J Adv Prosthodont.

2013 May;5(2):153-160. 10.4047/jap.2013.5.2.153.

Mechanical and thermal properties of polyamide versus reinforced PMMA denture base materials

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, Cumhuriyet University, Sivas, Turkey. koraysoygun@hotmail.com

- 2Department of Chemical Engineering, Faculty of Engineering, Tunceli University, Tunceli, Turkey.

- KMID: 2284755

- DOI: http://doi.org/10.4047/jap.2013.5.2.153

Abstract

- PURPOSE

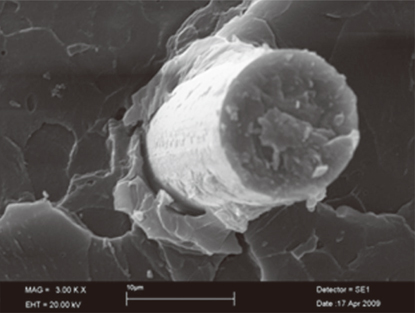

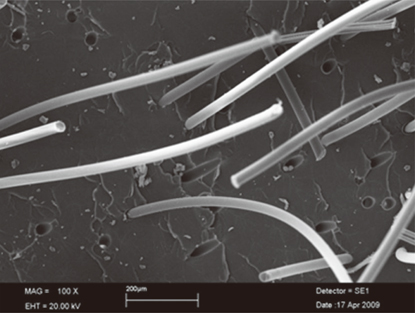

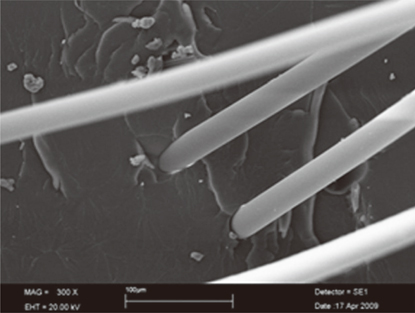

This in vitro study intended to investigate the mechanical and thermal characteristics of Valplast, and of polymethyl methacrylate denture base resin in which different esthetic fibers (E-glass, nylon 6 or nylon 6.6) were added.

