J Adv Prosthodont.

2018 Feb;10(1):65-72. 10.4047/jap.2018.10.1.65.

Fracture resistance of implant- supported monolithic crowns cemented to zirconia hybrid-abutments: zirconia-based crowns vs. lithium disilicate crowns

- Affiliations

-

- 1School of Dentistry and Oral Health, Griffith University, Gold Coast, Queensland, Australia. sh.elshiyab@gmail.com

- 2Faculty of Applied Medical Sciences, Jordan University of Science and Technology, Irbid, Jordan.

- 3School of Engineering, Griffith University, Gold Coast, Queensland, Australia.

- KMID: 2404000

- DOI: http://doi.org/10.4047/jap.2018.10.1.65

Abstract

- PURPOSE

The aim of this in vitro study was to investigate the fracture resistance under chewing simulation of implant-supported posterior restorations (crowns cemented to hybrid-abutments) made of different all-ceramic materials.

MATERIALS AND METHODS

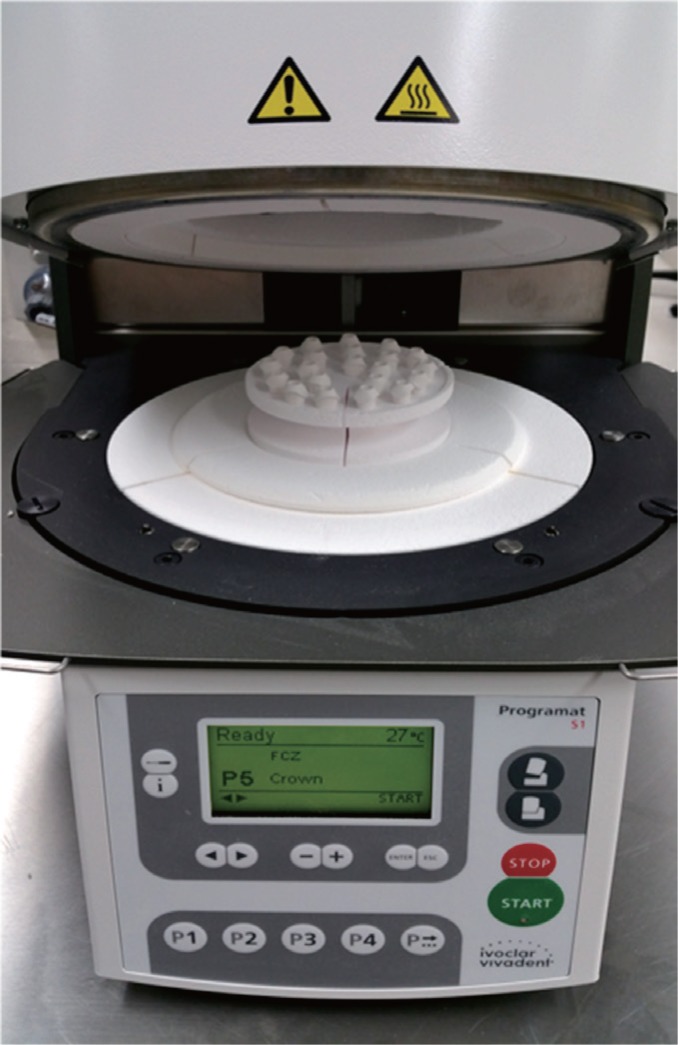

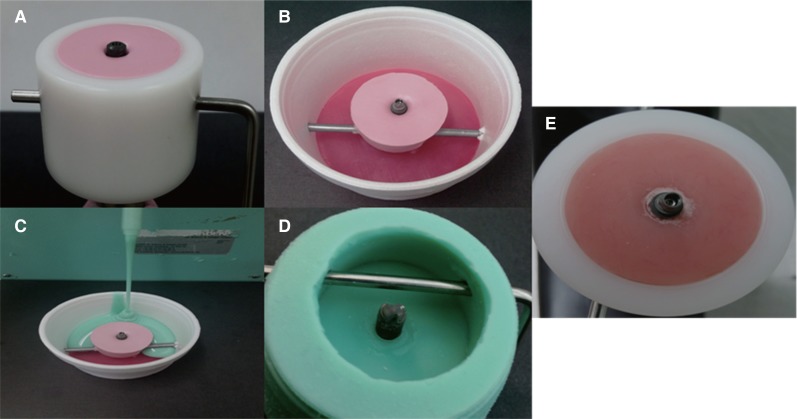

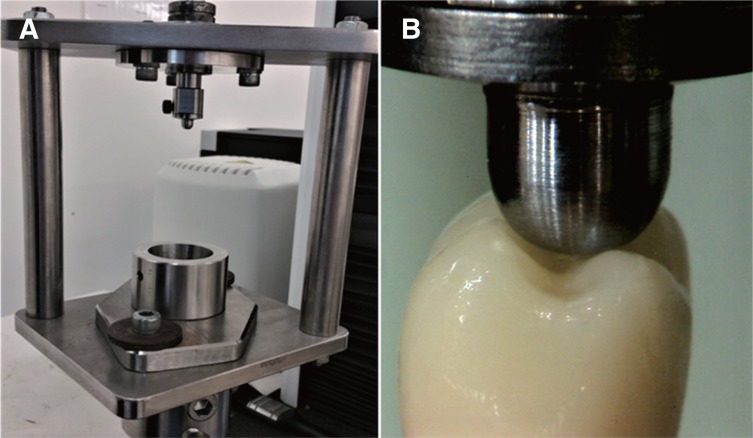

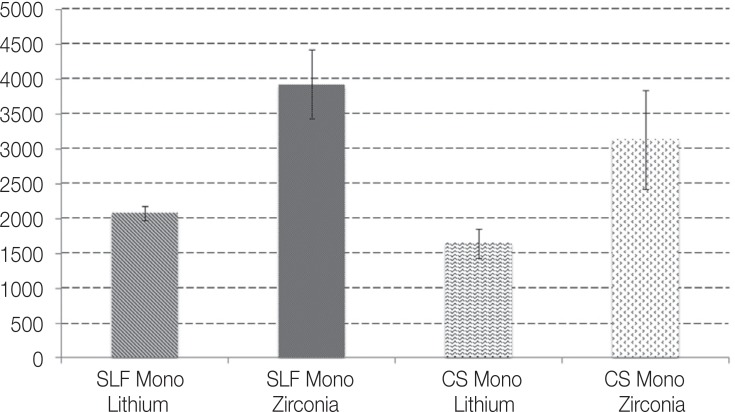

Monolithic zirconia (MZr) and monolithic lithium disilicate (MLD) crowns for mandibular first molar were fabricated using computer-aided design/computer-aided manufacturing technology and then cemented to zirconia hybrid-abutments (Ti-based). Each group was divided into two subgroups (n=10): (A) control group, crowns were subjected to single load to fracture; (B) test group, crowns underwent chewing simulation using multiple loads for 1.2 million cycles at 1.2 Hz with simultaneous thermocycling between 5℃ and 55℃. Data was statistically analyzed with one-way ANOVA and a Post-Hoc test.

