Evaluation of different approaches for using a laser scanner in digitization of dental impressions

- Affiliations

-

- 1Department of Health Science, Graduate School, Korea University, Seoul, Republic of Korea.

- 2Department of Dental Laboratory Science and Engineering, College of Health Science, Korea University, Seoul, Republic of Korea. kjh2804@korea.ac.kr

- 3Department of Public Health Science, Graduate School & BK21+ Program in Public Health Science, Korea University, Seoul, Republic of Korea.

- 4Department of Dental Laboratory, Sinheung University, Uijeongbu, Republic of Korea.

- KMID: 2176566

- DOI: http://doi.org/10.4047/jap.2014.6.1.22

Abstract

- PURPOSE

This study aimed to investigate the potential clinical application of digitized silicone rubber impressions by comparing the accuracy of zirconia 3-unit fixed partial dentures (FPDs) fabricated from 2 types of data (working model and impression) obtained from a laser scanner.

MATERIALS AND METHODS

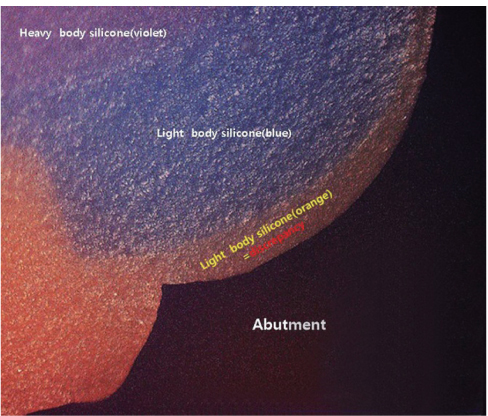

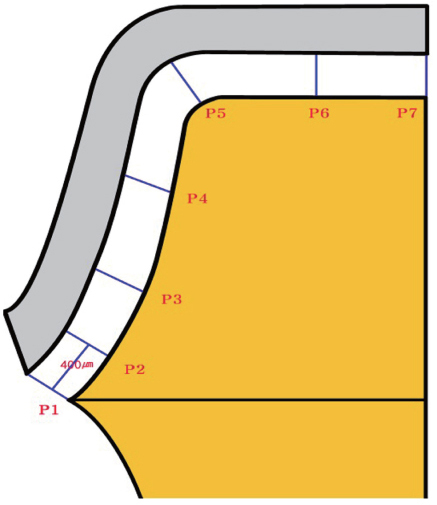

Ten working models and impressions were prepared with epoxy resin and vinyl polysiloxane, respectively. Based on the data obtained from the laser scanner (D-700; 3Shape A/S, Copenhagen, Denmark), a total of 20 zirconia frameworks were prepared using a dental CAD/CAM system (DentalDesigner; 3shape A/S, Copenhagen, Denmark / Ener-mill, Dentaim, Seoul, Korea). The silicone replicas were sectioned into four pieces to evaluate the framework fit. The replicas were imaged using a digital microscope, and the fit of the reference points (P1, P2, P3, P4, P5, P6, and P7) were measured using the program in the device. Measured discrepancies were divided into 5 categories of gaps (MG, CG, AWG, AOTG, OG). Data were analyzed with Student's t-test (alpha=0.05), repeated measures ANOVA and two-way ANOVA (alpha=0.05).

RESULTS

The mean gap of the zirconia framework prepared from the working models presented a narrower discrepancy than the frameworks fabricated from the impression bodies. The mean of the total gap in premolars (P=.003) and molars (P=.002) exhibited a statistical difference between two groups.

CONCLUSION

The mean gap dimensions of each category showed statistically significant difference. Nonetheless, the digitized impression bodies obtained with a laser scanner were applicable to clinical settings, considering the clinically acceptable marginal fit (120 microm).

