Korean J Orthod.

2021 Nov;51(6):375-386. 10.4041/kjod.2021.51.6.375.

Three-dimensional evaluation of the transfer accuracy of a bracket jig fabricated using computer-aided design and manufacturing to the anterior dentition: An in vitro study

- Affiliations

-

- 1Department of Orthodontics, Graduate School of Dentistry, Kyung Hee University, Seoul, Korea

- 2Department of Orthodontics, Institute of Craniofacial Deformity, Yonsei University College of Dentistry, Seoul, Korea

- KMID: 2522500

- DOI: http://doi.org/10.4041/kjod.2021.51.6.375

Abstract

Objective

To evaluate the accuracy of a one-piece bracket jig system fabricated using computer-aided design and manufacturing (CAD/CAM) by employing three-dimensional (3D) digital superimposition.

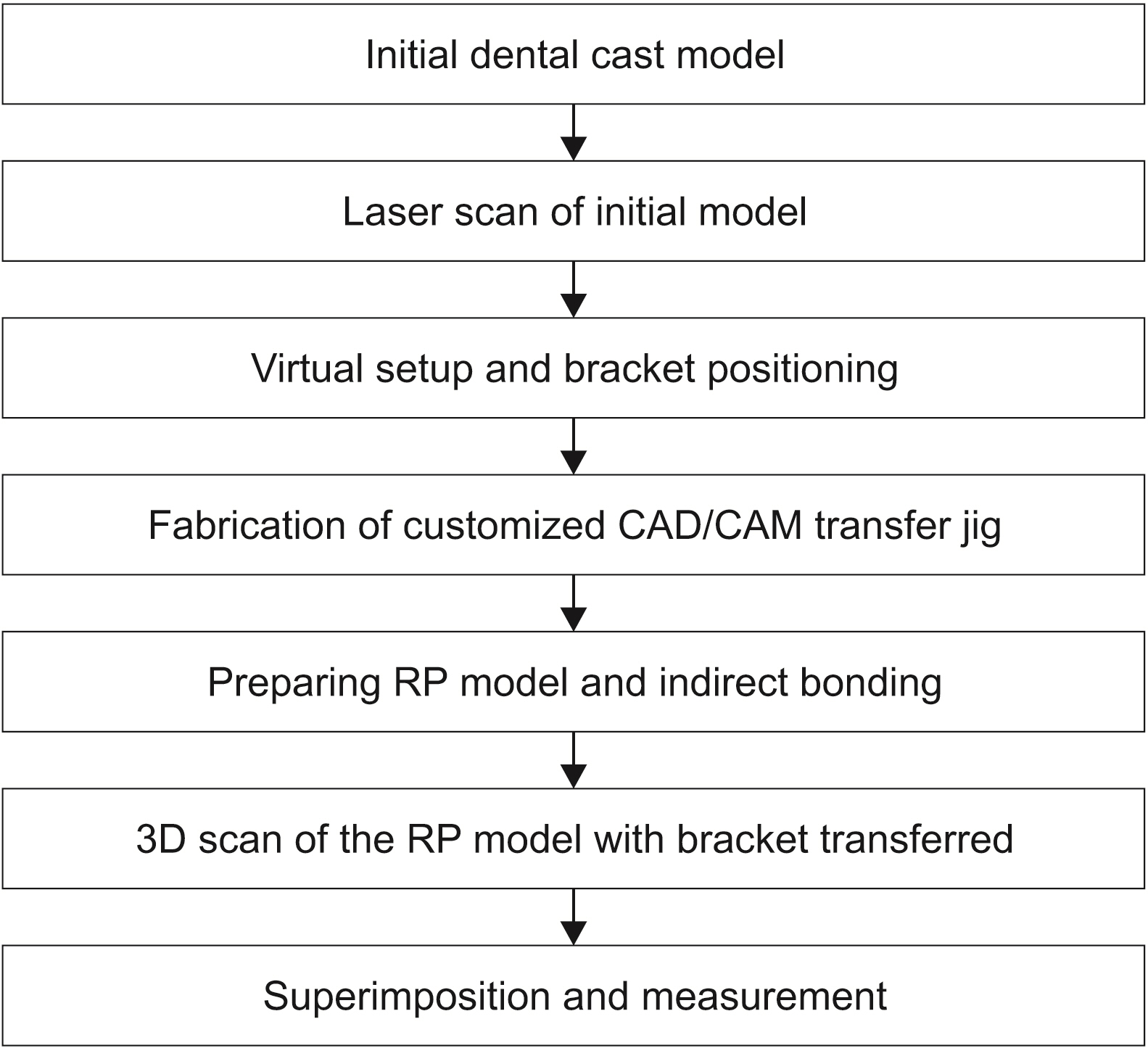

Methods

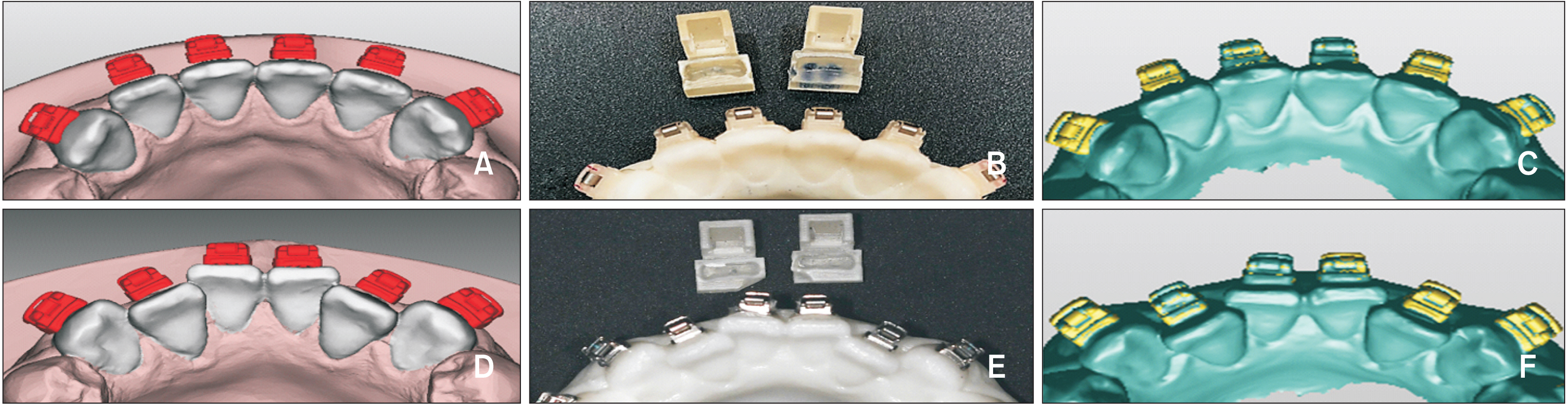

This in vitro study included 226 anterior teeth selected from 20 patients undergoing orthodontic treatment. Bracket position errors from each of the 40 arches were analyzed quantitatively via 3D digital superimposition (best-fit algorithm) of the virtual bracket and actual bracket after indirect bonding, after accounting for possible variables that may affect accuracy, such as crowding and presence of the resin base.

