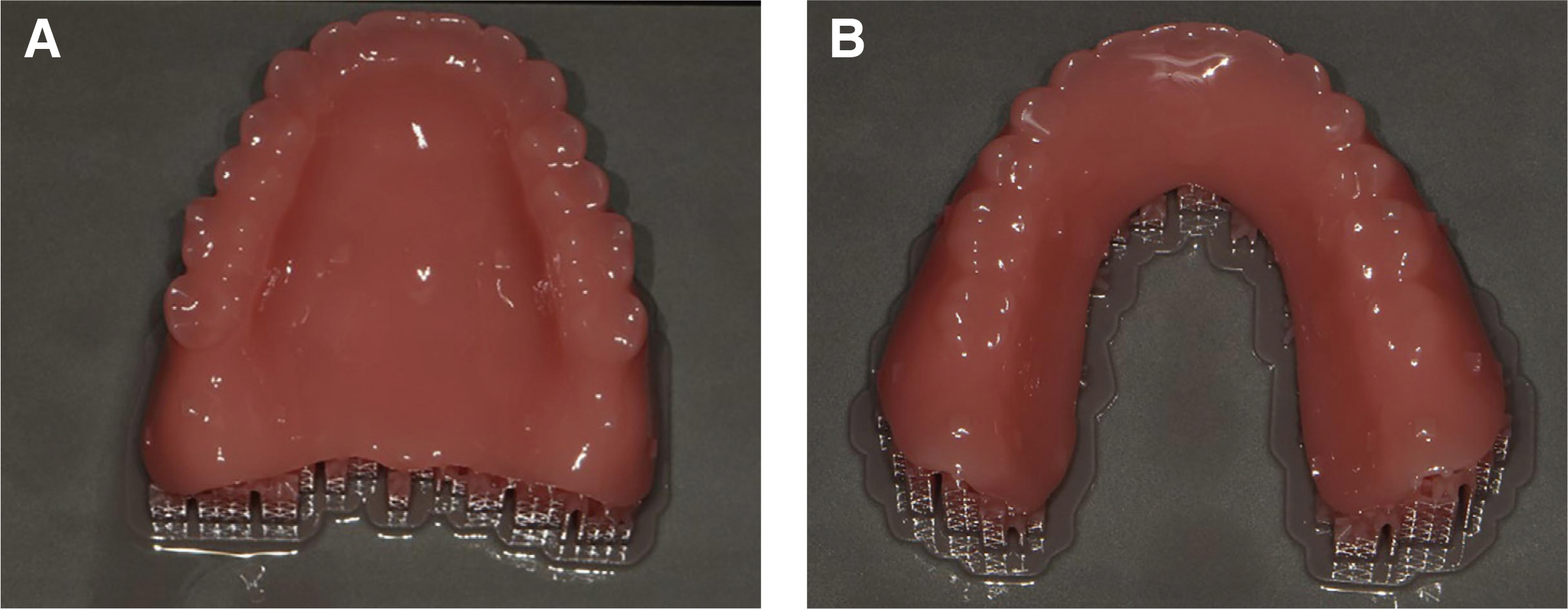

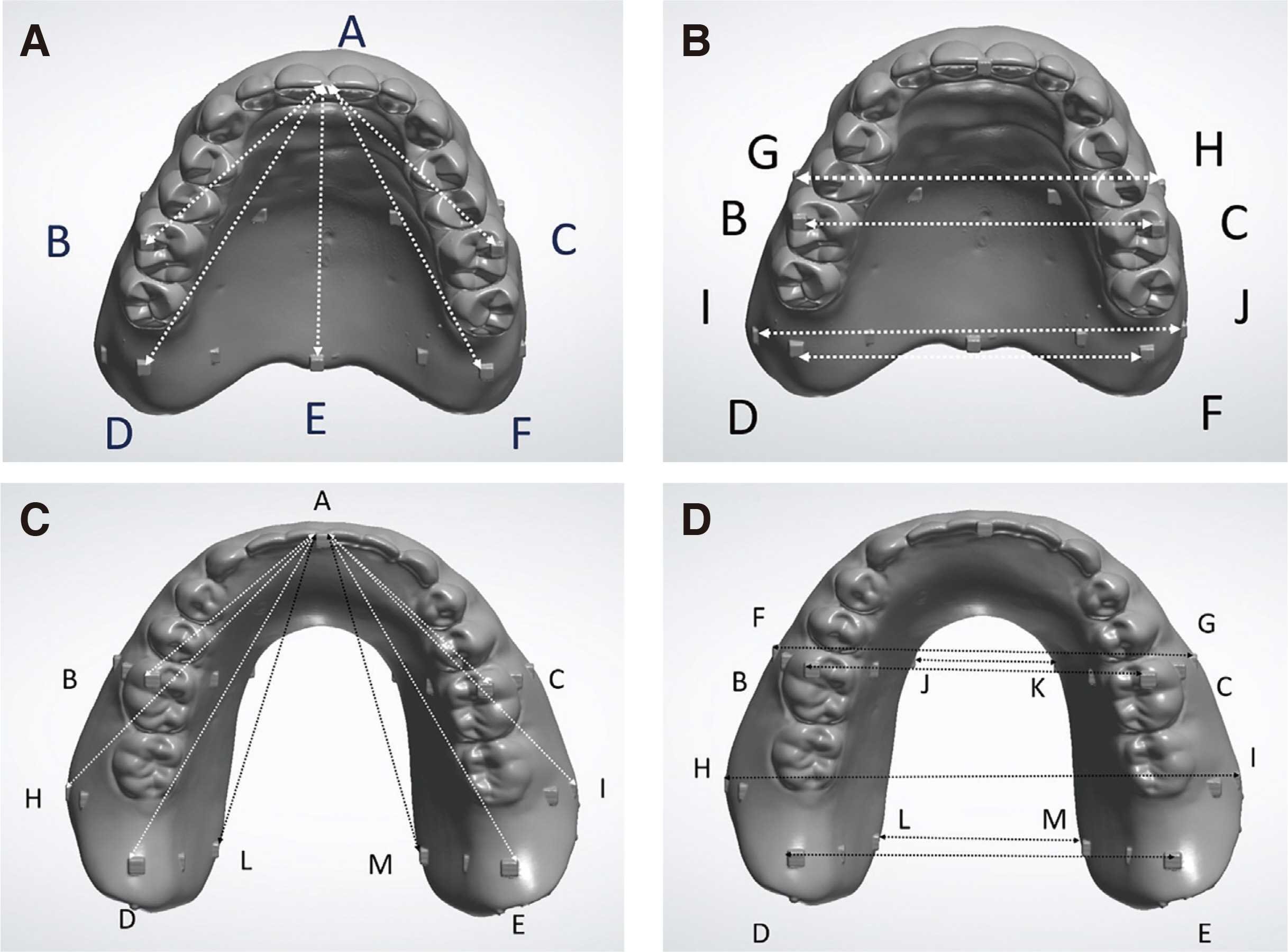

The upper and lower dentures were designed in Exocad DentalCAD software and exported as STL files. The upper and lower dentures were printed from 10 STL files using a DLP-type dental 3D printer. The printed upper and lower dentures were cleaned, and a scan file was created using a model scanner before and after post-curing. The dimensional change was evaluated by superimposing the scanned denture files before and after post-curing and measuring the distance between measurement points on the denture. SPSS was used for statistics, and the level of significance was 5%.

Results

The maxillary denture reduced in size during post-curing, with the most notable color change occurring in the posterior palatal region. The reduction in anteroposterior maxillary denture length (A-D, A-E, A-F), as well as the distance between the first molars on both sides (B-C), was statistically significant. After post-curing, the mandibular denture showed more noticeable color change in the posteriorly buccal and lingual region. The decrease of length on the posterior (A-M, A-D, A-E, A-L, A-H, A-I, H-I) and lingual (J-K, L-M) sides of the denture were statistically significant.

Conclusion

There was significant dimensional change in both the length and width of the 3D-printed maxillary and mandibular dentures after post-curing in this experiment. Consequently, it is seemed necessary to develop post-curing techniques and materials that reduce such denture deformation.

