J Adv Prosthodont.

2019 Dec;11(6):305-312. 10.4047/jap.2019.11.6.305.

Comparison of CAD/CAM abutment and prefabricated abutment in Morse taper internal type implant after cyclic loading: Axial displacement, removal torque, and tensile removal force

- Affiliations

-

- 1Department of Prosthodontics, Seoul National University Dental Hospital & Dental Research Institute, College of Dentistry, Seoul National University, Seoul, Republic of Korea. heosj@snu.ac.kr

- KMID: 2466245

- DOI: http://doi.org/10.4047/jap.2019.11.6.305

Abstract

- PURPOSE

The purpose of this study was to compare computer-aided design/computer-aided manufacturing (CAD/CAM) abutment and prefabricated abutment in Morse taper internal connection type implants after cyclic loading.

MATERIALS AND METHODS

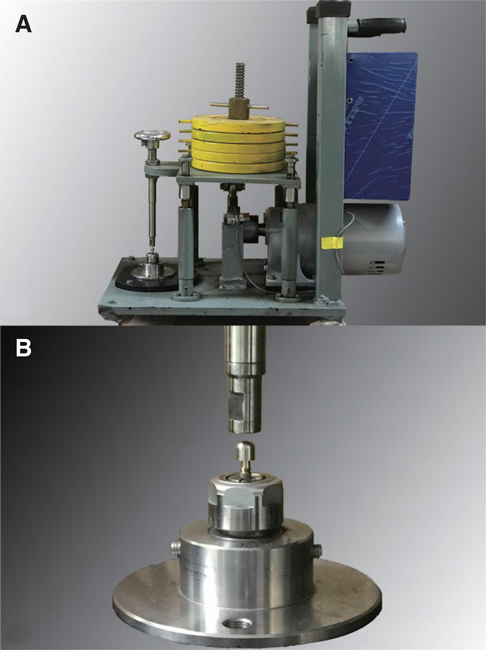

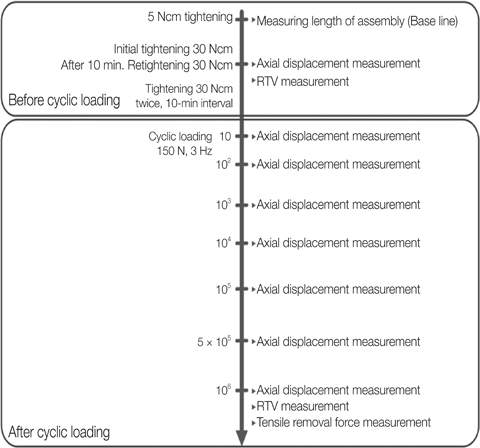

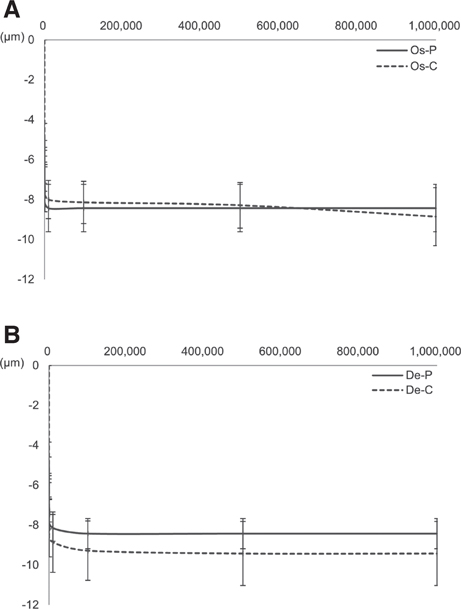

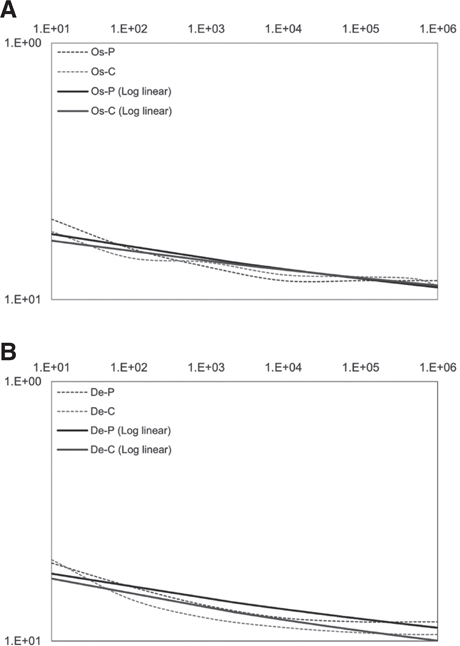

The study was conducted with internal type implants of two different manufacturers (Group Os, De). Fourteen assemblies were prepared for each manufacturer group and divided into 2 groups (n=7): prefabricated abutments (Os-P, De-P) and CAD/CAM abutments (Os-C, De-C). The amount of axial displacement and the removal torque values (RTVs) were measured before and after cyclic loading (10ⶠcycles, 3 Hz with 150 N), and the tensile removal force to dislodge the abutments was measured after cyclic loading. A repeated measures ANOVA and a pattern analysis based on the logarithmic regression model were conducted to evaluate the effect of cyclic loading on the axial displacement. The Wilcoxon signed-rank test and the Mann-Whitney test was conducted for comparison of RTV reduction% and tensile removal forces.

RESULTS

There was no significant difference between CAD/CAM abutments and prefabricated abutments in axial displacement and tensile removal force; however, significantly greater RTV reduction% after cyclic loading was observed in CAD/CAM abutments. The correlation among the axial displacement, the RTV, and the tensile removal force was not significant.

CONCLUSION

The use of CAD/CAM abutment did not significantly affect the amount of axial displacement and tensile removal force, but presented a significantly greater removal torque reduction% than prefabricated abutments. The connection stability due to the friction at the abutment-implant interface of CAD/CAM abutments may not be different from prefabricated abutment.