RESULTS

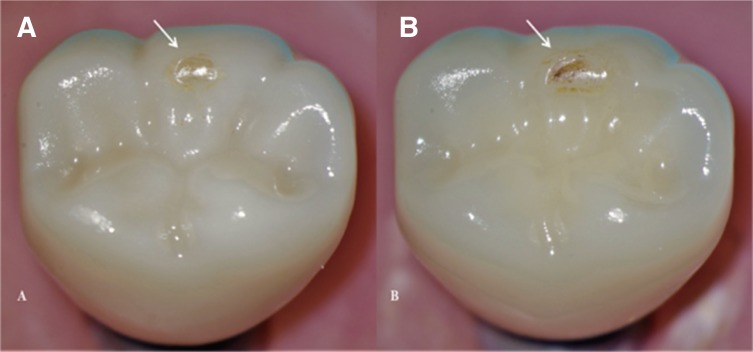

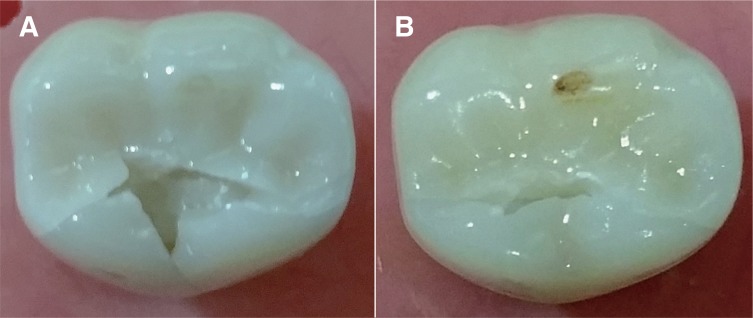

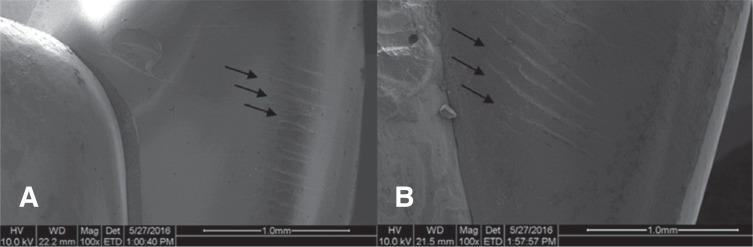

All tested crowns survived chewing simulation resulting in 100% survival rate. However, wear facets were observed on all the crowns at the occlusal contact point. Fracture load of monolithic lithium disilicate crowns was statistically significantly lower than that of monolithic zirconia crowns. Also, fracture load was significantly reduced in both of the all-ceramic materials after exposure to chewing simulation and thermocycling. Crowns of all test groups exhibited cohesive fracture within the monolithic crown structure only, and no abutment fractures or screw loosening were observed.

CONCLUSION

When supported by implants, monolithic zirconia restorations cemented to hybrid abutments withstand masticatory forces. Also, fatigue loading accompanied by simultaneous thermocycling significantly reduces the strength of both of the all-ceramic materials. Moreover, further research is needed to define potentials, limits, and long-term serviceability of the materials and hybrid abutments.

Keyword

Figure

Cited by 1 articles

-

Influence of abutment height and convergence angle on the retrievability of cement-retained implant prostheses with a lingual slot

Kyu-Hyung Choi, KeunBaDa Son, Du-Hyeong Lee, Kyu-Bok Lee

J Adv Prosthodont. 2018;10(5):381-387. doi: 10.4047/jap.2018.10.5.381.

Reference

-

1. Kapos T, Evans C. CAD/CAM technology for implant abutments, crowns, and superstructures. Int J Oral Maxillofac Implants. 2014; 29:117–136. PMID: 24660194.

Article2. Santos MJ, Costa MD, Rubo JH, Pegoraro LF, Santos GC Jr. Current all-ceramic systems in dentistry: a review. Compend Contin Educ Dent. 2015; 36:31–37. quiz 38, 40. PMID: 25822404.3. Pallis K, Griggs JA, Woody RD, Guillen GE, Miller AW. Fracture resistance of three all-ceramic restorative systems for posterior applications. J Prosthet Dent. 2004; 91:561–569. PMID: 15211299.

Article4. Batson ER, Cooper LF, Duqum I, Mendonça G. Clinical outcomes of three different crown systems with CAD/CAM technology. J Prosthet Dent. 2014; 112:770–777. PMID: 24980739.

Article5. Larsson C, Wennerberg A. The clinical success of zirconia-based crowns: a systematic review. Int J Prosthodont. 2014; 27:33–43. PMID: 24392475.

Article6. Fasbinder DJ, Dennison JB, Heys D, Neiva G. A clinical evaluation of chairside lithium disilicate CAD/CAM crowns: a two-year report. J Am Dent Assoc. 2010; 141:10S–14S. PMID: 20516109.7. Avivi-Arber L, Zarb GA. Clinical effectiveness of implant-supported single-tooth replacement: the Toronto Study. Int J Oral Maxillofac Implants. 1996; 11:311–321. PMID: 8752552.8. Scheller H, Urgell JP, Kultje C, Klineberg I, Goldberg PV, Stevenson-Moore P, Alonso JM, Schaller M, Corria RM, Engquist B, Toreskog S, Kastenbaum F, Smith CR. A 5-year multicenter study on implant-supported single crown restorations. Int J Oral Maxillofac Implants. 1998; 13:212–218. PMID: 9581407.9. Prestipino V, Ingber A. Esthetic high-strength implant abutments. Part I. J Esthet Dent. 1993; 5:29–36. PMID: 8507510.10. Prestipino V, Ingber A. Esthetic high-strength implant abutments. Part II. J Esthet Dent. 1993; 5:63–68. PMID: 8240848.

Article11. Glauser R, Sailer I, Wohlwend A, Studer S, Schibli M, Schärer P. Experimental zirconia abutments for implant-supported single-tooth restorations in esthetically demanding regions: 4-year results of a prospective clinical study. Int J Prosthodont. 2004; 17:285–290. PMID: 15237873.12. Sailer I, Sailer T, Stawarczyk B, Jung RE, Hämmerle CH. In vitro study of the influence of the type of connection on the fracture load of zirconia abutments with internal and external implant-abutment connections. Int J Oral Maxillofac Implants. 2009; 24:850–858. PMID: 19865625.13. Nascimento C, Pita MS, Fernandes FH, Pedrazzi V, de Albuquerque Junior RF, Ribeiro RF. Bacterial adhesion on the titanium and zirconia abutment surfaces. Clin Oral Implants Res. 2014; 25:337–343. PMID: 23316996.

