J Adv Prosthodont.

2015 Apr;7(2):160-165. 10.4047/jap.2015.7.2.160.

In-vitro development of a temporal abutment screw to protect osseointegration in immediate loaded implants

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Universitat Internacional de Catalunya, Barcelona, Spain. drhgarciaroncero@gmail.com

- 2Department of Oral and Maxillofacial Surgery, School of Dentistry, Universitat Internacional de Catalunya, Barcelona, Spain.

- KMID: 2118247

- DOI: http://doi.org/10.4047/jap.2015.7.2.160

Abstract

- PURPOSE

In this study, a temporal abutment fixation screw, designed to fracture in a controlled way upon application of an occlusal force sufficient to produce critical micromotion was developed. The purpose of the screw was to protect the osseointegration of immediate loaded single implants.

MATERIALS AND METHODS

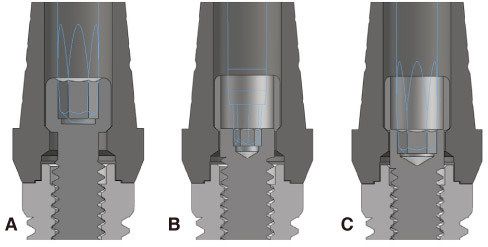

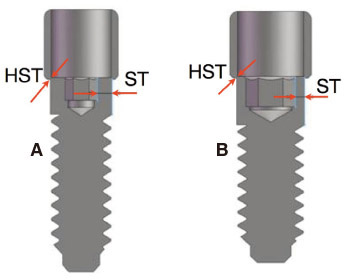

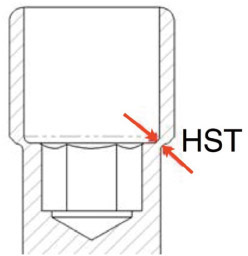

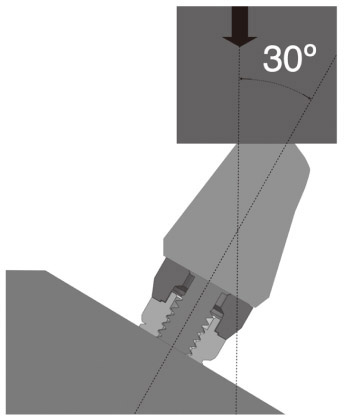

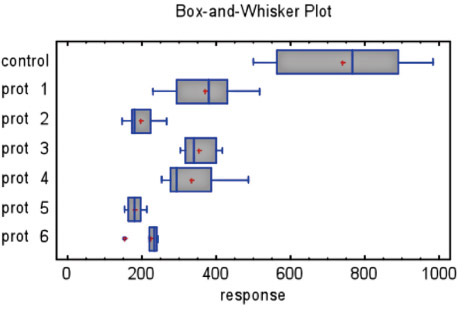

Seven different screw prototypes were examined by fixing titanium abutments to 112 Mozo-Grau external hexagon implants (MG Osseous(R); Mozo-Grau, S.A., Valladolid, Spain). Fracture strength was tested at 30degrees in two subgroups per screw: one under dynamic loading and the other without prior dynamic loading. Dynamic loading was performed in a single-axis chewing simulator using 150,000 load cycles at 50 N. After normal distribution of obtained data was verified by Kolmogorov-Smirnov test, fracture resistance between samples submitted and not submitted to dynamic loading was compared by the use of Student's t-test. Comparison of fracture resistance among different screw designs was performed by the use of one-way analysis of variance. Confidence interval was set at 95%.

RESULTS

Fractures occurred in all screws, allowing easy retrieval. Screw Prototypes 2, 5 and 6 failed during dynamic loading and exhibited statistically significant differences from the other prototypes.

CONCLUSION

Prototypes 2, 5 and 6 may offer a useful protective mechanism during occlusal overload in immediate loaded implants.

