J Adv Prosthodont.

2017 Apr;9(2):104-109. 10.4047/jap.2017.9.2.104.

Acid etching of glass-infiltrated zirconia and its biological response

- Affiliations

-

- 1Department of Prosthodontics, Dental Science Research Institute, School of Dentistry, Chonnam National University, Gwangju, Republic of Korea. psw320@jnu.ac.kr

- 2RIS Foundation for Advanced Biomaterial, School of Dentistry, Chonnam National University, Gwangju, Republic of Korea.

- KMID: 2376297

- DOI: http://doi.org/10.4047/jap.2017.9.2.104

Abstract

- PURPOSE

The purpose of this study was to evaluate the influence of acid etching treatment on surface characteristics and biological response of glass-infiltrated zirconia.

MATERIALS AND METHODS

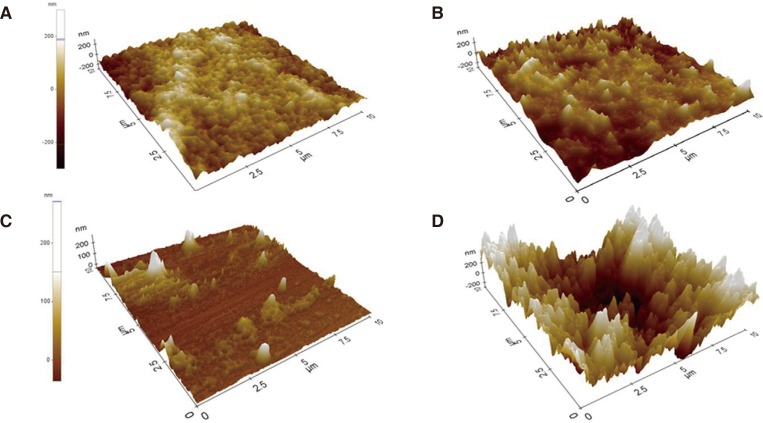

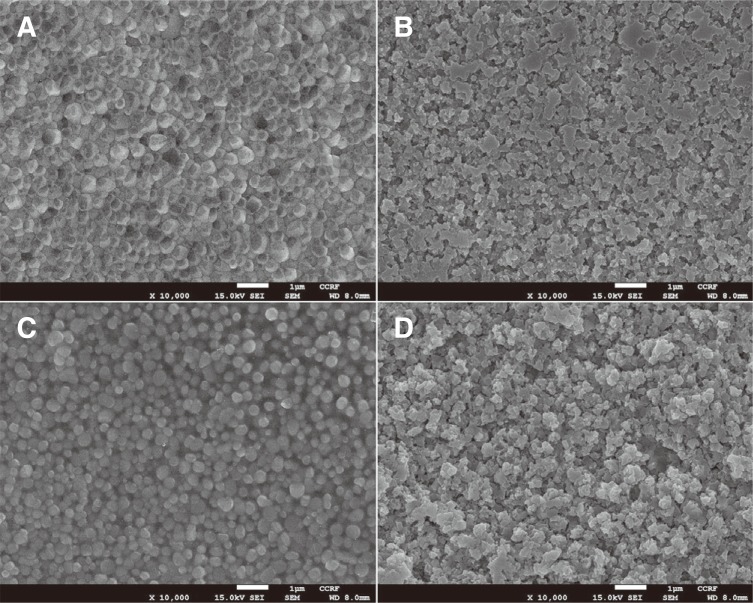

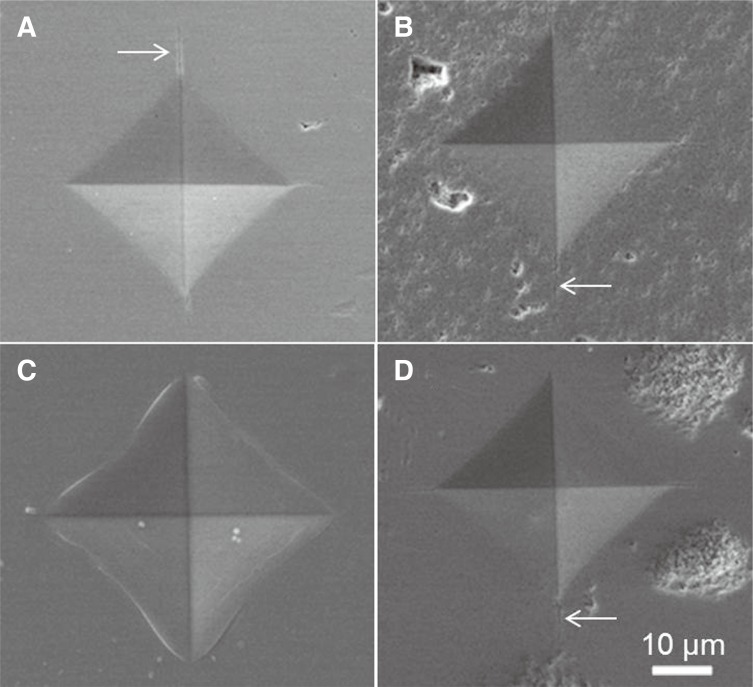

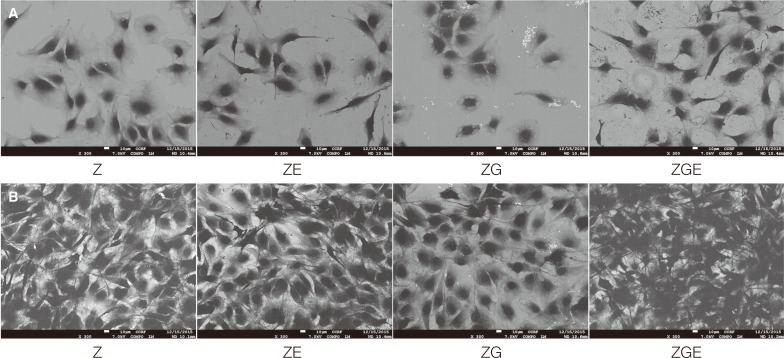

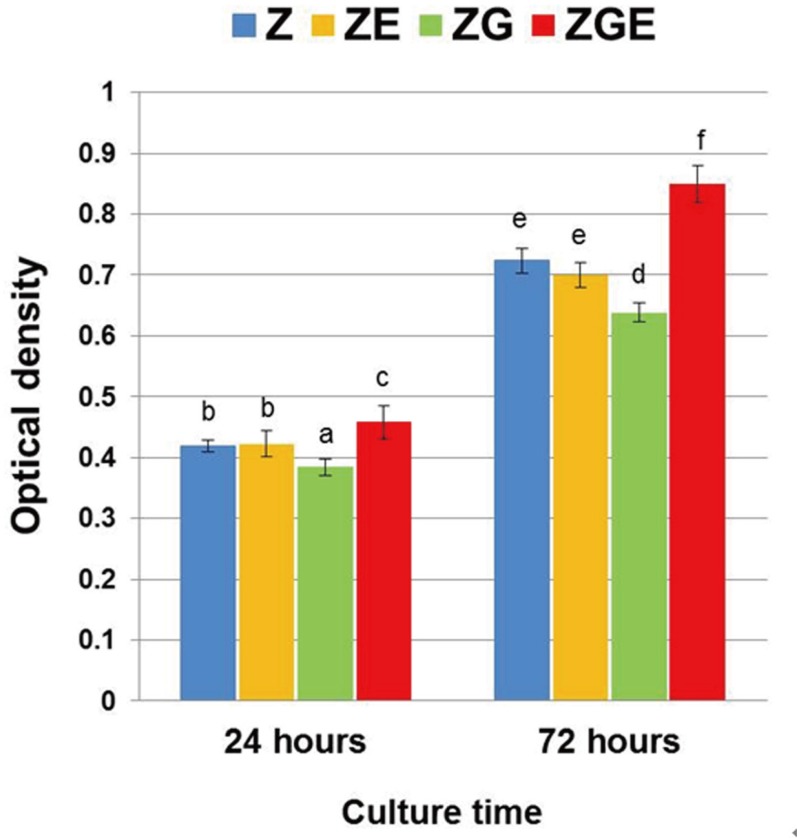

A hundred zirconia specimens were divided into four groups depending on surface treatments: untreated zirconia (group Z); acid-etched zirconia (group ZE); glass-infiltrated zirconia (group ZG); and glass-infiltrated and acid-etched zirconia (group ZGE). Surface roughness, surface topography, surface morphology, and Vickers hardness of specimens were evaluated. For biological response test, MC3T3-E1 cell attachment and proliferation on surface of the specimens were examined. The data were statistically analyzed using one-way ANOVA and Tukey's HSD test at a significance level of 0.05.

