J Bacteriol Virol.

2010 Dec;40(4):213-217. 10.4167/jbv.2010.40.4.213.

Glass Capping of Bacterial Culture Flasks

- Affiliations

-

- 1Centre for Research in Medical Entomology (Indian Council of Medical Research), Chinna Chokkikulam, Madurai, India. mmuniaraj@gmail.com

- KMID: 2168586

- DOI: http://doi.org/10.4167/jbv.2010.40.4.213

Abstract

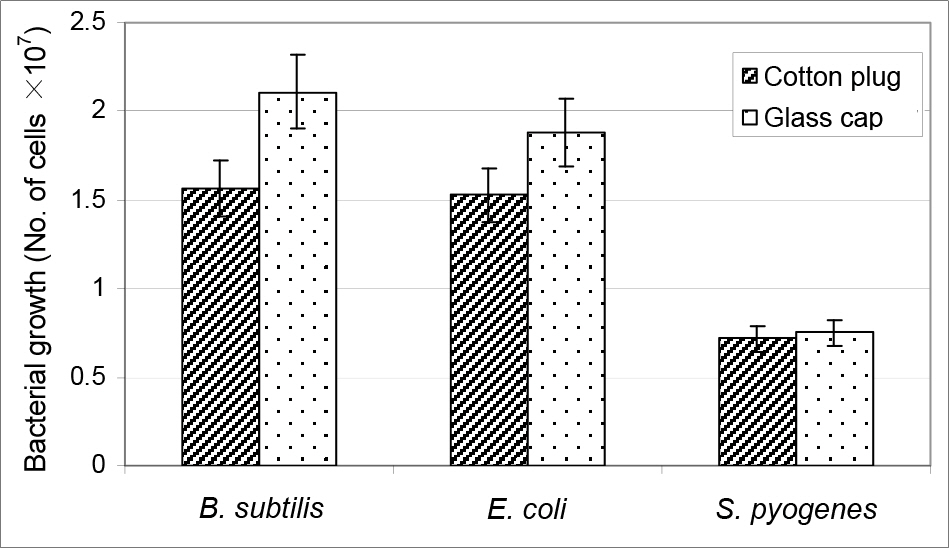

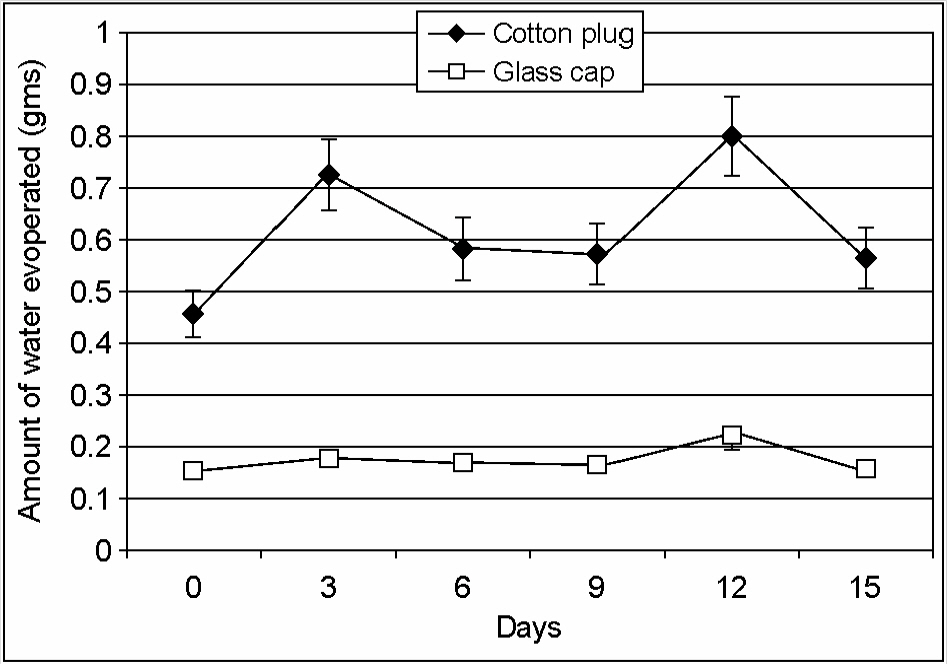

- The use of cotton plug as closure of a bacterial culture flask had been reported to have many disadvantages such as inhibitory nature of cotton to certain microbes, chances of contamination during handling and accumulation of used cotton as biological waste. To overcome the disadvantages of cotton plugs, we have developed a new method of capping bacterial culture flasks. In the present study, three sets of experiments were conducted, one was to find out the efficiency of bacterial growth in culture flasks closed by either glass caps or cotton plugs and the second set was to find out the chances of getting contamination of sterile broth closed by either glass caps or cotton plugs and the third set was to find out the evaporation of water in conical flasks closed by glass caps or cotton plug. The results showed that the bacterial cultures closed by glass caps showed better growth with less chance of contamination and evaporation of the culture media. By this method, the bacterial culture work is made very simpler than using cotton plug.

Keyword

Figure

Reference

-

1). Schröder H., von Dusch T. Ueber Filtration der Luft in Beziehungen auf Fäulniss und Gährung. Ann Chem Pharm. 1854. 39:232–3.2). Pasteur L. Memoire sur les corpuscles organises qui existent dans l'atmosphere. Examen de la doctrine des generations spontanees. Annales des Science naturelles, 4th Series, 1861; 16:5-98. Milestones in Microbiology: 1556 to 1940. translated and edited by. Brock Thomas D., editorASM Press;1998. p. p. 43–53.3). Visvesvara GS., Garcia LS. Culture of protozoan parasites. Clin Microbiol Rev. 2002. 15:327–8.

Article4). Wright HD. A substance in cotton-wool inhibitory to the growth of the pneumococcus. J Pathol Bacteriol. 1934. 38:499–501.

