J Adv Prosthodont.

2014 Apr;6(2):138-145. 10.4047/jap.2014.6.2.138.

Physico-mechanical properties and prosthodontic applications of Co-Cr dental alloys: a review of the literature

- Affiliations

-

- 1Dental Biomaterials Research and Development Chair, College of Dentistry, King Saud University, Saudi Arabia. yaljabbari@ksu.edu.sa

- 2Department of Prosthetic Dental Sciences, College of Dentistry, King Saud University, Saudi Arabia.

- KMID: 2233343

- DOI: http://doi.org/10.4047/jap.2014.6.2.138

Abstract

- Cobalt-Chromium (Co-Cr) alloys are classified as predominantly base-metal alloys and are widely known for their biomedical applications in the orthopedic and dental fields. In dentistry, Co-Cr alloys are commonly used for the fabrication of metallic frameworks of removable partial dentures and recently have been used as metallic substructures for the fabrication of porcelain-fused-to-metal restorations and implant frameworks. The increased worldwide interest in utilizing Co-Cr alloys for dental applications is related to their low cost and adequate physico-mechanical properties. Additionally, among base-metal alloys, Co-Cr alloys are used more frequently in many countries to replace Nickel-Chromium (Ni-Cr) alloys. This is mainly due to the increased concern regarding the toxic effects of Ni on the human body when alloys containing Ni are exposed to the oral cavity. This review article describes dental applications, metallurgical characterization, and physico-mechanical properties of Co-Cr alloys and also addresses their clinical and laboratory behavior in relation to those properties.

Keyword

MeSH Terms

Figure

Cited by 1 articles

-

Metal-ceramic bond strength between a feldspathic porcelain and a Co-Cr alloy fabricated with Direct Metal Laser Sintering technique

Konstantinos Dimitriadis, Konstantinos Spyropoulos, Triantafillos Papadopoulos

J Adv Prosthodont. 2018;10(1):25-31. doi: 10.4047/jap.2018.10.1.25.