RESULTS

Group ZGE showed the highest surface roughness (Ra = 1.54 µm) compared with other groups (P < .05). Meanwhile, the hardness of group Z was significantly higher than those of other groups (P < .05). Cell attachment and cell proliferation were significantly higher in group ZGE (P < .05).

CONCLUSION

We concluded that effective surface roughness on zirconia could be made by acid etching treatment after glass infiltration. This surface showed significantly enhanced osteoblast cell response.

MeSH Terms

Figure

Reference

-

1. Kelly JR, Denry I. Stabilized zirconia as a structural ceramic: an overview. Dent Mater. 2008; 24:289–298. PMID: 17624420.

Article2. Zarone F, Russo S, Sorrentino R. From porcelain-fused-to metal to zirconia: clinical and experimental considerations. Dent Mater. 2011; 27:83–96. PMID: 21094996.3. Uo M, Sjogren G, Sundh A, Watari F, Bergman M, Lerner U. Cytotoxicity and bonding property of dental ceramics. Dent Mater. 2003; 19:487–492. PMID: 12837396.

Article4. Yamashita D, Machigashira M, Miyamoto M, Takeuchi H, Noguchi K, Izumi Y, Ban S. Effect of surface roughness on initial responses of osteoblast-like cells on two types of zirconia. Dent Mater J. 2009; 28:461–470. PMID: 19721284.

Article5. Bächle M, Butz F, Hübner U, Bakalinis E, Kohal RJ. Behavior of CAL72 osteoblast-like cells cultured on zirconia ceramics with different surface topographies. Clin Oral Implants Res. 2007; 18:53–59. PMID: 17224024.

