Korean J Orthod.

2018 Sep;48(5):316-325. 10.4041/kjod.2018.48.5.316.

Effects of thermoforming on the physical and mechanical properties of thermoplastic materials for transparent orthodontic aligners

- Affiliations

-

- 1Department and Research Institute for Dental Biomaterials and Bioengineering, Yonsei University College of Dentistry, Seoul, Korea. kmkim@yuhs.ac

- 2BK21 PLUS Project for Interdisciplinary Oral Science Graduate Program, Yonsei University College of Dentistry, Seoul, Korea.

- 3School of Stomatology, Taishan Medical University, Tai'an, Shandong, PR China.

- 4Department of Orthodontics, The Institute of Craniofacial Deformity, Yonsei University College of Dentistry, Seoul, Korea.

- KMID: 2421316

- DOI: http://doi.org/10.4041/kjod.2018.48.5.316

Abstract

OBJECTIVE

The aim of this systematic multiscale analysis was to evaluate the effects of thermoforming on the physical and mechanical properties of thermoplastic materials used to fabricate transparent orthodontic aligners (TOAs).

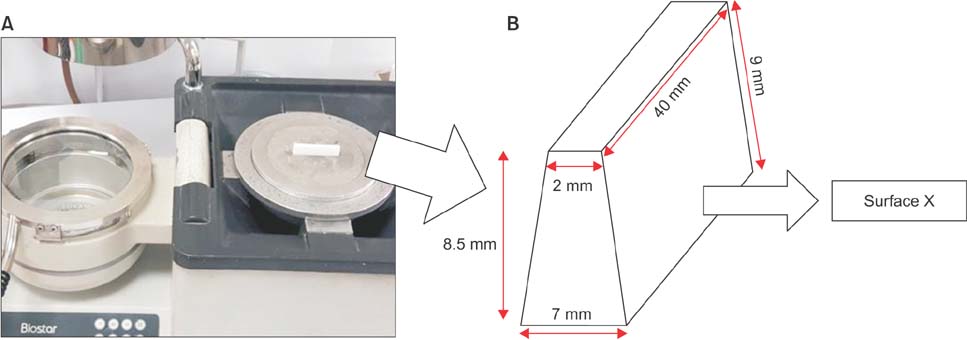

METHODS

Specimens were fabricated using four types of thermoplastic materials with different thicknesses under a thermal vacuum. Transparency, water absorption and solubility, surface hardness, and the results of three-point bending and tensile tests were evaluated before and after thermoforming. Data were analyzed using one-way analysis of variance and Student's t-test.

RESULTS

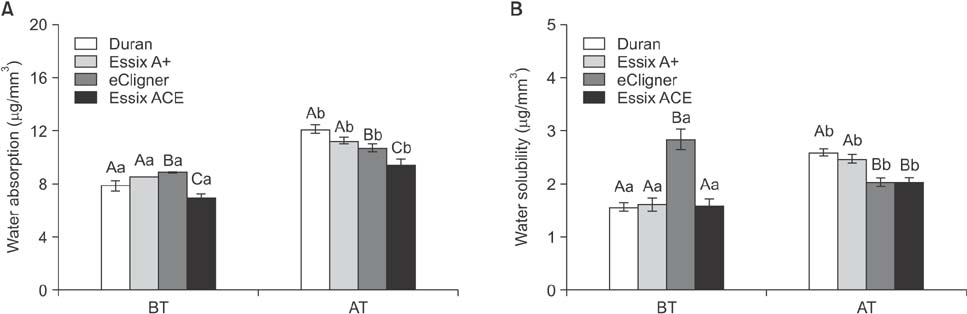

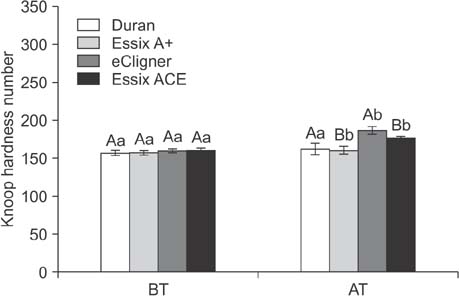

After thermoforming, the transparency of Duran and Essix A+ decreased, while the water absorption ability of all materials; the water solubility of Duran, Essix A+, and Essix ACE; and the surface hardness of Duran and Essix A+ increased. The flexure modulus for the 0.5-mm-thick Duran, Essix A+, and eCligner specimens increased, whereas that for the 0.75-/1.0-mm-thick Duran and eClginer specimens decreased. In addition, the elastic modulus increased for the 0.5-mm-thick Essix A+ specimens and decreased for the 0.75-mm-thick Duran and Essix ACE and the 1.0-mm-thick Essix ACE specimens.

