Korean J Orthod.

2017 Jul;47(4):238-247. 10.4041/kjod.2017.47.4.238.

Effects of recycling on the biomechanical characteristics of retrieved orthodontic miniscrews

- Affiliations

-

- 1Department of Orthodontics, The Institute of Cranio-Facial Deformity, College of Dentistry, Yonsei University, Seoul, Korea. hwang@yuhs.ac

- 2Department and Research Institute of Dental Biomaterials and Bioengineering, BK21 PLUS Project, College of Dentistry, Yonsei University, Seoul, Korea.

- 3Oral Cancer Research Institute, Department of Oral Pathology, College of Dentistry, Yonsei University, Seoul, Korea.

- KMID: 2379556

- DOI: http://doi.org/10.4041/kjod.2017.47.4.238

Abstract

OBJECTIVE

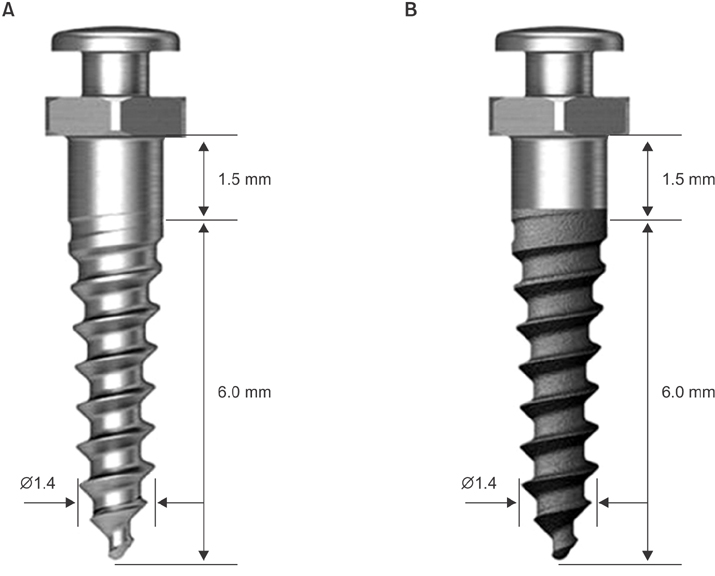

The aim of this study was to compare recycled and unused orthodontic miniscrews to determine the feasibility of reuse. The comparisons included both miniscrews with machined surfaces (MS), and those with etched surfaces (ES).

