J Adv Prosthodont.

2013 May;5(2):92-97. 10.4047/jap.2013.5.2.92.

Comparative fracture strength analysis of Lava and Digident CAD/CAM zirconia ceramic crowns

- Affiliations

-

- 1Department of Dentistry, St. Catholic Hospital, Catholic University of Korea, Suwon, Republic of Korea.

- 2Department of Prosthodontics, School of Dentistry and Dental Research Institute, Seoul National University, Seoul, Republic of Korea. pros53@snu.ac.kr, jhoyang@snu.ac.kr

- KMID: 2284746

- DOI: http://doi.org/10.4047/jap.2013.5.2.92

Abstract

- PURPOSE

All-ceramic crowns are subject to fracture during function. To minimize this common clinical complication, zirconium oxide has been used as the framework for all-ceramic crowns. The aim of this study was to compare the fracture strengths of two computer-aided design/computer-aided manufacturing (CAD/CAM) zirconia crown systems: Lava and Digident.

MATERIALS AND METHODS

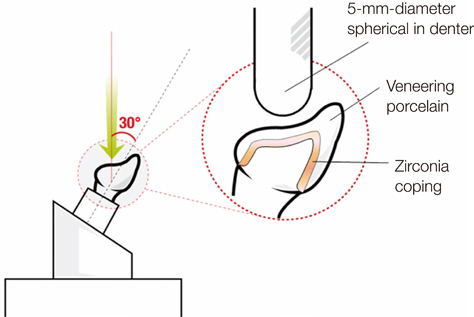

Twenty Lava CAD/CAM zirconia crowns and twenty Digident CAD/CAM zirconia crowns were fabricated. A metal die was also duplicated from the original prepared tooth for fracture testing. A universal testing machine was used to determine the fracture strength of the crowns.

RESULTS

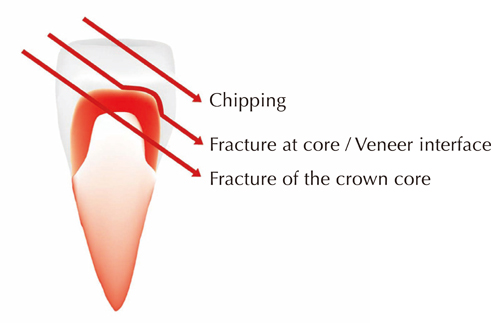

The mean fracture strengths were as follows: 54.9 +/- 15.6 N for the Lava CAD/CAM zirconia crowns and 87.0 +/- 16.0 N for the Digident CAD/CAM zirconia crowns. The difference between the mean fracture strengths of the Lava and Digident crowns was statistically significant (P<.001). Lava CAD/CAM zirconia crowns showed a complete fracture of both the veneering porcelain and the core whereas the Digident CAD/CAM zirconia crowns showed fracture only of the veneering porcelain.

CONCLUSION

The fracture strengths of CAD/CAM zirconia crowns differ depending on the compatibility of the core material and the veneering porcelain.