CONCLUSIONS

Our findings suggest that the physical and mechanical properties of thermoplastic materials used for the fabrication of TOAs should be evaluated after thermoforming in order to characterize their properties for clinical application.

Figure

Cited by 2 articles

-

Micro-computed tomography evaluation of general trends in aligner thickness and gap width after thermoforming procedures involving six commercial clear aligners: An

in vitro study

Mario Palone, Mattia Longo, Niki Arveda, Michele Nacucchi, Fabio De Pascalis, Giorgio Alfredo Spedicato, Giuseppe Siciliani, Luca Lombardo

Korean J Orthod. 2021;51(2):135-141. doi: 10.4041/kjod.2021.51.2.135.Force and moment analysis of clear aligners: Impact of material properties and design on premolar rotation

Dong-Woo Kim, Hyun-Jun Lee, Ki Beom Kim, Sung-Hun Kim, Seong-Sik Kim, Soo-Byung Park, Youn-Kyung Choi, Yong-Il Kim

Korean J Orthod. 2025;55(3):212-223. doi: 10.4041/kjod24.114.

Reference

-

1. Martorelli M, Gerbino S, Giudice M, Ausiello P. A comparison between customized clear and removable orthodontic appliances manufactured using RP and CNC techniques. Dent Mater. 2013; 29:e1–e10.

Article2. Ogaard B, Rølla G, Arends J. Orthodontic appliances and enamel demineralization. Part 1. Lesion development. Am J Orthod Dentofacial Orthop. 1988; 94:68–73.3. Featherstone JD. Dental caries: a dynamic disease process. Aust Dent J. 2008; 53:286–291.

Article4. Joffe L. Invisalign: early experiences. J Orthod. 2003; 30:348–352.

Article5. Shalish M, Cooper-Kazaz R, Ivgi I, Canetti L, Tsur B, Bachar E, et al. Adult patients' adjustability to orthodontic appliances. Part I: a comparison between Labial, Lingual, and Invisalign™. Eur J Orthod. 2012; 34:724–730.

Article6. Kesling HD. The philosophy of the tooth positioning appliance. Am J Orthod Oral Surg. 1945; 31:297–304.

Article7. Sheridan JJ. The Readers' Corner. 2. What percentage of your patients are being treated with Invisalign appliances? J Clin Orthod. 2004; 38:544–545.8. Nahoum H. The vacuum formed dental contour appliance. N Y State Dent J. 1964; 9:385–390.9. Ponitz RJ. Invisible retainers. Am J Orthod. 1971; 59:266–272.

Article10. Melkos AB. Advances in digital technology and orthodontics: a reference to the Invisalign method. Med Sci Monit. 2005; 11:PI39–PI42.11. Cassetta M, Altieri F, Pandolfi S, Giansanti M. The combined use of computer-guided, minimally invasive, flapless corticotomy and clear aligners as a novel approach to moderate crowding: a case report. Korean J Orthod. 2017; 47:130–141.

Article12. Boyd RL, Miller RJ, Vlaskalic V. The Invisalign system in adult orthodontics: mild crowding and space closure cases. J Clin Orthod. 2000; 34:203–212.13. Kravitz ND, Kusnoto B, BeGole E, Obrez A, Agran B. How well does Invisalign work? A prospective clinical study evaluating the efficacy of tooth movement with Invisalign. Am J Orthod Dentofacial Orthop. 2009; 135:27–35.

Article14. Lagravère MO, Flores-Mir C. The treatment effects of Invisalign orthodontic aligners: a systematic review. J Am Dent Assoc. 2005; 136:1724–1729.15. Barone S, Paoli A, Razionale AV, Savignano R. Computer aided modelling to simulate the biomechanical behaviour of customised orthodontic removable appliances. IJIDeM. 2016; 10:387–400.

Article16. Hahn W, Zapf A, Dathe H, Fialka-Fricke J, Fricke-Zech S, Gruber R, et al. Torquing an upper central incisor with aligners--acting forces and biomechanical principles. Eur J Orthod. 2010; 32:607–613.

Article17. Simon M, Keilig L, Schwarze J, Jung BA, Bourauel C. Forces and moments generated by removable thermoplastic aligners: incisor torque, premolar derotation, and molar distalization. Am J Orthod Dentofacial Orthop. 2014; 145:728–736.