METHODS

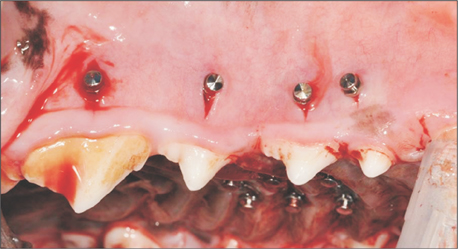

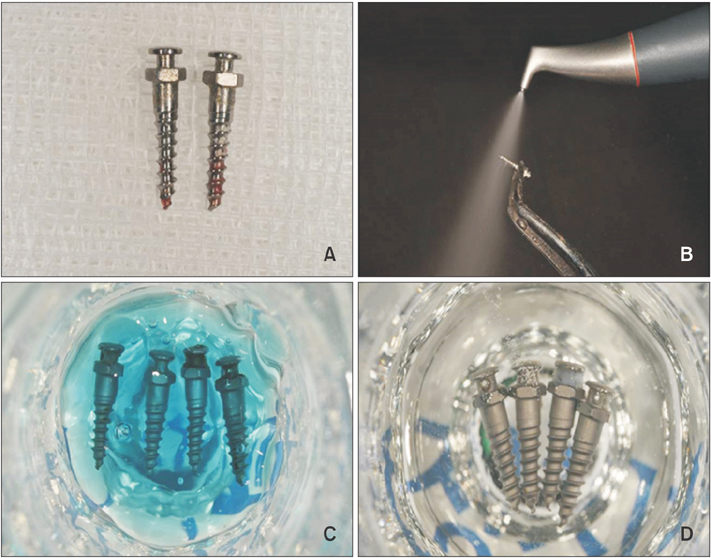

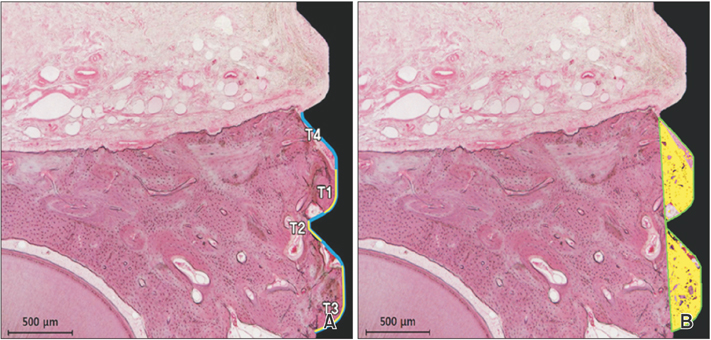

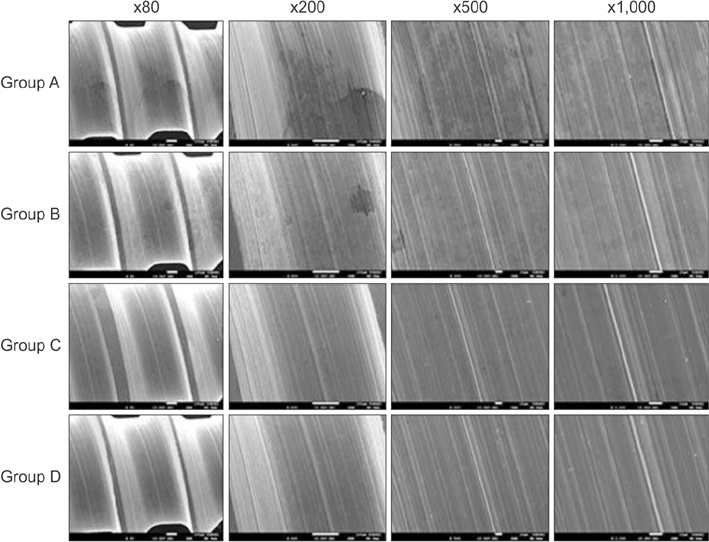

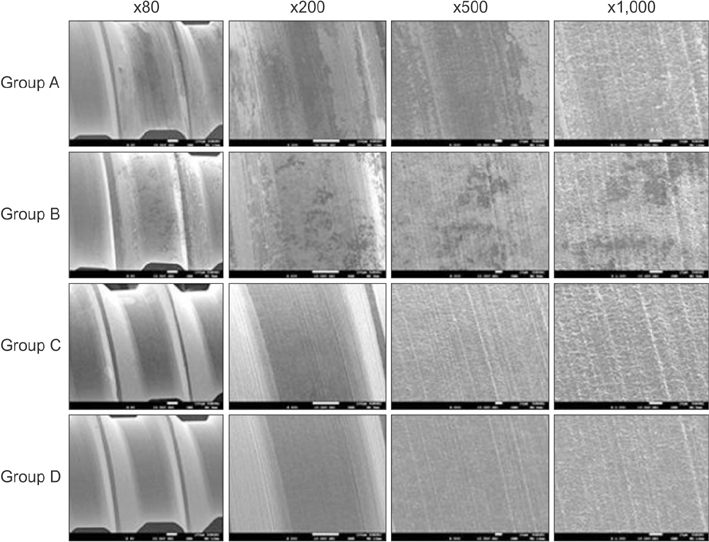

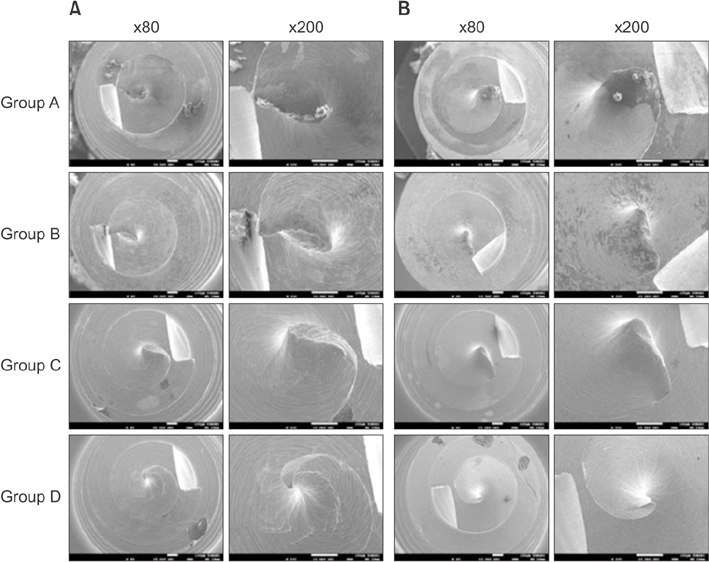

Retrieved MS and ES were further divided into three subgroups according to the assigned recycling procedure: group A, air-water spray; group B, mechanical cleaning; and group C, mechanical and chemical cleaning. Unused screws were used as controls. Scanning electron microscopy, energy-dispersive X-ray spectrometry, insertion time and maximum insertion torque measurements in artificial bone, and biological responses in the form of periotest values (PTV), bone-implant contact ratio (BIC), and bone volume ratio (BV) were assessed.

RESULTS

Morphological changes after recycling mainly occurred at the screw tip, and the cortical bone penetration success rate of recycled screws was lower than that of unused screws. Retrieved ES needed more thorough cleaning than retrieved MS to produce a surface composition similar to that of unused screws. There were no significant differences in PTV or BIC between recycled and unused screws, while the BV of the former was significantly lower than that of the latter (p < 0.05).

CONCLUSIONS

These results indicate that reuse of recycled orthodontic miniscrews may not be feasible from the biomechanical aspect.

Keyword

Figure

Reference

-

1. Park HS, Kwon TG. Sliding mechanics with microscrew implant anchorage. Angle Orthod. 2004; 74:703–710.2. Choi SH, Jang SH, Cha JY, Hwang CJ. Evaluation of the surface characteristics of anodic oxidized miniscrews and their impact on biomechanical stability: An experimental study in beagle dogs. Am J Orthod Dentofacial Orthop. 2016; 149:31–38.