MATERIALS AND METHODS

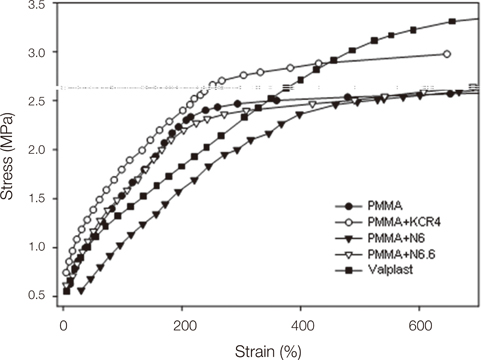

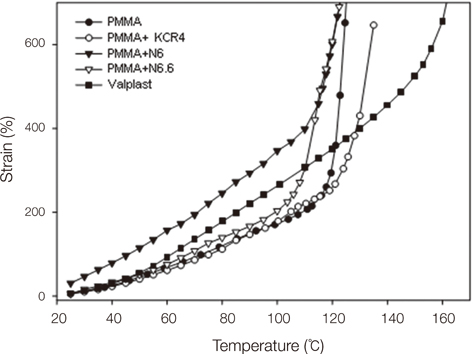

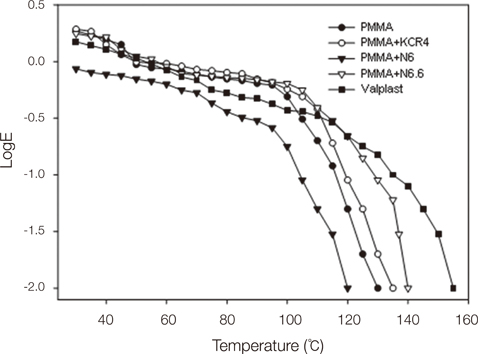

Five groups were formed: control (PMMA), PMMA-E glass, PMMA-nylon 6, PMMA-nylon 6.6 and Valplast resin. For the transverse strength test the specimens were prepared in accordance with ANSI/ADA specification No.12, and for the impact test ASTM D-256 standard were used. With the intent to evaluate the properties of transverse strength, the three-point bending (n=7) test instrument (Lloyd NK5, Lloyd Instruments Ltd, Fareham Hampshire, UK) was used at 5 mm/min. A Dynatup 9250 HV (Instron, UK) device was employed for the impact strength (n=7). All of the resin samples were tested by using thermo-mechanical analysis (Shimadzu TMA 50, Shimadzu, Japan). The data were analyzed by Kruskal-Wallis and Tukey tests for pairwise comparisons of the groups at the 0.05 level of significance.

RESULTS

In all mechanical tests, the highest values were observed in Valplast group (transverse strength: 117.22 +/- 37.80 MPa, maximum deflection: 27.55 +/- 1.48 mm, impact strength: 0.76 +/- 0.03 kN). Upon examining the thermo-mechanical analysis data, it was seen that the E value of the control sample was 8.08 MPa, higher than that of the all other samples.

CONCLUSION

Although Valplast denture material has good mechanical strength, its elastic modulus is not high enough to meet the standard of PMMA materials.

