J Adv Prosthodont.

2013 Nov;5(4):485-493. 10.4047/jap.2013.5.4.485.

Bond strength of veneer ceramic and zirconia cores with different surface modifications after microwave sintering

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, Baskent University, Ankara, Turkey. bulemy@gmail.com

- KMID: 2176543

- DOI: http://doi.org/10.4047/jap.2013.5.4.485

Abstract

- PURPOSE

To evaluate the effects of surface treatments on shear bond strength (SBS) between microwave and conventionally sintered zirconia core/veneers.

MATERIALS AND METHODS

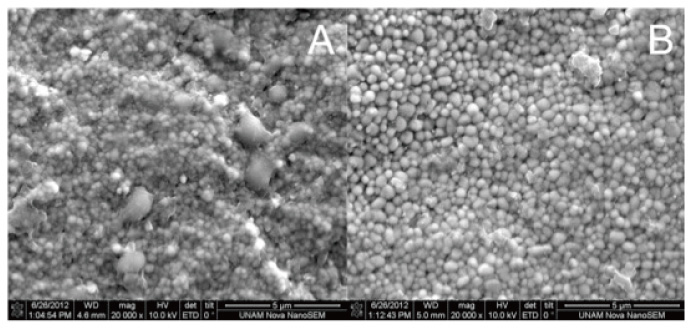

96 disc shaped Noritake Alliance zirconia specimens were fabricated using YenaDent CAM unit and were divided in 2 groups with respect to microwave or conventional methods (n=48/group). Surface roughness (Ra) evaluation was made with a profilometer on randomly selected microwave (n=10) and conventionally sintered (n=10) cores. Specimens were then assessed into 4 subgroups according to surface treatments applied (n=12/group). Groups for microwave (M) and conventionally (C) sintered core specimens were as follows; M(C),C(C): untreated (control group), M1,C1:Al2O3 sandblasting, M2,C2:liner, M3,C3:Al2O3 sandblasting followed by liner. Veneer ceramic was fired on zirconia cores and specimens were thermocycled (6000 cycles between 5degrees-55degrees C). All specimens were subjected to SBS test using a universal testing machine at 0.5 mm/min, failure were evaluated under an optical microscope. Data were statistically analyzed using Shapiro Wilk, Levene, Post-hoc Tukey HSD and Student's t tests, Two-Way-Variance-Analysis and One-Way-Variance-Analysis (alpha=.05).

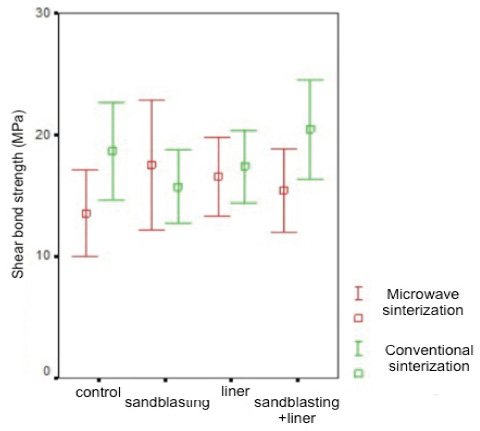

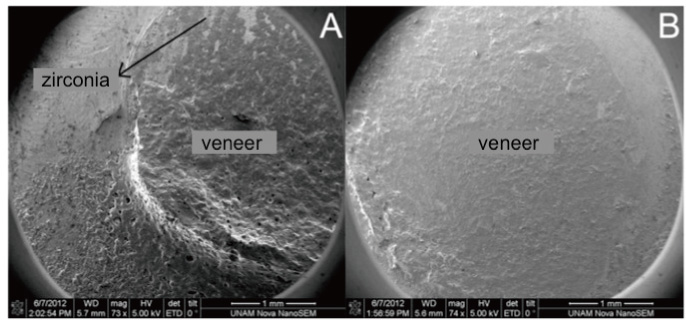

RESULTS

Conventionally sintered specimens (1.06 +/- 0.32 microm) showed rougher surfaces compared to microwave sintered ones (0.76 +/- 0.32 microm)(P=.046), however, no correlation was found between SBS and surface roughness (r=-0.109, P=.658). The statistical comparison of the shear bond strengths of C3 and C1 group (P=.015); C(C) and M(C) group (P=.004) and C3 and M3 group presented statistically higher (P=.005) values. While adhesive failure was not seen in any of the groups, cohesive and combined patterns were seen in all groups.