Results

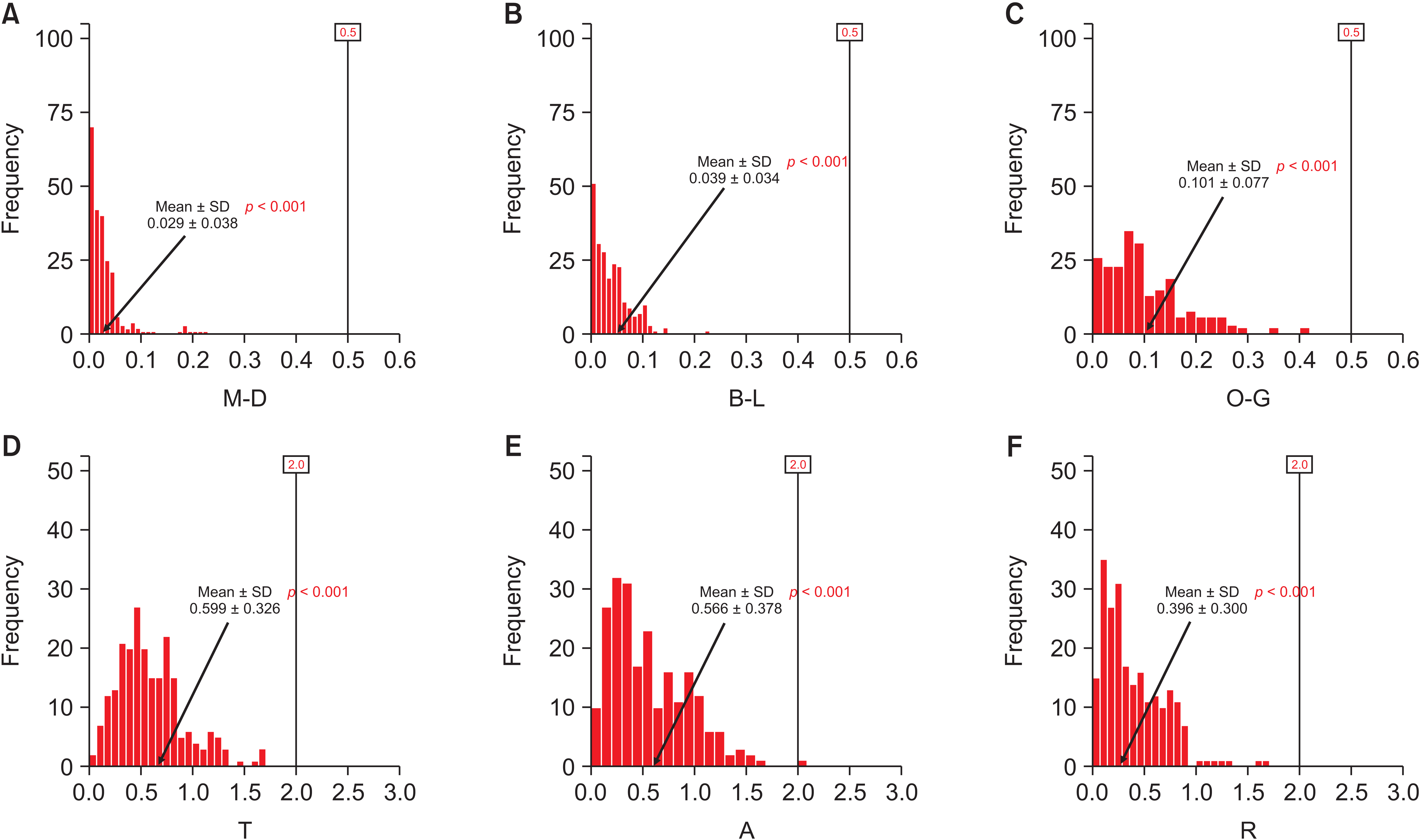

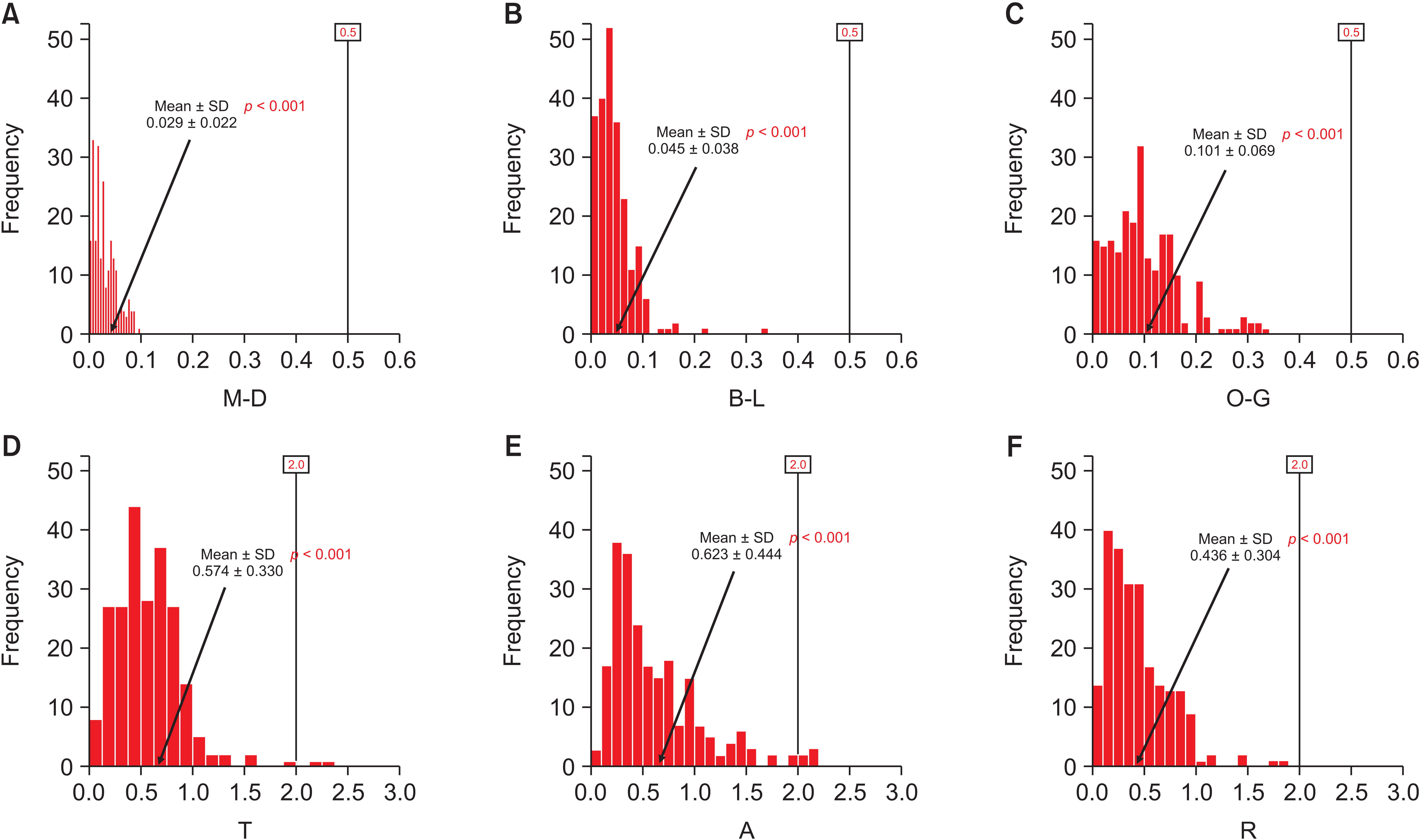

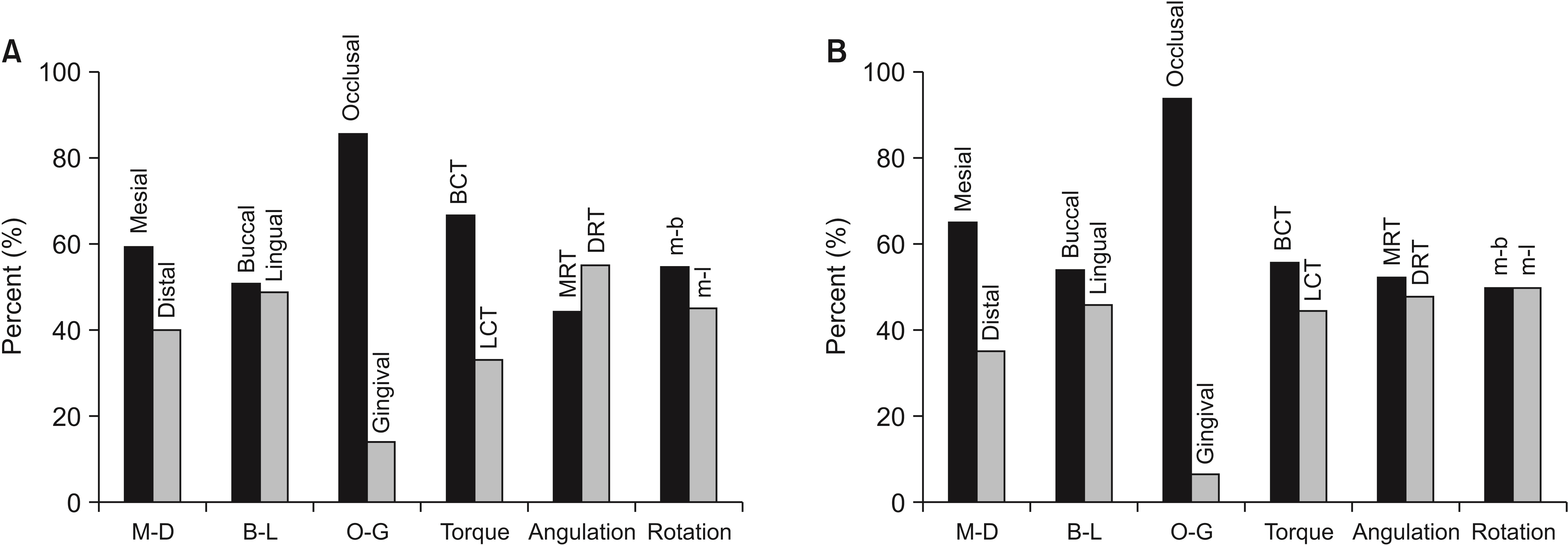

The device could transfer the bracket accurately to the desired position of the patient’s dentition within a clinically acceptable range of ± 0.05 mm and 2.0° for linear and angular measurements, respectively. The average linear measurements ranged from 0.029 to 0.101 mm. Among the angular measurements, rotation values showed the least deviation and ranged from 0.396° to 0.623°. Directional bias was pronounced in the vertical direction, and many brackets were bonded toward the occlusal surface. However, no statistical difference was found for the three angular measurement values (torque, angulation, and rotation) in any of the groups classified according to crowding. When the teeth were moderately crowded, the mesio-distal, bucco-lingual, and rotation measurement values were affected by the presence of the resin base.

Conclusions

The characteristics of the CAD/CAM one-piece jig system were demonstrated according to the influencing factors, and the transfer accuracy was verified to be within a clinically acceptable level for the indirect bracket bonding of anterior teeth.

Keyword

Figure

Reference

-

