J Korean Acad Prosthodont.

2019 Apr;57(2):110-117. 10.4047/jkap.2019.57.2.110.

In vitro evaluation of the wear resistance of provisional resin materials fabricated by different methods

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Pusan National University, Yangsan, Republic of Korea. won9180@hanmail.net

- 2Institute of Translational Dental Sciences, Pusan National University, Yangsan, Republic of Korea.

- KMID: 2444179

- DOI: http://doi.org/10.4047/jkap.2019.57.2.110

Abstract

- PURPOSE

This study was to evaluate the wear resistance of 3D printed, milled, and conventionally cured provisional resin materials.

MATERIALS AND METHODS

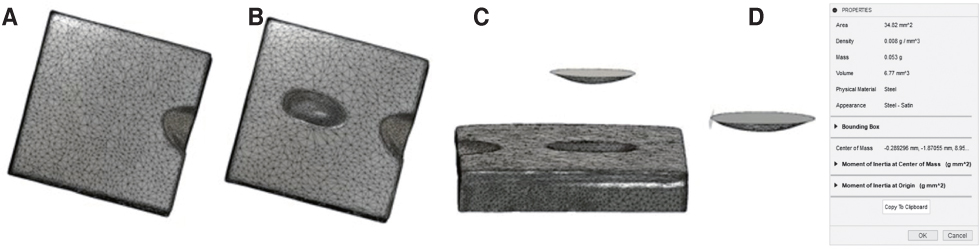

Four types of resin materials made with different methods were examined: Stereolithography apparatus (SLA) 3D printed resin (S3P), digital light processing (DLP) 3D printed resin (D3P), milled resin (MIL), conventionally self-cured resin (CON). In the 3D printed resin specimens, the build orientation and layer thickness were set to 0° and 100 µm, respectively. The specimens were tested in a 2-axis chewing simulator with the steatite as the antagonist under thermocycling condition (5 kg, 30,000 cycles, 0.8 Hz, 5℃/55℃). Wear losses of the specimens were calculated using CAD software and scanning electron microscope (SEM) was used to investigate wear surface of the specimens. Statistical significance was determined using One-way ANOVA and Dunnett T3 analysis (α = .05).

RESULTS

Wear losses of the S3P, D3P, and MIL groups significantly smaller than those of the CON group (P < .05). There was no significant difference among S3P, D3P, and MIL group (P > .05). In the SEM observations, in the S3P and D3P groups, vertical cracks were observed in the sliding direction of the antagonist. In the MIL group, there was an overall uniform wear surface, whereas in the CON group, a distinct wear track and numerous bubbles were observed.

CONCLUSION

Within the limits of this study, provisional resin materials made with 3D printing show adequate wear resistance for applications in dentistry.

Figure

Cited by 1 articles

-

Marginal and internal discrepancy of 3-unit fixed dental prostheses fabricated by subtractive and additive manufacturing

Jae-Won Choi

J Korean Acad Prosthodont. 2020;58(1):7-13. doi: 10.4047/jkap.2020.58.1.7.

Reference

-

1. Takamizawa T, Barkmeier WW, Tsujimoto A, Scheidel D, Erickson RL, Latta MA, Miyazaki M. Mechanical properties and simulated wear of provisional resin materials. Oper Dent. 2015; 40:603–613.

Article2. Gough M. A review of temporary crowns and bridges. Dent Update. 1994; 21:203–207.3. Fisher DW, Shillingburg HT Jr, Dewhirst RB. Indirect temporary restorations. J Am Dent Assoc. 1971; 82:160–163.

Article4. Melton D, Cobb S, Krell KV. A comparison of two temporary restorations: light-cured resin versus a self-polymerizing temporary restoration. Oral Surg Oral Med Oral Pathol. 1990; 70:221–225.

Article5. Shillingburg HT, Sather DA, Wilson EL, Cain JR, Mitchell DL, Blanco LJ, Kessler JC. Fundamentals of fixed prosthodontics. 4th ed. Chicago: Quintessence Publishing;2012. p. 149–163.6. Nigel Tom T, Uthappa MA, Sunny K, Begum F, Nautiyal M, Tamore S. Provisional restorations: An overview of materials used. J Adv Clin Res Insights. 2016; 3:212–214.

Article7. van Dijken JW. Direct resin composite inlays/onlays: an 11 year follow-up. J Dent. 2000; 28:299–306.

Article8. Seo HS, Park JW, Hong SM, Lee SR. Comparative analysis of immediate functional loading and conventional loading about implant survival rate in the completely edentulous: Retrospective study. J Korean Dent Assoc. 2014; 52:771–782.9. Bennani V. Fabrication of an indirect-direct provisional fixed partial denture. J Prosthet Dent. 2000; 84:364–365.

Article10. Song KY, Sorensen JA. Marginal adaptation of new provisional materials for fixed prosthodontics. J Korean Acad Stomatognathic Funct Occlusion. 1997; 13:247–255.11. Lee S. Prospect for 3D printing technology in medical, dental, and pediatric dental field. J Korean Acad Pediatr Dent. 2016; 43:93–108.

Article12. Strub JR, Rekow ED, Witkowski S. Computer-aided design and fabrication of dental restorations: current systems and future possibilities. J Am Dent Assoc. 2006; 137:1289–1296.13. Kim SJ, Jo KH, Lee KB. A comparison of the fidelity of various zirconia-based all-ceramic crowns fabricated with CAD/CAM systems. J Korean Acad Prosthodont. 2009; 47:148–155.

