J Korean Acad Prosthodont.

2012 Jul;50(3):169-175. 10.4047/jkap.2012.50.3.169.

Brazing characteristics of ZrO2 and Ti-6Al-4V brazed joints with increasing temperature

- Affiliations

-

- 1Department of Materials Science and Engineering, University of Seoul, Seoul, Korea. wjkim@uos.ac.kr

- 2NeoBiotech, Seoul, Korea.

- KMID: 2000205

- DOI: http://doi.org/10.4047/jkap.2012.50.3.169

Abstract

- PURPOSE

In this study, brazing characteristics of ZrO2 and Ti-6Al-4V brazed joints with increasing temperature were investigated.

MATERIALS AND METHODS

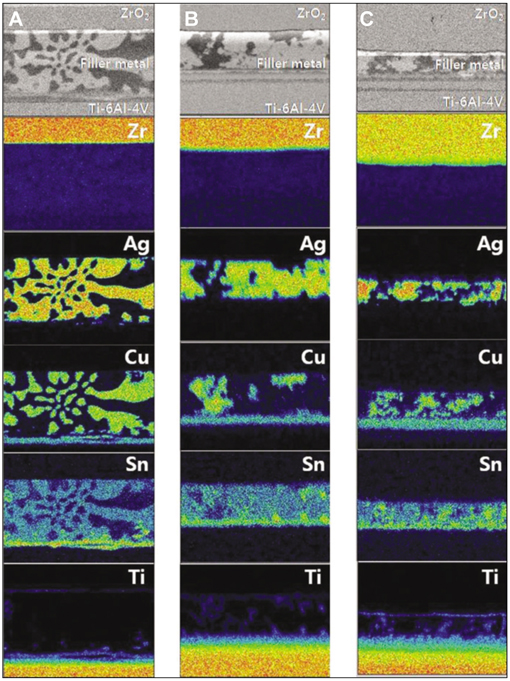

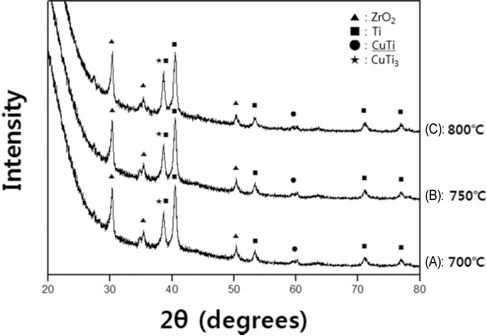

The sample size of the ZrO2 was 3 mm x 3 mm x 3 mm (thickness), and Ti-6Al-4V was 10 mm (diameter) x 5 mm (thickness). The filler metal consisted of Ag-Cu-Sn-Ti was prepared in powder form. The brazing sample was heated in a vacuum furnace under 5 x 10(-6) torr atmosphere, while the brazing temperature was changed from 700 to 800degrees C for 30 min.

RESULTS

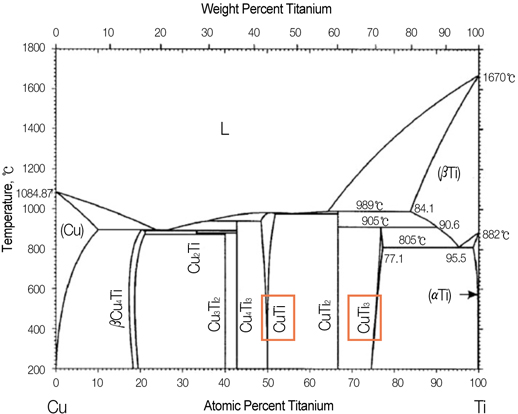

The experimental results shows that brazed joint of ZrO2 and Ti-6Al-4V occurred at 700 - 800degrees C. Brazed joint consisted of Ag-rich matrix and Cu-rich phase. A Cu-Ti intermetallic compounds and a Ti-Sn-Cu-Ag alloy were produced along the Ti-6Al-4V bonded interface. Thickness of the reacted layer along the Ti-6Al-4V bonded interface was increased with brazing temperature. Defect ratios of ZrO2 and Ti-6Al-4V bonded interfaces decreased with brazing temperature.

CONCLUSION

Thickness and defect ratio of brazed joints were decreased with increasing temperature. Zirconia was not wetting with filler metal, because the reaction between ZrO2 and Ti did not occur enough.

Keyword

MeSH Terms

Figure

Reference

-

1. Lee JB, Kim DC, Nam DG, Kang NH, Kim SK, Yu JH, Rhym YM, Park YD. Assessment of Resistance Spot Weldability of Dissimilar Joints of Austenitic Stainless Steels/IF Steels and Ferritic Stainless Steels/IF Steels. J Korean Inst Met Mater. 2011. 49:64–72.

Article2. Shinozaki K, Koyama K. Development of Al/Cu Dissimilar Brazing Joint Controlled Form of Intermetallic Compound. Mater Sci Forum. 2007. 539:4075–4080.

Article3. Hanson WB, Ironside KI, Fernie JA. Active metal brazing of zirconia. Acta Mater. 2000. 48:4673–4676.

Article4. Smorygo O, Kim JS, Kim MD, Eom TG. Evolution of the interlayermicrostructure and the fracturemodes of the zirconia/Cu-Ag-Ti filler/Ti active brazing joints. Mater Lett. 2007. 61:613–616.

Article5. Sciti D, Bellosi A, Esposito L. Bonding of zirconia to super alloy with the active brazing technique. J Euro Ceram Soc. 2001. 21:45–52.

Article6. Manicone PF, Rossi Iommetti P, Raffaelli L. An overview of zirconia ceramics: basic properties and clinical applications. J Dent. 2007. 35:819–826.

Article7. Botstein O, Schwarzman A, Rabinkin A. Inductionbrazing of Ti-6Al-4Valloy with amorphous25Ti-25Zr-50Cu brazing filler metal. Mater Sci Eng A. 1996. 206:14–23.

Article8. Akselsen OM. Advances in brazing of ceramics. J Mater Sci. 1992. 27:1989–2000.

Article9. Liu GW, Qiao GJ, Wang HJ, Yang JF, Lu TJ. Pressureless brazing of zirconia to stainless steel with Ag-Cu filler metal and TiH2 powder. J Eur Ceram Soc. 2008. 28:2701–2708.

Article10. Kee SH, Zengfeng Xu, Jung JP, Kim WJ. Joining of ceramic and metal using active metal brazing. J Microelec Pack Soc. 2011. 18:1–7.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Osteoblastic behavior to zirconium coating on Ti-6Al-4V alloy

- The evaluation of cytotoxicity and biocompatibility of Ti-Ta-Nb-base alloy

- A HISTOMORPHOMETRIC STUDY OF BONE APPOSITION TO NEWLY DEVELOPED TI-BASED ALLOYS IN RABBIT BONE

- Comparison of Cytocompatibility Between Grit Blasted Titanium Alloy (Ti-6Al-4V) with or without Pure Titanium Coating

- The effect of Zirconium Nitride coating on shear bond strength with denture base resin in Co-Cr alloy and titanium alloy