J Korean Acad Prosthodont.

2016 Jul;54(3):259-266. 10.4047/jkap.2016.54.3.259.

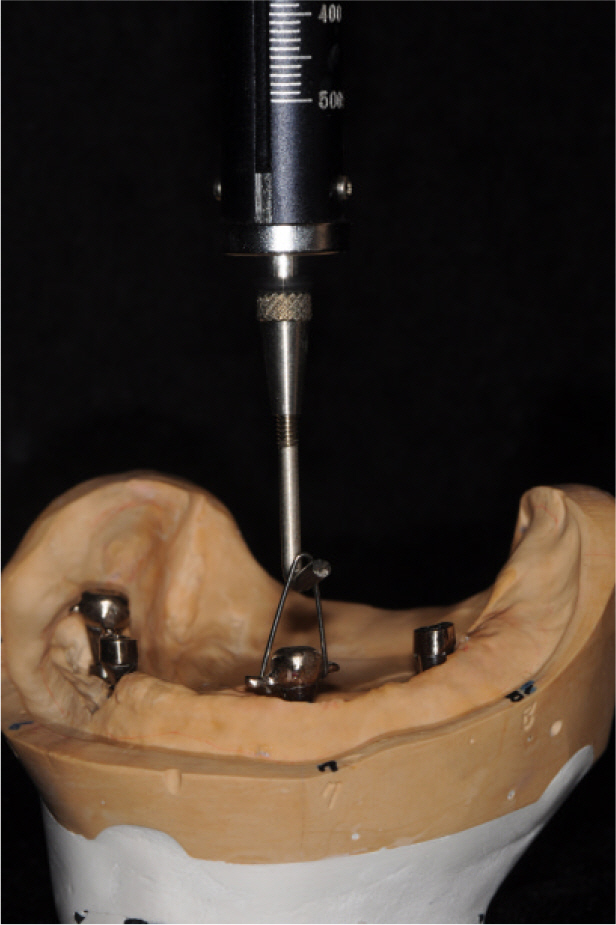

Mandibular implant-supported overdenture using CAD-CAM Konus type attachment: A case report

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry and Institute of Oral Bio-Science, Chonbuk National University, Jeonju, Republic of Korea. jmseo@jbnu.ac.kr

- 2Department of Dentistry, School of Medicine, Eulji University, Daejeon, Republic of Korea.