MeSH Terms

Figure

Reference

-

1. Ku CW, Park SW, Yang HS. Comparison of the fracture strengths of metal-ceramic crowns and three ceromer crowns. J Prosthet Dent. 2002; 88:170–175.2. Zahran M, El-Mowafy O, Tam L, Watson PA, Finer Y. Fracture strength and fatigue resistance of all-ceramic molar crowns manufactured with CAD/CAM technology. J Prosthodont. 2008; 17:370–377.3. Rosenstiel SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. St. Louis: Mosby;2001. p. 262–271.4. Sjögren G, Sletten G, Dahl JE. Cytotoxicity of dental alloys, metals, and ceramics assessed by millipore filter, agar overlay, and MTT tests. J Prosthet Dent. 2000; 84:229–236.5. Siervo S, Pampalone A, Siervo P, Siervo R. Where is the gap? Machinable ceramic systems and conventional laboratory restorations at a glance. Quintessence Int. 1994; 25:773–779.6. Drummond JL. Ceramic behavior under different environmental and loading conditions. In : Eliades G, Eliades T, Brantley WA, Watts DC, editors. Dental materials in vivo: aging and related phenomena. Chicago: Quintessence;2003. p. 35–45.7. Rosenstiel SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. St. Louis: Mosby;2001. p. 643–672.8. Evans AG. Slow crack growth in brittle materials under dynamic loading conditions. Int J Fract. 1974; 10:251–259.9. Evans AG, Johnson H. The Fracture stress and its dependence on slow crack growth. J Mater Sci. 1975; 10:214–222.10. Goodacre CJ, Bernal G, Rungcharassaeng K, Kan JY. Clinical complications in fixed prosthodontics. J Prosthet Dent. 2003; 90:31–41.11. Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005; 33:9–18.12. Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004; 20:449–456.13. Steger T. Digident CAD/CAM production--growing with the possibilities. Int J Comput Dent. 2004; 7:77–84.14. Piwowarczyk A, Ottl P, Lauer HC, Kuretzky T. A clinical report and overview of scientific studies and clinical procedures conducted on the 3M ESPE Lava All-Ceramic System. J Prosthodont. 2005; 14:39–45.15. White SN, Miklus VG, McLaren EA, Lang LA, Caputo AA. Flexural strength of a layered zirconia and porcelain dental all-ceramic system. J Prosthet Dent. 2005; 94:125–131.16. Luthardt RG, Sandkuhl O, Reitz B. Zirconia-TZP and alumina--advanced technologies for the manufacturing of single crowns. Eur J Prosthodont Restor Dent. 1999; 7:113–119.17. Snyder MD, Hogg KD. Load-to-fracture value of different all-ceramic crown systems. J Contemp Dent Pract. 2005; 6:54–63.18. Sundh A, Sjögren G. A comparison of fracture strength of yttrium-oxide-partially-stabilized zirconia ceramic crowns with varying core thickness, shapes and veneer ceramics. J Oral Rehabil. 2004; 31:682–688.19. Vult von Steyern P, Ebbesson S, Holmgren J, Haag P, Nilner K. Fracture strength of two oxide ceramic crown systems after cyclic pre-loading and thermocycling. J Oral Rehabil. 2006; 33:682–689.20. Wood KC, Berzins DW, Luo Q, Thompson GA, Toth JM, Nagy WW. Resistance to fracture of two all-ceramic crown materials following endodontic access. J Prosthet Dent. 2006; 95:33–41.21. Kelly JR. Clinically relevant approach to failure testing of all-ceramic restorations. J Prosthet Dent. 1999; 81:652–661.22. Scherrer SS, de Rijk WG. The fracture resistance of all-ceramic crowns on supporting structures with different elastic moduli. Int J Prosthodont. 1993; 6:462–467.23. Potiket N, Chiche G, Finger IM. In vitro fracture strength of teeth restored with different all-ceramic crown systems. J Prosthet Dent. 2004; 92:491–495.24. Baldassarri M, Stappert CF, Wolff MS, Thompson VP, Zhang Y. Residual stresses in porcelain-veneered zirconia prostheses. Dent Mater. 2012; 28:873–879.25. Rosentritt M, Behr M, Thaller C, Rudolph H, Feilzer A. Fracture performance of computer-aided manufactured zirconia and alloy crowns. Quintessence Int. 2009; 40:655–662.26. Beuer F, Schweiger J, Eichberger M, Kappert HF, Gernet W, Edelhoff D. High-strength CAD/CAM-fabricated veneering material sintered to zirconia copings-a new fabrication mode for all-ceramic restorations. Dent Mater. 2009; 25:121–128.27. Guazzato M, Proos K, Quach L, Swain MV. Strength, reliability and mode of fracture of bilayered porcelain/zirconia (Y-TZP) dental ceramics. Biomaterials. 2004; 25:5045–5052.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Marginal fit of the digident CAD/CAM zirconia ceramic crowns

- Influence of porcelain veneering on the marginal fit of Digident and Lava CAD/CAM zirconia ceramic crowns

- Fracture strength of zirconia ceramic crowns according to tooth position

- Comparative study in fracture strength of zirconia cores fabricated with three different CAD/CAM systems

- Fracture strength of zirconia monolithic crowns and metal-ceramic crowns after cyclic loading and thermocycling