Article6. Ewais OH, Al AF, Ghoneim MM, Aboushelib MN. Novel zirconia surface treatments for enhanced osseointegration: laboratory characterization. Int J Dent. 2014; 2014:203940. PMID: 25349610.

Article7. Schwartz Z, Boyan BD. Underlying mechanisms at the bone-biomaterial interface. J Cell Biochem. 1994; 56:340–347. PMID: 7876327.

Article8. Krajewski A, Malavolti R, Piancastelli A. Albumin adhesion on some biological and non-biological glasses and connection with their Z-potentials. Biomaterials. 1996; 17:53–60. PMID: 8962948.

Article9. Hench LL. The story of Bioglass. J Mater Sci Mater Med. 2006; 17:967–978. PMID: 17122907.

Article10. Kristen A, Hausmann A, Weber M, Fisher J, Fisher H. Bioactive and thermally compatible glass coating on zirconia dental implants. J Dent Res. 2015; 94:297–303. PMID: 25421839.

Article11. Srikanth R, Kosmac T, Bona AD, Yin L, Zhang Y. Effects of cementation surface modifications on fracture resistance of zirconia. Dent Mater. 2015; 31:435–442. PMID: 25687628.

Article12. Suresh S. Graded materials for resistance to contact deformation and damage. Science. 2001; 292:2447–2451. PMID: 11431558.

Article13. Iwaya Y, Machigashira M, Kanbara K, Miyamoto M, Noguchi K, Izumi Y, Ban S. Surface properties and biocompatibility of acid-etched titanium. Dent Mater J. 2008; 27:415–421. PMID: 18717170.

Article14. Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cementation to zirconia and other non-silicate ceramics: where are we now? Dent Mater. 2011; 27:71–82. PMID: 21094526.

