J Adv Prosthodont.

2016 Feb;8(1):1-8. 10.4047/jap.2016.8.1.1.

Effect of metal conditioner on bonding of porcelain to cobalt-chromium alloy

- Affiliations

-

- 1Kagoshima University Medical and Dental Hospital, Fixed Prosthetic Clinic, Kagoshima, Japan.

- 2Kagoshima University Graduate School of Medical and Dental Sciences, Department of Fixed Prosthodontics, Kagoshima, Japan. murasada@dent.kagoshima-u.ac.jp

- 3A Dental Lab, Private Dental Laboratory, Kagoshima, Japan.

- 4School of Dentistry, University of Alabama at Birmingham, Division of Biomaterials, Birmingham, Alabama, United States of America.

- KMID: 2393189

- DOI: http://doi.org/10.4047/jap.2016.8.1.1

Abstract

- PURPOSE

The purpose of this study was to evaluate the efficacy of two different metal conditioners for non-precious metal alloys for the bonding of porcelain to a cobalt-chromium (Co-Cr) alloy.

MATERIALS AND METHODS

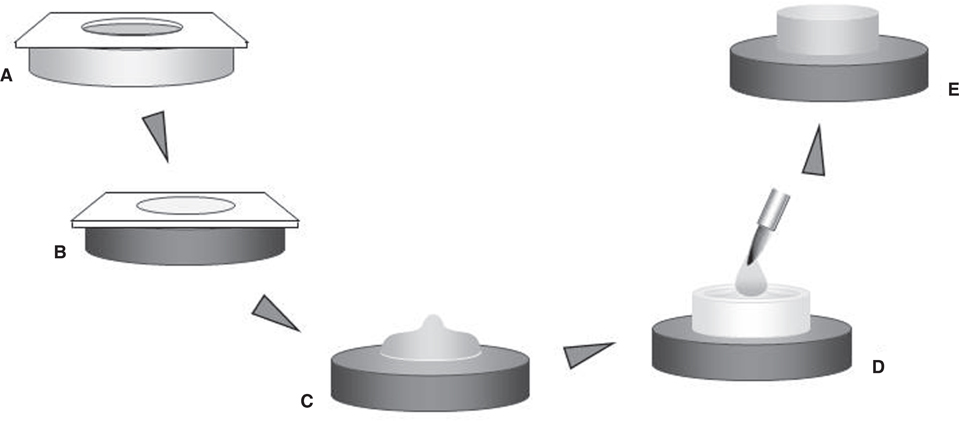

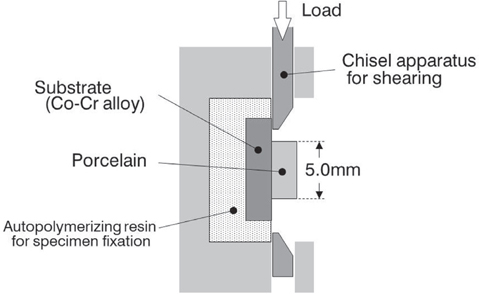

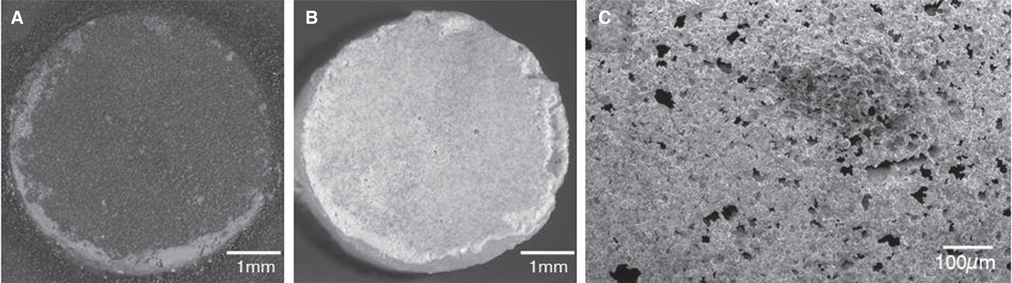

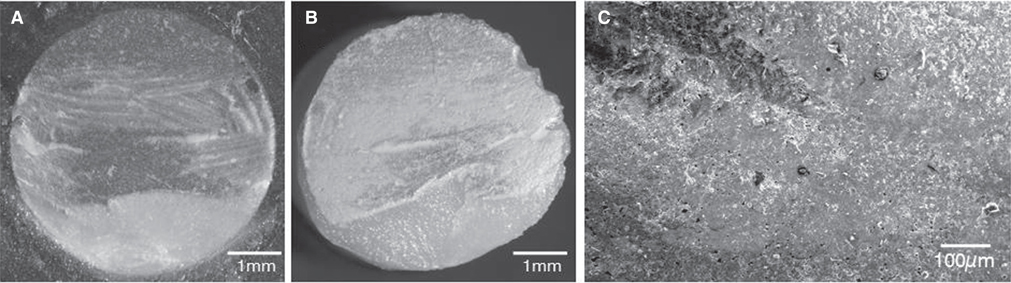

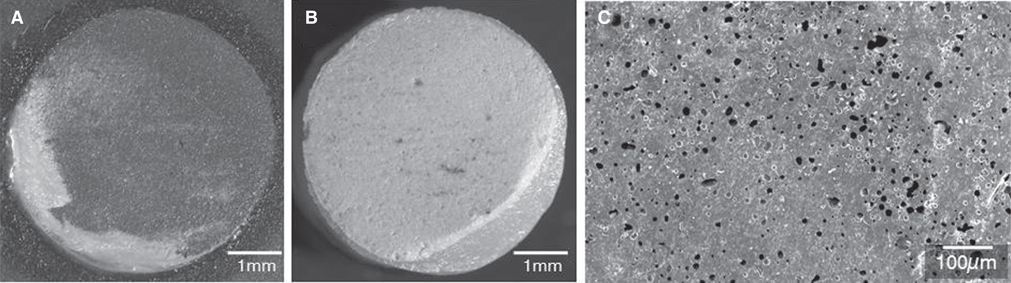

Disk-shaped specimens (2.5x10.0 mm) were cast with Co-Cr alloy and used as adherend materials. The bonding surfaces were polished with a 600-grid silicon carbide paper and airborne-particle abraded using 110 microm alumina particles. Bonding specimens