J Adv Prosthodont.

2016 Apr;8(2):137-143. 10.4047/jap.2016.8.2.137.

Effect of different grinding burs on the physical properties of zirconia

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Chosun University, Gwangju, Republic of Korea. son0513@chosun.ac.kr

- 2Department of Dental Materials, School of Dentistry, Chosun University, Gwangju, Republic of Korea.

- 3Department of Computer Science and Statistics, College of Natural Sciences, Chosun University, Gwangju, Republic of Korea.

- KMID: 2176655

- DOI: http://doi.org/10.4047/jap.2016.8.2.137

Abstract

- PURPOSE

Grinding with less stress on 3Y-TZP through proper selection of methods and instruments can lead to a long-term success of prosthesis. The purpose of this study was to compare the phase transformation and physical properties after zirconia surface grinding with 3 different grinding burs.

MATERIALS AND METHODS

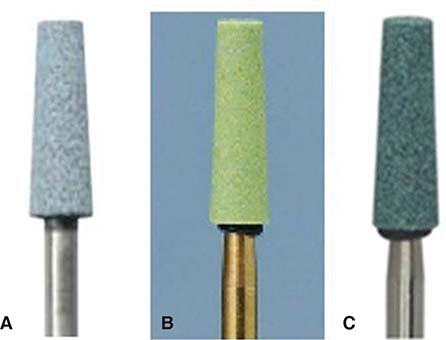

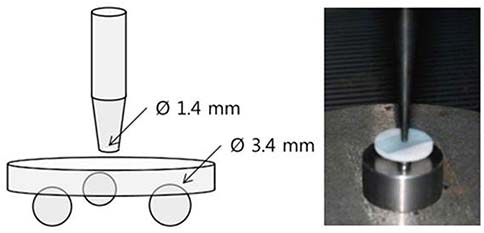

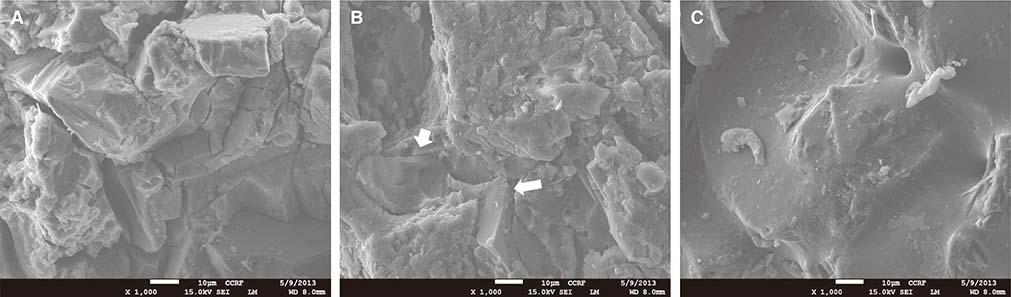

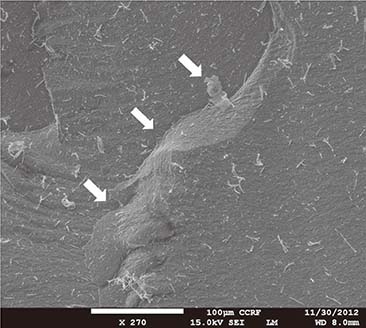

Forty disc-shaped zirconia specimens were fabricated. Each Ten specimens were ground with AllCeramic SuperMax (NTI, Kahla, Germany), Dura-Green DIA (Shofu Inc., Kyoto, Japan), and Dura-Green (Shofu Inc., Kyoto, Japan). Ten specimens were not ground and used as a control group. After the specimen grinding, XRD analysis, surface roughness test, FE-SEM imaging, and biaxial flexural strength test were performed.

RESULTS

After surface grinding, small amount of monoclinic phase in all experimental groups was observed. The phase change was higher in specimens, which were ground with Dura-Green DIA and AllCeramic SuperMax burs. The roughness of surfaces increased in specimens, which were ground with Dura-Green DIA and AllCeramic SuperMax burs than control groups and ground with Dura-Green. All experimental groups showed lower flexural strength than control group, but there was no statistically significant difference between control group and ground with Dura-Green DIA and AllCeramic SuperMax burs. The specimens, which were ground with Dura- Green showed the lowest strength.

CONCLUSION

The use of dedicated zirconia-specific grinding burs such as Dura-Green DIA and AllCeramic SuperMax burs decreases the grinding time and did not significantly affect the flexural strength of zirconia, and therefore, they may be recommended. However, a fine polishing process should be accompanied to reduce the surface roughness after grinding.

Keyword

MeSH Terms

Figure

Cited by 2 articles

-

The effect of various polishing systems on surface roughness and phase transformation of monolithic zirconia

Ipek Caglar, Sabit Melih Ates, Zeynep Yesil Duymus

J Adv Prosthodont. 2018;10(2):132-137. doi: 10.4047/jap.2018.10.2.132.Effects of different surface finishing protocols for zirconia on surface roughness and bacterial biofilm formation

Du-Hyeong Lee, Hang-Nga Mai, Phyu Pwint Thant, Su-Hyung Hong, Jaewon Kim, Seung-Mi Jeong, Keun-Woo Lee

J Adv Prosthodont. 2019;11(1):41-47. doi: 10.4047/jap.2019.11.1.41.