Article15. Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent. 2003; 89:268–274. PMID: 12644802.

Article16. Canay S, Hersek N, Ertan A. Effect of different acid treatments on a porcelain surface. J Oral Rehabil. 2001; 28:95–101. PMID: 11298915.17. Borges GA, Sophr AM, de Goes MF, Sobrinho LC, Chan DC. Effect of etching and airborne particle abrasion on the microstructure of different dental ceramics. J Prosthet Dent. 2003; 89:479–488. PMID: 12806326.

Article18. Pisani-Proenca J, Erhardt MC, Valandro LF, Gutierrez-Aceves G, Bolanos-Carmona MV, Del Castillo-Salmeron R, Bottino MA. Influence of ceramic surface conditioning and resin cements on microtensile bond strength to a glass ceramic. J Prosthet Dent. 2006; 96:412–417. PMID: 17174658.

Article19. Sykaras N, Iacopino AM, Marker VA, Triplett RG, Woody RD. Implant materials, designs, and surface topographies: their effect on osseointegration. A literature review. Int J Oral Maxillofac Implants. 2000; 15:675–690. PMID: 11055135.20. Bona A, Donassollo TA, Demarco FF, Barrett AA, Mecholsky JJ Jr. Characterization and surface treatment effects on topography of a glass-infiltrated alumina/zirconia-reinforced ceramic. Dent Mater. 2007; 23:769–775. PMID: 17112579.21. Flury S, Peuzfeldt A, Lussi A. Influence of surface roughness on mechanical properties of two computer-aided design/computer-aided manufacturing (CAD/CAM) ceramic materials. Oper Dent. 2012; 37:617–624. PMID: 22616923.

Article22. Keshavarz M, Idris MH, Ahmad N. Mechanical properties of stabilized zirconia nanocrystalline EB-PVD coating evaluated by micro and nanoindentation. J Adv Ceram. 2013; 2:333–340.23. Jamie JK, Robert OR. Determining the toughness of ceramics from Vickers indentation using the crack-opening displacements: an experimental study. J Am Ceram Soc. 2003; 86:1433–1436.24. Zhang Y, Ma L. Optimizaion of ceramic strength using elastic gradients. Acta Mater. 2009; 57:2721–2729. PMID: 20161019.25. Zhang Y, Sun MJ, Zhang DZ. Designing functionally graded materials with superior load bearing properties. Acta Biomater. 2012; 8:1101–1108. PMID: 22178651.26. Anselme K. Osteoblast adhesion on biomaterials. Biomaterials. 2000; 21:667–681. PMID: 10711964.

Article27. Carlsson L, Rostlund T, Albrektsson B, Albrektsson T, Branemark PI. Osseointegration of titanium implants. Acta Orthop Scand. 1986; 57:285–289. PMID: 3788488.

Article28. Bowers KT, Keller JC, Randolph BA, Wick DG, Michaels CM. Optimization of surface micromorphology for enhanced osteoblast responses in vitro. Int J Oral Maxillofac Implants. 1992; 7:302–310. PMID: 1289255.29. Teughels W, Van AN. Effect of material characteristics and/surface topography on biofilm development. Clin Oral Implants Res. 2006; 17:68–81. PMID: 16968383.30. Abbasi Z, Bahrololoom ME, Shariat MH, Bagheri R. Bioactive glasses in dentistry: a review. J Dent Biomater. 2015; 2:1–9.31. Melchers S, Uesbeck T, Winter O, Eckert H, Eder D. Effect of aluminum ion incorporation on the bioactivity and structure in mesoporous bioactive glasses. Chem Mater. 2016; 28:3254–3264.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of glass-infiltration treatments on the shear bond strength between zirconia and ultra low-fusing porcelain veneer

- A comparative study on the fracture behavior of zironia, glass infiltrated alumina and PFM full crown system

- Investigation of effect of zirconia on osseointegration by surface treatments

- Comparison of two fracture toughness testing methods using a glass-infiltrated and a zirconia dental ceramic

- The effect of silane applied to glass ceramics on surface structure and bonding strength at different temperatures