J Korean Acad Prosthodont.

2012 Jan;50(1):36-43.

Evaluation of the stress distribution in the external hexagon implant system with different hexagon height by FEM-3D

- Affiliations

-

- 1Asan Moa Dental Clinic, Asan, Korea.

- 2Department of Prosthodontics, School of Dentistry, Pusan National University, Yangsan, Korea. neoplasia96@hanmail.net

- 3Bestden Dental Clinic, Suwon, Korea.

Abstract

- PURPOSE

To analyze the stress distribution of the implant and its supporting structures through 3D finite elements analysis for implants with different hexagon heights and to make the assessment of the mechanical stability and the effect of the elements.

MATERIALS AND METHODS

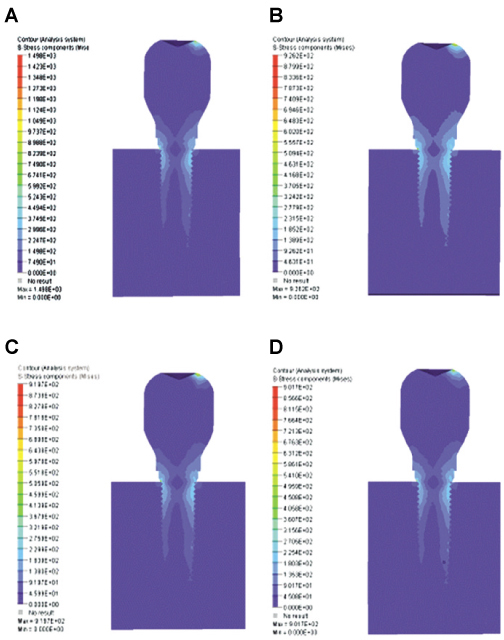

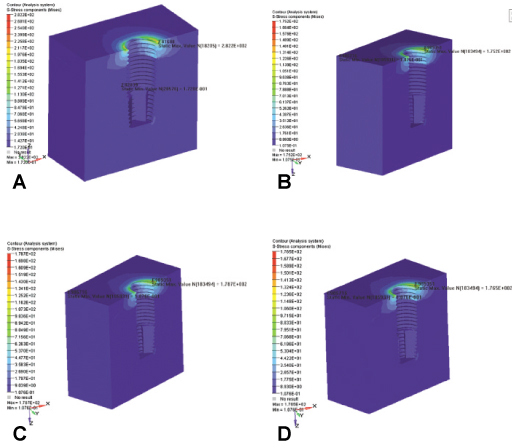

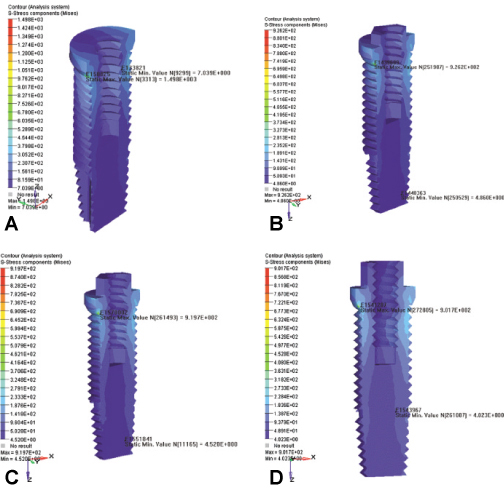

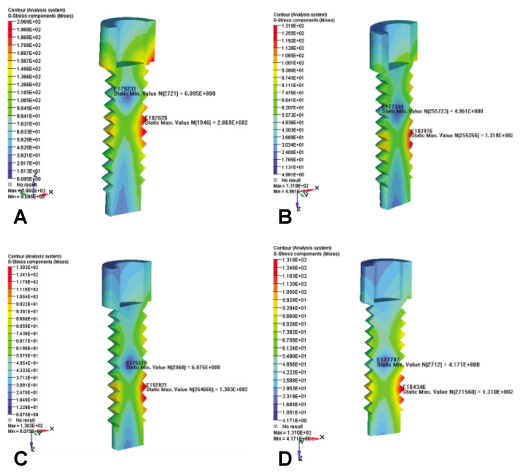

Infinite elements modeling with CAD data was designed. The modeling was done as follows; an external connection type Phi 4.0 mm x11.5 mm Osste(R) USII (Osstem Co., Pusan, Korea) implant system was used, the implant was planted in the mandibular first molar region with appropriate prosthetic restoration, the hexagon (implant fixture's external connection) height of 0.0, 0.7, 1.2, and 1.5 mm were applied. ABAQUS 6.4 (ABAQUS, Inc., Providence, USA) was used to calculate the stress value. The force distribution via color distribution on each experimental group's implant fixture and titanium screw was studied based on the equivalent stress (von Mises stress). The maximum stress level of each element (crown, implant screw, implant fixture, cortical bone and cancellous bone) was compared.

RESULTS

The hexagonal height of the implant with external connection had an influence on the stress distribution of the fixture, screw and upper prosthesis and the surrounding supporting bone. As the hexagon height increased, the stress was well distributed and there was a decrease in the maximum stress value. If the height of the hexagon reached over 1.2 mm, there was no significant influence on the stress distribution.

