J Dent Rehabil Appl Sci.

2021 Mar;37(1):39-47. 10.14368/jdras.2021.37.1.39.

Cr-Co removable partial denture treatment fabricated by selective laser melting: a case report

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Dankook University, Cheonan, Republic of Korea

- KMID: 2525977

- DOI: http://doi.org/10.14368/jdras.2021.37.1.39

Abstract

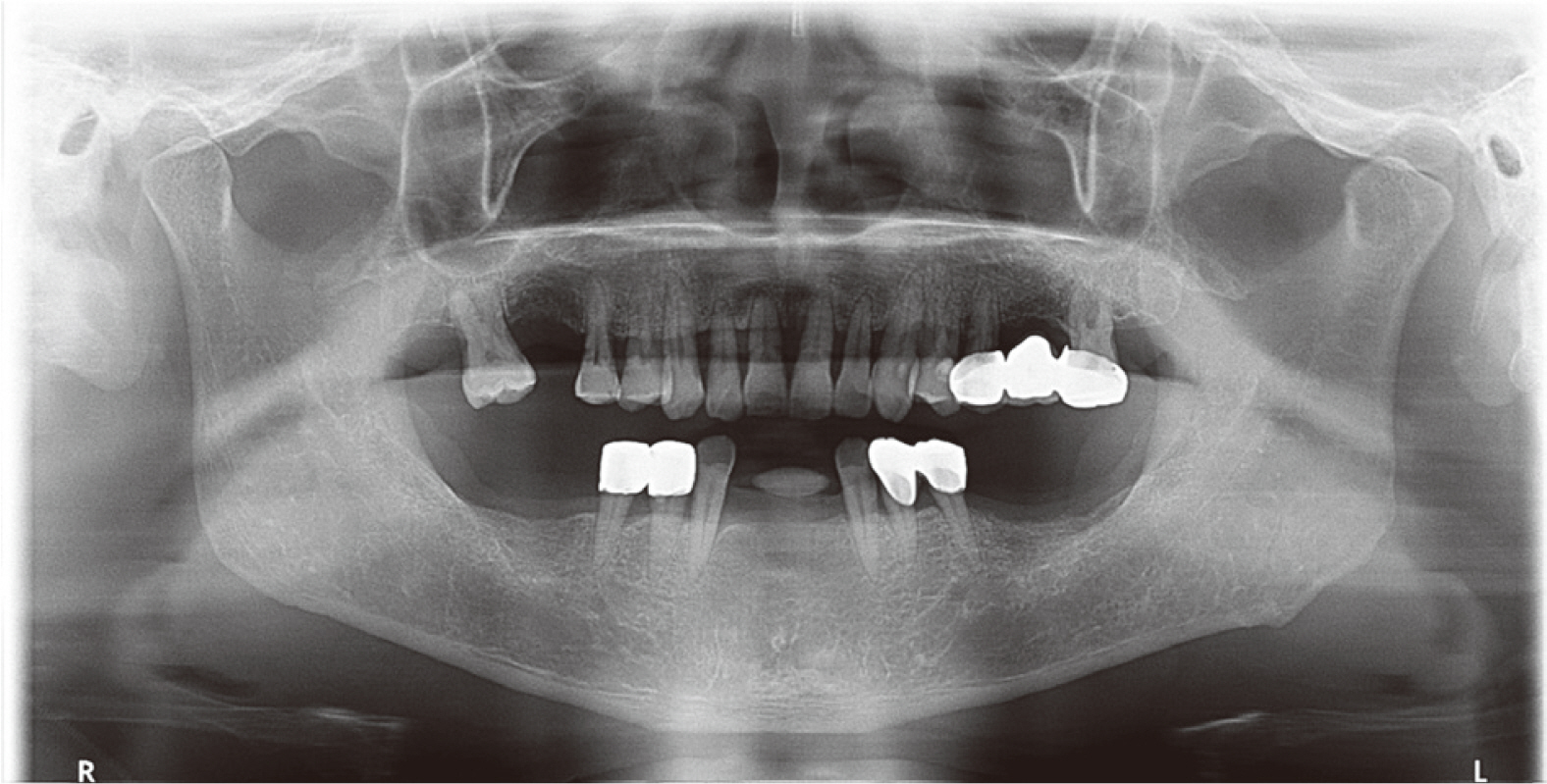

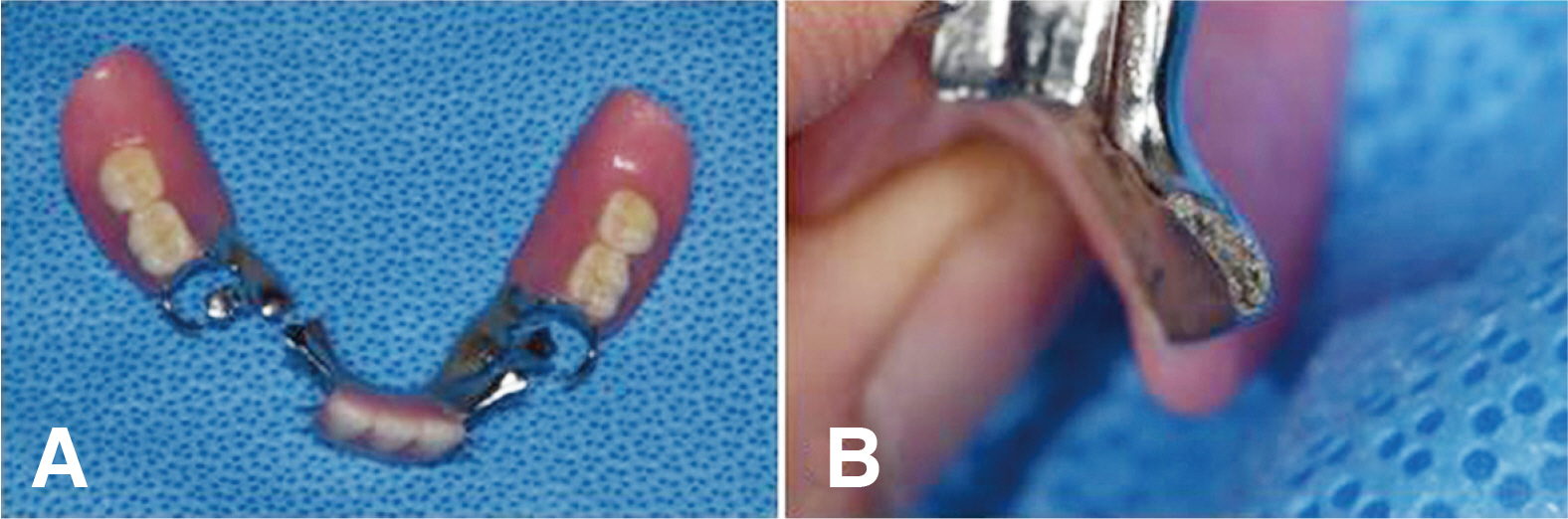

