J Adv Prosthodont.

2019 Dec;11(6):350-357. 10.4047/jap.2019.11.6.350.

Accuracy of different electronic torque drivers: A comparative evaluation

- Affiliations

-

- 1Department of Dentistry, Graduate School, Kyungpook National University, Daegu, Republic of Korea. kblee@knu.ac.kr

- 2Department of Dental Science, Graduate School, Kyungpook National University, Daegu, Republic of Korea.

- 3Advanced Dental Device Development Institute, Kyungpook National University, Daegu, Republic of Korea.

- KMID: 2466250

- DOI: http://doi.org/10.4047/jap.2019.11.6.350

Abstract

- PURPOSE

This study aims to evaluate the loosening torque on the implant fixture, and to assess the accuracy of difference electronic torque drivers.

MATERIALS AND METHODS

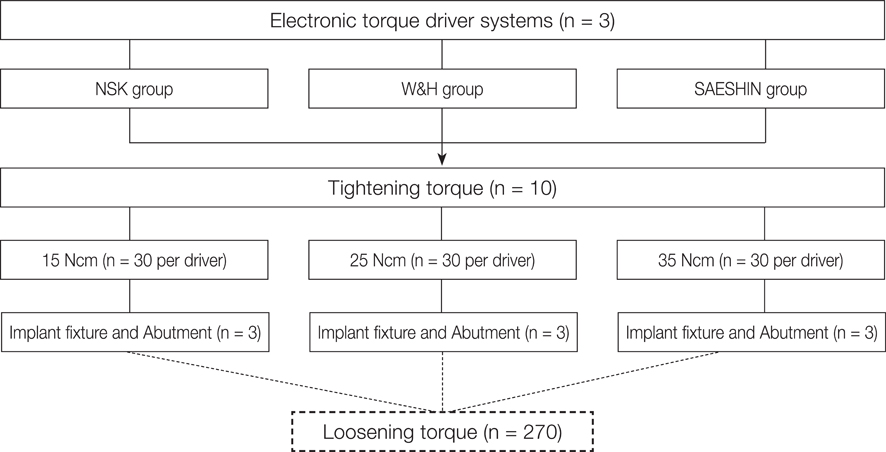

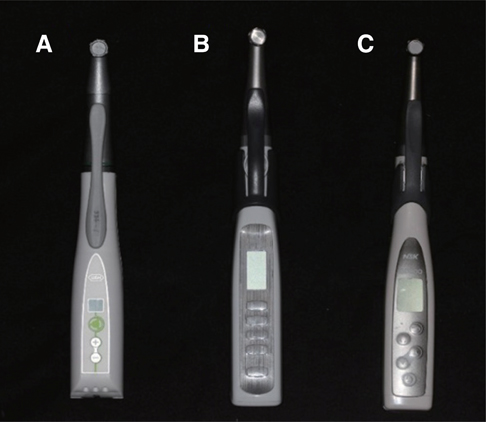

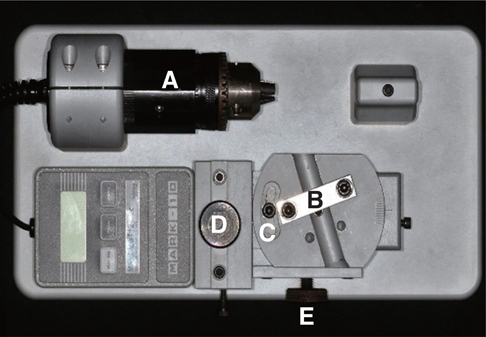

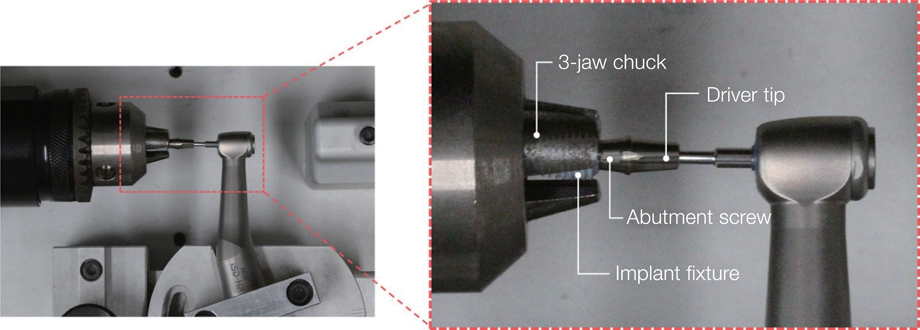

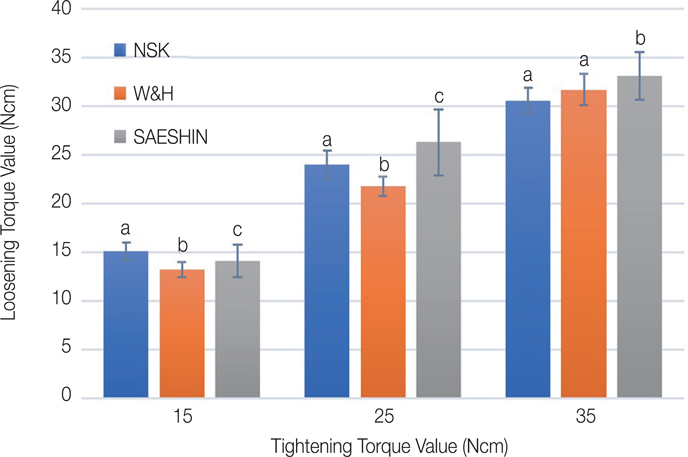

Three electronic torque drivers were used to measure the loosening torque on the implant system (AnyOne; MegaGen). The implant fixtures were divided among the 3 electronic torque driver types (W&H, SAESHIN, and NSK group) and 9 for each group. The screws were fastened at the implant fixture by three electronic torque drivers using the tightening torques recommended by the manufacturers of the drivers. After 10 minutes, the screws were again fastened at the implant fixture with equal torque. Then, the loosening torques were measured with an MGT12 torque gauge (MARK-10, Inc.). This measurement procedure was repeated 10 times under loosening torques of 15 Ncm, 25 Ncm, and 35 Ncm. In the statistical analysis, all values of loosening torque were analyzed with the one-way ANOVA and Kruskal-Wallis test (α=.05) for comparative evaluation.

RESULTS

There were significant inter-group differences at loosening torques of 15 Ncm and 25 Ncm (P<.05). The accuracy of the NSK driver was the highest, followed by SAESHIN and W&H. There was no significant difference between NSK and W&H at 35 Ncm (P>.05). The SAESHIN driver showed the closest loosening torque at 35 Ncm.

CONCLUSION

The most accurate loosening torques were SAESHIN at 35 Ncm, and NSK at 15 Ncm and 25 Ncm. Since the loosening torque may vary depending on the tightening torques and electronic torque drivers, periodic calibration of the electronic torque driver is recommended.