Article14. Gomes AL, Montero J. Zirconia implant abutments: a review. Med Oral Patol Oral Cir Bucal. 2011; 16:e50–e55. PMID: 20526253.

Article15. Kohal RJ, Att W, Bächle M, Butz F. Ceramic abutments and ceramic oral implants. An update. Periodontol 2000. 2008; 47:224–243. PMID: 18412584.

Article16. Lin WS, Harris BT, Zandinejad A, Martin WC, Morton D. Use of prefabricated titanium abutments and customized anatomic lithium disilicate structures for cement-retained implant restorations in the esthetic zone. J Prosthet Dent. 2014; 111:181–185. PMID: 24360007.

Article17. Hornbrook D. Case report using the “H” abutment: achieving esthetics, strength, and predictability for the anterior implant. Compend Contin Educ Dent. 2015; 36:192194–198. 200–201. PMID: 25822745.18. Traini T, Pettinicchio M, Murmura G, Varvara G, Di Lullo N, Sinjari B, Caputi S. Esthetic outcome of an immediately placed maxillary anterior single-tooth implant restored with a custom-made zirconia-ceramic abutment and crown: a staged treatment. Quintessence Int. 2011; 42:103–108. PMID: 21359243.19. Selz CF, Vuck A, Guess PC. Full-mouth rehabilitation with monolithic CAD/CAM-fabricated hybrid and all-ceramic materials: A case report and 3-year follow up. Quintessence Int. 2016; 47:115–121. PMID: 26417616.20. Rosentritt M, Hagemann A, Hahnel S, Behr M, Preis V. In vitro performance of zirconia and titanium implant/abutment systems for anterior application. J Dent. 2014; 42:1019–1026. PMID: 24699071.

Article21. Silva NR, Teixeira HS, Silveira LM, Bonfante EA, Coelho PG, Thompson VP. Reliability and Failure Modes of a Hybrid Ceramic Abutment Prototype. J Prosthodont. Epub 2016 Feb 24.

Article22. Honda J, Komine F, Kamio S, Taguchi K, Blatz MB, Matsumura H. Fracture resistance of implant-supported screw-retained zirconia-based molar restorations. Clin Oral Implants Res. 2017; 28:1119–1126. PMID: 27412687.

Article23. Kelly JR, Rungruanganunt P. Fatigue Behavior of Computer-Aided Design/Computer-Assisted Manufacture Ceramic Abutments as a Function of Design and Ceramics Processing. Int J Oral Maxillofac Implants. 2016; 31:601–609. PMID: 27183069.

Article24. Stimmelmayr M, Heiss P, Erdelt K, Schweiger J, Beuer F. Fracture resistance of different implant abutments supporting all-ceramic single crowns after aging. Int J Comput Dent. 2017; 20:53–64. PMID: 28294205.25. Att W, Kurun S, Gerds T, Strub JR. Fracture resistance of single-tooth implant-supported all-ceramic restorations: an in vitro study. J Prosthet Dent. 2006; 95:111–116. PMID: 16473084.

Article26. Coelho PG, Silva NR, Bonfante EA, Guess PC, Rekow ED, Thompson VP. Fatigue testing of two porcelain-zirconia all-ceramic crown systems. Dent Mater. 2009; 25:1122–1127. PMID: 19395078.

Article27. Gibbs CH, Lundeen HC, Mahan PE, Fujimoto J. Chewing movements in relation to border movements at the first molar. J Prosthet Dent. 1981; 46:308–322. PMID: 6943340.

Article28. Strub JR, Gerds T. Fracture strength and failure mode of five different single-tooth implant-abutment combinations. Int J Prosthodont. 2003; 16:167–171. PMID: 12737249.29. Ouzer A. The evolution and fabrication of implant-supported full-arch hybrid prostheses. From conventional casted metal to an all-ceramic zirconia. N Y State Dent J. 2015; 81:44–49.30. Kern M, Strub JR, Lü XY. Wear of composite resin veneering materials in a dual-axis chewing simulator. J Oral Rehabil. 1999; 26:372–378. PMID: 10373083.

Article31. Kelly JR. Clinically relevant approach to failure testing of all-ceramic restorations. J Prosthet Dent. 1999; 81:652–661. PMID: 10347352.

