J Adv Prosthodont.

2013 Feb;5(1):44-50. 10.4047/jap.2013.5.1.44.

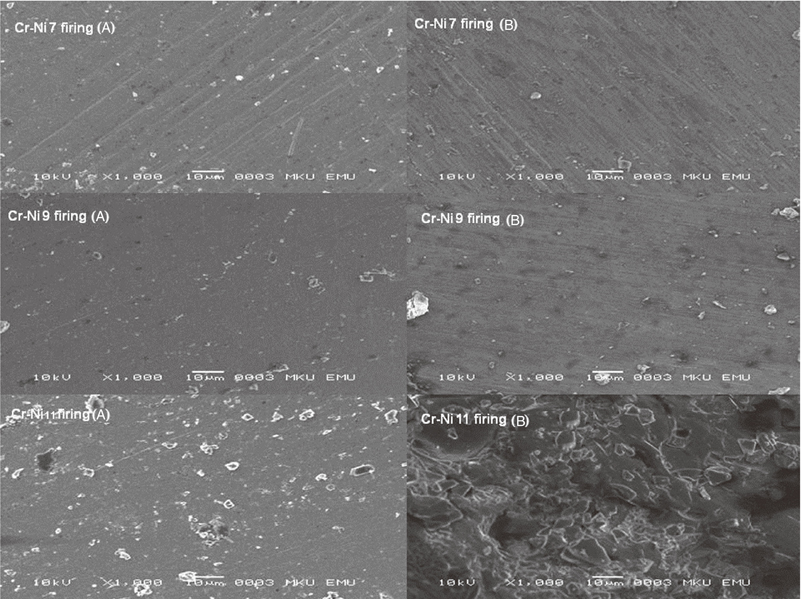

The effect of repeated porcelain firings on corrosion resistance of different dental alloys

- Affiliations

-

- 1Department of Prosthetic Dentistry, Mustafa Kemal University, Hatay, Turkey. alirizatuncdemir@gmail.com

- 2Department of Physics, Mustafa Kemal University, Hatay, Turkey.

- 3Department of Prosthetic Dentistry, Inonu University, Malatya, Turkey.

- KMID: 2284771

- DOI: http://doi.org/10.4047/jap.2013.5.1.44

Abstract

- PURPOSE

The aim of this study was to evaluate the effects of repeated porcelain firing process on the corrosion rates of the dental alloys.

MATERIALS AND METHODS

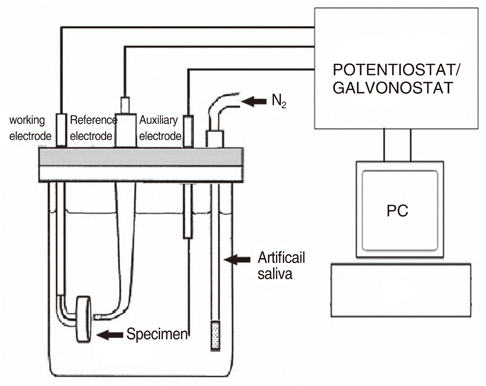

Cr-Co, Cr-Ni and Pd-Ag alloys were used for this study. Each metal supported porcelain consisted of 30 specimens of 10 for 7, 9 and 11 firing each. Disc-shaped specimens 10 mm diameter and 3 mm thickness were formed by melting alloys with a propane-oxygen flame and casted with a centrifuge casting machine and then with the porcelain veneer fired onto the metal alloys. Corrosion tests were performed in quintuplicate for each alloy (after repeated porcelain firing) in Fusayama artificial saliva solution (pH = 5) in a low thermal-expansion borosilicate glass cell. Tamhane and Sheffe test was used to compare corrosion differences in the results after repeated firings and among 7, 9 and 11 firing for each alloy. The probability level for statistical significance was set at alpha=0.05.