Reference

-

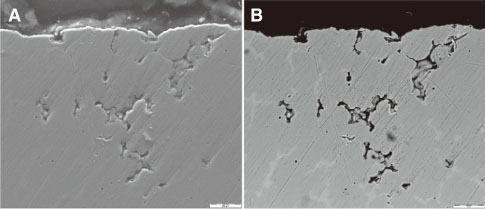

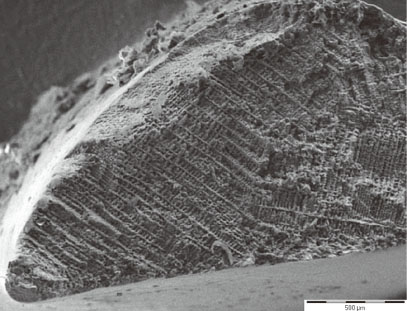

1. Crook P. Corrosion of cobalt based alloys. In : Davis J, editor. Corrosion. Materials Park OH. ASM International;1987. p. 657–700.2. Evans EJ, Thomas IT. The in vitro toxicity of cobalt-chromemolybdenum alloy and its constituent metals. Biomaterials. 1986; 7:25–29.3. Craig RG, Hanks CT. Reaction of fibroblasts to various dental casting alloys. J Oral Pathol. 1988; 17:341–347.4. Viennot S, Dalard F, Lissac M, Grosgogeat B. Corrosion resistance of cobalt-chromium and palladium-silver alloys used in fixed prosthetic restorations. Eur J Oral Sci. 2005; 113:90–95.5. Mueller H. Tarnish and corrosion of dental alloys. In : Davis J, editor. Corrosion. Materials Park OH. ASM International;1987. p. 1351–1352.6. Marti A. Cobalt-base alloys used in bone surgery. Injury. 2000; 31:18–21.7. ANSI/ADA Specification No. 38. Classification system for cast alloys. Council on Dental Materials, Instruments, and Equipment. J Am Dent Assoc. 1984; 109:766.8. ISO 6871-1. Dental base metal alloys. Part 1: Cobalt-based alloys. 1st ed. Geneva: International Organization for Standardization;1994.9. Wataha JC. Alloys for prosthodontic restorations. J Prosthet Dent. 2002; 87:351–363.10. Asgar K, Peyton FA. Effect of microstructure on the physical properties of cobalt-base alloys. J Dent Res. 1961; 40:63–72.11. Herö H, Syverud M, Gjönnes J, Horst JA. Ductility and structure of some cobalt-base dental casting alloys. Biomaterials. 1984; 5:201–208.12. Asgar K, Allan FC. Microstructure and physical properties of alloys for partial denture castings. J Dent Res. 1968; 47:189–197.13. Anusavice KJ, Phillips RW. Phillips' science of dental materials. Philadelphia: WB Saunders;1996. p. 423–459.14. van Noort R, Lamb DJ. A scanning electron microscope study of Co-Cr partial dentures fractured in service. J Dent. 1984; 12:122–126.15. Geis-Gerstorfer J, Sauer KH, Pässler K. Ion release from Ni-Cr-Mo and Co-Cr-Mo casting alloys. Int J Prosthodont. 1991; 4:152–158.16. Geis-Gerstorfer J, Weber H. In vitro corrosion behavior of four Ni-Cr dental alloys in lactic acid and sodium chloride solutions. Dent Mater. 1987; 3:289–295.17. Okazaki Y, Gotoh E. Comparison of metal release from various metallic biomaterials in vitro. Biomaterials. 2005; 26:11–21.18. Montero-Ocampo C, Rodriguez AS. Effect of carbon content on the resistance to localized corrosion of as-cast cobalt-based alloys in an aqueous chloride solution. J Biomed Mater Res. 1995; 29:441–453.19. Yeung AL, Lo EC, Chow TW, Clark RK. Oral health status of patients 5-6 years after placement of cobalt-chromium removable partial dentures. J Oral Rehabil. 2000; 27:183–189.20. Chandler JA, Brudvik JS. Clinical evaluation of patients eight to nine years after placement of removable partial dentures. J Prosthet Dent. 1984; 51:736–743.21. Schwalm CA, Smith DE, Erickson JD. A clinical study of patients 1 to 2 years after placement of removable partial dentures. J Prosthet Dent. 1977; 38:380–391.22. Bergman B, Ericson G. Cross-sectional study of the periodontal status of removable partial denture patients. J Prosthet Dent. 1989; 61:208–211.23. Budtz-Jørgensen E, Isidor F. A 5-year longitudinal study of cantilevered fixed partial dentures compared with removable partial dentures in a geriatric population. J Prosthet Dent. 1990; 64:42–47.24. Yannikakis SA, Zissis AJ, Polyzois GL. Removable partial denture repairs: A survey. Quintessence Dent Technol. 2000; 23:184–190.25. Körber E, Lehmann K, Pangidis C. Control studies on periodontal and periodontal-gingival retention of partial prosthesis. Dtsch Zahnarztl Z. 1975; 30:77–84.26. Vermeulen AH, Keltjens HM, van't Hof MA, Kayser AF. Ten-year evaluation of removable partial dentures: survival rates based on retreatment, not wearing and replacement. J Prosthet Dent. 1996; 76:267–272.27. Bates JF. Studies related to the fracture of partial dentures; Flexural fatigue of a cobalt-chromium alloy. Br Dent J. 1965; 118:532–537.28. Bates JF. Studies related to the fracture of partial dentures. The functional strain in cobalt-chromium dentures. A preliminary report. Br Dent J. 1966; 120:79–83.29. Elarbi EA, Ismail YH, Azarbal M, Saini TS. Radiographic detection of porosities in removable partial denture castings. J Prosthet Dent. 1985; 54:674–677.30. Dharmar S, Rathnasamy RJ, Swaminathan TN. Radiographic and metallographic evaluation of porosity defects and grain structure of cast chromium cobalt removable partial dentures. J Prosthet Dent. 1993; 69:369–373.31. Lewis AJ. Radiographic evaluation of porosities in removable partial denture castings. J Prosthet Dent. 1978; 39:278–281.32. Lewis AJ. Failure of removable partial denture castings during service. J Prosthet Dent. 1978; 39:147–149.33. Lewis AJ. Microporosity in casting alloys. Aust Dent J. 1975; 20:161–166.34. Wictorin L, Julin P, Möllersten L. Roentgenological detection of casting defects in cobalt-chromium alloy frameworks. J Oral Rehabil. 1979; 6:137–146.35. Eisenburger M, Addy M. Radiological examination of dental castings - a review of the method and comparisons of the equipment. J Oral Rehabil. 2002; 29:609–614.36. Jang KS, Youn SJ, Kim YS. Comparison of castability and surface roughness of commercially pure titanium and cobaltchromium denture frameworks. J Prosthet Dent. 2001; 86:93–98.37. Morris H, Farah JW, Craig RG, Hood JA. Stress distribution within circumferential clasp arms. J Oral Rehabil. 1976; 3:387–394.38. Bridgeman JT, Marker VA, Hummel SK, Benson BW, Pace LL. Comparison of titanium and cobalt-chromium removable partial denture clasps. J Prosthet Dent. 1997; 78:187–193.39. Au AR, Lechner SK, Thomas CJ, Mori T, Chung P. Titanium for removable partial dentures (III): 2-year clinical follow-up in an undergraduate programme. J Oral Rehabil. 2000; 27:979–985.40. Lassila LV, Vallittu PK. Effect of water and artificial saliva on the low cycle fatigue resistance of cobalt-chromium dental alloy. J Prosthet Dent. 1998; 80:708–713.41. Angelini E, Bonino P, Pezzoli M, Zucchi F. Tensile strength of Cr-Co dental alloys solder joints. Dent Mater. 1989; 5:13–17.42. Louly AC, Mora AF, Moore BK, Andres CJ, Goodacre CJ. Tensile strength of preceramic solder joints formed using an infrared heat source. Int J Prosthodont. 1991; 4:425–431.43. Pattee HE. High temperature brazing. In : Schwartz MM, editor. Source book on brazing and brazing technology. Materials Park OH. ASM International;1980. p. 17–63.44. Luthy H, Marinello CP, Reclaru L, Scharer P. Corrosion considerations in the brazing repair of cobalt-based partial dentures. J Prosthet Dent. 1996; 75:515–524.45. Bertrand C, Le Petitcorps Y, Albingre L, Dupuis V. The laser welding technique applied to the non precious dental alloys procedure and results. Br Dent J. 2001; 190:255–257.46. Bertrand C, Poulon-Quintin A. Proposals for optimization of laser welding in prosthetic dentistry. J Prosthodont. 2010; 19:69–76.47. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Dental Co-Cr alloys fabricated by selective laser melting: A review article

- Comparison of Mechanical Properties of Milled and Casted Cobalt-Chromium Alloys Using Three-point Bending Test

- Comparison of the mechanical properties and microstructures of fractured surface for Co-Cr alloy fabricated by conventional cast, 3-D printing laser-sintered and CAD/CAM milled techniques

- A STUDY OF ION BEAM ASSISTED DEPOSITION(IBAD) OF TiN ON Ni-Cr Be ALLOY FOR SURFACE CHARACTERISTIC

- Properties of experimental copper-aluminium-nickel alloys for dental post-and-core applications