Keyword

Figure

Reference

-

References

1. Sa L, Kaiwu L, Shenggui C, Junzhong Y, Yongguang J, Lin W, Li R. 2019; 3D printing dental composite resins with sustaining antibacterial ability. J Mater Sci. 54:3309–18. DOI: 10.1007/s10853-018-2801-7. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85056359647&origin=inward.

Article2. van Noort R. 2012; The future of dental devices is digital. Dent Mater. 28:3–12. DOI: 10.1016/j.dental.2011.10.014. PMID: 22119539. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=84355161961&origin=inward.

Article3. Alsandi Q, Ikeda M, Arisaka Y, Nikaido T, Tsuchida Y, Sadr A, Yui N, Tagami J. 2021; Evaluation of mechanical and physical properties of light and heat polymerized UDMA for DLP 3D printer. Sensors. 21:3331. DOI: 10.3390/s21103331. PMID: 34064860. PMCID: PMC8151691. PMID: 7ff3c90e783d4af89a2881e0ca616a8c. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85105702624&origin=inward.

Article4. Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D. 2018; Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos B Eng. 143:172–96. DOI: 10.1016/j.compositesb.2018.02.012. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85042370094&origin=inward.

Article5. Kessler A, Hickel R, Reymus M. 2020; 3D printing in dentistry-state of the art. Oper Dent. 45:30–40. DOI: 10.2341/18-229-L. PMID: 31172871. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85077403555&origin=inward.

Article6. Dawood A, Marti Marti B, Sauret-Jackson V, Darwood A. 2015; 3D printing in dentistry. Br Dent J. 219:521–9. DOI: 10.1038/sj.bdj.2015.914. PMID: 26657435. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=84949575378&origin=inward.

Article7. Hwang HJ, Lee SJ, Park EJ, Yoon HI. 2019; Assessment of the trueness and tissue surface adaptation of CAD-CAM maxillary denture bases manufactured using digital light processing. J Prosthet Dent. 121:110–7. DOI: 10.1016/j.prosdent.2018.02.018. PMID: 30006217. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85049605702&origin=inward.

Article8. Han H, Cho S. 2018; Fabrication of conducting polyacrylate resin solution with polyaniline nanofiber and graphene for conductive 3D printing application. Polymers. 10:1003. DOI: 10.3390/polym10091003. PMID: 30960928. PMCID: PMC6403923. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85053378268&origin=inward.

Article9. Kalberer N, Mehl A, Schimmel M, Müller F, inivasan M Sr. 2019; CAD-CAM milled versus rapidly prototyped (3D-printed) complete dentures: an in vitro evaluation of trueness. J Prosthet Dent. 121:637–43. DOI: 10.1016/j.prosdent.2018.09.001. PMID: 30711292. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85060737754&origin=inward.10. Lee S, Hong SJ, Paek J, Pae A, Kwon KR, Noh K. 2019; Comparing accuracy of denture bases fabricated by injection molding, CAD/CAM milling, and rapid prototyping method. J Adv Prosthodont. 11:55–64. DOI: 10.4047/jap.2019.11.1.55. PMID: 30847050. PMCID: PMC6400705. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85063210417&origin=inward.

Article11. Yoon HI, Hwang HJ, Ohkubo C, Han JS, Park EJ. 2018; Evaluation of the trueness and tissue surface adaptation of CAD-CAM mandibular denture bases manufactured using digital light processing. J Prosthet Dent. 120:919–26. DOI: 10.1016/j.prosdent.2018.01.027. PMID: 29961610. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85049096349&origin=inward.

Article12. Tasaka A, Matsunaga S, Odaka K, Ishizakic K, Uedac T, Abe S, Yoshinarid M, Yamashita S, Sakurai K. 2019; Accuracy and retention of denture base fabricated by heat curing and additive manufacturing. J Prosthodont Res. 63:85–9. DOI: 10.1016/j.jpor.2018.08.007. PMID: 30584053. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85058820298&origin=inward.