Figure

Reference

-

1. Merz BR, Hunenbart S, Belser UC. Mechanics of the implant-abutment connection: an 8-degree taper compared to a butt joint connection. Int J Oral Maxillofac Implants. 2000; 15:519–526.2. Rack T, Zabler S, Rack A, Riesemeier H, Nelson K. An in vitro pilot study of abutment stability during loading in new and fatigue-loaded conical dental implants using synchrotron-based radiography. Int J Oral Maxillofac Implants. 2013; 28:44–50.3. Gehrke SA, Pereira Fde A. Changes in the abutment-implant interface in Morse taper implant connections after mechanical cycling: a pilot study. Int J Oral Maxillofac Implants. 2014; 29:791–797.4. Bozkaya D, Müftü S. Mechanics of the tapered interference fit in dental implants. J Biomech. 2003; 36:1649–1658.5. Seol HW, Heo SJ, Koak JY, Kim SK, Kim SK. Axial displacement of external and internal implant-abutment connection evaluated by linear mixed model analysis. Int J Oral Maxillofac Implants. 2015; 30:1387–1399.6. Norton MR. An in vitro evaluation of the strength of an internal conical interface compared to a butt joint interface in implant design. Clin Oral Implants Res. 1997; 8:290–298.7. Hansson S. Implant-abutment interface: biomechanical study of flat top versus conical. Clin Implant Dent Relat Res. 2000; 2:33–41.8. Siamos G, Winkler S, Boberick KG. Relationship between implant preload and screw loosening on implant-supported prostheses. J Oral Implantol. 2002; 28:67–73.9. Gil FJ, Herrero-Climent M, Lázaro P, Rios JV. Implant-abutment connections: influence of the design on the microgap and their fatigue and fracture behavior of dental implants. J Mater Sci Mater Med. 2014; 25:1825–1830.10. Sumi T, Braian M, Shimada A, Shibata N, Takeshita K, Vandeweghe S, Coelho PG, Wennerberg A, Jimbo R. Characteristics of implant-CAD/CAM abutment connections of two different internal connection systems. J Oral Rehabil. 2012; 39:391–398.11. Lee JH, Park JM, Park EJ, Koak JY, Kim SK, Heo SJ. Comparison of customized abutments made from titanium and a machinable precious alloy. Int J Oral Maxillofac Implants. 2016; 31:92–100.12. Park JM, Baek CH, Heo SJ, Kim SK, Koak JY, Kim SK, Belser UC. An in vitro evaluation of the loosening of different interchangeable abutments in internal-connection-type implants. Int J Oral Maxillofac Implants. 2017; 32:350–355.13. Widmalm SE, Ericsson SG. Maximal bite force with centric and eccentric load. J Oral Rehabil. 1982; 9:445–450.14. Richter EJ. In vivo vertical forces on implants. Int J Oral Maxillofac Implants. 1995; 10:99–108.15. Rosentritt M, Behr M, Gebhard R, Handel G. Influence of stress simulation parameters on the fracture strength of all-ceramic fixed-partial dentures. Dent Mater. 2006; 22:176–182.16. Delben JA, Gomes EA, Barão VA, Assunção WG. Evaluation of the effect of retightening and mechanical cycling on preload maintenance of retention screws. Int J Oral Maxillofac Implants. 2011; 26:251–256.17. Cerutti-Kopplin D, Rodrigues Neto DJ, Lins do, Pereira JR. Influence of reverse torque values in abutments with or without internal hexagon indexes. J Prosthet Dent. 2014; 112:824–827.18. de Oliveira Silva TS, Mendes Alencar SM, da Silva Valente V, de Moura CDVS. Effect of internal hexagonal index on removal torque and tensile removal force of different Morse taper connection abutments. J Prosthet Dent. 2017; 117:621–627.19. Winkler S, Ring K, Ring JD, Boberick KG. Implant screw mechanics and the settling effect: overview. J Oral Implantol. 