Article3. Miyawaki S, Koyama I, Inoue M, Mishima K, Sugahara T, Takano-Yamamoto T. Factors associated with the stability of titanium screws placed in the posterior region for orthodontic anchorage. Am J Orthod Dentofacial Orthop. 2003; 124:373–378.

Article4. Cheng SJ, Tseng IY, Lee JJ, Kok SH. A prospective study of the risk factors associated with failure of mini-implants used for orthodontic anchorage. Int J Oral Maxillofac Implants. 2004; 19:100–106.5. Hong SB, Kusnoto B, Kim EJ, BeGole EA, Hwang HS, Lim HJ. Prognostic factors associated with the success rates of posterior orthodontic miniscrew implants: A subgroup meta-analysis. Korean J Orthod. 2016; 46:111–126.

Article6. Chung CJ, Jung KY, Choi YJ, Kim KH. Biomechanical characteristics and reinsertion guidelines for retrieved orthodontic miniscrews. Angle Orthod. 2014; 84:878–884.

Article7. Noorollahian S, Alavi S, Rafiei E. The effect of multiple processing and re-use on orthodontic mini-screw torque values. Dent Res J (Isfahan). 2015; 12:243–247.8. Noorollahian S, Alavi S, Monirifard M. A processing method for orthodontic mini-screws reuse. Dent Res J (Isfahan). 2012; 9:447–451.9. Choi SH, Cha JY, Joo UH, Hwang CJ. Surface changes of anodic oxidized orthodontic titanium miniscrew. Angle Orthod. 2012; 82:522–528.

Article10. Cho YC, Cha JY, Hwang CJ, Park YC, Jung HS, Yu HS. Biologic stability of plasma ion-implanted miniscrews. Korean J Orthod. 2013; 43:120–126.

Article11. Park JH, Olivares-Navarrete R, Baier RE, Meyer AE, Tannenbaum R, Boyan BD, et al. Effect of cleaning and sterilization on titanium implant surface properties and cellular response. Acta Biomater. 2012; 8:1966–1975.