Article13. Masri G, Mortada R, Ounsi H, Alharbi N, Boulos P, Salameh Z. 2020; Adaptation of complete denture base fabricated by conventional, milling, and 3-D printing techniques: An in vitro study. J Contemp Dent Pract. 21:367–71. DOI: 10.5005/jp-journals-10024-2770. PMID: 32584270. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85086328600&origin=inward.

Article14. Steinmassl O, Offermanns V, Stöckl W, Dumfahrt H, Grunert I, Steinmassl PA. 2018; In vitro analysis of the fracture resistance of CAD/CAM denture base resins. Materials. 11:401. DOI: 10.3390/ma11030401. PMID: 29518022. PMCID: PMC5872980. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85043326238&origin=inward.

Article15. Bayarsaikhan E, Lim JH, Shin SH, Park KH, Park YB, Lee JH, Kim JE. 2021; Effects of post-curing temperature on the mechanical properties and biocompatibility of three-dimensional printed dental resin material. Polymers. 13:1180. DOI: 10.3390/polym13081180. PMID: 33916899. PMCID: PMC8067535. PMID: 1df9c765128a4be4ae1b24ee71dc2dc4. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85104200872&origin=inward.

Article16. Reymus M, Lümkemann N, Stawarczyk B. 2019; 3D-printed material for temporary restorations: Impact of print layer thickness and post-curing method on degree of conversion. Int J Comput Dent. 22:231–7. PMID: 31463487. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85071608405&origin=inward.17. Calheiros FC, Daronch M, Rueggeberg FA, Braga RR. 2008; Degree of conversion and mechanical properties of a BisGMA:TEGDMA composite as a function of the applied radiant exposure. J Biomed Mater Res B Appl Biomater. 84:503–9. DOI: 10.1002/jbm.b.30897. PMID: 17635039. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=38349175690&origin=inward.

Article18. dos Santos RL, de Sampaio GA, de Carvalho FG, Pithon MM, Guênes GM, Alves PM. 2014; Influence of degree of conversion on the biocompatibility of different composites in vivo. J Adhes Dent. 16:15–20. DOI: 10.3290/j.jad.a29704. PMID: 23678480. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=84899408325&origin=inward.19. Durner J, Dębiak M, Bürkle A, Hickel R, Reichl FX. 2011; Induction of DNA strand breaks by dental composite components compared to X-ray exposure in human gingival fibroblasts. Arch Toxicol. 85:143–8. DOI: 10.1007/s00204-010-0558-0. PMID: 20490463. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=79954427384&origin=inward.

Article20. Jin MC, Yoon HI, Yeo IS, Kim SH, Han JS. 2020; The effect of build angle on the tissue surface adaptation of maxillary and mandibular complete denture bases manufactured by digital light processing. J Prosthet Dent. 123:473–82. DOI: 10.1016/j.prosdent.2018.12.014. PMID: 31227240. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85067295540&origin=inward.

Article21. Doh RM, Kim JE, Nam NE, Shin SH, Lim JH, Shim JS. 2021; Evaluation of Dimensional Changes during Post-curing of a Three-Dimensionally Printed Denture Base According to the Curing Time and the Time of Removal of the Support Structure: An In Vitro Study. Appl Sci. 11:10000. DOI: 10.3390/app112110000. PMID: 0e153710e0974f7d83a78b570aa8913c. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=85118226862&origin=inward.

Article22. Mahler DB. 1951; Inarticulation of complete dentures processed by the compression molding technique. J Prosthet Dent. 1:551–9. DOI: 10.1016/0022-3913(51)90040-6. PMID: 14881112. PMID: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=2442459399&origin=inward.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Three-dimensional printed complete denture fabrication using the scan data from the conventional denture-making process

- Evaluation of Mechanical Properties of Threedimensional Printed Flexible Denture Resin according to Post-polymerization Conditions: A Pilot Study

- Fabrication of computer-aided design/computer-aided manufacturing complete denture and conventional complete denture: case report

- Three dimensional deformation of dry-stored complete denture base at room temperature

- Evaluation of functional suitable digital complete denture system based on 3D printing technology