MeSH Terms

Figure

Reference

-

1. Brånemark PI. Osseointegration and its experimental background. J Prosthet Dent. 1983; 50:399–410.2. Sumi T, Braian M, Shimada A, Shibata N, Takeshita K, Vandeweghe S, Coelho PG, Wennerberg A, Jimbo R. Characteristics of implant-CAD/CAM abutment connections of two different internal connection systems. J Oral Rehabil. 2012; 39:391–398.3. Lang LA, Sierraalta M, Hoffensperger M, Wang RF. Evaluation of the precision of fit between the Procera custom abutment and various implant systems. Int J Oral Maxillofac Implants. 2003; 18:652–658.4. Adell R, Eriksson B, Lekholm U, Brånemark PI, Jemt T. Long-term follow-up study of osseointegrated implants in the treatment of totally edentulous jaws. Int J Oral Maxillofac Implants. 1990; 5:347–359.5. Binon PP. The effect of implant/abutment hexagonal misfit on screw joint stability. Int J Prosthodont. 1996; 9:149–160.6. Lee WJ, Lim JH, Cho IH. Stress of dental implant abutment screw by the tightening torque. J Korean Acad Prosthodont. 1998; 36:721–737.7. Lim JB, Yim SH, Cho IH. The effect of screw hole sealing method on abutment screw loosening in dental implant. J Korean Acad Prosthodont. 1997; 35:767–780.8. Cho SM, Lim JH, Cho IH. A study on geometric comparison of four interchangeable implant prosthetic retaining screws and measurement of loosening torgue. J Korean Acad Prosthodont. 1998; 36:468–482.9. Balshi TJ, Hernandez RE, Pryszlak MC, Rangert B. A comparative study of one implant versus two replacing a single molar. Int J Oral Maxillofac Implants. 1996; 11:372–378.10. Kemppainen P, Eskola S, Ylipaavalniemi P. A comparative prospective clinical study of two single-tooth implants: a preliminary report of 102 implants. J Prosthet Dent. 1997; 77:382–387.11. Cho IH. Biomechanical analysis of implant prosthodontic restorations. J Korean Dent Assoc. 1993; 31:438–443.12. Binon PP. The effect of implant/abutment hexagonal misfit on screw joint stability. Int J Prosthodont. 1996; 9:149–160.13. Binon PP. Implants and components: entering the new millennium. Int J Oral Maxillofac Implants. 2000; 15:76–94.14. Misch CE. Principles for screw-retained prostheses. In : Misch CE, editor. Contemporary implant dentistry. 2nd ed. Missouri: CV Mosby;1999. p. 669–685.15. Ivanoff CJ, Sennerby L, Lekholm U. Reintegration of mobilized titanium implants. An experimental study in rabbit tibia. Int J Oral Maxillofac Surg. 1997; 26:310–315.16. Ko SM, Park SJ, Kim IS, Song SI, Lee IK. Observation of the change of the dental implant stability and bone density evaluation methods. J Korean Acad Periodontol. 2009; 39:185–192.17. Park YS, Yi KY, Lee IS, Jung YC. Correlation between microtomography and histomorphometry for assessment of implant osseointegration. Clin Oral Implants Res. 2005; 16:156–160.18. Sennerby L, Dasmah A, Larsson B, Iverhed M. Bone tissue responses to surface-modified zirconia implants: A histomorphometric and removal torque study in the rabbit. Clin Implant Dent Relat Res. 2005; 7:S13–S20.19. Klokkevold PR, Johnson P, Dadgostari S, Caputo A, Davies JE, Nishimura RD. Early endosseous integration enhanced by dual acid etching of titanium: a torque removal study in the rabbit. Clin Oral Implants Res. 2001; 12:350–357.20. Westover L, Faulkner G, Hodgetts W, Raboud D. Comparison of implant stability measurement devices for bone-anchored hearing aid systems. J Prosthet Dent. 2018; 119:178–184.21. Friberg B, Sennerby L, Linden B, Gröndahl K, Lekholm U. Stability measurements of one-stage Brånemark implants during healing in mandibles. A clinical resonance frequency analysis study. Int J Oral Maxillofac Surg. 1999; 28:266–272.22. Meredith N, Shagaldi F, Alleyne D, Sennerby L, Cawley P. The application of resonance frequency measurements