CONCLUSION

For implants with external connections, a hexagon is vital for stress distribution. As the height of the hexagon increased, the more effective stress distribution was observed.

Figure

Reference

-

1. Haraldson T, Carlsson GE. Bite force and oral function in patients with osseointegrated oral implants. Scand J Dent Res. 1977. 85:200–208.

Article2. Binon PP. Screw joints, components, and other intimate relationships. J Prosthet Dent. 1994. 72:625–628.3. Tolman DE, Laney WR. Tissue-integrated prosthesis complications. Int J Oral Maxillofac Implants. 1992. 7:477–484.

Article4. Lang LA, Wang RF, May KB. The influence of abutment screw tightening on screw joint configuration. J Prosthet Dent. 2002. 87:74–79.

Article5. Binon PP. The effect of implant/abutment hexagonal misfit on screw joint stability. Int J Prosthodont. 1996. 9:149–160.6. Binon PP, McHugh MJ. The effect of eliminating implant/abutment rotational misfit on screw joint stability. Int J Prosthodont. 1996. 9:511–519.7. Beaty K. The role of screws in implant systems. Int J Oral Maxillofac implants. 1994. 9:52–54.8. English CE. Externally hexed implants, abutments, and transfer devices: a comprehensive overview. Implant Dent. 1992. 1:273–282.

Article9. Ohrnell LO, Hirsch JM, Ericsson I, Brånemark PI. Single-tooth rehabilitation using osseointegration. A modified surgical and prosthodontic approach. Quintessence Int. 1988. 19:871–876.10. Patra AK, DePaolo JM, D'Souza KS, DeTolla D, Meenaghan MA. Guidelines for analysis and redesign of dental implants. Implant Dent. 1998. 7:355–368.

Article11. Chung KM, Chung CH, Jeong SM. Finite element stress analysis of implant prosthesis according to platform width of fixture. J Korean Acad Prosthodont. 2003. 41:674–688.12. Bates JF, Stafford GD, Harrison A. Masticatory function - a review of the literature. III. Masticatory performance and efficiency. J Oral Rehabil. 1976. 3:57–67.13. Jeong CM. Three-dimensional finite element analysis of the effect of cortical engagement on implant load transfer in posterior mandible. J Korean Acad Prosthodont. 1999. 37:607–619.14. Jemt T, Laney WR, Harris D, Henry PJ, Krogh PH Jr, Polizzi G, Zarb GA, Herrmann I. Osseointegrated implants for single tooth replacement: a 1-year report from a multicenter prospective study. Int J Oral Maxillofac Implants. 1991. 6:29–36.15. Jemt T, Lindén B, Lekholm U. Failures and complications in 127 consecutively placed fixed partial prostheses supported by Braånemark implants: from prosthetic treatment to first annual checkup. Int J Oral Maxillofac Implants. 1992. 7:40–44.16. Jemt T, Lekholm U. Oral implant treatment in posterior partially edentulous jaws: a 5-year follow-up report. Int J Oral Maxillofac Implants. 1993. 8:635–640.17. Jemt T. Fixed implant-supported prostheses in the edentulous maxilla. A five-year follow-up report. Clin Oral Implants Res. 1994. 5:142–147.

Article18. McGlumphy EA, Mendel DA, Holloway JA. Implant screw mechanics. Dent Clin North Am. 1998. 42:71–89.

Article19. Tolman DE, Laney WR. Tissue-integrated prosthesis complications. Int J Oral Maxillofac Implants. 1992. 7:477–484.

Article20. Rangert BR, Sullivan RM, Jemt TM. Load factor control for implants in the posterior partially edentulous segment. Int J Oral Maxillofac Implants. 1997. 12:360–370.21. Weinberg LA. The biomechanics of force distribution in implantsupported prostheses. Int J Oral Maxillofac Implants. 1993. 8:19–31.22. Weinberg LA, Kruger B. A comparison of implant/prosthesis loading with four clinical variables. Int J Prosthodont. 1995. 8:421–433.23. Rieger MR, Mayberry M, Brose MO. Finite element analysis of six endosseous implants. J Prosthet Dent. 1990. 63:671–676.

Article24. Brunski JB. Biomechanical factors affecting the bone-dental implant interface. Clin Mater. 1992. 10:153–201.

Article25. Bergman B. Evaluation of the results of treatment with osseointegrated implants by the Swedish National Board of Health and Welfare. J Prosthet Dent. 1983. 50:114–115.

Article26. Sertgöz A, Güvener S. Finite element analysis of the effect of cantilever and implant length on stress distribution in an implant-supported fixed prosthesis. J Prosthet Dent. 1996. 76:165–169.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of a counter-torque device and the internal hexagon of abutment on the tightening torque transmitted to the implant

- Surface change of external hexagon of implant fixture and internal hexagon of abutment after repeated delivery and removal of abutment

- Retrospective study on marginal bone resorption around immediately loaded implants

- Joint stability of internal conical connection abutments with or without hexagon indexes: an in vitro study

- A Numerical Study For The Variation Of Cortical Bone Thickness With 6 Endosseous Implant Shapes