1. Andrews LF. 1976; The straight-wire appliance. Explained and compared. J Clin Orthod. 10:174–95. PMID: 1074877.2. Andrews LF. 1979; The straight-wire appliance. Br J Orthod. 6:125–43. DOI: 10.1179/bjo.6.3.125. PMID: 297458.

Article3. Zachrisson BU, Brobakken BO. 1978; Clinical comparison of direct versus indirect bonding with different bracket types and adhesives. Am J Orthod. 74:62–78. DOI: 10.1016/0002-9416(78)90046-5. PMID: 356618.

Article4. Aguirre MJ, King GJ, Waldron JM. 1982; Assessment of bracket placement and bond strength when comparing direct bonding to indirect bonding techniques. Am J Orthod. 82:269–76. DOI: 10.1016/0002-9416(82)90461-4. PMID: 6760721.

Article5. Koo BC, Chung CH, Vanarsdall RL. 1999; Comparison of the accuracy of bracket placement between direct and indirect bonding techniques. Am J Orthod Dentofacial Orthop. 116:346–51. DOI: 10.1016/S0889-5406(99)70248-9. PMID: 10474109.

Article6. Hodge TM, Dhopatkar AA, Rock WP, Spary DJ. 2004; A randomized clinical trial comparing the accuracy of direct versus indirect bracket placement. J Orthod. 31:132–7. DOI: 10.1179/146531204225020427. PMID: 15210929.