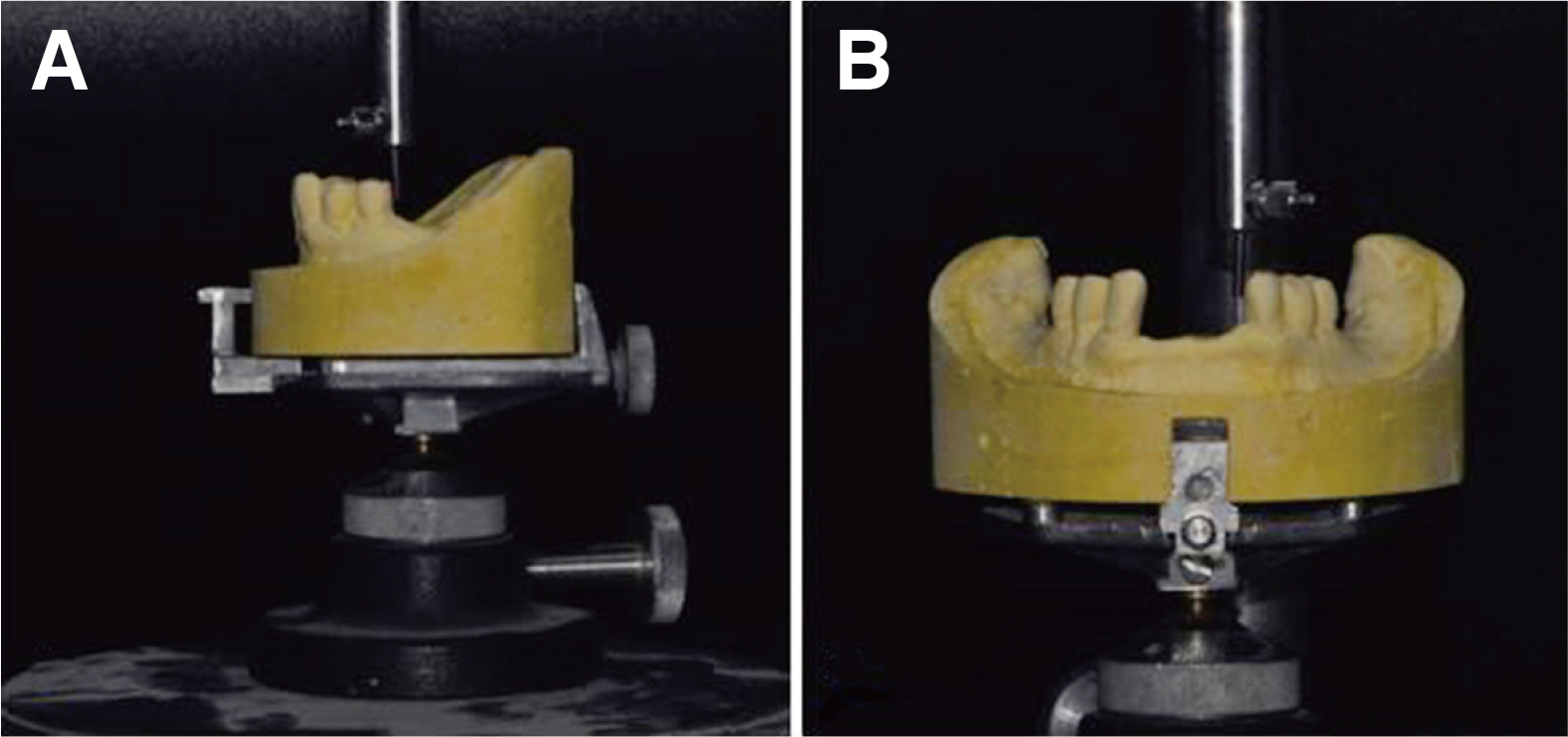

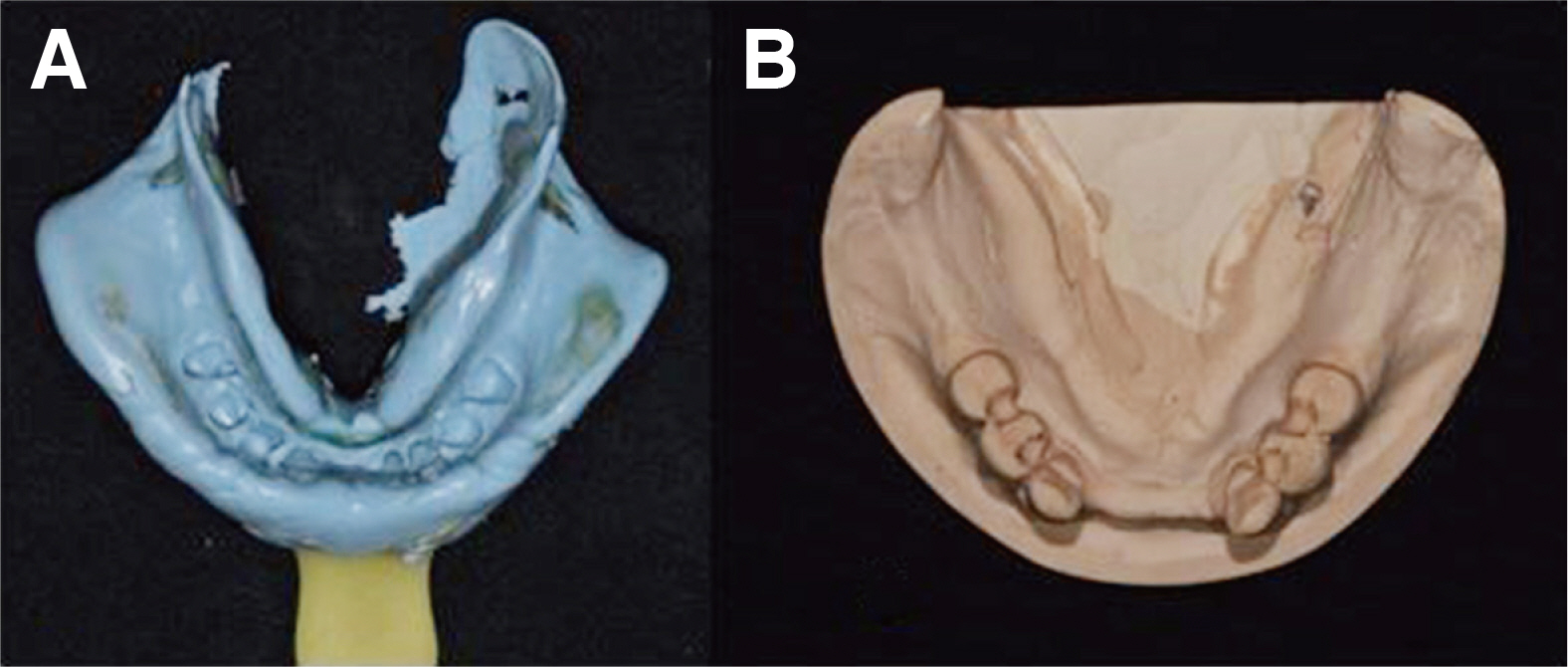

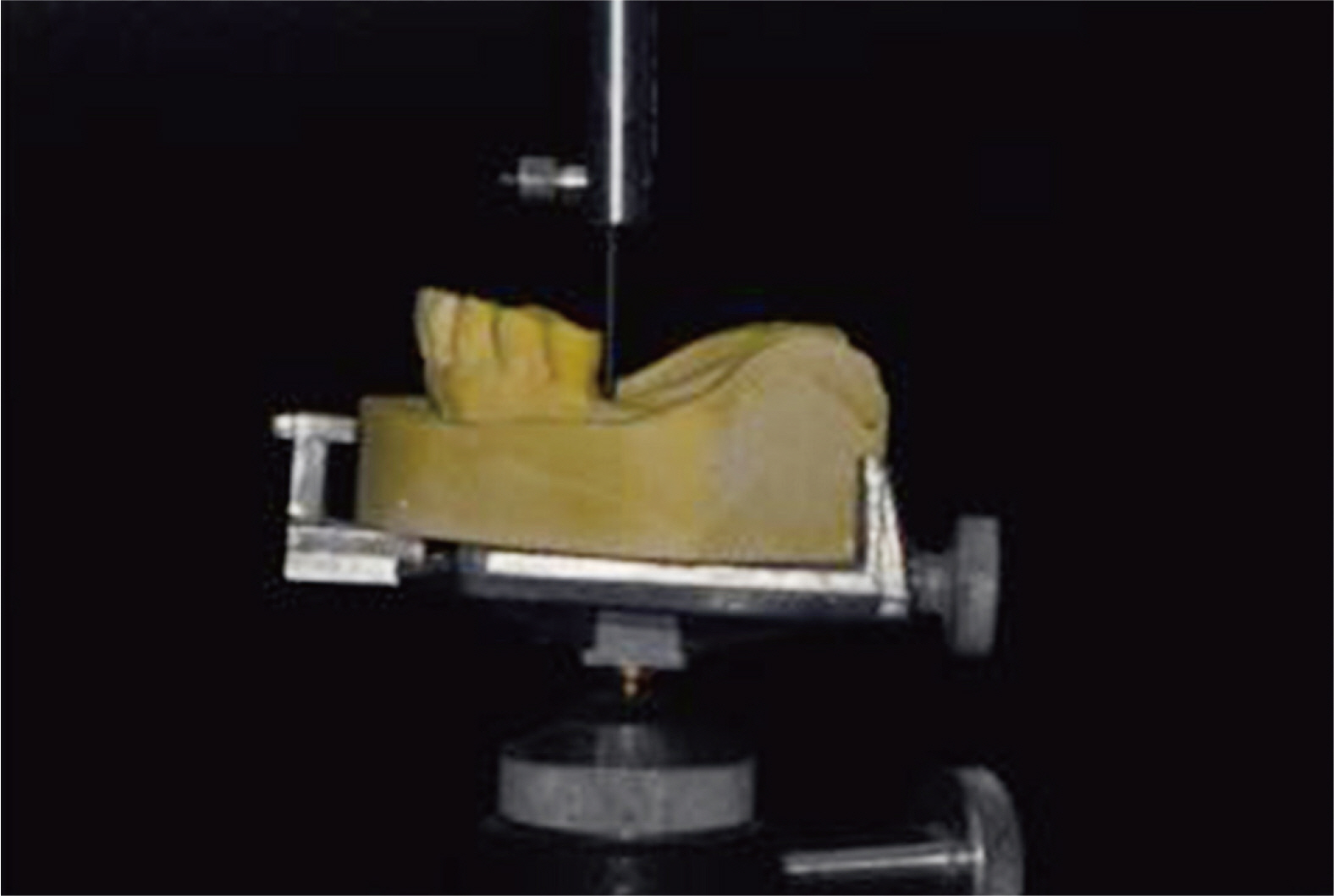

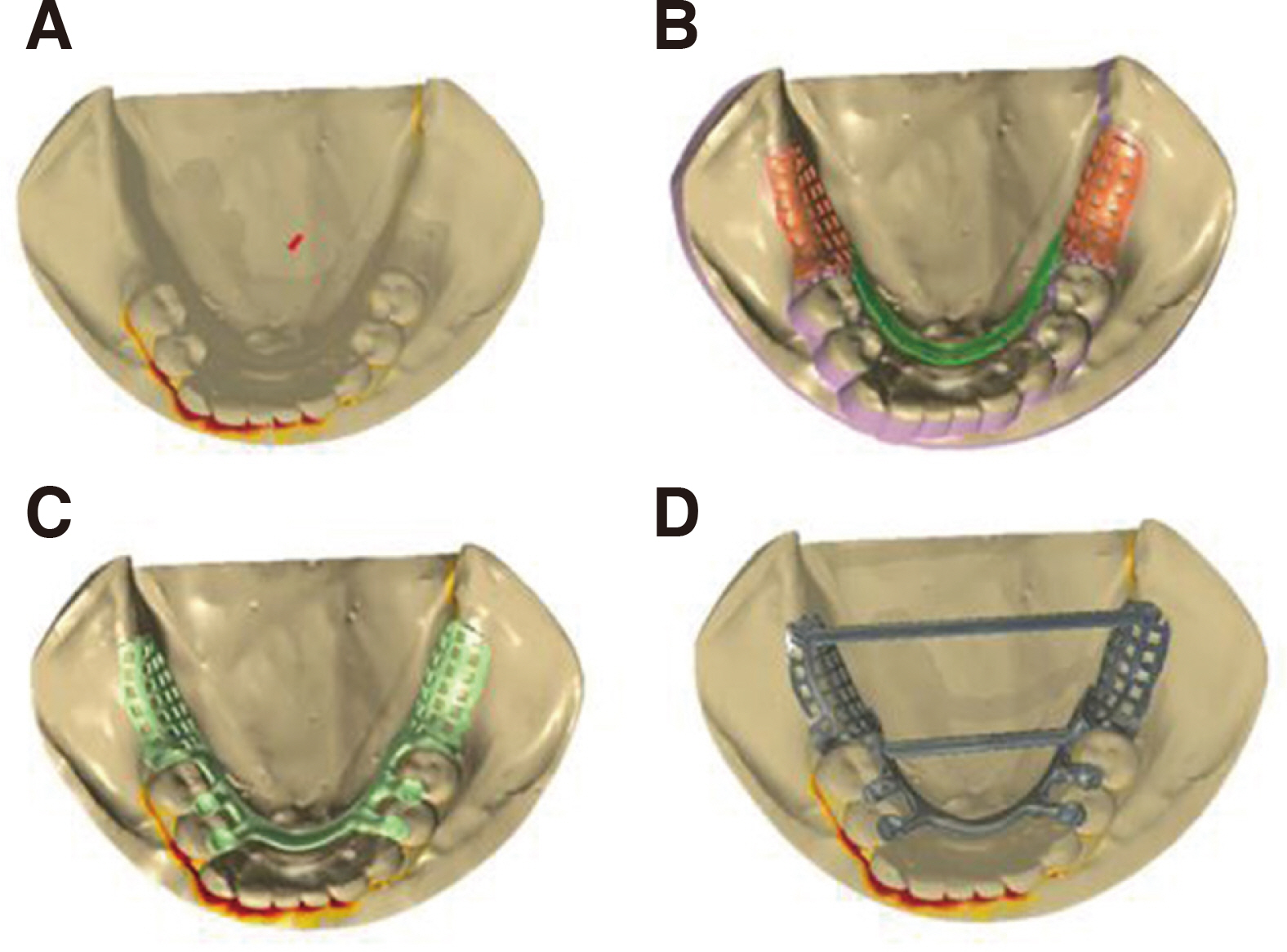

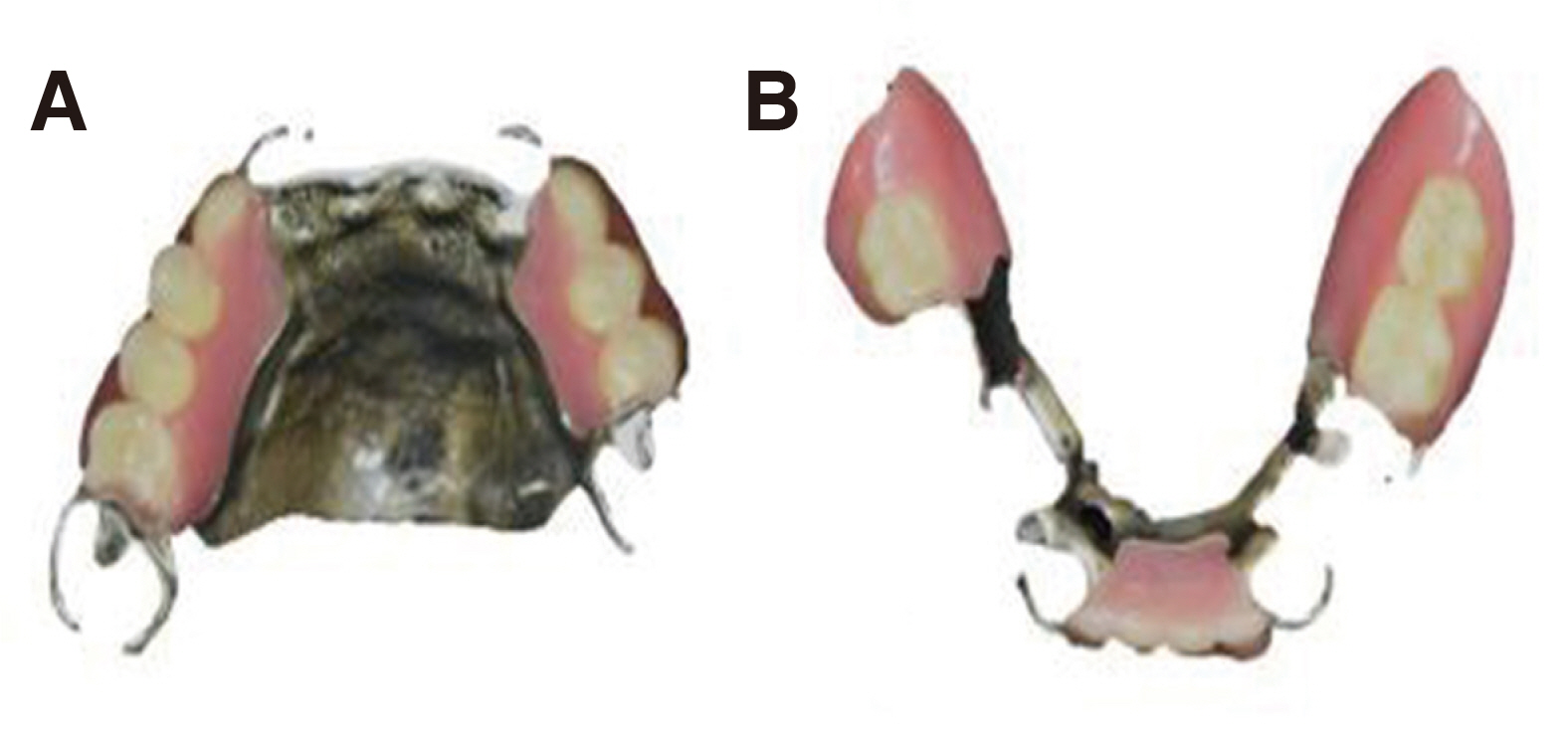

