J Korean Acad Prosthodont.

2013 Jan;51(1):1-10. 10.4047/jkap.2013.51.1.1.

Three-dimensional finite element analysis of stress distribution for different implant thread slope and implant angulation

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Chonnam National University, Gwangju, Korea. msvang@chonnam.ac.kr

- 2Department of Oral and Maxillofacial Radiology, School of Dentistry, Chonnam National University, Gwangju, Korea.

- KMID: 2000180

- DOI: http://doi.org/10.4047/jkap.2013.51.1.1

Abstract

- PURPOSE

The purpose of this study was to find an inclination slope of the screw thread that is favorable in distributing the stresses to alveolar bone by using three dimensional finite element analysis.

MATERIALS AND METHODS

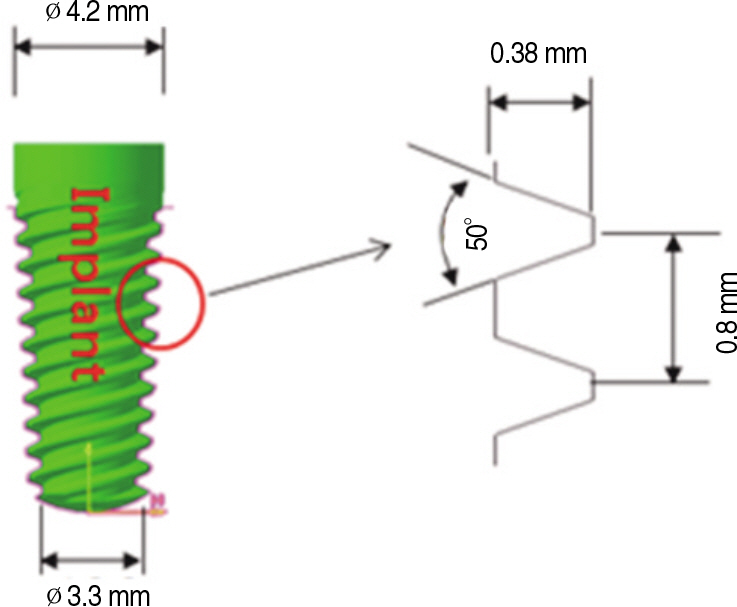

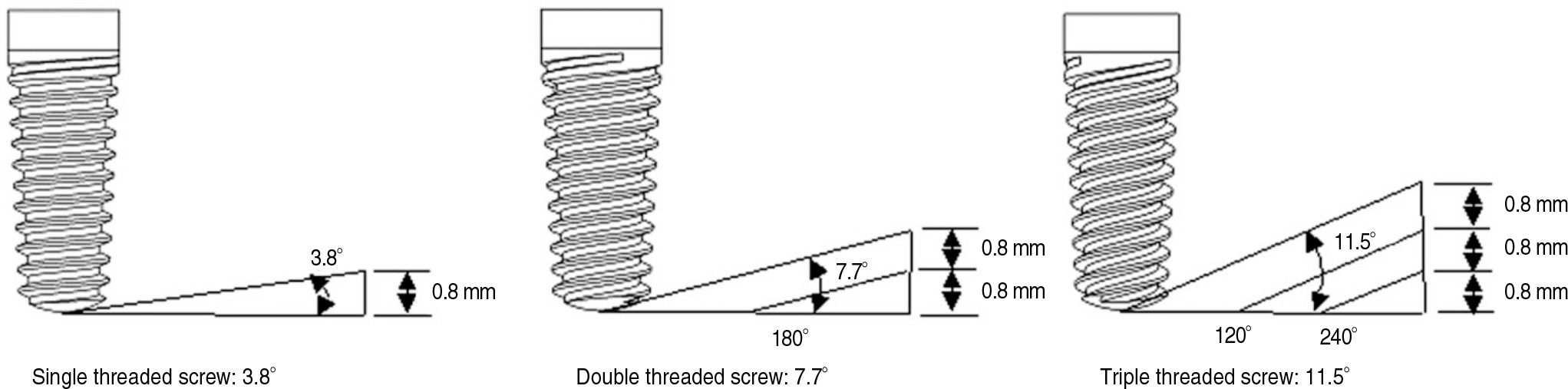

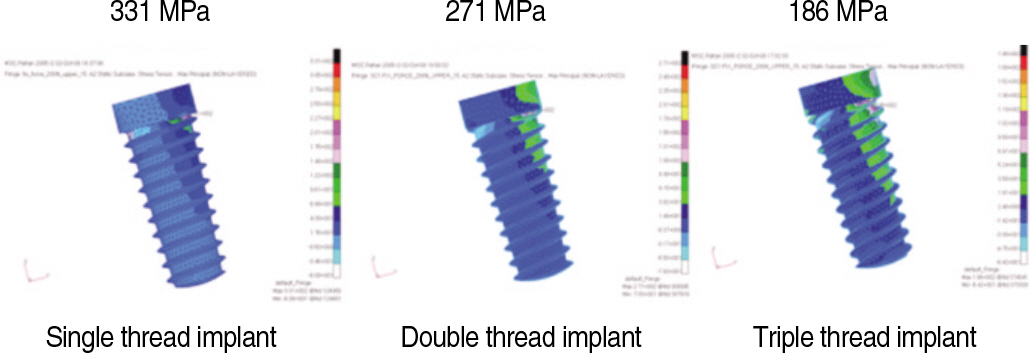

Three types modelling changed implant thread with fixed pitch of 0.8 mm is the single thread implant with 3.8degrees inclination, double thread implant with 7.7degrees inclination and the triple thread implant with 