to study the stability of titanium implants during healing in the rabbit tibia. Clin Oral Implants Res. 1997; 8:234–243.23. Sennerby L, Wennerberg A, Pasop F. A new microtomographic technique for non-invasive evaluation of the bone structure around implants. Clin Oral Implants Res. 2001; 12:91–94.24. Fanuscu MI, Chang TL. Three-dimensional morphometric analysis of human cadaver bone: microstructural data from maxilla and mandible. Clin Oral Implants Res. 2004; 15:213–218.25. Brandt J, Bierögel C, Holweg K, Hein W, Grellmann W. Extended push-out test to characterize the failure of bone-implant interface. Biomed Tech (Berl). 2005; 50:201–206.26. Dhert WJ, Verheyen CC, Braak LH, de Wijn JR, Klein CP, de Groot K, Rozing PM. A finite element analysis of the push-out test: influence of test conditions. J Biomed Mater Res. 1992; 26:119–130.27. Cibirka RM, Nelson SK, Lang BR, Rueggeberg FA. Examination of the implant-abutment interface after fatigue testing. J Prosthet Dent. 2001; 85:268–275.28. Elshahawy W, Ajlouni R, Ajlouni K, Sadakah A. Failure torque of ceramic neck titanium implant. J Prosthet Dent. 2018; 119:432–436.29. Faulkner MG, Wolfaardt JF, Chan A. Measuring abutment/implant joint integrity with the Periotest instrument. Int J Oral Maxillofac Implants. 1999; 14:681–688.30. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995; 10:529–536.31. Martin WC, Woody RD, Miller BH, Miller AW. Implant abutment screw rotations and preloads for four different screw materials and surfaces. J Prosthet Dent. 2001; 86:24–32.32. Gross M, Abramovich I, Weiss EI. Microleakage at the abutment-implant interface of osseointegrated implants: a comparative study. Int J Oral Maxillofac Implants. 1999; 14:94–100.33. Kim DG, Park CJ, Cho LR. Comparative analysis of the implant torque controller. J Dent Rehabil Appl Sci. 2012; 28:27–36.34. Jaarda MJ, Razzoog ME, Gratton DG. Providing optimum torque to implant prostheses: a pilot study. Implant Dent. 1993; 2:50–52.35. Goheen KL, Vermilyea SG, Vossoughi J, Agar JR. Torque generated by handheld screwdrivers and mechanical torquing devices for osseointegrated implants. Int J Oral Maxillofac Implants. 1994; 9:149–155.36. Tan KB, Nicholls JI. The effect of 3 torque delivery systems on gold screw preload at the gold cylinder-abutment screw joint. Int J Oral Maxillofac Implants. 2002; 17:175–183.37. Vallee MC, Conrad HJ, Basu S, Seong WJ. Accuracy of friction-style and spring-style mechanical torque limiting devices for dental implants. J Prosthet Dent. 2008; 100:86–92.38. Dellinges MA, Tebrock OC. A measurement of torque values obtained with hand-held drivers in a simulated clinical setting. J Prosthodont. 1993; 2:212–214.39. Gross M, Kozak D, Laufer BZ, Weiss EI. Manual closing torque in five implant abutment systems: an in vitro comparative study. J Prosthet Dent. 1999; 81:574–578.40. Jaarda MJ, Razzoog ME, Gratton DG. Providing optimum torque to implant prostheses: a pilot study. Implant Dent. 1993; 2:50–52.41. Tan KB, Nicholls JI. The effect of 3 torque delivery systems on gold screw preload at the gold cylinder-abutment screw joint. Int J Oral Maxillofac Implants. 2002; 17:175–183.42. Johansson CB. Sennerby L, Albrektsson T. A removal torque and histomorphometric study of bone tissue reaction to commercially pure titanium and vitallium implant. Int J Oral Maxillofac Implants. 1991; 6:437–441.43. Johansson CB, Albrektsson T. A removal torque and histomorphometric study of commercially pure niobium and titanium implants in rabbit bone. Clin Oral Implants Res. 1991; 2:24–29.44. Klokkevold PR, Nishimura RD, Adachi M, Caputo A. Osseointegration enhanced by chemical etching of the titanium surface. A torque removal study in the rabbit. Clin Oral Implants Res. 1997; 8:442–447.45. Buser D, Nydegger T, Hirt HP, Cochran DL, Nolte LP. Removal torque values of titanium implants in the maxilla of miniature pigs. Int J Oral Maxillofac Implants. 