Article18. Li X, Ren C, Wang Z, Zhao P, Wang H, Bai Y. Changes in force associated with the amount of aligner activation and lingual bodily movement of the maxillary central incisor. Korean J Orthod. 2016; 46:65–72.

Article19. Rossini G, Parrini S, Castroflorio T, Deregibus A, Debernardi CL. Efficacy of clear aligners in controlling orthodontic tooth movement: a systematic review. Angle Orthod. 2015; 85:881–889.

Article20. Dupaix RB, Boyce MC. Finite strain behavior of poly (ethylene terephthalate)(PET) and poly (ethylene terephthalate)-glycol (PETG). Polymer. 2005; 46:4827–4838.

Article21. Fang D, Zhang N, Chen H, Bai Y. Dynamic stress relaxation of orthodontic thermoplastic materials in a simulated oral environment. Dent Mater J. 2013; 32:946–951.

Article22. Lombardo L, Martines E, Mazzanti V, Arreghini A, Mollica F, Siciliani G. Stress relaxation properties of four orthodontic aligner materials: A 24-hour in vitro study. Angle Orthod. 2017; 87:11–18.

Article23. Ryokawa H, Miyazaki Y, Fujishima A, Miyazaki T, Maki K. The mechanical properties of dental thermoplastic materials in a simulated intraoral environment. Orthod Waves. 2006; 65:64–72.

Article24. Min S, Hwang CJ, Yu HS, Lee SB, Cha JY. The effect of thickness and deflection of orthodontic thermoplastic materials on its mechanical properties. Korean J Orthod. 2010; 40:16–26.

Article25. Kwon JS, Lee YK, Lim BS, Lim YK. Force delivery properties of thermoplastic orthodontic materials. Am J Orthod Dentofacial Orthop. 2008; 133:228–234. quiz 328.e1.

Article26. Ahn HW, Kim KA, Kim SH. A new type of clear orthodontic retainer incorporating multi-layer hybrid materials. Korean J Orthod. 2015; 45:268–272.

Article27. International Organization for Standardization (ISO). ISO 20795-2:2013 Dentistry-base polymers--Part 2: orthodontic base polymers. Geneva: ISO;2013.28. Azhikannickal E, Bates PJ, Zak G. Laser light transmission through thermoplastics as a function of thickness and laser incidence angle: experimental and modeling. J Manuf Sci Eng. 2012; 134:061007.

Article29. Kattan M, Dargent E, Ledru J, Grenet J. Strain-induced crystallization in uniaxially drawn PETG plates. J Appl Polym Sci. 2001; 81:3405–3412.

Article30. Zhang N, Bai Y, Ding X, Zhang Y. Preparation and characterization of thermoplastic materials for invisible orthodontics. Dent Mater J. 2011; 30:954–959.

Article31. Gardner GD, Dunn WJ, Taloumis L. Wear comparison of thermoplastic materials used for orthodontic retainers. Am J Orthod Dentofacial Orthop. 2003; 124:294–297.

Article32. Alexandropoulos A, Al Jabbari YS, Zinelis S, Eliades T. Chemical and mechanical characteristics of contemporary thermoplastic orthodontic materials. Aust Orthod J. 2015; 31:165–170.

Article33. Kohda N, Iijima M, Muguruma T, Brantley WA, Ahluwalia KS, Mizoguchi I. Effects of mechanical properties of thermoplastic materials on the initial force of thermoplastic appliances. Angle Orthod. 2013; 83:476–483.

Article34. Brazel CS, Rosen SL. Fundamental principles of polymeric materials. 3rd ed. London: John Wiley;2010. p. 53.35. Elkholy F, Schmidt F, Jäger R, Lapatki BG. Forces and moments applied during derotation of a maxillary central incisor with thinner aligners: an in-vitro study. Am J Orthod Dentofacial Orthop. 2017; 151:407–415.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Changes in force associated with the amount of aligner activation and lingual bodily movement of the maxillary central incisor

- The effect of thickness and deflection of orthodontic thermoplastic materials on its mechanical properties

- A new type of clear orthodontic retainer incorporating multi-layer hybrid materials

- Intraoral ageing of aligners and attachments: Adverse effects on clinical efficiency and release of biologically-active compounds

- Micro-computed tomography evaluation of general trends in aligner thickness and gap width after thermoforming procedures involving six commercial clear aligners: An in vitro study