Article7. Thomas RG. 1979; Indirect bonding: simplicity in action. J Clin Orthod. 13:93–106. PMID: 397232.8. Kalange JT. 2004; Indirect bonding: a comprehensive review of the advantages. World J Orthod. 5:301–7. PMID: 15633375.9. Wendl B, Droschl H, Muchitsch P. 2008; Indirect bonding--a new transfer method. Eur J Orthod. 30:100–7. DOI: 10.1093/ejo/cjm094. PMID: 18276930.

Article10. Lee MS. 2014. Indirect bonding of orthodontic brackets: an evaluation of transfer accuracy and reliability [Master's thesis]. University of Minnesota;Minnesota:11. Castilla AE, Crowe JJ, Moses JR, Wang M, Ferracane JL, Covell DA Jr. 2014; Measurement and comparison of bracket transfer accuracy of five indirect bonding techniques. Angle Orthod. 84:607–14. DOI: 10.2319/070113-484.1. PMID: 24555689.

Article12. Seo H. 2016. Accuracy of indirect bracket bonding via virtual setup and 3D printing [Master's thesis]. Yonsei University;Seoul:13. Niu Y, Zeng Y, Zhang Z, Xu W, Xiao L. 2021; Comparison of the transfer accuracy of two digital indirect bonding trays for labial bracket bonding. Angle Orthod. 91:67–73. DOI: 10.2319/013120-70.1. PMID: 33289807. PMCID: PMC8032273.

Article14. Gelin E, Seidel L, Bruwier A, Albert A, Charavet C. 2020; Innovative customized CAD/CAM nickel-titanium lingual retainer versus standard stainless-steel lingual retainer: a randomized controlled trial. Korean J Orthod. 50:373–82. DOI: 10.4041/kjod.2020.50.6.373. PMID: 33144526. PMCID: PMC7642231.