RESULTS

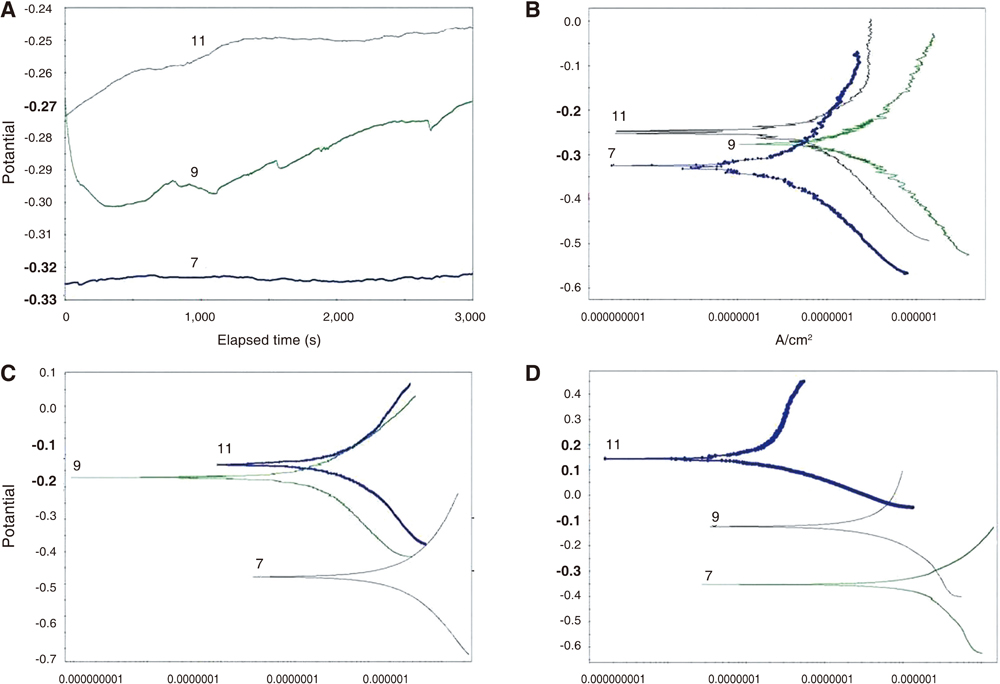

The corrosion resistance was higher (30 mV), in case of 7 times firing (Commercial). On the other hand, it was lower in case of 11 times firing (5 mV) (P<.05).

CONCLUSION

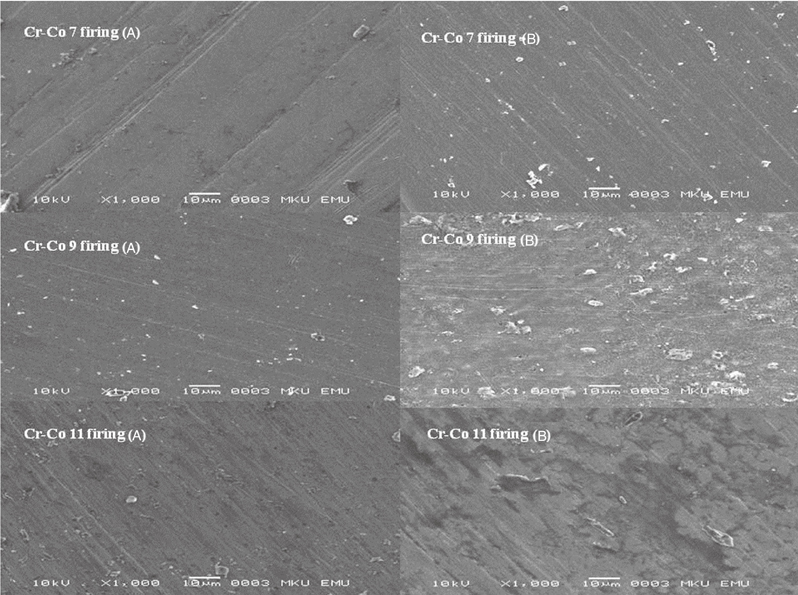

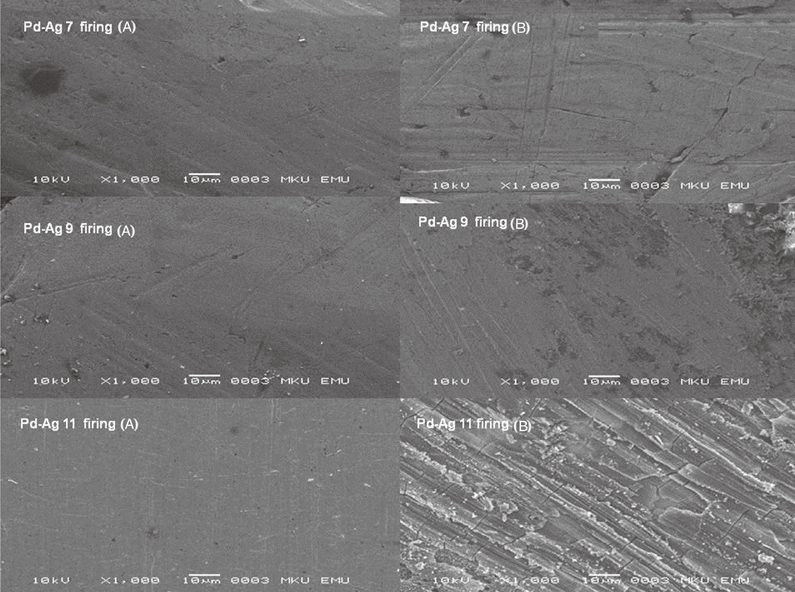

Repeated firings decreased corrosion resistance of Pd-Ag, Cr-Co and Cr-Ni alloys. The Pd-Ag alloy exhibited little corrosion in in vitro tests. The Cr-Ni alloy exhibited higher corrosion resistance than Cr-Co alloys in in vitro tests.