Article14. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12.

Article15. Landers R, Pfister A, Hübner U, John H, Schmelzeisen R, Mülhaupt R. Fabrication of soft tissue engineering scaffolds by means of rapid prototyping techniques. J Mater Sci. 2002; 37:3107.16. Barry B. 3-D printing: The new industrial revolution. Business Horizons. 2012; 55:155–162.

Article17. Santosa RE. Provisional restoration options in implant dentistry. Aust Dent J. 2007; 52:234–242.18. Givens EJ Jr, Neiva G, Yaman P, Dennison JB. Marginal adaptation and color stability of four provisional materials. J Prosthodont. 2008; 17:97–101.

Article19. Fox CW, Abrams BL, Doukoudakis A. Provisional restorations for altered occlusions. J Prosthet Dent. 1984; 52:567–572.

Article20. Asefi S, Eskandarion S, Hamidiaval S. Fissure sealant materials: Wear resistance of flowable composite resins. J Dent Res Dent Clin Dent Prospects. 2016; 10:194–199.

Article21. Suwannaroop P, Chaijareenont P, Koottathape N, Takahashi H, Arksornnukit M. In vitro wear resistance, hardness and elastic modulus of artificial denture teeth. Dent Mater J. 2011; 30:461–468.

Article22. Park JM, Ahn JS, Cha HS, Lee JH. Wear resistance of 3D printing resin material opposing zirconia and metal antagonists. Materials (Basel). 2018; 11:1043.

Article23. Astudillo Rubio D, Delgado Gaete A, Bellot-Arcís C, Montiel-Company JM, Pascual-Moscardó A, Almerich-Silla JM. Mechanical properties of provisional dental materials: A systematic review and meta-analysis. PLoS One. 2018; 13:e0193162.

Article24. Tahayeri A, Morgan M, Fugolin AP, Bompolaki D, Athirasala A, Pfeifer CS, Ferracane JL, Bertassoni LE. 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent Mater. 2018; 34:192–200.

Article25. Alharbi N, Osman R, Wismeijer D. Effects of build direction on the mechanical properties of 3D-printed complete coverage interim dental restorations. J Prosthet Dent. 2016; 115:760–767.

Article26. Digholkar S, Madhav VN, Palaskar J. Evaluation of the flexural strength and microhardness of provisional crown and bridge materials fabricated by different methods. J Indian Prosthodont Soc. 2016; 16:328–334.

Article27. Alharbi N, Osman RB, Wismeijer D. Factors influencing the dimensional accuracy of 3D-printed full-coverage dental restorations using stereolithography technology. Int J Prosthodont. 2016; 29:503–510.

Article28. Lambrechts P, Braem M, Vuylsteke-Wauters M, Vanherle G. Quantitative in vivo wear of human enamel. J Dent Res. 1989; 68:1752–1754.

Article29. Yi HJ, Jeon YC, Jeong CM, Jeong HC. An in-vitro wear study of indirect composite resins against human enamel. J Korean Acad Prosthodont. 2007; 45:611–620.30. Kern M, Strub JR, Lü XY. Wear of composite resin veneering materials in a dual-axis chewing simulator. J Oral Rehabil. 1999; 26:372–378.

Article31. Heintze SD, Zappini G, Rousson V. Wear of ten dental restorative materials in five wear simulators--results of a round robin test. Dent Mater. 2005; 21:304–317.

Article32. DeLong R, Sakaguchi RL, Douglas WH, Pintado MR. The wear of dental amalgam in an artificial mouth: a clinical correlation. Dent Mater. 1985; 1:238–242.

Article33. Alt V, Hannig M, Wöstmann B, Balkenhol M. Fracture strength of temporary fixed partial dentures: CAD/CAM versus directly fabricated restorations. Dent Mater. 2011; 27:339–347.

Article34. Albashaireh ZS, Ghazal M, Kern M. Two-body wear of different ceramic materials opposed to zirconia ceramic. J Prosthet Dent. 2010; 104:105–113.

Article35. Chadwick RG. Thermocycling-the effects upon the compressive strength and abrasion resistance of three composite resins. J Oral Rehabil. 1994; 21:533–543.

Article36. Mair LH, Stolarski TA, Vowles RW, Lloyd CH. Wear: mechanisms, manifestations and measurement. Report of a workshop. J Dent. 1996; 24:141–148.

Article37. Bae EJ, Jeong ID, Kim WC, Kim JH. A comparative study of additive and subtractive manufacturing for dental restorations. J Prosthet Dent. 2017; 118:187–193.

Article38. Park C, Kim MH, Go JS, Hong SM, Shin BS. A study on the comparison mechanical properties of 3D printing prototypes with laminating direction. J Manuf Eng Technol. 2015; 24:334–341.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- COMPARISON OF WEAR RESISTANCE AMONG RESIN DENTURE TEETH OPPOSING VARIOUS RESTORATIVE MATERIALS

- Comparative evaluation of the subtractive and additive manufacturing on the color stability of fixed provisional prosthesis materials

- Wear of contemporary dental composite resin restorations: a literature review

- Wear resistance of indirect composite resins used for provisional restorations supported by implants

- A study on the shear bond strength between 3D printed resin and provisional resin after thermal cycling