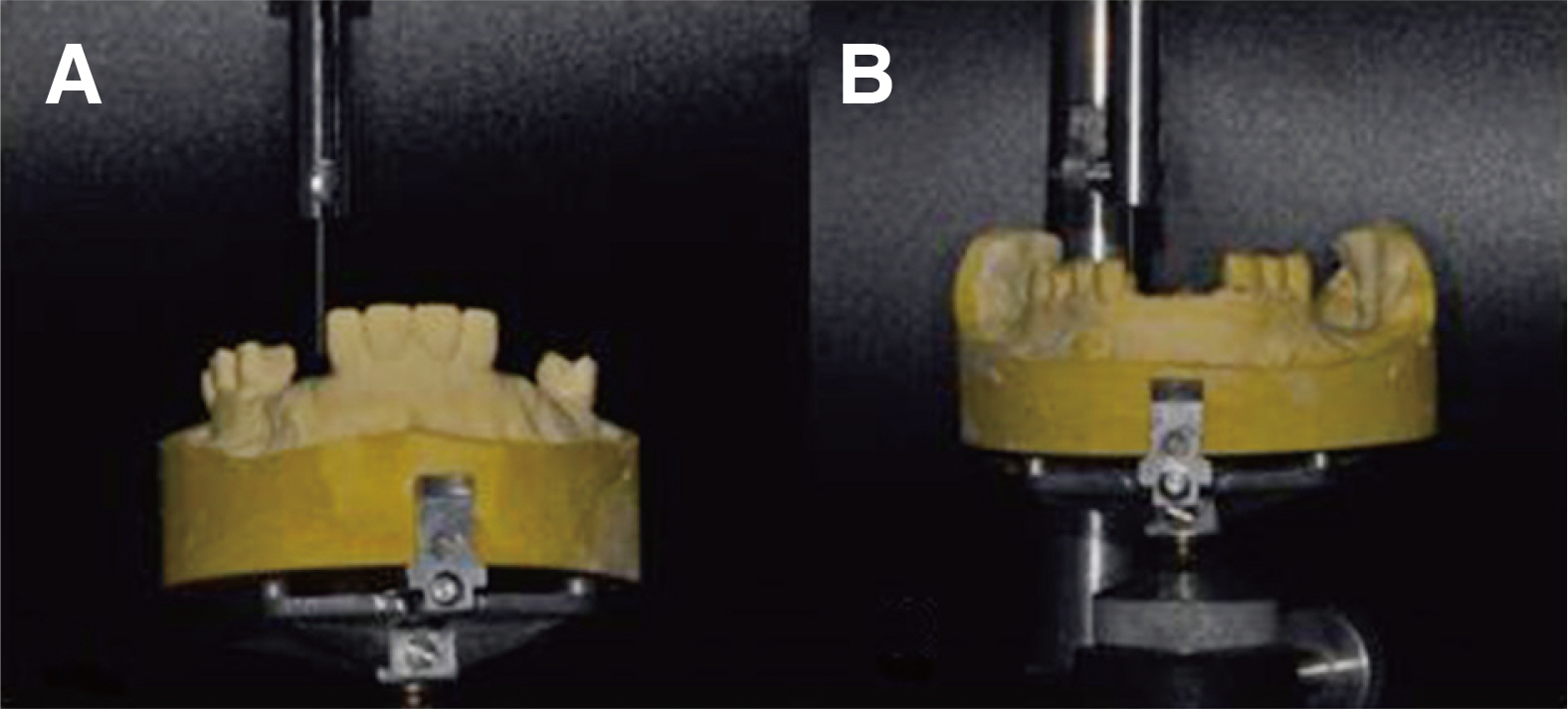

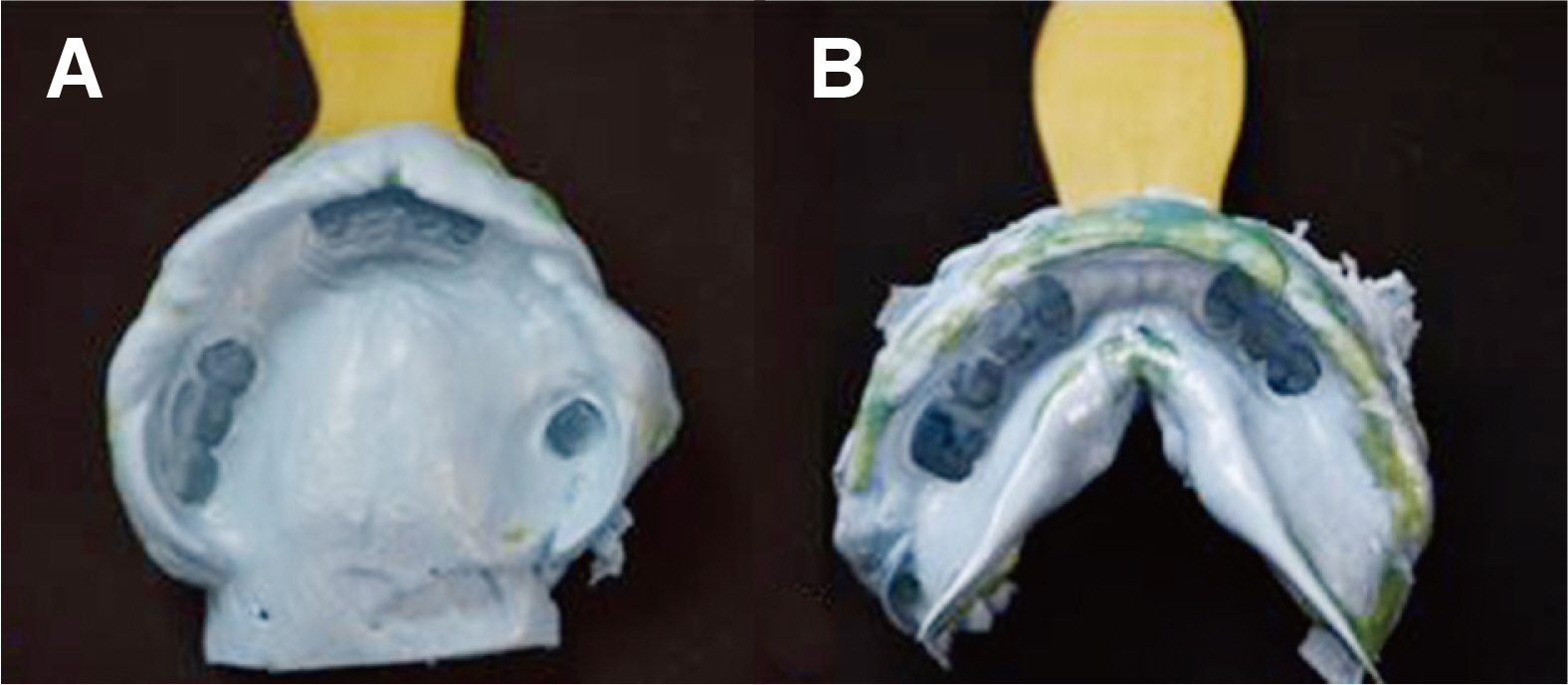

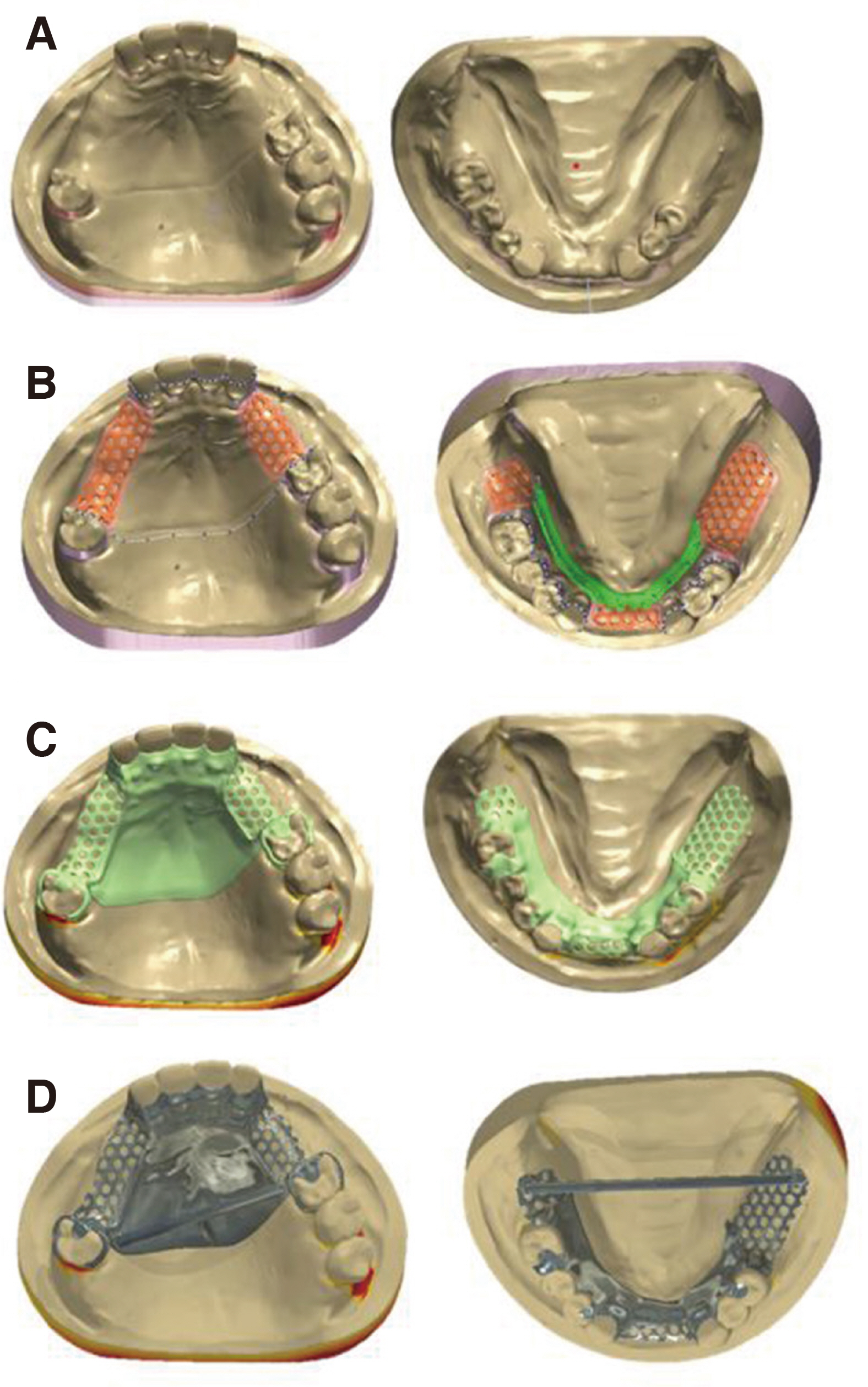

- Compared to conventional method, if metal framework of removable partial denture is fabricated by selective laser melting, various laboratory works are omitted, saving time and simplifying the process. In addition, metal framework with homogeneous density can be obtained, expecting excellent mechanical properties, especially resistance to fatigue fracture. In these cases, impression were taken using conventional methods in partial edentulous patients, master casts were fabricated and scanned to obtain digital data. After designing the metal frameworks on the scanned data, removable partial dentures were fabricated using selective laser melting methods. Through these procedure, satisfactory outcomes were achieved both in functional and esthetic aspects.