11.5degrees inclination. And three types implant angulation is the 0degrees, 10degrees and 15degrees on alveolar bone. The 9 modelling fabricated for three dimensional finite element analysis that restored prosthesis crown. The crown center applied on 200 N vertical load and 15degrees tilting load.

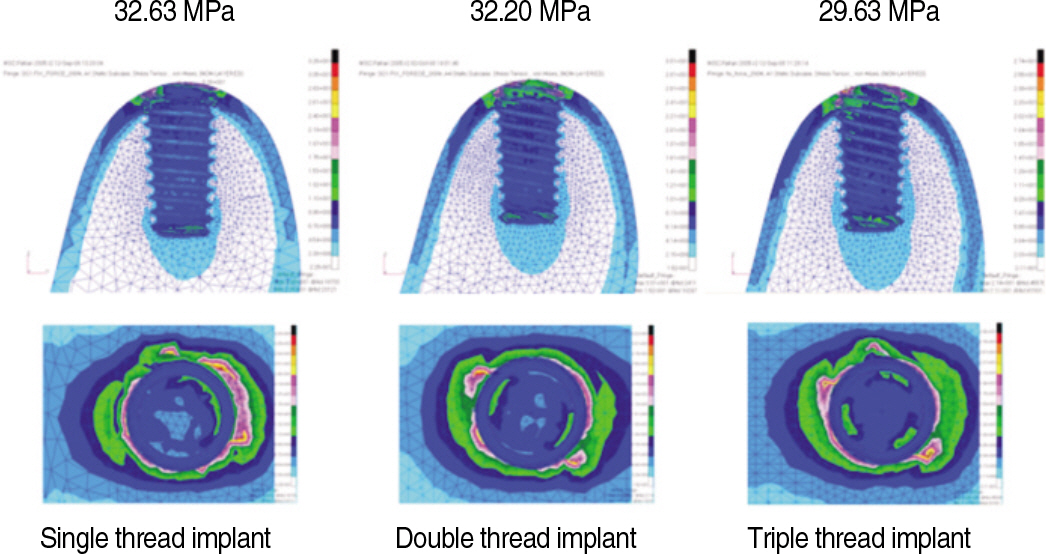

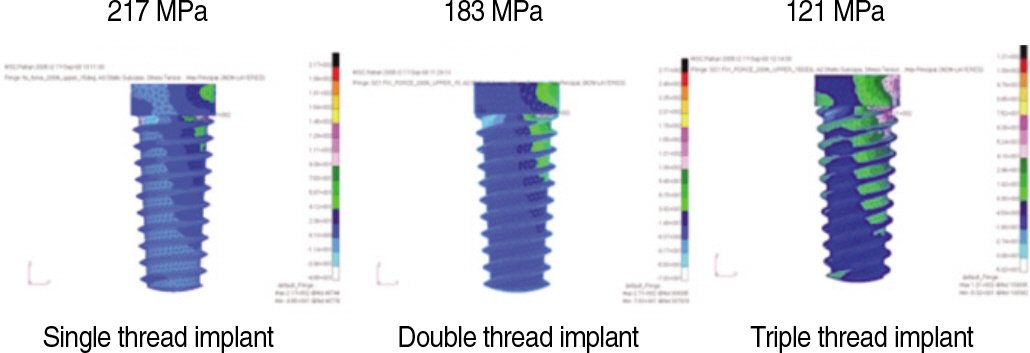

RESULTS

1. The more tilting of implant angulation, the more Von-Mises stress and Max principal stress is increasing. 2. Von-Mises stress and Max principal stress is increasing when applied 15degrees tilting load than vertical load on the bone. 3. When the number of thread increased, the amount of Von-Mises stress, Max principal stress was reduced since the generated stress was effectively distributed. 4. Since the maximum principal stress affects on the alveolar bone can influence deeply on the longevity of the implants. When comparing the magnitude of the maximum principal stress, the triple thread implant had a least amount of stress. This shows that the triple thread implant gave a best result.