Keyword

MeSH Terms

Figure

Cited by 3 articles

-

Comparison of the marginal fit of milled yttrium stabilized zirconium dioxide crowns obtained by scanning silicone impressions and by scanning stone replicas

Estefanía Aranda Yus, Josep Maria Anglada Cantarell, Antonio Miñarro Alonso

J Adv Prosthodont. 2018;10(3):236-244. doi: 10.4047/jap.2018.10.3.236.Verification of a computer-aided replica technique for evaluating prosthesis adaptation using statistical agreement analysis

Hang-Nga Mai, Kyeong Eun Lee, Kyu-Bok Lee, Seung-Mi Jeong, Seok-Jae Lee, Cheong-Hee Lee, Seo-Young An, Du-Hyeong Lee

J Adv Prosthodont. 2017;9(5):358-363. doi: 10.4047/jap.2017.9.5.358.Comparison of patient satisfaction with digital and conventional impression for prosthodontic treatment

Hyung-In Yoon, Su-Min Lee, Eun-Jin Park

J Korean Acad Prosthodont. 2016;54(4):379-386. doi: 10.4047/jkap.2016.54.4.379.

Reference

-

1. Miyazaki T, Hotta Y, Kunii J, Kuriyama S, Tamaki Y. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009; 28:44–56.2. Birnbaum NS, Aaronson HB. Dental impressions using 3D digital scanners: virtual becomes reality. Compend Contin Educ Dent. 2008; 29:494496498–505.3. Ender A, Wiedhahn K, Mörmann WH. Chairside multi-unit restoration of a quadrant using the new Cerec 3D software. Int J Comput Dent. 2003; 6:89–94.4. Christensen GJ. In-office CAD/CAM milling of restorations: the future? J Am Dent Assoc. 2008; 139:83–85.5. Kurbad A. The optical conditioning of Cerec preparations with scan spray. Int J Comput Dent. 2000; 3:269–279.6. Luthardt RG, Loos R, Quaas S. Accuracy of intraoral data acquisition in comparison to the conventional impression. Int J Comput Dent. 2005; 8:283–294.7. Persson AS, Odén A, Andersson M, Sandborgh-Englund G. Digitization of simulated clinical dental impressions: virtual three-dimensional analysis of exactness. Dent Mater. 2009; 25:929–936.8. Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989; 62:405–408.9. Grenade C, Mainjot A, Vanheusden A. Fit of single tooth zirconia copings: comparison between various manufacturing processes. J Prosthet Dent. 2011; 105:249–255.10. Martínez-Rus F, Suárez MJ, Rivera B, Pradíes G. Evaluation of the absolute marginal discrepancy of zirconia-based ceramic copings. J Prosthet Dent. 2011; 105:108–114.11. Baig MR, Tan KB, Nicholls JI. Evaluation of the marginal fit of a zirconia ceramic computer-aided machined (CAM) crown system. J Prosthet Dent. 2010; 104:216–227.12. Att W, Komine F, Gerds T, Strub JR. Marginal adaptation of three different zirconium dioxide three-unit fixed dental prostheses. J Prosthet Dent. 2009; 101:239–247.13. Tao J, Yoda M, Kimura K, Okuno O. Fit of metal ceramic crowns cast in Au-1.6 wt% Ti alloy for different abutment finish line curvature. Dent Mater. 2006; 22:397–404.14. Yeo IS, Yang JH, Lee JB. In vitro marginal fit of three all-ceramic crown systems. J Prosthet Dent. 2003; 90:459–464.15. Akbar JH, Petrie CS, Walker MP, Williams K, Eick JD. Marginal adaptation of Cerec 3 CAD/CAM composite crowns using two different finish line preparation designs. J Prosthodont. 