were fabricated by applying and firing either of the metal conditioners on the airborne-particle abraded surface, followed by firing porcelain into 5 mm in diameter and 3 mm in height. Specimens without metal conditioner were also fabricated. Shear bond strength for each group (n=8) were measured and compared (alpha=.05). Sectional view of bonding interface was observed by SEM. EDS analysis was performed to determine the chemical elements of metal conditioners and to determine the failure modes after shear test.

RESULTS

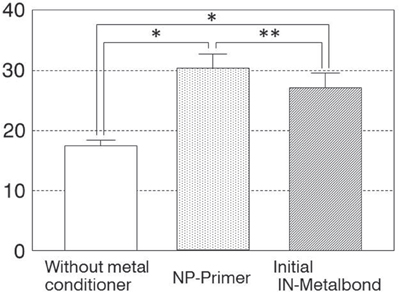

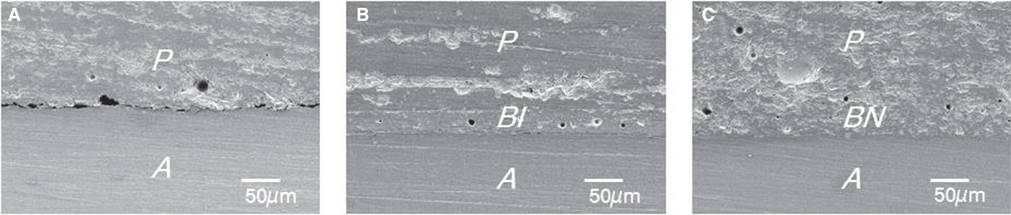

There were significant differences among three groups, and two metal conditioner-applied groups showed significantly higher values compared to the non-metal conditioner group. The SEM observation of the sectional view at bonding interface revealed loose contact at porcelain-alloy surface for non-metal conditioner group, however, close contact at both alloy-metal conditioner and metal conditioner-porcelain interfaces for both metal conditioner-applied groups. All the specimens showed mixed failures. EDS analysis showed that one metal conditioner was Si-based material, and another was Ti-based material. Si-based metal conditioner showed higher bond strengths compared to the Ti-based metal conditioner, but exhibited more porous failure surface failure.