CONCLUSION

A triple thread implant to increase in the thread slope inclination and number of thread is more effective on the distribution of stress than the single and double thread implants especially, implant angulation is more tilting than 10degrees on alveolar bone. Thus, effective combination of thread number and thread slope inclination can help prolonging the longevity of implant.

Keyword

Figure

Reference

-

1.Branemark PI. Osseointegration and its experimental background. J Prosthet Dent. 1983. 50:399–410.

Article2.Adell R., Lekholm U., Rockler B., Branemark PI. A 15-year study of osseointegrated implants in the treatment of the edentulous jaw. Int J Oral Surg. 1981. 10:387–416.

Article3.Skalak R. Biomechanical considerations in osseointegrated prostheses. J Prosthet Dent. 1983. 49:843–8.

Article4.Holmes DC., Grigsby WR., Goel VK., Keller JC. Comparison of stress transmission in the IMZ implant system with polyoxymethylene or titanium intramobile element: a finite element stress analysis. Int J Oral Maxillofac Implants. 1992. 7:450–8.5.Brunski JB. Biomaterials and biomechanics in dental implant design. Int J Oral Maxillofac Implants. 1988. 3:85–97.6.Rangert B., Jemt T., Jo¨rneus L. Forces and moments on Branemark implants. Int J Oral Maxillofac Implants. 1989. 4:241–7.7.Holmgren EP., Seckinger RJ., Kilgren LM., Mante F. Evaluating parameters of osseointegrated dental implants using finite element analysis-a two-dimensional comparative study examining the effects of implant diameter, implant shape, and load direction. J Oral Implantol. 1998. 24:80–8.

Article8.Hoshaw SJ., Brunski JB., Cochran GVB. Mechanical loading of Branemark implants affects interfacial bone modeling and remodeling. Int J Oral Maxillofac Implants. 1994. 9:345–60.9.Isidor F. Loss of osseointegration caused by occlusal load of oral implants. A clinical and radiographic study in monkeys. Clin Oral Implants Res. 1996. 7:143–52.

Article10.Rieger MR., Adams WK., Kinzel GL. A finite element survey of eleven endosseous implants. J Prosthet Dent. 1990. 63:457–65.

Article11.Siegele D., Soltesz U. Numerical investigations of the influence of implant shape on stress distribution in the jaw bone. Int J Oral Maxillofac Implants. 1989. 4:333–40.12.Holmes DC., Loftus JT. Influence of bone quality on stress distribution for endosseous implants. J Oral Implantol. 1997. 23:104–11.13.Bergman B. Evaluation of the results of treatment with os-seointegrated implants by the Swedish National Board of Health and Welfare. J Prosthet Dent. 1983. 50:114–5.

Article14.Bidez MW., Chen Y., McLoughlin SW., English CE. Finite element analysis of four-abutment Hader bar designs. Implant Dent. 1993. 2:171–6.

Article15.Borchers L., Reichart P. Three-dimensional stress distribution around a dental implant at different stages of interface development. J Dent Res. 1983. 62:155–9.

Article16.Papavasiliou G., Kamposiora P., Bayne SC., Felton DA. Three-dimensional finite element analysis of stress-distribution around single tooth implants as a function of bony support, prosthesis type, and loading during function. J Prosthet Dent. 1996. 76:633–40.

Article17.Rieger MR., Adams WK., Kinzel GL., Brose MO. Alternative materials for three endosseous implants. J Prosthet Dent. 1989. 61:717–22.

Article18.Rieger MR., Mayberry M., Brose MO. Finite element analysis of six endosseous implants. J Prosthet Dent. 1990. 63:671–6.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Three-dimentional finite element analysis of stress distribution for different implant thread slope

- The three dimensional finite element analysis of the stress distribution according to the implant and thread designs

- studies of Osseointegrated Implant-Models on Stress Distribution

- The Three Dimensional Finite Element Analysis of Stress according to Implant Thread Design under the Axial Load

- Stress dissipation characteristics of four implant thread designs evaluated by 3D finite element modeling