Keyword

MeSH Terms

Figure

Reference

-

1. Marei MK. Reinforcement of denture base resin with glass filler. J Prosthodont. 1999; 8:18–26.2. Stipho HD. Effect of glass fiber reinforcernent on some mechanical properties of autopolymerizing polymethyl methacrylate. J Prosthet Dent. 1998; 79:580–584.3. Jagger D, Harrison A, Jagger R, Milward P. The effect of the addition of poly (methyl methacrylate) fibres on some properties of high strength heat-cured acrylic resin denture base material. J Oral Rehabil. 2003; 30:231–235.4. Jagger DC, Harrison A, Jandt KD. The reinforcement of dentures. J Oral Rehabil. 1999; 26:185–194.5. Dogan OM, Bolayır G, Keskin S, Doğan A, Bek B, Boztuğ A. The effect of esthetic fibers on impact resistance of a conventional heat-cured denture base resin. Dent Mater J. 2007; 26:232–239.6. Nakamura M, Takahashi H, Hayakawa I. Reinforcement of denture base resin with short-rod glass fiber. Dent Mater J. 2007; 26:733–738.7. Uçar Y, Akova T, Aysan I. Mechanical properties of polyamide versus different PMMA denture base materials. J Prosthodont. 2012; 21:173–176.8. Chen SY, Liang WM, Yen PS. Reinforcement of acrylic denture base resin by incorporation of various fibers. J Biomed Mater Res. 2001; 58:203–208.9. Schreiber CK. Polymethyl metacrylate reinforced with carbon fibers. Br Dent J. 1971; 130:29–30.10. Gutteridge DL. The effect ofincluding ultra-high-modulus polyethylene fibre on the impact strength of acrylic resin. Br Dent J. 1988; 164:177–180.11. Kanie T, Fujii K, Arikawa H, Inoue K. Flexural properties and impact strength of denture base polymer reinforced with woven glass fibers. Dent Mater. 2000; 16:150–158.12. Solnit GS. The effect of methyl methacrylate reinforcement with silane-treated and untreated glass fibers. J Prosthet Dent. 1991; 66:310–314.13. Vallittu PK. Curing of a silane coupling agent and its effect on the transverse strength of autopolymerizing polymethylmethacrylate-glass fibre composite. J Oral Rehabil. 1997; 24:124–130.14. Yunus N, Rashid AA, Azmi LL, Abu-Hassan MI. Some flexural properties of a nylon denture base polymer. J Oral Rehabil. 2005; 32:65–71.15. Jagger DC, Jagger RG, Allen SM, Harrison A. An investigation into the transverse and impact strength of "high strength" denture base acrylic resins. J Oral Rehabil. 2002; 29:263–267.16. Phoenix RD, Mansueto MA, Ackerman NA, Jones RE. Evaluation of mechanical and thermal properties of commonly used denture base resins. J Prosthodont. 2004; 13:17–27.17. Jerolimov V, Jagger RG, Milward PJ. Effect of the curing cycle on acrylic denture base glass transition temperatures. J Dent. 1991; 19:245–248.18. Huggett R, Brooks SC, Campbell AM, Satguranathan R, Bell GA. Evaluation of analytical techniques for measurement of denture-base acrylic resin glass-transition temperature. Dent Mater. 1990; 6:17–19.19. Laird JL, Liolios G. Thermal analysis techniques for the rubber laboratory. Am Lab. 1990; 46–50.20. Boztug A, Coşkun A, Bolayır G, Zengin HB, Özdemir AK. Preparation of compatible blends of poly(methyl metacrylate) used in dentistry with a reactive terpolymer containing maleic anhydride and their thermomechanical characterization. J Appl Polym Sci. 2006; 100:363–367.21. McCabe JF, Walls AWG. Applied dental materials. 9th ed. Copenhagen: Blackwell Munksgaard;2008.22. Vallittu PK, Lassila VP, Lappalainen R. Transverse strength and fatigue of denture acrylic-glass fiber composite. Dent Mater. 1994; 10:116–121.23. Karacaer O, Polat TN, Tezvergil A, Lassila LV, Vallittu PK. The effect of length and concentration of glass fibers on the mechanical properties of an injection- and a compression-molded denture base polymer. J Prosthet Dent. 2003; 90:385–393.24. Gutteridge DL. Reinforcement of poly (methyl methacrylate) with ultra-high-modulus polyethylene fiber. J Dent. 1992; 20:50–54.25. John J, Gangadhar SA, Shah I. Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J Prosthet Dent. 2001; 86:424–427.26. Doğan OM, Bolayir G, Keskin S, Doğan A, Bek B. The evaluation of some flexural properties of a denture base resin reinforced with various aesthetic fibers. J Mater Sci Mater Med. 2008; 19:2343–2349.27. Stafford GD, Huggett R, MacGregor AR, Graham J. The use of nylon as a denture-base material. J Dent. 1986; 14:18–22.28. Takabayashi Y. Characteristics of denture thermoplastic resins for non-metal clasp dentures. Dent Mater J. 2010; 29:353–361.29. Gruszka I, Lewandowski S, Benko E, Perzyna M. Structure and mechanical properties of polyamid fibres. Fibers Text Eastern Eur. 2005; 13:133–136.30. Zappini G, Kammann A, Wachter W. Comparison of fracture tests of denture base materials. J Prosthet Dent. 2003; 90:578–585.31. Chen SY, Liang WM. Effects of fillers on fiber reinforced acrylic denture base resins. Mid Taiwan J Med. 2004; 9:203–210.32. Clarke RL. Dynamic mechanical thermal analysis of dental polymers I Heat-cured poly(methyl methacrylate)-based materials. Biomaterials. 1989; 10:494–498.33. Tezvergil A, Lassila LV, Vallittu PK. The effect of fiber orientation on the thermal expansion coefficients of fiber-reinforced composites. Dent Mater. 2003; 19:471–477.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of polymethyl methacrylate resin mechanical properties with incorporated halloysite nanotubes

- Effect of surface treatment methods on the shear bond strength of auto-polymerized resin to thermoplastic denture base polymer

- Comparison of flexural strength according to thickness between CAD/CAM denture base resins and conventional denture base resins

- Physical properties and color stability of injection-molded thermoplastic denture base resins

- Peel strength of denture liner to PMMA and polyamide: laser versus air-abrasion