CONCLUSION

Based on the results of this study, it can be stated that the application of metal conditioner is recommended for the bonding of porcelain to cobalt-chromium alloys.

Keyword

MeSH Terms

Figure

Reference

-

1. Schweitzer DM, Goldstein GR, Ricci JL, Silva NR, Hittelman EL. Comparison of bond strength of a pressed ceramic fused to metal versus feldspathic porcelain fused to metal. J Prosthodont. 2005; 14:239–247.2. Zarone F, Russo S, Sorrentino R. From porcelain-fused-tometal to zirconia: clinical and experimental considerations. Dent Mater. 2011; 27:83–96.3. Kern M, Sasse M, Wolfart S. Ten-year outcome of three-unit fixed dental prostheses made from monolithic lithium disilicate ceramic. J Am Dent Assoc. 2012; 143:234–240.4. Raigrodski AJ, Hillstead MB, Meng GK, Chung KH. Survival and complications of zirconia-based fixed dental prostheses: a systematic review. J Prosthet Dent. 2012; 107:170–177.5. Drummond JL, Randolph RG, Jekkals VJ, Lenke JW. Shear testing of the porcelain-metal bond. J Dent Res. 1984; 63:1400–1401.6. Rake PC, Goodacre CJ, Moore BK, Munoz CA. Effect of two opaquing techniques and two metal surface conditions on metal-ceramic bond strength. J Prosthet Dent. 1995; 74:8–17.7. Venkatachalam B, Goldstein GR, Pines MS, Hittelman EL. Ceramic pressed to metal versus feldspathic porcelain fused to metal: a comparative study of bond strength. Int J Prosthodont. 2009; 22:94–100.8. Paulino SM, Leal MB, Pagnano VO, Bezzon OL. The castability of pure titanium compared with Ni-Cr and Ni-Cr-Be alloys. J Prosthet Dent. 2007; 98:445–454.9. Nogueira F, Fais LM, Fonseca RG, Adabo GL. The influence of short-heating-cycle investments on the quality of commercially pure titanium castings. J Prosthet Dent. 2010; 104:265–272.10. Homann F, Waddell JN, Swain MV. Influence of water, loading rate and bonder on the adhesion of porcelain to titanium. J Dent. 2006; 34:485–490.11. Tholey MJ, Waddell JN, Swain MV. Influence of the bonder on the adhesion of porcelain to machined titanium as determined by the strain energy release rate. Dent Mater. 2007; 23:822–828.12. Vásquez VZ, Ozcan M, Kimpara ET. Evaluation of interface characterization and adhesion of glass ceramics to commercially pure titanium and gold alloy after thermal- and mechanical-loading. Dent Mater. 2009; 25:221–231.13. Eliasson A, Arnelund CF, Johansson A. A clinical evaluation of cobalt-chromium metal-ceramic fixed partial dentures and crowns: A three- to seven-year retrospective study. J Prosthet Dent. 2007; 98:6–16.14. Sailer I, Pjetursson BE, Zwahlen M, Hämmerle CH. A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3 years. Part II: Fixed dental prostheses. Clin Oral Implants Res. 2007; 18:86–96.15. Lombardo GH, Nishioka RS, Souza RO, Michida SM, Kojima AN, Mesquita AM, Buso L. Influence of surface treatment on the shear bond strength of ceramics fused to cobalt-chromium. J Prosthodont. 2010; 19:103–111.16. Grimaudo NJ. Biocompatibility of nickel and cobalt dental alloys. Gen Dent. 2001; 49:498–503.17. Wassell RW, Walls AW, Steele JG. Crowns and extra-coronal restorations: materials selection. Br Dent J. 2002; 192:199–202. 