2003; 29:242–245.20. Jorge JR, Barao VA, Delben JA, Assuncao WG. The role of implant/abutment system on torque maintenance of retention screws and vertical misfit of implant-supported crowns before and after mechanical cycling. Int J Oral Maxillofac Implants. 2013; 28:415–422.21. Delben JA, Gomes EA, Barão VA, Assunção WG. Evaluation of the effect of retightening and mechanical cycling on preload maintenance of retention screws. Int J Oral Maxillofac Implants. 2011; 26:251–256.22. Assunção WG, Barão VA, Delben JA, Gomes ÉA, Garcia IR Jr. Effect of unilateral misfit on preload of retention screws of implant-supported prostheses submitted to mechanical cycling. J Prosthodont Res. 2011; 55:12–18.23. Jo JY, Yang DS, Huh JB, Heo JC, Yun MJ, Jeong CM. Influence of abutment materials on the implant-abutment joint stability in internal conical connection type implant systems. J Adv Prosthodont. 2014; 6:491–497.24. Breeding LC, Dixon DL, Nelson EW, Tietge JD. Torque required to loosen single-tooth implant abutment screws before and after simulated function. Int J Prosthodont. 1993; 6:435–439.25. Dixon DL, Breeding LC, Sadler JP, McKay ML. Comparison of screw loosening, rotation, and deflection among three implant designs. J Prosthet Dent. 1995; 74:270–278.26. Theoharidou A, Petridis HP, Tzannas K, Garefis P. Abutment screw loosening in single-implant restorations: a systematic review. Int J Oral Maxillofac Implants. 2008; 23:681–690.27. Burguete RL, Johns RB, King T, Patterson EA. Tightening characteristics for screwed joints in osseointegrated dental implants. J Prosthet Dent. 1994; 71:592–599.28. Coelho AL, Suzuki M, Dibart S, DA Silva N, Coelho PG. Cross-sectional analysis of the implant-abutment interface. J Oral Rehabil. 2007; 34:508–516.29. Bernardes SR, da Gloria Chiarello de Mattos M, Hobkirk J, Ribeiro RF. Loss of preload in screwed implant joints as a function of time and tightening/untightening sequences. Int J Oral Maxillofac Implants. 2014; 29:89–96.30. Geng JP, Tan KB, Liu GR. Application of finite element analysis in implant dentistry: a review of the literature. J Prosthet Dent. 2001; 85:585–598.31. Ricciardi Coppedê A, de Mattos Mda G, Rodrigues RC, Ribeiro RF. Effect of repeated torque/mechanical loading cycles on two different abutment types in implants with internal tapered connections: an in vitro study. Clin Oral Implants Res. 2009; 20:624–632.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Joint stability of internal conical connection abutments with or without hexagon indexes: an in vitro study

- Comparison of removal torque between prefabricated and customized abutment screw

- Pull-off resistance of a screwless implantabutment connection and surface evaluation after cyclic loading

- Influence of the implant abutment types and the dynamic loading on initial screw loosening

- The influence of abutment screw tightening timing and DLC coating of conical connection implant system