J Adv Prosthodont.

2016 Oct;8(5):372-379. 10.4047/jap.2016.8.5.372.

Empirical study of alginate impression materials by customized proportioning system

- Affiliations

-

- 1Suleyman Demirel Universitesi Muhendislik Fakultesi - Mechanical Engineering Dept. Isparta, Turkey. karanikurtulus@sdu.edu.tr

- KMID: 2355441

- DOI: http://doi.org/10.4047/jap.2016.8.5.372

Abstract

- PURPOSE

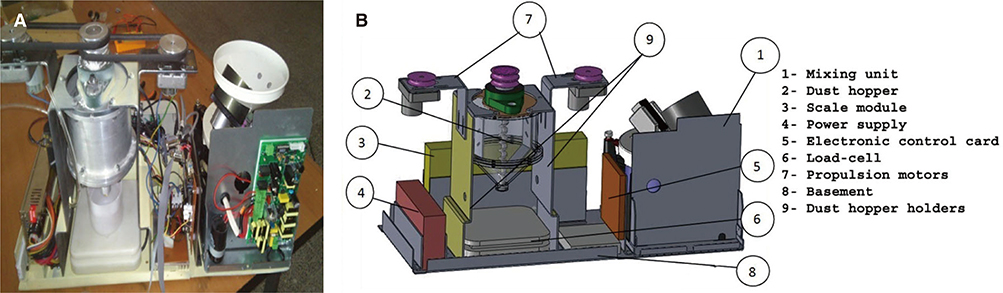

Alginate mixers available in the market do not have the automatic proportioning unit. In this study, an automatic proportioning unit for the alginate mixer and controller software were designed and produced for a new automatic proportioning unit. With this device, it was ensured that proportioning operation could arrange weight-based alginate impression materials.