Reference

-

1. Kim DJ. Transformation of tetragonal zirconia. Sci Technol Ceram Mater. 1993; 8:157–165.2. Işeri U, Ozkurt Z, Yalnız A, Kazazoğlu E. Comparison of different grinding procedures on the flexural strength of zirconia. J Prosthet Dent. 2012; 107:309–315.3. Garvie RC, Hannink RH, Pascoe RT. Ceramic steel? Nature. 1975; 258:703–704.4. Sakuma T, Yoshizawa YI, Suto H. The rhombohedral phase produced in partially-stabilized zirconia. J Mater Sci Lett. 1985; 4:29–30.5. Karakoca S, Yilmaz H. Influence of surface treatments on surface roughness, phase transformation, and biaxial flexural strength of Y-TZP ceramics. J Biomed Mater Res B Appl Biomater. 2009; 91:930–937.6. Denry IL, Holloway JA. Microstructural and crystallographic surface changes after grinding zirconia-based dental ceramics. J Biomed Mater Res B Appl Biomater. 2006; 76:440–448.7. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999; 15:426–433.8. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. Strength and reliability of surface treated Y-TZP dental ceramics. J Biomed Mater Res. 2000; 53:304–313.9. Gupta TK. Strengthening by surface damage in metastable tetragonal zirconia. J Am Ceram Soc. 1980; 63:117.10. Yamaguchi H, Ino S, Hamano N, Okada S, Teranaka T. Examination of bond strength and mechanical properties of Y-TZP zirconia ceramics with different surface modifications. Dent Mater J. 2012; 31:472–480.11. Guess PC, Zhang Y, Kim JW, Rekow ED, Thompson VP. Damage and reliability of Y-TZP after cementation surface treatment. J Dent Res. 2010; 89:592–596.12. Subaşı MG, Demir N, Kara Ö, Ozturk AN, Özel F. Mechanical properties of zirconia after different surface treatments and repeated firings. J Adv Prosthodont. 2014; 6:462–467.13. Işerı U, Ozkurt Z, Kazazoğlu E, Küçükoğlu D. Influence of grinding procedures on the flexural strength of zirconia ceramics. Braz Dent J. 2010; 21:528–532.14. Garvie RC, Nicholson PS. Phase analysis in zirconia systems. J Am Ceram Soc. 1972; 55:303–305.15. Kosmac T, Wagner R, Claussen N. X-Ray determination of transformation depths in ceramics containing tetragonal ZrO2. J Am Ceram Soc. 1981; 64:c72–c73.16. International Organization for Standardization ISO 6872: 1995(E). Dental Ceramics. 2nd ed. Geneva, Switzerland: ISO;1995.17. Kao HC, Ho FY, Yang CC, Wei WJ. Surface machining of fine-grain Y-TZP. J Eur Ceram Soc. 2000; 20:2447–2455.18. Kou W, Molin M, Sjögren G. Surface roughness of five different dental ceramic core materials after grinding and polishing. J Oral Rehabil. 2006; 33:117–124.19. Kim HT, Han JS, Yang JH, Lee JB, Kim SH. The effect of low temperature aging on the mechanical property & phase stability of Y-TZP ceramics. J Adv Prosthodont. 2009; 1:113–117.20. Swain MV, Hannink RHJ. Metastability of the martensitic transformation in a 12 mol% ceria-zirconia alloy: II, grinding studies. J Am Ceram Soc. 1989; 72:1358–1364.21. Gross V, Swain MV. Mechanical properties and microstructure of sintered and hot isostatically pressed yttria partially stabilized zirconia(Y-PSZ). J Aust Ceram Soc. 1986; 22:1–12.22. Urabe K, Nakajima A. Characteristic microstructure of CeO2-Y2O3 doped tetragonal zirconia polycrystals. Adv Ceram. 1988; 24:345–355.23. Albakry M, Guazzato M, Swain MV. Biaxial flexural strength, elastic moduli, and x-ray diffraction characterization of three pressable all-ceramic materials. J Prosthet Dent. 2003; 89:374–380.24. Oh GJ, Yun KD, Lee KM, Lim HP, Park SW. Sintering behavior and mechanical properties of zirconia compacts fabricated by uniaxial press forming. J Adv Prosthodont. 2010; 2:81–87.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of surface topography and roughness in different yttrium oxide compositions of dental zirconia after grinding and polishing

- The effects of surface grinding and polishing on the phase transformation and flexural strength of zirconia

- Effects of different surface finishing protocols for zirconia on surface roughness and bacterial biofilm formation

- Review on factors affecting the optical properties of dental zirconia

- Influence of surface modification techniques on shear bond strength between different zirconia cores and veneering ceramics