CONCLUSION

Based on the results of this in-vitro study, Al2O3-sandblasting followed by liner application on conventionally sintered zirconia cores may be preferred to enhance bond strength.

Keyword

MeSH Terms

Figure

Cited by 1 articles

-

Shear bond strength of veneering ceramic to coping materials with different pre-surface treatments

Natasya Ahmad Tarib, Norsamihah Anuar, Marlynda Ahmad

J Adv Prosthodont. 2016;8(5):339-344. doi: 10.4047/jap.2016.8.5.339.

Reference

-

1. Denry I, Holloway JA. Ceramics for dental applications: A review. Materials. 2010; 3:351–368.2. Beuer F, Schweiger J, Eichberger M, Kappert HF, Gernet W, Edelhoff D. igh-strength CAD/CAM-fabricated veneering material sintered to zirconia copings-a new fabrication mode for all-ceramic restorations. Dent Mater. 2009; 25:121–128.3. Huang SG, Li L, van der Biest O, Vleugels J. Microwave sintering of CeO2 and Y2O3 co-stabilised ZrO2 from stabilisercoated nanopowders. J Eur Ceram Soc. 2007; 27:689–693.4. Roy R, Agrawal D, Cheng J, Gedevanishvili S. Full sintering of powdered-metal bodies in a microwave field. Nature. 1999; 399:668–670.5. Katz JD. Microwave sintering of ceramics. Annu Rev Mater Sci. 1992; 22:153–170.6. Ruiz L, Readey MJ. Effect of heat-treatment on grain size, phase assemblage and mechanical properties of 3 mol% Y-TZP. J Am Ceram Soc. 1996; 79:2331–2340.7. Upadhyaya DD, Ghosh A, Dey GK, Prasad R, Suri AK. Microwave sintering of zirconia ceramics. J Mater Sci. 2001; 36:4707–4710.8. Deng Y, Miranda P, Pajares A, Guiberteau F, Lawn BR. Fracture of ceramic/ceramic/polymer trilayers for biomechanical applications. J Biomed Mater Res A. 2003; 67:828–833.9. Al-Dohan HM, Yaman P, Dennison JB, Razzoog ME, Lang BR. Shear strength of core-veneer interface in bi-layered ceramics. J Prosthet Dent. 2004; 91:349–355.10. Saito A, Komine F, Blatz MB, Matsumura H. A comparison of bond strength of layered veneering porcelains to zirconia and metal. J Prosthet Dent. 2010; 104:247–257.11. Guess PC, Kulis A, Witkowski S, Wolkewitz M, Zhang Y, Strub JR. Shear bond strengths between different zirconia cores and veneering ceramics and their susceptibility to thermocycling. Dent Mater. 2008; 24:1556–1567.12. Guazzato M, Proos K, Sara G, Swain MV. Strength, reliability, and mode of fracture of bilayered porcelain/core ceramics. Int J Prosthodont. 2004; 17:142–149.13. Raigrodski AJ, Chiche GJ, Potiket N, Hochstedler JL, Mohamed SE, Billiot S, Mercante DE. The efficacy of posterior three-unit zirconium-oxide-based ceramic fixed partial dental prostheses: a prospective clinical pilot study. J Prosthet Dent. 2006; 96:237–244.14. Isgrò G, Pallav P, van der Zel JM, Feilzer AJ. The influence of the veneering porcelain and different surface treatments on the biaxial flexural strength of a heat-pressed ceramic. J Prosthet Dent. 2003; 90:465–473.15. al-Shehri SA, Mohammed H, Wilson CA. Influence of lamination on the flexural strength of a dental castable glass ceramic. J Prosthet Dent. 1996; 76:23–28.16. Özkurt Z, Kazazoğlu Z, Ünal A. In vitro evaluation of shear bond strength of veneering ceramics to zirconia. Dent Mater J. 2010; 29:138–146.17. Sailer I, Fehér A, Filser F, Lüthy H, Gauckler LJ, Schärer P, Franz Hämmerle CH. Prospective clinical study of zirconia posterior fixed partial dentures: 3-year follow-up. Quintessence Int. 2006; 37:685–693.18. Prasad S, Monaco EA Jr, Kim H, Davis EL, Brewer JD. Comparison of porcelain surface and flexural strength obtained by microwave and conventional oven glazing. J Prosthet Dent. 2009; 101:20–28.19. Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008; 24:299–307.20. Creugers NH, Käyser AF, van 't Hof MA. A meta-analysis of durability data on conventional fixed bridges. Community Dent Oral Epidemiol. 1994; 22:448–452.21. Coornaert J, Adriaens P, De Boever J. Long-term clinical study of porcelain-fused-to-gold restorations. J Prosthet Dent. 1984; 51:338–342.22. Valderhaug J. A 15-year clinical evaluation of fixed prosthodontics. Acta Odontol Scand. 1991; 49:35–40.23. Harding AB, Norling BK, Teixeira EC. The effect of surface treatment of the interfacial surface on fatigue-related microtensile bond strength of milled zirconia to veneering porcelain. J Prosthodont. 2012; 21:346–352.24. Mosharraf R, Rismanchian M, Savabi O, Ashtiani AH. Influence of surface modification techniques on shear bond strength between different zirconia cores and veneering ceramics. J Adv Prosthodont. 2011; 3:221–228.25. Fischer J, Grohmann P, Stawarczyk B. Effect of zirconia surface treatments on the shear strength of zirconia/veneering ceramic composites. Dent Mater J. 2008; 27:448–454.26. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent Mater. 2006; 22:857–863.27. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991.28. Guazzato M, Albakry M, Quach L, Swain MV. Influence of surface and heat treatments on the flexural strength of a glass-infiltrated alumina/zirconia-reinforced dental ceramic. Dent Mater. 2005; 21:454–463.29. Çelebi N, Yüzügüllü B, Canay Ş, Yücel Ü. Effect of polymerization methods on the residual monomer level of acrylic resin denture base polymers. Polym Adv Technol. 2008; 19:201–206.30. Vasconcelos LR, Consani RL, Mesquita MF, Sinhoreti MA. Effect of chemical and microwave disinfection on the surface microhardness of acrylic resin denture teeth. J Prosthodont. 2013; 22:298–303.31. Kim HJ, Lim HP, Park YJ, Vang MS. Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J Prosthet Dent. 2011; 105:315–322.32. DeHoff PH, Anusavice KJ, Wang Z. Three-dimensional finite element analysis of the shear bond test. Dent Mater. 1995; 11:126–131.33. Cheung KC, Darvell BW. Sintering of dental porcelain: effect of time and temperature on appearance and porosity. Dent Mater. 2002; 18:163–173.34. Craig RG, Powers JM, Wataha JC. Dental materials: properties and manuplation. 8th ed. St Louis: Mosby;2004. p. 578–580.35. Sobrinho LC, Cattell MJ, Glover RH, Knowles JC. Investigation of the dry and wet fatigue properties of three all-ceramic crown systems. Int J Prosthodont. 1998; 11:255–262.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of surface treatmet on the shear bond strength of a zirconia core to veneering ceramic

- Repair bond strength of composite resin to zirconia restorations after different thermal cycles

- Shear bond strength of veneer ceramic and colored zirconia by using aqueous metal chloride solutions

- The effect of zirconia surface architecturing technique on the zirconia/veneer interfacial bond strength

- Effect of glass-infiltration treatments on the shear bond strength between zirconia and ultra low-fusing porcelain veneer