Article12. Cochis A, Fini M, Carrassi A, Migliario M, Visai L, Rimondini L. Effect of air polishing with glycine powder on titanium abutment surfaces. Clin Oral Implants Res. 2013; 24:904–909.

Article13. Sahrmann P, Ronay V, Sener B, Jung RE, Attin T, Schmidlin PR. Cleaning potential of glycine air-flow application in an in vitro peri-implantitis model. Clin Oral Implants Res. 2013; 24:666–670.

Article14. Chairay JP, Boulekbache H, Jean A, Soyer A, Bouchard P. Scanning electron microscopic evaluation of the effects of an air-abrasive system on dental implants: a comparative in vitro study between machined and plasma-sprayed titanium surfaces. J Periodontol. 1997; 68:1215–1222.

Article15. Zafar MS, Ahmed N. The effects of acid etching time on surface mechanical properties of dental hard tissues. Dent Mater J. 2015; 34:315–320.

Article16. Kamburis JJ, Barker TH, Barfield RD, Eleazer PD. Removal of organic debris from bovine dentin shavings. J Endod. 2003; 29:559–561.

Article17. Eliades T, Zinelis S, Papadopoulos MA, Eliades G. Characterization of retrieved orthodontic miniscrew implants. Am J Orthod Dentofacial Orthop. 2009; 135:10.e1–10.e7. discussion 10-1.

Article18. Shank SB, Beck FM, D'Atri AM, Huja SS. Bone damage associated with orthodontic placement of miniscrew implants in an animal model. Am J Orthod Dentofacial Orthop. 2012; 141:412–418.

Article19. Yadav S, Upadhyay M, Liu S, Roberts E, Neace WP, Nanda R. Microdamage of the cortical bone during mini-implant insertion with self-drilling and self-tapping techniques: a randomized controlled trial. Am J Orthod Dentofacial Orthop. 2012; 141:538–546.

Article20. Youn JW, Cha JY, Yu HS, Hwang CJ. Biologic evaluation of a hollow-type miniscrew implant: an experimental study in beagles. Am J Orthod Dentofacial Orthop. 2014; 145:626–637.

Article21. Jung UW, Kim S, Kim YH, Cha JK, Lee IS, Choi SH. Osseointegration of dental implants installed without mechanical engagement: a histometric analysis in dogs. Clin Oral Implants Res. 2012; 23:1297–1301.

Article22. Eom TG, Jeon GR, Jeong CM, Kim YK, Kim SG, Cho IH, et al. Experimental study of bone response to hydroxyapatite coating implants: bone-implant contact and removal torque test. Oral Surg Oral Med Oral Pathol Oral Radiol. 2012; 114:411–418.

Article23. Cha JY, Lim JK, Song JW, Sato D, Kenmotsu M, Inoue T, et al. Influence of the length of the loading period after placement of orthodontic mini-implants on changes in bone histomorphology: microcomputed tomographic and histologic analysis. Int J Oral Maxillofac Implants. 2009; 24:842–849.24. Wei G, Hu Y, Zheng L, Huo J, Tang T, Deng F. Bone remodeling at microscrew interface near extraction site in the beagle dog mandible-histologic and immunohistochemical analyses. J Appl Oral Sci. 2013; 21:443–451.

Article25. Oh EJ, Nguyen TD, Lee SY, Jeon YM, Bae TS, Kim JG. Enhanced compatibility and initial stability of Ti6Al4V alloy orthodontic miniscrews subjected to anodization, cyclic precalcification, and heat treatment. Korean J Orthod. 2014; 44:246–253.

Article26. Chang CS, Lee TM, Chang CH, Liu JK. The effect of microrough surface treatment on miniscrews used as orthodontic anchors. Clin Oral Implants Res. 2009; 20:1178–1184.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Influence of immediate loading on the removal torque value of mini-screws

- Effect of a miniscrew surgical guide on the success rate and root proximity of orthodontic miniscrews: A retrospective cohort study

- Enhanced compatibility and initial stability of Ti6Al4V alloy orthodontic miniscrews subjected to anodization, cyclic precalcification, and heat treatment

- Comparison of insertion torque regarding changes in shape, diameter, and length of orthodontic miniscrews

- A study on titanium miniscrew as orthodontic anchorage: An experimental investigation in dogs