Keyword

MeSH Terms

Figure

Reference

-

1. Kedici SP, Aksüt AA, Kílíçarslan MA, Bayramoğlu G, Gökdemir K. Corrosion behaviour of dental metals and alloys in different media. J Oral Rehabil. 1998. 25:800–808.2. Elshahawy W, Watanabe I, Koike M. Elemental ion release from four different fixed prosthodontic materials. Dent Mater. 2009. 25:976–981.3. Viennot S, Dalard F, Lissac M, Grosgogeat B. Corrosion resistance of cobalt-chromium and palladium-silver alloys used in fixed prosthetic restorations. Eur J Oral Sci. 2005. 113:90–95.4. McLean J. The science and art of dental ceramics. The nature of dental ceramics and their clinical use. 1979. 1st ed. Chicago: Quintessence Publishing.5. Schmalz G, Garhammer P. Biological interactions of dental cast alloys with oral tissues. Dent Mater. 2002. 18:396–406.6. Wataha JC. Biocompatibility of dental casting alloys: a review. J Prosthet Dent. 2000. 83:223–234.7. Johnson T, van Noort R, Stokes CW. Surface analysis of porcelain fused to metal systems. Dent Mater. 2006. 22:330–337.8. Roach MD, Wolan JT, Parsell DE, Bumgardner JD. Use of x-ray photoelectron spectroscopy and cyclic polarization to evaluate the corrosion behavior of six nickel-chromium alloys before and after porcelain-fused-to-metal firing. J Prosthet Dent. 2000. 84:623–634.9. Bumgardner JD, Lucas LC. Surface analysis of nickel-chromium dental alloys. Dent Mater. 1993. 9:252–259.10. Lin HY, Bowers B, Wolan JT, Cai Z, Bumgardner JD. Metallurgical, surface, and corrosion analysis of Ni-Cr dental casting alloys before and after porcelain firing. Dent Mater. 2008. 24:378–385.11. Reclaru L, Lüthy H, Eschler PY, Blatter A, Susz C. Corrosion behaviour of cobalt-chromium dental alloys doped with precious metals. Biomaterials. 2005. 26:4358–4365.12. Matković T, Matković P, Malina J. Effects of Ni and Mo on the microstructure and some other properties of Co-Cr dental alloys. J Alloys Compd. 2004. 366:293–297.13. Huang HH. Effect of chemical composition on the corrosion behavior of Ni-Cr-Mo dental casting alloys. J Biomed Mater Res. 2002. 60:458–465.14. Beck KA, Sarantopoulos DM, Kawashima I, Berzins DW. Elemental release from CoCr and NiCr alloys containing palladium. J Prosthodont. 2012. 21:88–93.15. Manaranche C, Hornberger H. A proposal for the classification of dental alloys according to their resistance to corrosion. Dent Mater. 2007. 23:1428–1437.16. Benatti OF, Miranda WG Jr, Muench A. In vitro and in vivo corrosion evaluation of nickel-chromium- and copper-aluminum-based alloys. J Prosthet Dent. 2000. 84:360–363.17. Rao SB, Chowdhary R. Evaluation on the corrosion of the three Ni-Cr alloys with different composition. Int J Dent. 2011. 2011:397029.18. Geis-Gerstorfer J, Weber H. In vitro corrosion behavior of four Ni-Cr dental alloys in lactic acid and sodium chloride solutions. Dent Mater. 1987. 3:289–295.19. Wylie CM, Shelton RM, Fleming GJ, Davenport AJ. Corrosion of nickel-based dental casting alloys. Dent Mater. 2007. 23:714–723.20. Goodall TG, Lewis AJ. The metallography of heat treatment effects in a nickel-base casting alloy. A preliminary report. Aust Dent J. 1979. 24:235–237.21. Lewis AJ. Metallographic changes and phase identification in a nickel base alloy upon fusion and casting. Aust Dent J. 1975. 20:378–383.22. Leung VW, Darvell BW. Artificial salivas for in vitro studies of dental materials. J Dent. 1997. 25:475–484.23. Reclaru L, Meyer JM. Zonal coulometric analysis of the corrosion resistance of dental alloys. J Dent. 1995. 23:301–311.24. Holland RI. Corrosion testing by potentiodynamic polarization in various electrolytes. Dent Mater. 1992. 8:241–245.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The effect of repeated firings on the color change and surface roughness of dental ceramics

- A study on the bond strength between reused dental alloys and porcelain

- The effect of repeated firings on the color change of dental ceramics using different glazing methods

- Bonding strength of the porcelain laminate to Ni-Cr alloy

- Shear bond strength of porcelain repair resins to nonprecious ceramo-metal alloy