Article32. Kobayashi K, Kuwajima H, Masaki T. Phase change and mechanical properties of ZrO2-Y2O3 solid electrolyte after ageing. Solid State Ionics. 1981; 3:489–495.33. Beuer F, Schweiger J, Eichberger M, Kappert HF, Gernet W, Edelhoff D. High-strength CAD/CAM-fabricated veneering material sintered to zirconia copings-a new fabrication mode for all-ceramic restorations. Dent Mater. 2009; 25:121–128. PMID: 18620748.34. Lughi V, Sergo V. Low temperature degradation -aging- of zirconia: A critical review of the relevant aspects in dentistry. Dent Mater. 2010; 26:807–820. PMID: 20537701.

Article35. Chai J, Chong KH. Probability of failure of machined zirconia dental ceramic core materials. Int J Prosthodont. 2009; 22:340–341. PMID: 19639068.36. Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008; 24:299–307. PMID: 17659331.

Article37. Zhang Y, Mai Z, Barani A, Bush M, Lawn B. Fracture-resistant monolithic dental crowns. Dent Mater. 2016; 32:442–449. PMID: 26792623.

Article38. de Kok P, Kleverlaan CJ, de Jager N, Kuijs R, Feilzer AJ. Mechanical performance of implant-supported posterior crowns. J Prosthet Dent. 2015; 114:59–66. PMID: 25819357.

Article39. Zesewitz TF, Knauber AW, Nothdurft FP. Fracture resistance of a selection of full-contour all-ceramic crowns: an in vitro study. Int J Prosthodont. 2014; 27:264–266. PMID: 24905268.

Article40. Kelly JR. Dental ceramics: current thinking and trends. Dent Clin North Am. 2004; 48:513–530.41. Ritter JE. Predicting lifetimes of materials and material structures. Dent Mater. 1995; 11:142–146. PMID: 8621036.

Article42. Yildirim M, Fischer H, Marx R, Edelhoff D. In vivo fracture resistance of implant-supported all-ceramic restorations. J Prosthet Dent. 2003; 90:325–331. PMID: 14564286.

Article43. Sailer I, Philipp A, Zembic A, Pjetursson BE, Hämmerle CH, Zwahlen M. A systematic review of the performance of ceramic and metal implant abutments supporting fixed implant reconstructions. Clin Oral Implants Res. 2009; 20:4–31. PMID: 19663946.

Article44. Rosentritt M, Hahnel S, Engelhardt F, Behr M, Preis V. In vitro performance and fracture resistance of CAD/CAM-fabricated implant supported molar crowns. Clin Oral Investig. 2017; 21:1213–1219.

Article45. Taskonak B, Sertgöz A. Two-year clinical evaluation of lithia-disilicate-based all-ceramic crowns and fixed partial dentures. Dent Mater. 2006; 22:1008–1013. PMID: 16375961.

Article46. Gehrt M, Wolfart S, Rafai N, Reich S, Edelhoff D. Clinical results of lithium-disilicate crowns after up to 9 years of service. Clin Oral Investig. 2013; 17:275–284.

Article47. Zhao K, Wei YR, Pan Y, Zhang XP, Swain MV, Guess PC. Influence of veneer and cyclic loading on failure behavior of lithium disilicate glass-ceramic molar crowns. Dent Mater. 2014; 30:164–171. PMID: 24331550.

Article48. Silva NR, Bonfante EA, Martins LM, Valverde GB, Thompson VP, Ferencz JL, Coelho PG. Reliability of reduced-thickness and thinly veneered lithium disilicate crowns. J Dent Res. 2012; 91:305–310. PMID: 22205635.

Article49. Kelly JR, Rungruanganunt P, Hunter B, Vailati F. Development of a clinically validated bulk failure test for ceramic crowns. J Prosthet Dent. 2010; 104:228–238. PMID: 20875527.

Article50. Patzelt SB, Spies BC, Kohal RJ. CAD/CAM-fabricated implant-supported restorations: a systematic review. Clin Oral Implants Res. 2015; 26:77–85.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Fracture resistance and marginal fit of the zirconia crowns with varied occlusal thickness

- Effect of cement type, luting protocol, and ceramic abutment material on the shade of cemented titanium-based lithium disilicate crowns and surrounding peri-implant soft tissue: a spectrophotometric analysis

- Effect of the shades of background substructures on the overall color of zirconia-based all-ceramic crowns

- Fracture strength of zirconia monolithic crowns and metal-ceramic crowns after cyclic loading and thermocycling

- Effect of core design on fracture resistance of zirconia-lithium disilicate anterior bilayered crowns