Article5). Drea WF. Growth of small numbers of tubercle bacilli, H37, in Long's liquid synthetic medium and some interfering factors. J Bacteriol. 1942. 44:149–61.

Article6). Pollock MR. Unsaturated Fatty Acids in Cotton Wool Plugs. Nature. 1948. 161:853.

Article7). Boyd DM., Casman EP. Inhibition of a strain of Brucella abortus by medium filtered through cotton. Public Health Rep. 1951. 66:44–9.8). Pine L. Studies on the growth of Histoplasma capsulatum. I. Growth of the yeast phase in liquid media. J Bacteriol. 1954. 68:671–9.9). Schultz JS. Cotton Closure as an Aeration Barrier in Shaken Flask Fermentations. Appl Microbiol. 1964. 12:305–10.

Article10). Koch R. Zur Untersuchung von pathogenen Organismen. Mitth. a. d. Kaiserl. Gesundheitsampte 1881; 1:1-48. Milestones in Microbiology: 1556 to 1940. translated and edited by. Brock Thomas D., editorASM Press;1998. p. p. 101–8.11). Morton HE. Stainless-Steel closures for replacement of cotton plugs in culture tubes. Science. 1957. 126:1248.

Article12). Sutter RP. Comparison of Stainless-Steel Closures and Cotton Plugs in Maintaining Contamination-free Medium in Circulating Air. Appl Microbiol. 1969. 18:525.

Article13). Betts JI., Baganz F. Miniature bioreactors: Current practices and future opportunities. Microb Cell Fact. 2006. 5:21.14). Delgado G., Topete M., Galindo E. Interaction of cultural conditions and end product distribution in Bacillus subtilis grown in shake flasks. Appl Microbiol Biotechnol. 1989. 31:288–92.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Microscopic Examination and Bacterial Culture of the Prostatic Secretion of Chronic Prostatitis: Its Diagnostic Significance

- Comparison of the Microleakage and Shear Bond Strength to Dentine of Different Tricalcium Silicate-based Pulp Capping Materials

- Effects of Capping of the Tracheostomy Tube in Stroke Patients With Dysphagia

- Influence of Different Methods of Cutting Ampules on Drug Contamination by Glass Flakes from the Ampule

- The Effect of 3-Dimensional Microcarrier Culture on Chondrocyte Proliferation and Matrix Production