2006; 15:155–163.16. Kohorst P, Brinkmann H, Li J, Borchers L, Stiesch M. Marginal accuracy of four-unit zirconia fixed dental prostheses fabricated using different computer-aided design/computer-aided manufacturing systems. Eur J Oral Sci. 2009; 117:319–325.17. Reich S, Kappe K, Teschner H, Schmitt J. Clinical fit of four-unit zirconia posterior fixed dental prostheses. Eur J Oral Sci. 2008; 116:579–584.18. Reich S, Wichmann M, Nkenke E, Proeschel P. Clinical fit of all-ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci. 2005; 113:174–179.19. Wettstein F, Sailer I, Roos M, Hämmerle CH. Clinical study of the internal gaps of zirconia and metal frameworks for fixed partial dentures. Eur J Oral Sci. 2008; 116:272–279.20. Boening KW, Wolf BH, Schmidt AE, Kästner K, Walter MH. Clinical fit of Procera AllCeram crowns. J Prosthet Dent. 2000; 84:419–424.21. Tinschert J, Natt G, Mautsch W, Spiekermann H, Anusavice KJ. Marginal fit of alumina-and zirconia-based fixed partial dentures produced by a CAD/CAM system. Oper Dent. 2001; 26:367–374.22. Coli P, Karlsson S. Fit of a new pressure-sintered zirconium dioxide coping. Int J Prosthodont. 2004; 17:59–64.23. Beuer F, Aggstaller H, Edelhoff D, Gernet W, Sorensen J. Marginal and internal fits of fixed dental prostheses zirconia retainers. Dent Mater. 2009; 25:94–102.24. Beuer F, Naumann M, Gernet W, Sorensen JA. Precision of fit: zirconia three-unit fixed dental prostheses. Clin Oral Investig. 2009; 13:343–349.25. Bindl A, Mörmann WH. Fit of all-ceramic posterior fixed partial denture frameworks in vitro. Int J Periodontics Restorative Dent. 2007; 27:567–575.26. Gonzalo E, Suárez MJ, Serrano B, Lozano JF. Marginal fit of Zirconia posterior fixed partial dentures. Int J Prosthodont. 2008; 21:398–399.27. Coli P, Karlsson S. Precision of a CAD/CAM technique for the production of zirconium dioxide copings. Int J Prosthodont. 2004; 17:577–580.28. McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971; 131:107–111.29. Bindl A, Mörmann WH. Marginal and internal fit of all-ceramic CAD/CAM crown-copings on chamfer preparations. J Oral Rehabil. 2005; 32:441–447.30. Moldovan O, Luthardt RG, Corcodel N, Rudolph H. Three-dimensional fit of CAD/CAM-made zirconia copings. Dent Mater. 2011; 27:1273–1278.31. Borba M, Cesar PF, Griggs JA, Della Bona Á. Adaptation of all-ceramic fixed partial dentures. Dent Mater. 2011; 27:1119–1126.32. Dittmer MP, Borchers L, Stiesch M, Kohorst P. Stresses and distortions within zirconia-fixed dental prostheses due to the veneering process. Acta Biomater. 2009; 5:3231–3239.33. Pfeiffer J. Dental CAD/CAM technologies: the optical impression (II). Int J Comput Dent. 1999; 2:65–72.34. Feng HY, Liu Y, Xi F. Analysis of digitizing errors of a laser scanning system. Precis Eng. 2001; 25:185–191.35. DeLong R, Pintado MR, Ko CC, Hodges JS, Douglas WH. Factors influencing optical 3D scanning of vinyl polysiloxane impression materials. J Prosthodont. 2001; 10:78–85.36. Rudolph H, Luthardt RG, Walter MH. Computer-aided analysis of the influence of digitizing and surfacing on the accuracy in dental CAD/CAM technology. Comput Biol Med. 2007; 37:579–587.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- White light scanner-based repeatability of 3-dimensional digitizing of silicon rubber abutment teeth impressions

- Accuracy of intraoral scans of edentulous jaws with different generations of intraoral scanners compared to laboratory scans

- Three dimensional accuracy analysis of dental stone casts fabricated using irreversible hydrocolloid impressions

- Clinical application of an intraoral scanner for serial evaluation of orthodontic tooth movement: A preliminary study

- Comparison of the accuracy of digital impressions and traditional impressions: Systematic review