MATERIALS AND METHODS

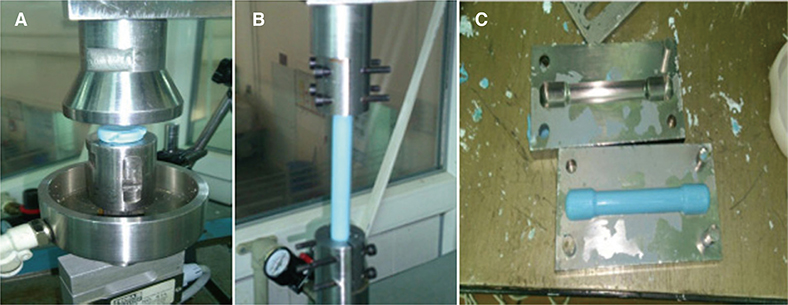

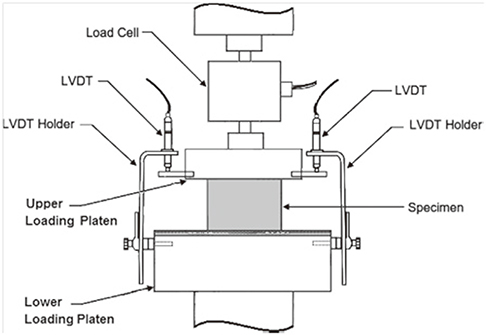

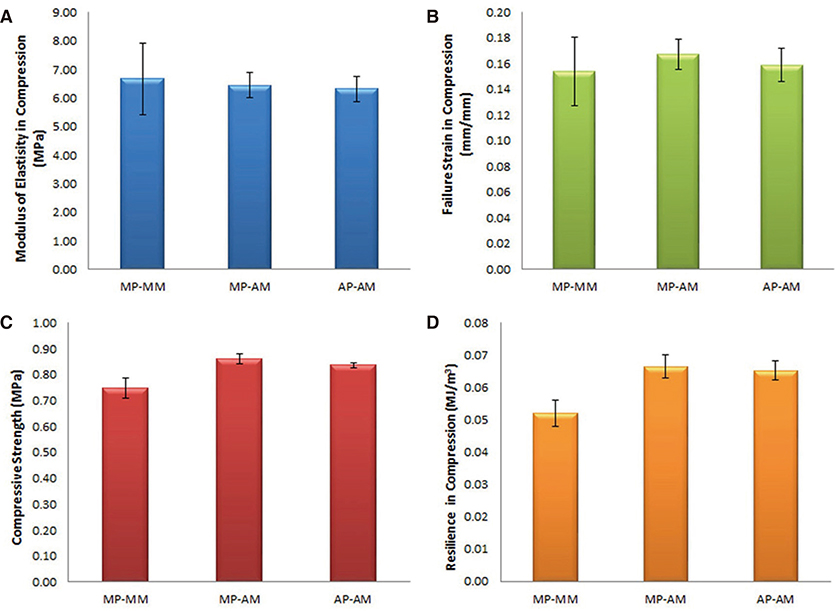

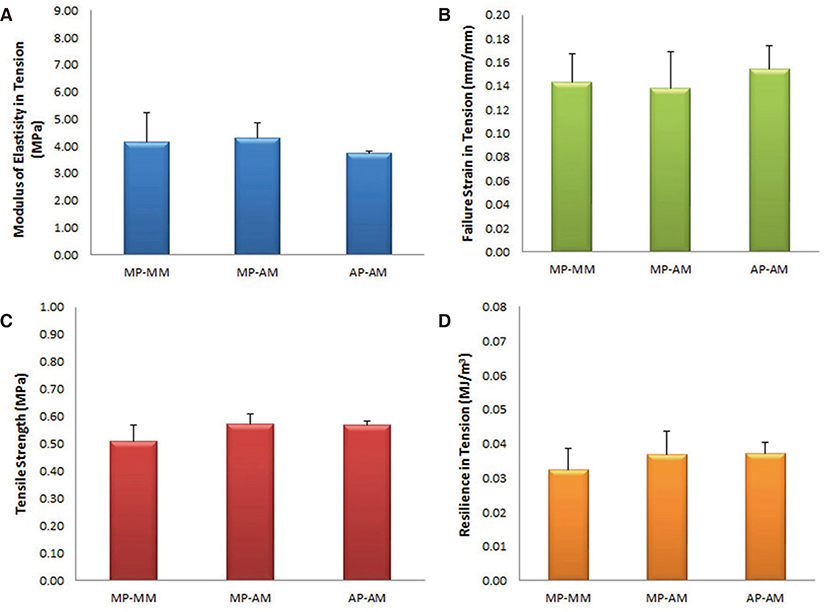

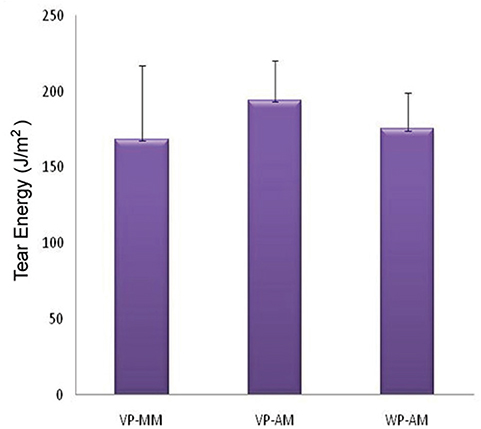

The variation of coefficient in the tested groups was compared with the manual proportioning. Compression tension and tear tests were conducted to determine the mechanical properties of alginate impression materials. The experimental data were statistically analyzed using one way ANOVA and Tukey test at the 0.05 level of significance.

RESULTS

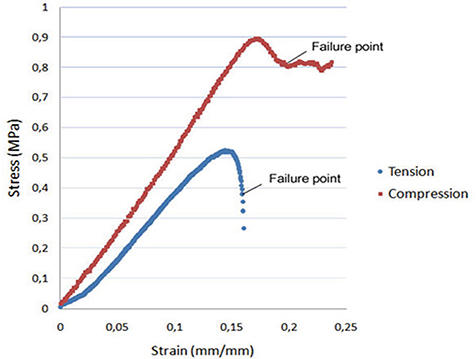

No statistically significant differences in modulus of elastisity (P>0.3), tensional/compresional strength (P>0.3), resilience (P>0.2), strain in failure (P>0.4), and tear energy (P>0.7) of alginate impression materials were seen. However, a decrease in the standard deviation of tested groups was observed when the customized machine was used. To verify the efficiency of the system, powder and powder/water mixing were weighed and significant decrease was observed.