Figure

Reference

-

References

1. Williams RJ, Bibb R, Rafik T. 2004; A technique for fabricating patterns for removable partial denture frameworks using digitized casts and electronic surveying. J Prosthet Dent. 91:85–8. DOI: 10.1016/j.prosdent.2003.10.002. PMID: 14739899.2. Williams RJ, Bibb R, Eggbeer D, Collis J. 2006; Use of CAD/CAM technology to fabricate a removable partial denture framework. J Prosthet Dent. 96:96–9. DOI: 10.1016/j.prosdent.2006.05.029. PMID: 16911885.3. Eggbeer D, Bibb R, Williams R. 2005; The computeraided design and rapid prototyping fabrication of removable partial denture frameworks. Proc Inst Mech Eng H. 219:195–202. DOI: 10.1243/095441105X9372. PMID: 15934395.4. Smith S, Dvorak D. 1998; Tool path strategies for high speed milling aluminum workpieces with thin webs. Mechatronics. 8:291–300. DOI: 10.1016/S0957-4158(97)00058-5.5. Dizon JRC, Espera AH, Chen Q, Advincula RC. 2018; Mechanical characterization of 3D-printed polymers. Addit Manufac. 20:44–67. DOI: 10.1016/j.addma.2017.12.002.6. Tasaka A, Shimizu T, Kato Y, Okano H, Ida Y, Higuchi S, Yamashita S. 2020; Accuracy of removable partial denture framework fabricated by casting with a 3D printed pattern and selective laser sintering. J Prosthodont Res. 64:224–30. DOI: 10.1016/j.jpor.2019.07.009. PMID: 31466919.7. Zhou Y, Li N, Yan J, Zeng Q. 2018; Comparative analysis of the microstructures and mechanical properties of Co-Cr dental alloys fabricated by different methods. J Prosthet Dent. 120:617–23. DOI: 10.1016/j.prosdent.2017.11.015. PMID: 29627206.8. Kim HR, Jang SH, Kim YK, Son JS, Min BK, Kim KH, Kwon TY. 2016; Microstructures and mechanical properties of Co-Cr dental alloys fabricated by three CAD/CAM-based processing techniques. Materials. 9:596. DOI: 10.3390/ma9070596. PMID: 28773718. PMCID: PMC5456947.9. Takaichi A, Nakamoto T, Joko N, Nomura N, Tsutsumi Y, Migita S, Doi H, Kurosu S, Chiba A, Wakabayashi N, Igarashi Y, Hanawa T. 2013; Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications. J Mech Behav Biomed Mater. 21:67–76. DOI: 10.1016/j.jmbbm.2013.01.021. PMID: 23500549.10. Schweiger J, Güth JF, Erdelt KJ, Edelhoff D, Schubert O. 2020; Internal porosities, retentive force, and survival of cobalt-chromium alloy clasps fabricated by selective laser-sintering. J Prosthodont Res. 64:210–16. DOI: 10.1016/j.jpor.2019.07.006. PMID: 31680054.11. Lapcevic AR, Jevremovic DP, Puskar TM, Williams RJ, Eggbeer D. 2016; Comparative analysis of structure and hardness of cast and direct metal laser sintering produced Co-Cr alloys used for dental devices. Rapid Prototyp J. 22:144–51. DOI: 10.1108/RPJ-04-2014-0051.12. Tuna SH, Pekmez NÖ, Kürkçüoğlu I. 2015; Corrosion resistance assessment of Co-Cr alloy frameworks fabricated by CAD/CAM milling, laser sintering, and casting methods. J Prosthet Dent. 114:725–34. DOI: 10.1016/j.prosdent.2015.02.031. PMID: 26187104.13. Hedberg YS, Qian B, Shen Z, Virtanen S, Wallinder IO. 2014; In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting. Dent Mater. 30:525–34. DOI: 10.1016/j.dental.2014.02.008. PMID: 24598762.14. Mansour M, Sanchez E, Machado C. 2016; The use of digital impressions to fabricate tooth-supported partial removable dental prostheses: A clinical Report. J Prosthodont. 25:495–7. DOI: 10.1111/jopr.12346. PMID: 26371612.15. Al Jabbari YS, Koutsoukis T, Barmpagadaki X, Zinelis S. 2014; Metallurgical and interfacial characterization of PFM Co-Cr dental alloys fabricated via casting, milling or selective laser melting. Dent Mater. 30:79–88. DOI: 10.1016/j.dental.2014.01.008. PMID: 24534375.16. Kajima Y, Takaichi A, Nakamoto T, Kimura T, Yogo Y, Ashida M, Doi H, Nomura N, Takahashi H, Hanawa T, Wakabayashi N. 2016; Fatigue strength of Co-Cr-Mo alloy clasps prepared by selective laser melting. J Mech Behav Biomed Mater. 59:446–58. DOI: 10.1016/j.jmbbm.2016.02.032. PMID: 26974490.17. Tregerman I, Renne W, Kelly A, Wilson D. 2019; Evaluation of removable partial denture frameworks fabricated using 3 different techniques. J Prosthet Dent. 122:390–5. DOI: 10.1016/j.prosdent.2018.10.013. PMID: 30948301.18. Ye H, Ning J, Li M, Niu L, Yang J, Sun Y, Zhou Y. 2017; Preliminary clinical application of removable partial denture frameworks fabricated using computer aided design and rapid prototyping techniques. Int J Prosthodont. 30:348–53. DOI: 10.11607/ijp.5270. PMID: 28697204.19. Tasaka A, Kato Y, Odaka K, Matsunaga S, Goto TK, Abe S, Yamashita S. 2019; Accuracy of Clasps Fabricated with Three Different CAD/CAM Technologies: Casting, Milling, and Selective Laser Sintering. Int J Prosthodont. 32:526–9. DOI: 10.11607/ijp.6363. PMID: 31664269.20. Kanazawa M, Iwaki M, Minakuchi S, Nomura N. 2014; Fabrication of titanium alloy frameworks for complete dentures by selective laser melting. J Prosthet Dent. 112:1441–7. DOI: 10.1016/j.prosdent.2014.06.017. PMID: 25258261.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Dental Co-Cr alloys fabricated by selective laser melting: A review article

- Restoration of bilateral distal extension removable partial denture using a fixed implant prosthesis in unilateral partial edentulous patient: A case report

- Esthetic removable partial denture with implants and resin clasp: Case report

- Digital interim immediate denture fabrication and implant-supported removable partial denture fabrication after multiple teeth extraction in patient with chronic periodontitis: a case report

- Rehabilitation of maxillary partial edentulous patients using implant assisted removable partial denture