205–211.18. Yfantis C, Yfantis D, Anastassopoulou J, Theophanides T. Analytical and electrochemical evaluation of the in vitro corrosion behavior of nickel-chrome and cobalt-chrome casting alloys for metal-ceramic restorations. Eur J Prosthodont Restor Dent. 2007; 15:33–40.19. Mackert JR Jr, Ringle RD, Parry EE, Evans AL, Fairhurst CW. The relationship between oxide adherence and porcelain-metal bonding. J Dent Res. 1988; 67:474–478.20. Yilmaz H, Dinçer C. Comparison of the bond compatibility of titanium and an NiCr alloy to dental porcelain. J Dent. 1999; 27:215–222.21. Hegedus C, Daróczi L, Kökényesi V, Beke DL. Comparative microstructural study of the diffusion zone between NiCr alloy and different dental ceramics. J Dent Res. 2002; 81:334–337.22. Bowers JE, Vermilyea SG, Griswold WH. Effect of metal conditioners on porcelain-alloy bond strength. J Prosthet Dent. 1985; 54:201–203.23. Roberts HW, Berzins DW, Moore BK, Charlton DG. Metal-ceramic alloys in dentistry: a review. J Prosthodont. 2009; 18:188–194.24. Sarantopoulos DM, Beck KA, Holsen R, Berzins DW. Corrosion of CoCr and NiCr dental alloys alloyed with palladium. J Prosthet Dent. 2011; 105:35–43.25. Wu Y, Moser JB, Jameson LM, Malone WF. The effect of oxidation heat treatment of porcelain bond strength in selected base metal alloys. J Prosthet Dent. 1991; 66:439–444.26. de Vasconcellos LG, Buso L, Lombardo GH, Souza RO, Nogueira L Jr, Bottino MA, Ozcan M. Opaque layer firing temperature and aging effect on the flexural strength of ceramic fused to cobalt-chromium alloy. J Prosthodont. 2010; 19:471–477.27. Oliveira de Vasconcellos LG, Silva LH, Reis de Vasconcellos LM, Balducci I, Takahashi FE, Bottino MA. Effect of airborne-particle abrasion and mechanico-thermal cycling on the flexural strength of glass ceramic fused to gold or cobaltchromium alloy. J Prosthodont. 2011; 20:553–560.28. Gavelis JR, Lim SB, Guckes AD, Morency JD, Sozio RB. A comparison of the bond strength of two ceramometal systems. J Prosthet Dent. 1982; 48:424–428.29. Bienia J, Surowska B, Stoch A, Matraszek H, Walczak M. The influence of SiO2 and SiO2-TiO2 intermediate coatings on bond strength of titanium and Ti6Al4V alloy to dental porcelain. Dent Mater. 2009; 25:1128–1135.30. Saito A, Komine F, Blatz MB, Matsumura H. A comparison of bond strength of layered veneering porcelains to zirconia and metal. J Prosthet Dent. 2010; 104:247–257.31. Wu Y, Moser JB, Jameson LM, Malone WF. The effect of oxidation heat treatment of porcelain bond strength in selected base metal alloys. J Prosthet Dent. 1991; 66:439–444.32. Könönen M, Kivilahti J. Fusing of dental ceramics to titanium. J Dent Res. 2001; 80:848–854.33. Al Hussaini I, Al Wazzan KA. Effect of surface treatment on bond strength of low-fusing porcelain to commercially pure titanium. J Prosthet Dent. 2005; 94:350–356.34. Külünk T, Kurt M, Ural Ç, Külünk Ş, Baba S. Effect of different air-abrasion particles on metal-ceramic bond strength. J Dent Sci. 2011; 6:140–146.35. Sipahi C, Ozcan M. Interfacial shear bond strength between different base metal alloys and five low fusing feldspathic ceramic systems. Dent Mater J. 2012; 31:333–337.36. Graham JD, Johnson A, Wildgoose DG, Shareef MY, Cannavina G. The effect of surface treatments on the bond strength of a nonprecious alloy-ceramic interface. Int J Prosthodont. 1999; 12:330–334.37. Shimoe S, Tanoue N, Yanagida H, Atsuta M, Koizumi H, Matsumura H. Comparative strength of metal-ceramic and metal-composite bonds after extended thermocycling. J Oral Rehabil. 2004; 31:689–694.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- BOND STRENGTH BETWEEN COBALT-CHROMIUM ALLOY AND DENTURE BASE RESIN ACCORDING TO ADHESIVE PRIMERS

- Bond-strength of several metal-meramic alloys and meneered-porcelain

- Effect of adhesive primers on bonding strength of heat cure denture base resin to cast titanium and cobalt-chromium alloy

- Comparative study of shear bond strength between cp-Ti / Co-Cr alloy and composite resins

- A comparative study on the bond strength of porcelain to the millingable Pd-Ag alloy