MeSH Terms

Figure

Reference

-

1. Esposito M, Grusovin MG, Maghaireh H, Worthington HV. Interventions for replacing missing teeth: different times for loading dental implants. Cochrane Database Syst Rev. 2013; 3:CD003878.2. Szmukler-Moncler S, Salama H, Reingewirtz Y, Dubruille JH. Timing of loading and effect of micromotion on bone-dental implant interface: review of experimental literature. J Biomed Mater Res. 1998; 43:192–203.3. Misch CE, Wang HL, Misch CM, Sharawy M, Lemons J, Judy KW. Rationale for the application of immediate load in implant dentistry: Part I. Implant Dent. 2004; 13:207–217.4. Brunski JB. Avoid pitfalls of overloading and micromotion of intraosseous implants. Dent Implantol Update. 1993; 4:77–81.5. Kawahara H, Kawahara D, Hayakawa M, Tamai Y, Kuremoto T, Matsuda S. Osseointegration under immediate loading: biomechanical stress-strain and bone formation-resorption. Implant Dent. 2003; 12:61–68.6. Chang PK, Chen YC, Huang CC, Lu WH, Chen YC, Tsai HH. Distribution of micromotion in implants and alveolar bone with different thread profiles in immediate loading: a finite element study. Int J Oral Maxillofac Implants. 2012; 27:e96–e101.7. Javed F, Romanos GE. The role of primary stability for successful immediate loading of dental implants. A literature review. J Dent. 2010; 38:612–620.8. Trisi P, Perfetti G, Baldoni E, Berardi D, Colagiovanni M, Scogna G. Implant micromotion is related to peak insertion torque and bone density. Clin Oral Implants Res. 2009; 20:467–471.9. Wazen RM, Currey JA, Guo H, Brunski JB, Helms JA, Nanci A. Micromotion-induced strain fields influence early stages of repair at bone-implant interfaces. Acta Biomater. 2013; 9:6663–6674.10. Winter W, Klein D, Karl M. Effect of model parameters on finite element analysis of micromotions in implant dentistry. J Oral Implantol. 2013; 39:23–29.11. Mericske-Stern R, Assal P, Mericske E, Bürgin W. Occlusal force and oral tactile sensibility measured in partially edentulous patients with ITI implants. Int J Oral Maxillofac Implants. 1995; 10:345–353.12. Waltimo A, Könönen M. Maximal bite force and its association with signs and symptoms of craniomandibular disorders in young Finnish non-patients. Acta Odontol Scand. 1995; 53:254–258.13. Flanagan D, Ilies H, Lasko B, Stack J. Force and movement of non-osseointegrated implants: an in vitro study. J Oral Implantol. 2009; 35:270–276.14. Fazel A, Aalai S, Rismanchian M. Effect of macro-design of immediately loaded implants on micromotion and stress distribution in surrounding bone using finite element analysis. Implant Dent. 2009; 18:345–352.15. Freitas AC Jr, Bonfante EA, Giro G, Janal MN, Coelho PG. The effect of implant design on insertion torque and immediate micromotion. Clin Oral Implants Res. 2012; 23:113–118.16. Engelke W, Decco OA, Rau MJ, Massoni MC, Schwarzwäller W. In vitro evaluation of horizontal implant micromovement in bone specimen with contact endoscopy. Implant Dent. 2004; 13:88–94.17. Steinebrunner L, Wolfart S, Ludwig K, Kern M. Implant-abutment interface design affects fatigue and fracture strength of implants. Clin Oral Implants Res. 2008; 19:1276–1284.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Screw loosening and changes in removal torque relative to abutment screw length in a dental implant with external abutment connection after oblique cyclic loading

- Effects of implant tilting and the loading direction on the displacement and micromotion of immediately loaded implants: an in vitro experiment and finite element analysis

- THE EFFECT OF SCREW HOLE SEALING METHOD ON ABUTMENT SCREW LOOSENING IN DENTAL IMPLANT

- Repairment of abutment and abutment screw fracture in implant prosthesis: A case report

- Long-term cumulative survival and mechanical complications of single-tooth Ankylos Implants: focus on the abutment neck fractures