CONCLUSION

It was possible to obtain more mechanically stable alginate impression materials by using the custom-made proportioning unit.

Keyword

MeSH Terms

Figure

Reference

-

1. Haralur SB, Al-Dowah OS, Gana NS, Al-Hytham A. Effect of alginate chemical disinfection on bacterial count over gypsum cast. J Adv Prosthodont. 2012; 4:84–88.2. Doubleday B. Impression materials. Br J Orthod. 1998; 25:133–140.3. Cook W. Alginate dental impression materials: chemistry, structure, and properties. J Biomed Mater Res. 1986; 20:1–24.4. Inoue K, Song YX, Kamiunten O, Oku J, Terao T, Fujii K. Effect of mixing method on rheological properties of alginate impression materials. J Oral Rehabil. 2002; 29:615–619.5. Re D, De Angelis F, Augusti G, Augusti D, Caputi S, D'Amario M, D'Arcangelo C. Mechanical properties of elastomeric impression materials: An in vitro comparison. Int J Dent. 2015; 2015:428286.6. American National Standard/American Dental Association Specification No. 18. Alginate Impression Materials;1992.7. Vrijhoef MM, Battistuzzi PG. Tear energy of impression materials. J Dent. 1986; 14:175–177.8. Wilson HJ. Some properties of alginate impression materials relevant to clinical practice. Br Dent J. 1966; 121:463–467.9. Jörgensen KD. A new method of recording the elastic recovery of dental impression materials. Scand J Dent Res. 1976; 84:175–182.10. Frey G, Lu H, Powers J. Effect of mixing methods on mechanical properties of alginate impression materials. J Prosthodont. 2005; 14:221–225.11. Caswell CW, von Gonten AS, Meng TR. Volumetric proportioning techniques for irreversible hydrocolloids: a comparative study. J Am Dent Assoc. 1986; 112:859–861.12. Tüfekci K, Kayacan R, Kurbanoğlu C. Effects of gamma radiation sterilization and strain rate on compressive behavior of equine cortical bone. J Mech Behav Biomed Mater. 2014; 34:231–242.13. Sneed WD, Miller R, Olson J. Tear strength of ten elastomeric impression materials. J Prosthet Dent. 1983; 49:511–513.14. Hondrum SO. Tear and energy properties of three impression materials. Int J Prosthodont. 1994; 7:517–521.15. Chai J, Takahashi Y, Lautenschlager EP. Clinically relevant mechanical properties of elastomeric impression materials. Int J Prosthodont. 1998; 11:219–223.16. Webber RL, Ryge G. The determination of tear energy of extensible materials of dental interest. J Biomed Mater Res. 1968; 2:281–296.17. ADA, Specification no. 19 for dental elastomeric impression material. Revised ANSI/ADA Specification no. 18-2004.18. Lee YK, Lim BS, Kim CW. Effect of fluoride addition on the properties of dental alginate impression materials. J Mater Sci Mater Med. 2004; 15:219–224.19. Nallamuthu NA, Braden M, Patel MP. Some aspects of the formulation of alginate dental impression materials-setting characteristics and mechanical properties. Dent Mater. 2012; 28:756–762.20. Gent AN. On the Relation Between Indentation Hardness and Young's Modulus. Trans Inst Rubber Ind. 1958; 34:47–57.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- COMPARISON OF THE ACCURACY OF STONE CASTS MADE FROM ALGINATE IMPRESSION MATERIAL BY MIXING METHODS AND APPLICATION OF TRAY ADHESIVE

- Effect of interproximal undercut on the dimensional accuracy of impression

- Influence of sodium alginate contents on the strain in compression, elastic recovery, and compressive strength of experimental alginate impression materials

- A Study on the Void Formation And Detail Reproduction According to The Various Impression Materials And Mixing Methods

- ACCURACY OF IMPROVED STONE CASTS FROM ELASTOMERIC IMPRESSION MATERIALS