Article15. Koch PJ. 2020; Measuring the accuracy of a computer-aided design and computer-aided manufacturing-based indirect bonding tray. Am J Orthod Dentofacial Orthop. 158:315. DOI: 10.1016/j.ajodo.2020.06.018. PMID: 32862927.

Article16. Xue C, Xu H, Guo Y, Xu L, Dhami Y, Wang H, et al. 2020; Accurate bracket placement using a computer-aided design and computer-aided manufacturing-guided bonding device: an in vivo study. Am J Orthod Dentofacial Orthop. 157:269–77. DOI: 10.1016/j.ajodo.2019.03.022. PMID: 32005479.17. SI Kwon KJ Lee . CENOS. 2020. Sep. 29. Bracket jig system for positioning an orthodontic bracket. Korea patent KR 10-2163625.18. Fillion D. 2010; Clinical advantages of the Orapix-straight wire lingual technique. Int Orthod. 8:125–51. DOI: 10.1016/j.ortho.2010.03.005. PMID: 20434419.

Article19. Fillion D. 2011; Lingual straightwire treatment with the Orapix system. J Clin Orthod. 45:488–97. quiz 515PMID: 22094863.20. Kim J, Chun YS, Kim M. 2018; Accuracy of bracket positions with a CAD/CAM indirect bonding system in posterior teeth with different cusp heights. Am J Orthod Dentofacial Orthop. 153:298–307. DOI: 10.1016/j.ajodo.2017.06.017. PMID: 29407508.

Article21. Little RM. 1975; The irregularity index: a quantitative score of mandibular anterior alignment. Am J Orthod. 68:554–63. DOI: 10.1016/0002-9416(75)90086-X. PMID: 1059332.

Article22. Park KH, Choi JY, Kim KA, Kim SJ, Chung KR, Kim SH. 2021; Critical issues concerning biocreative strategy in contemporary temporary skeletal anchorage device orthodontics: a narrative review. Orthod Craniofac Res. 24 Suppl 1:39–47. DOI: 10.1111/ocr.12444. PMID: 33237622.

Article23. Casko JS, Vaden JL, Kokich VG, Damone J, James RD, Cangialosi TJ, et al. 1998; Objective grading system for dental casts and panoramic radiographs. American Board of Orthodontics. Am J Orthod Dentofacial Orthop. 114:589–99. DOI: 10.1016/S0889-5406(98)70179-9. PMID: 9810056.24. Wan Hassan WN, Yusoff Y, Mardi NA. 2017; Comparison of reconstructed rapid prototyping models produced by 3-dimensional printing and conventional stone models with different degrees of crowding. Am J Orthod Dentofacial Orthop. 151:209–18. DOI: 10.1016/j.ajodo.2016.08.019. PMID: 28024776.

Article25. Hazeveld A, Huddleston Slater JJ, Ren Y. 2014; Accuracy and reproducibility of dental replica models reconstructed by different rapid prototyping techniques. Am J Orthod Dentofacial Orthop. 145:108–15. DOI: 10.1016/j.ajodo.2013.05.011. PMID: 24373661.

Article26. Dietrich CA, Ender A, Baumgartner S, Mehl A. 2017; A validation study of reconstructed rapid prototyping models produced by two technologies. Angle Orthod. 87:782–7. DOI: 10.2319/01091-727.1. PMID: 28459285. PMCID: PMC8357202.

Article27. Gyllenhaal KA. 2015. Accuracy of two indirect bonding transfer methods: a three-dimensional, in-vivo analysis [Master's thesis]. University of Minnesota;Minnesota:28. Pottier T, Brient A, Turpin YL, Chauvel B, Meuric V, Sorel O, et al. 2020; Accuracy evaluation of bracket repositioning by indirect bonding: hard acrylic CAD/CAM versus soft one-layer silicone trays, an in vitro study. Clin Oral Investig. 24:3889–97. DOI: 10.1007/s00784-020-03256-x. PMID: 32236724.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Use of an Extraoral Transfer Jig and a Handheld Face Scanner App for Integrating Face Scan Data into Prosthesis Design

- CAD/CAM fabricated complete denture using 3D face scan: A case report

- Accuracy of CAD-CAM RPD framework according to manufacturing method: A literature review

- Computer-aided design and manufacturing-based full mouth rehabilitation for a patient with excessive attrition and restricted vertical dimension: A case report

- Functional and esthetic improvement through reconstruction of anterior guidance using the modified Dahl principle and copy-milled technique of CAD/CAM system: A case report