1998; 13:611–619.46. Buser D, Nydegger T, Oxland T, Cochran DL, Schenk RK, Hirt HP, Snétivy D, Nolte LP. Interface shear strength of titanium implants with a sandblasted and acid-etched surface: a biomechanical study in the maxilla of miniature pigs. J Biomed Mater Res. 1999; 45:75–83.47. Inadome T, Hayashi K, Nakashima Y, Tsumura H, Sugioka Y. Comparison of bone-implant interface shear strength of hydroxyapatite-coated and alumina-coated metal implants. J Biomed Mater Res. 1995; 29:19–24.48. Ellingsen JE, Johansson CB, Wennerberg A, Holmén A. Improved retention and bone-tolmplant contact with fluoride-modified titanium implants. Int J Oral Maxillofac Implants. 2004; 19:659–666.49. Paepoemsin T, Reichart PA, Chaijareenont P, Strietzel FP, Khongkhunthian P. Removal torque evaluation of three different abutment screws for single implant restorations after mechanical cyclic loading. Oral Implantol (Rome). 2016; 9:213–221.50. Stüker RA, Teixeira ER, Beck JC, da Costa NP. Preload and torque removal evaluation of three different abutment screws for single standing implant restorations. J Appl Oral Sci. 2008; 16:55–58.51. Ghanbarzadeh J, Rajabzadeh M, Nakhaei M, Rajatihaghi H, Tayarani Najjaran N. Torque removal evaluation of screw in one-piece and two-piece abutments tightened with a handheld screwdriver. J Dent Mater Tech. 2013; 3:11–15.52. Saliba FM, Cardoso M, Torres MF, Teixeira AC, Lourenço EJ, Telles Dde M. A rationale method for evaluating unscrewing torque values of prosthetic screws in dental implants. J Appl Oral Sci. 2011; 19:63–67.53. Hwang YJ, Cho JH, Lee CH. Investigation of osseointegration according to the healing time after having iatrogenic mobility of implant fixtures. J Korean Acad Prosthodont. 2010; 48:308–314.54. Koh YH, Kim YJ, Chung HJ. Bone healing around screw-shaped titanium implants with three different surface topographies. J Korean Acad Periodontol. 2001; 31:41–55.55. Yi YA, Park YB, Choi H, Kim SJ, Kim KM, Oh S, Shim JS. The evaluation of osseointegration of dental implant surface with different size of TiO 2 nanotube in rats. J Nanomater. 2015; 2:1–10.56. Buser D, Nydegger T, Hirt HP, Cochran DL, Nolte LP. Removal torque values of titanium implants in the maxilla of miniature pigs. Int J Oral Maxillofac Implants. 1998; 13:611–619.57. Albayrak H, Gumus HO, Tursun F, Kocaagaoglu HH, Kilinc HI. Accuracy of torque-limiting devices: A comparative evaluation. J Prosthet Dent. 2017; 117:81–86.58. Wadhwani CPK, O'Brien R, Rosen PS, Chung KH. Testing and calibrating the mechanical-type toggle torque wrenches used in implant dentistry: A dental technique. J Prosthet Dent. 2019; 08. 02. S0022-3913(19)30342-7.59. Kreissl ME, Gerds T, Muche R, Heydecke G, Strub JR. Technical complications of implant-supported fixed partial dentures in partially edentulous cases after an average observation period of 5 years. Clin Oral Implants Res. 2007; 18:720–726.60. Sananez A, Lefebvre C, Looney S, Baker P, Mettenburg D, Rueggeberg FA. In vitro mechanical analysis of complete-arch mandibular implant-supported fixed prostheses abutment screws after cyclic loading. J Prosthet Dent. 2015; 113:432–439.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Accuracy of spring-style and friction-style mechanical implant torque wrench

- Comparative analysis of accuracy of how to use the implant torque controllers

- THE EFFECTS OF FABRICATION AND TIGHTENING METHODS OF GOLD CYLINDER ON THE PRELOAD OF THE IMPLANT ABUTMENT

- Driver Rehabilitation

- A study on accuracy and application of the implant torque controller used in dental clinic