- KMID: 2344865

- DOI: http://doi.org/10.4047/jkap.2016.54.3.259

Abstract

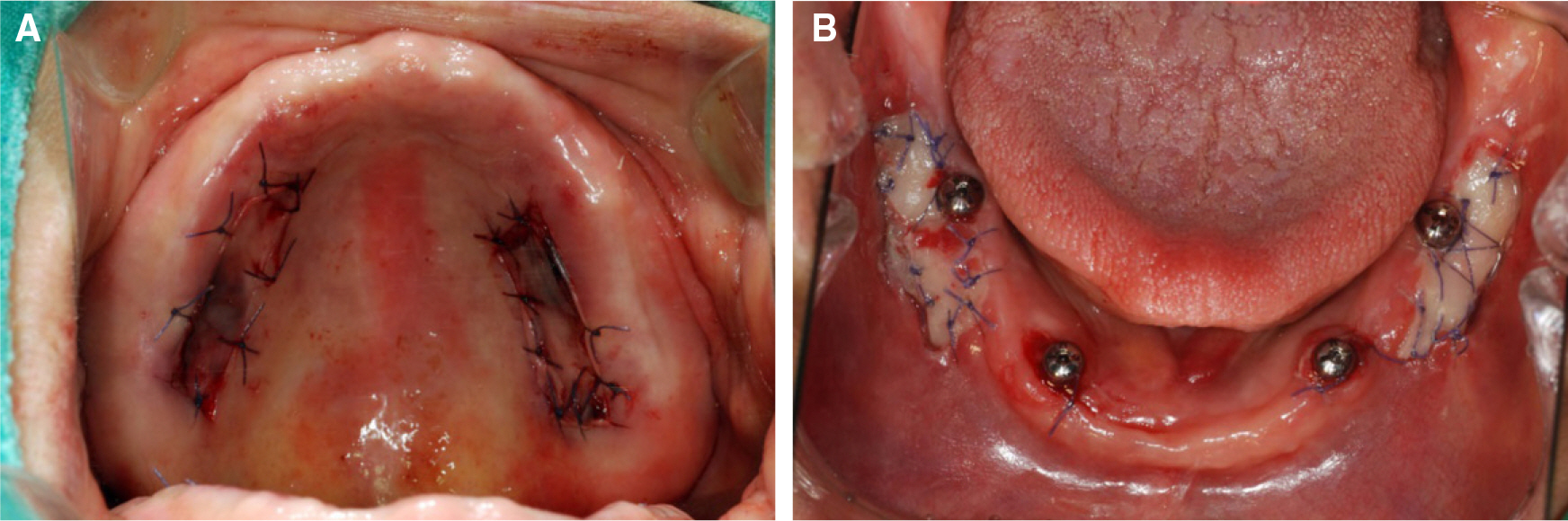

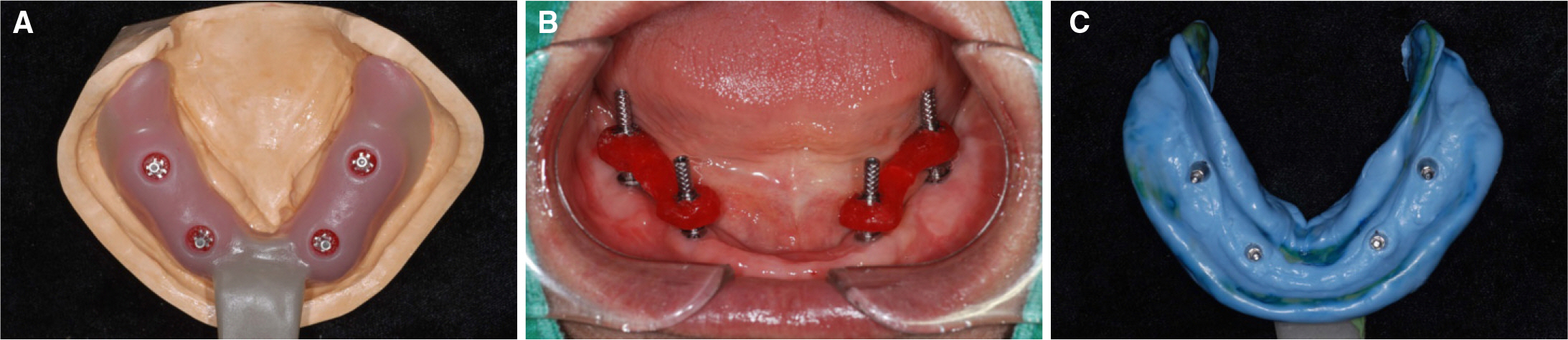

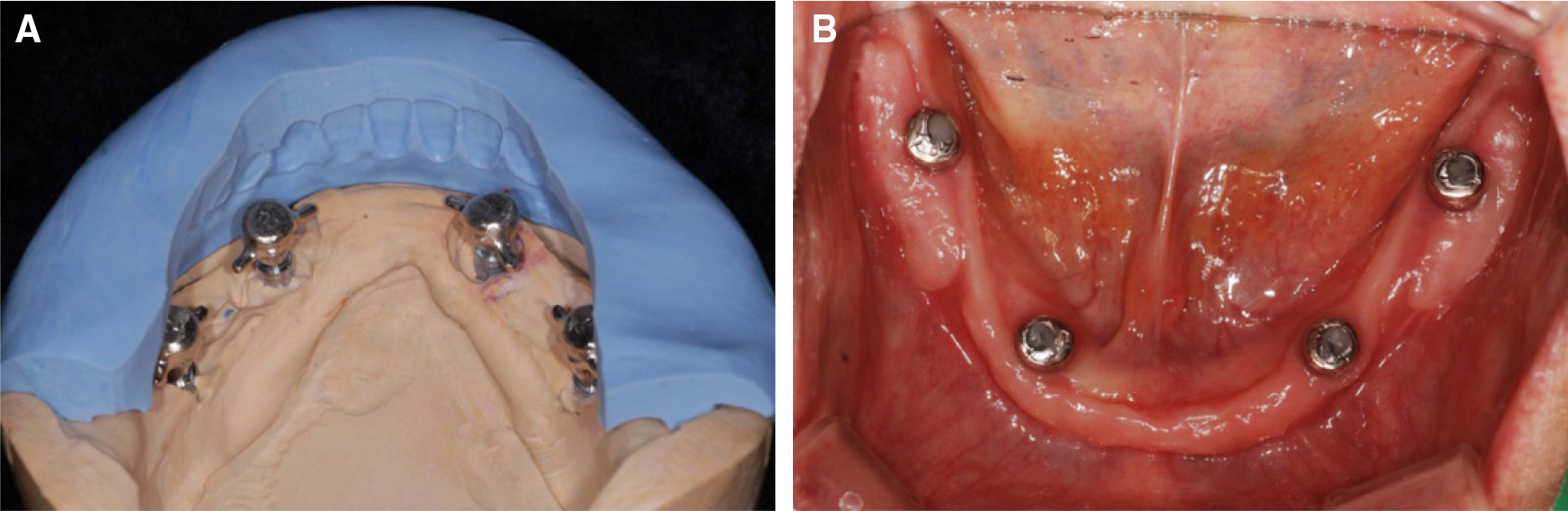

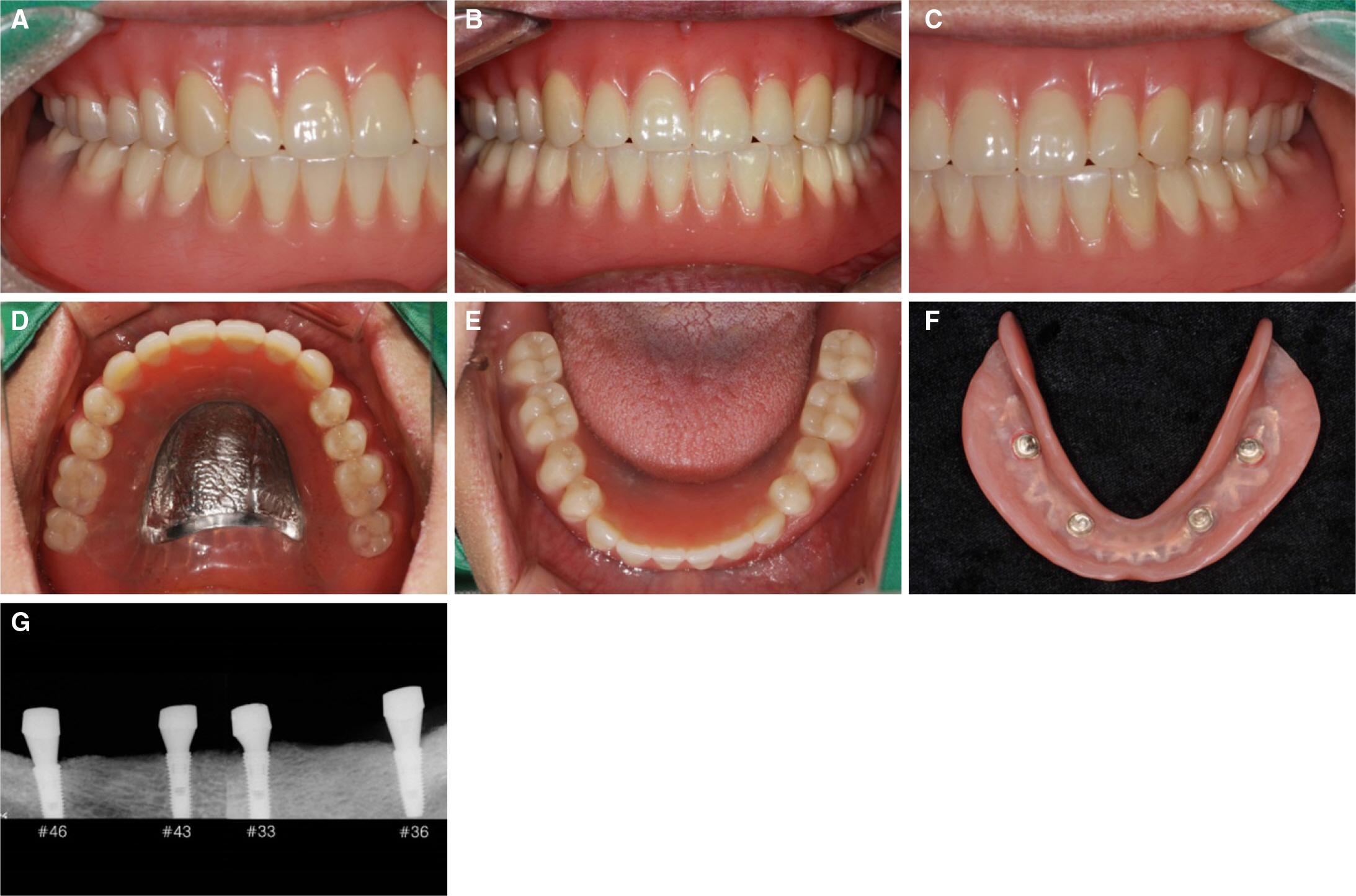

- In edentulous mandible, implant supported overdenture was considered as a first treatment option. Konus type attachment supplies rigid support and cross arch stabilization so that more favorable force transmission and distribution can be attained. In the dentistry, computer aided design-computer aided manufacturing (CAD-CAM) system makes it possible to fabricate restorations with high precision and effectiveness. Recently, Palladium-silver (Pd-Ag) alloy which is millable has been developed. This article presents that application of CAD-CAM Konus type attachment can be provide satisfactory stability and function on four-implant supported mandibular overdenture.

MeSH Terms

Figure

Reference

-

1.Zarb GA., Bolender CL., Eckert S., Fenton A., Jacob R., Mericske-Stern R. Prosthodontic treatment for edentulous patients. Complete dentures and implant supported prostheses. 12th ed.St. Louis: Mosby;2004.2.Feine JS., Carlsson GE., Awad MA., Chehade A., Duncan WJ., Gizani S., Head T., Lund JP., MacEntee M., Mericske-Stern R., Mojon P., Morais J., Naert I., Payne AG., Penrod J., Stoker GT., Tawse-Smith A., Taylor TD., Thomason JM., Thomson WM., Wismeijer D. The McGill consensus statement on overdentures. Mandibular two-implant overdentures as first choice standard of care for edentulous patients. Montreal, Quebec, May 24-25, 2002. Int J Oral Maxillofac Implants. 2002. 17:601–2.3.Thomason JM., Feine J., Exley C., Moynihan P., Müller F., Naert I., Ellis JS., Barclay C., Butterworth C., Scott B., Lynch C., Stewardson D., Smith P., Welfare R., Hyde P., McAndrew R., Fenlon M., Barclay S., Barker D. Mandibular two implant-supported overdentures as the first choice standard of care for edentulous patients—the York Consensus Statement. Br Dent J. 2009. 207:185–6.4.Besimo C., Kempf B. In vitro investigation of various attachments for overdentures on osseointegrated implants. J Oral Rehabil. 1995. 22:691–8.

Article5.Meijer HJ., Kuiper JH., Starmans FJ., Bosman F. Stress distribution around dental implants: influence of superstructure, length of implants, and height of mandible. J Prosthet Dent. 1992. 68:96–102.

Article6.Breitman JB., Nakamura S., Freedman AL., Yalisove IL. Telescopic retainers: an old or new solution? A second chance to have normal dental function. J Prosthodont. 2012. 21:79–83.

Article7.Kim IS., Kang DW., Kim BO., Yoo KH. Design and fabrication of inner Konus crown using three dimensional computer graphics. J Korean Acad Prosthodont. 2000. 38:544–51.8.Shimakura M., Nagata T., Takeuchi M., Nemoto T. Retentive force of pure titanium konus telescope crowns fabricated using CAD/CAM system. Dent Mater J. 2008. 27:211–5.9.Miyazaki T., Hotta Y., Kunii J., Kuriyama S., Tamaki Y. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009. 28:44–56.

Article10.Goodacre CJ. Palladium-silver alloys: a review of the literature. J Prosthet Dent. 1989. 62:34–7.

Article11.Huget EF., Civjan S. Status report on palladium-silver-based crown and bridge alloys. J Am Dent Assoc. 1974. 89:383–5.

Article12.Bergler M., Holst S., Blatz MB., Eitner S., Wichmann M. CAD/CAM and telescopic technology: design options for implant-supported overdentures. Eur J Esthet Dent. 2008. 3:66–88.13.Beuer F., Schweiger J., Edelhoff D. Digital dentistry: an overview of recent developments for CAD/CAM generated restorations. Br Dent J. 2008. 204:505–11.

Article14.Kansu G., Aydin AK. Evaluation of the biocompatibility of various dental alloys: Part I-Toxic potentials. Eur J Prosthodont Restor Dent. 1996. 4:129–36.15.Ceragemgiosys. [cited 2015 February]. Available from. http://www.ceragembiosys.com.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Rehabilitation of edentulous maxilla with implant-supported milled bar overdenture using CAD/CAM customized abutment: A case report

- Fabrication of maxillary complete denture and mandibular implant retained overdenture using CAD-CAM system and Monolithic disc: a case report

- Rehabilitation using mandibular implant overdenture with CAD/CAM milled bar: A case report

- Maxillar implant-retained overdenture using CAD/CAM milled zirconia bar with PEKK sleeve: a case report

- Rehabilitation of the edentulous patient with implant overdenture using CAD-CAM denture system: A case report